Channel is a popular material used to create various metal structures and frame construction. The condition for the correct choice of profiles is selection by size, weight and determination of the required quantity. The Gosstandart developed the requirements to which the channels must meet. Dimensions, weight, density and their ratio - all this includes the corresponding tables of a specific GOST. Descriptions of the most common sizes are given in the article.

Content [Hide]

- 1 Tables of channel dimensions in accordance with GOST

- 2 Determination of the weight and price of the channel per meter: size table, cost of profiles

- 3 Characteristics of channel 10: dimensions, weight, cost

- 4 Main parameters of channel 12: dimensions, weight and cost

- 5 Variations of channel 14: dimensions, weight, scope

- 6 Features of channel 16: dimensions, weight and cost

- 7 Weight, price, dimensions of channel 20: all the necessary information about the profile

- 8 Channel: dimensions affecting the scope

Tables of channel dimensions in accordance with GOST

Channel is a fairly popular metal product made from different grades of steel. The term itself is of German origin. The main distinctive feature of the profile is the U-shape of the product in cross section.

The channels are manufactured using special equipment in accordance with the established quality standards

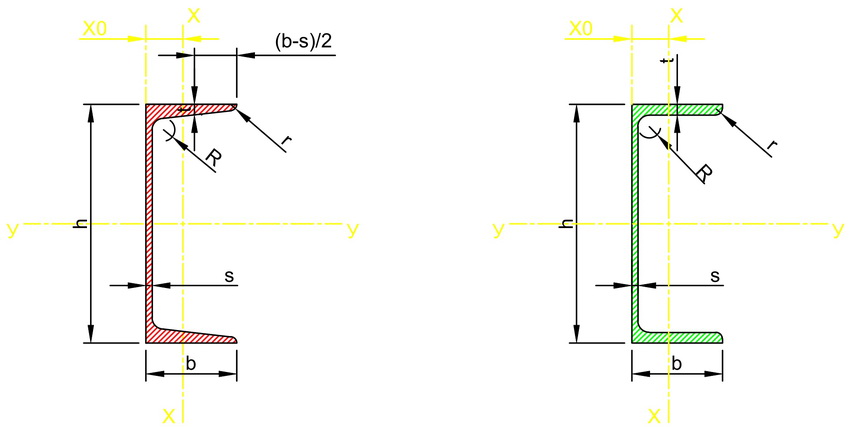

Special equipment is used for the manufacture of channels. Hot-rolled or bent profiles are distinguished by the production method. In the shape of the edges of the shelves, they can be parallel or have a certain slope inside. The classification is also based on a numerical value in the form of a number next to the corresponding marking. The numbers indicate the size, which is determined by the distance between the edges of the shelves outside.

The manufacture of channels, like other rolled metal products, is regulated by the relevant GOST, which clearly spells out the basic requirements for a particular type of profile. All data are clearly shown in tables. For example, the regulatory document “Hot-rolled steel channels. Assortment "(GOST 8240 97) contains 7 such expanded tables.

Using the appropriate tabular data, you can determine the quality of the product by correlating its real dimensions with those described in GOST. Ideally, the indicators should completely match, although sometimes metal products are made to order. Individual profiles are produced in small batches - for a specific project. Custom-made channel prices differ from the cost of serial production.

The GOST standards clearly state all the requirements that a channel of one type or another must meet.

The standard height of the channel bars ranges from 50 to 400 mm, the width of the shelves is from 32 to 115 mm.The permissible error (compared to the stated standard dimensions) can be a maximum of 3 mm. The measured length of the channels corresponds to an indicator from 4 to 13 m.

The weight of the channels, their markings and symbols

To designate different types of channels, special markings are used. The letter denotes the type of profile, characterizing the features of the structure and location of the edges:

- "P" - indicates parallelism;

- "Y" - denotes the presence of a slope on the edges;

- "E" - indicates efficiency;

- "L" - means lightness;

- "C" - speaks about the special purpose of the profile.

Useful advice! The numerical indicator near the letter indicates the size of the product, it corresponds to the height given in the GOST table. It should be noted that usually channels are marked with numerical values in centimeters, and their height in the table is indicated in millimeters. It looks like this: channel 8, channel weight 12 or channel size 16P.

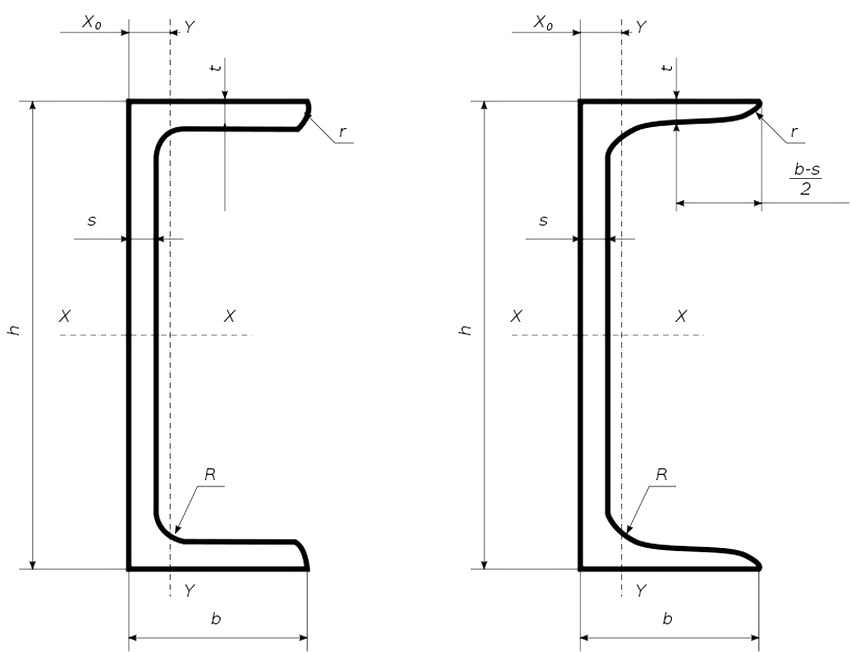

In addition to the height of the product, other dimensions are also used. In the tables, they have special designations:

- h is the profile height, which is the main value that determines the size of rolled metal products;

- b - indicates the width of the shelves;

- S - indicator of the thickness of the main wall;

- R - defines the radius of the rounded inner part of the shelf;

- t - indicates the thickness of the shelves;

- r is the total radius of curvature of the shelves.

An important indicator in the choice of material (in the design of construction) is the weight of the channel. Correct calculation of data allows you to accurately calculate the amount of required products and, thus, save on its purchase. There are several methods for calculating the weight of a running meter. They depend on the method of manufacturing rolled products. For example, to determine the specific gravity of a hot-rolled channel, the indicators of the radii of the internal rounding and rounding of the shelves are taken into account.

Determination of the weight and price of the channel per meter: size table, cost of profiles

Complex calculations of specific gravity, in addition to mathematical skills, also require updating the school course in physics and geometry. Therefore, it is better to use the ready-made calculations given in special tables, or use an online calculator. To do this, it is enough to enter the necessary data and get an accurate result.

The cost of channel bars is determined in accordance with running meters. The price formation is influenced by the profile height, which determines the product number, as well as the steel grade from which the products are made. For example, a channel made of low-alloy steel will cost an order of magnitude more than similar products made of carbon steel. This is due to the fact that the first type of raw material has increased strength characteristics.

The current average prices for channels in the Russian market of rolled metal are shown in the table:

| Channel number | Running meter weight, kg | Length in ton, m | Price per running meter, rub. |

| 5 | 4,8 | 207 | 200 |

| 6,5 | 5,9 | 169 | 240 |

| 8 | 7,1 | 142 | 265 |

| 10 | 8,6 | 115 | 350 |

| 12 | 10,4 | 97 | 420 |

| 14 | 12,3 | 82 | 480 |

| 16 | 14,2 | 71 | 520 |

| 18 | 16,3 | 60 | 600 |

| 20 | 18,4 | 55 | 760 |

| 22 | 21,0 | 48 | 870 |

| 24 | 24,0 | 42 | 1020 |

| 27 | 27,7 | 35 | 1150 |

| 30 | 31,8 | 32 | 1400 |

| 40 | 48,3 | 21 | 4250 |

Above is a general table. In order to have an idea of each type of channel, its individual features, dimensions and characteristics, it is worth getting to know each type in more detail. Below, as an example, consider the most common types and sizes of channels that are in high demand and are widely used.

Characteristics of channel 10: dimensions, weight, cost

The range of channel 10, as a fairly popular rolled metal product, is quite wide. The characteristics of its varieties and types are regulated by GOST 8240, developed back in 1989. The properties of the products include the parameters of the shelves and walls, in particular their height and width, and also the radii of curvatures for channels marked 10U are taken into account.

Channel 10 has three subtypes with corresponding markings:

- У - a profile in which the inner shelves are made with a slope;

- P - channel, where the edges of the shelves are parallel;

- E - economical products with parallel arrangement of shelves.

Useful advice! Each type of channel has its own designation, for example, 10P, 10U or 10E. The corresponding values are contained in a separate table. Despite the same numerical data, these are different types of products.

The most used in various industries is, due to its size, channel 10P. It is widely used in individual construction for the construction of load-bearing structures. The number 10 in the marking, in fact, indicates its height, equal to 100 mm, and the letter P - the type of profile, while emphasizing the parallel arrangement of the shelves. This type of channel has the following parameters:

- width is 46 mm;

- wall thickness - 4.5 mm;

- shelf thickness - 7.6 mm;

- radius of curvature - 7 mm;

- radius of curvature at the edge of the shelf - 4 mm.

To determine the weight of the channel 10, you need to know the cross-sectional area. This figure corresponds to 10.9 cm². Channel of this type is produced in lengths from 4 to 12 m. Longer products are made to order. The weight of 1 meter of channel 10 with a steel density of 7.85 g / cm³, according to calculations, is 8.59 kg. The error in the indicated mass values can be 3-5%. The average price of a channel 10 per meter is 356 rubles.

Main parameters of channel 12: dimensions, weight and cost

A metal product called channel 12 with parallel shelves has a body thickness of 7.8 mm, walls - 4.8 mm. Such products are produced in lengths from 2 to 12 m. Longer copies can be made to order. The popularity of this type of profile is due to its positive qualities, concluded in the optimal ratio of mass, strength and relatively low cost.

Low-alloy steel profiles can be used at high temperatures and under conditions of increased exposure to chemicals. Also, the products perfectly resist compression and bending, but at the same time they do not resist torsion well.

The weight of 1 meter of channel 12 can be found using the table above or using an online calculator. The price of the product depends on this parameter. According to the table, the weight of channel 12 per 1 meter is 10.4 kg.

Like channels of other sizes, this type of product has additional markings with different characteristics. The most popular is the 12P channel, which has parallel shelves with edges without a slope.

The dimensions of the 12P channel are shown below:

- width - 52 mm;

- running meter weight - 10.40 kg;

- length in a ton - 95.94 m.

Channel with 12 mark also has other series. For example, 12L is a rolled metal product with dimensions of 120x30 mm, characterized by inclined shelves. The weight of 1 m of such a profile is 5.02 kg, and the footage in 1 ton is 199 m.

Useful advice! The marking of the channel 12C indicates its special purpose, 12E - an economical series of products with shelves without inclination. Their size is standard - 120x52 mm, and their weight is slightly lower - 10.24 kg. Accordingly, a ton of material contains almost 97 m.

Together with a digital value indicating the width of the profile, they put a letter indicating the design features of the material

Variations of channel 14: dimensions, weight, scope

U-shaped products with marking 14, due to their high strength characteristics, are widely used in reinforcing reinforced concrete products, used for reinforcing metal structures, as well as in various construction and restoration works. This type of product has its own series:

- 14P is a hot-rolled channel for general use.It is produced according to GOST 8240-97.

- 14U is a special-purpose profile that is widely used in mechanical engineering.

- A steel bent channel with equal shelves is produced by means of specialized machines.

- A bent steel profile with unequal flanges is produced on roll forming equipment.

Channel 14, like others types of rolled metal, can be both with parallel shelves (marking "P"), and with inclined ones - brand "U". There are common characteristics for both series:

- height - 140 mm;

- width - 58 mm;

- shelf thickness - 8.1 mm;

- wall thickness - 4.9 mm;

- weight of 1 meter of channel 14 - 12.3 kg;

- 1 ton contains 81.3 m of the product.

It should be noted that the weight of channel 14 is strictly regulated by the requirements of a certain GOST. The maximum error cannot exceed 4.5% of the mass of all purchased products. Channels of this type are produced in lengths from 2 to 12 m. The cost of production depends on the series.

Features of channel 16: dimensions, weight and cost

Channel 16 is widely used to strengthen large-sized structures, such as bridges, supports, as well as when pouring the foundations of high-rise buildings. The technical features of a special series of rolled metal provide for its use in mechanical engineering, car building and shipbuilding.

Related article:

Range of channels: ratio of characteristics as a guarantee of reliability

Types, marking and characteristics of rolled u-shaped products. Requirements according to GOST, Gosstandart tables. The mass and dimensions of the channels.

The main feature is the slope of the edges in the middle of the products, which gives increased bending strength and torsional stability. This type of product has three series:

- 16P - used in installation work due to ease of installation;

- 16U - is distinguished by resistance to vertical loads, which suggests its use in areas with increased seismic activity;

- 16L - due to its low weight, it is used for the construction of monolithic structures and in shipbuilding.

All products comply with a specific GOST:

- 8240-97 - hot-rolled channels;

- 8278-83 - cold-formed channels with equal shelves;

- 8281-80 - bent with unequal shelves.

The standard dimensions of the channel 16 correspond to the following values:

- height - 160 mm;

- shelf width - 64 mm;

- wall thickness - 5 mm;

- shelf thickness - 8.4 mm.

The weight of the channel 16 corresponds to the value of 14.2 kg. There are about 70 m of rolled metal in one ton. These indicators directly affect the pricing of steel profiles. For example, the average price of a 16 channel per meter is 520 rubles. Products are produced in lengths from 2 to 12 m.

Useful advice! The length of the product affects the convenience of its transportation. That is why the production of channels over 12 m is not practiced. At the same time, it is this length that is the most running, just for it special auto platforms are designed.

Weight, price, dimensions of channel 20: all the necessary information about the profile

Channel 20 belongs to the category of universal metal products made of steel by hot-rolled method. It is used in almost all industries - not only in the construction of load-bearing structures, but also for the construction of bridges, in the automotive and carriage industries, as well as in heavy engineering. The production of products is regulated by several GOSTs, according to which technical characteristics and permissible deviations from the norm are established.

Channel 20 has three main types that meet the specific requirements of the State Standard:

- general use and special purpose - GOST 8240-97;

- special for the automotive industry - GOST 19425-74;

- special for car building - GOST 5267.1-90.

All these types of rolled products are characterized by common parameters, such as the height, width of the flanges and the weight of the channel 20. It should be noted that the profile can be either equal-flange or with inclined flange edges. The dimensional characteristics of profile 20 are as follows:

- height - 200 mm;

- shelf width - 76 mm;

- wall thickness - 52 mm;

- shelf thickness - 9 mm.

The weight of different types of channel can be slightly different. For example, a 20P channel has a weight of 1 meter equal to 18.4 kg. Series P channel 20 is most in demand in the construction market. It is used both for the construction of frames and for the construction of bridges, the creation of large machine tools, and also for other purposes. According to GOST 8240-89 for hot-rolled and GOST 8278-83 for bent channels, profiles are made in lengths from 4 to 12 m.

Channel: dimensions affecting the scope

Summing up the above, the conclusion suggests itself that the channel is a rolled metal product that is used to reinforce reinforced concrete structures, for the production of crane products, electrical supports, bridges, oil derricks and other large-scale structures. A wide range of applications is due to the high level of strength and stability with a relatively low weight of the product. At the same time, different sizes of channels are applicable in specific areas or have a special purpose.

So, due to its compact dimensions, channel 8 is widely used in individual construction as concrete lintels, and also serves for the manufacture of foundations in the construction of door and window openings. Wide application, due to its universal size and strength, has a channel 10, made by hot rolling.

Channel 12 is produced in the same way. Its main positive feature is excellent weldability. It is used to increase the bearing capacity of a structure and as a reinforcement of structures. Channel 14 is produced using rolling machines. Reinforced rigidity implies its use as load-bearing beams in ceilings for the construction of high-rise buildings, as well as in carriage building.

Useful advice! When choosing rolled metal products, remember about the existence of different series of channels. Profiles in which the edges of the flanges are located in parallel are marked with the letter "P"; special channels are marked "C". Models with inclined inner edges of the shelves are designated by the letter "U"; economical profiles correspond to the "E" mark; sign "L" means light version of channel bars.

Channel 16, manufactured by hot rolling, is widely used in the construction of high-rise buildings, as well as in the construction of metal supports for bridges. The dimensions of the channel 18 allow it to be used as reinforcement on high-rise buildings and in structures with a high degree of load.

Profiles with markings from 20 and above can be used for the construction of bridges and other large-sized objects with high loads

Profiles marked 20, 22, 24 are classified as high-strength. They are used in the construction of highly loaded buildings and structures that move. For example, the dimensions of channel 24 suggest its use in the construction of movable bridges, as well as cranes with high lifting capacity.

Channel 40, having maximum rigidity, is used in heavy industry, where colossal loads are envisaged, in shipbuilding, as well as for the construction of oil platforms.

Thus, channels are of great importance in construction, therefore they are widely used in various areas. When choosing a product, it is necessary to navigate the range of sizes and know the main characteristics of each type of channel. This will allow you to select the required series and use this type of rolled metal products as efficiently as possible.