Concrete is a fairly common material nowadays. It is used in the production of various works, from ordinary repairs in apartments, to capital construction. At the planning stage, selection of materials, calculation of their quantity, one has to ask the question: how much does a cube of concrete weigh. Let's try to figure out how to do it correctly and what this parameter depends on.

Content [Hide]

General information, characteristics of concrete

In fact, the concept of "weight" for this raw material does not have any precise figures. This is due to the fact that the building material of such a plan consists of different components, which differ significantly in weight. The components can be used:

- crushed stone;

- pebbles;

- gravel;

- pumice;

- expanded clay and others.

Under initially equal conditions, the weight of the two solutions can be very different. Even the size of the filler granules affects the weight. The larger the fraction, the less weight, since more voids are formed during mixing.

Related article:

|

At the same time, builders simply need information about how much a cube of concrete weighs. Based on these numbers, the scope of the material is determined. It is used in determining the type of foundation for various soils, as well as in calculating other supporting structures (walls, floors).

Important! Data on how much a concrete product weighs can be useful not only during construction, but also during the demolition of buildings.

Types of concrete

Depending on the proportion of raw materials and final mass, concretes are divided into several types. Allocate heavy and extra heavy materials, light and ultralight. For each individual species, its own niche is reserved on the market.

Heavy, extra heavy concrete

Heavy concrete, which contains hard rock, is used to create the foundations of buildings, foundations and other similar structures. However, when mixing the solution, the the ratio of its components can change, so it is almost impossible to say with accuracy how much a cube of concrete weighs. Usually this figure varies within the range: 1900-2500 kg / m³.

Particularly heavy materials are used relatively rarely. Hematite, barite and even cast iron and iron-ore elements can be added to the composition of such material.Cement of the highest grades is also used for production, which significantly affects the price of the entire structure. For the construction of private houses and apartments, their use is irrational. Particularly heavy options are suitable for the construction of large industrial buildings. The average weight of a cube of super heavy concrete can vary from 2500 to 3000 kg.

Lightweight, ultra-lightweight concrete

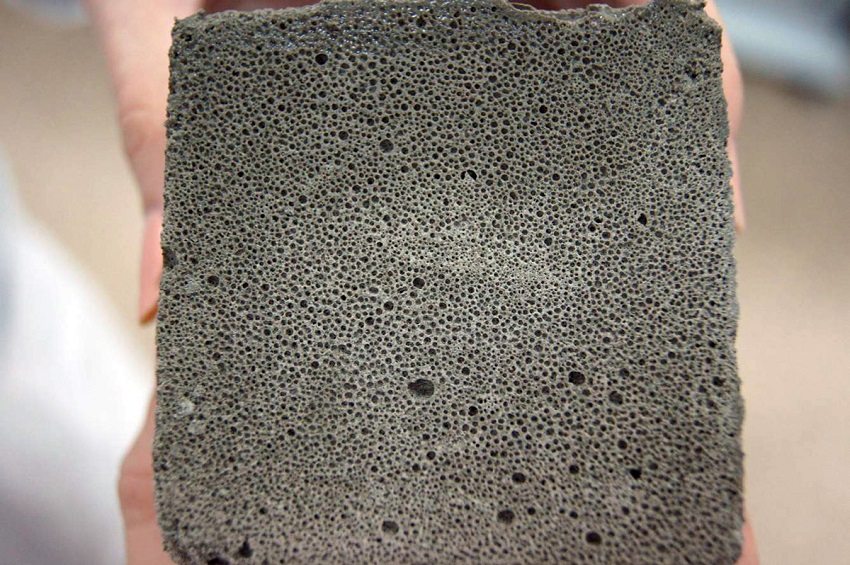

Such materials differ from their heavy counterparts in a more porous texture. Thanks to this, the weight of the cube is 500 - 1900 kg. Their use is limited to lightweight partitions and walls of small buildings. And how much does an ultralight cube of concrete weigh? The use of the following components: vermiculite, perlite, can significantly reduce weight. Therefore, the ultralight version can weigh less than 500 kg.

Particularly lightweight concretes include foam concrete or aerated concrete... The decrease in mass in this case occurs due to the volumetric, cellular structure. These are worthy competitors to conventional formulations, which have recently become very popular.

Important! The use of aerated concrete is also possible when creating load-bearing structures, provided that the load on them is not too great.

How much does a cube of concrete weigh?

Some characteristics of concrete can be clarified by opening SNiP 11-3. The table shows the weight of the material depending on the type of components:

| P / p No. | A kind of concrete | Weight in t / m³ |

| 1 | Reinforced concrete | 2,5 |

| 2 | Foam concrete | 0,3 — 1,0 |

| 3 | With the addition of rubble | 2,4 |

| 4 | With expanded clay sand | 0,5 — 1,6 |

| 5 | With quartz sand | 0,8 — 1,2 |

| 6 | Tuff | 1,2 — 1,6 |

| 7 | With perlite sand | 0,8 — 1,0 |

| 8 | Aerated concrete | 0,3 — 1,0 |

These are approximate figures, but they are used by professional builders to determine the total weight. More accurate data is almost impossible to obtain. Additionally, developers calculate the weight of 1 cubic meter, depending on the brand of cement. For heavy materials, this data will look like this:

| P / p No. | Cement grade | Liquid state (t / m³) | Dry condition (t / m³) |

| 1 | M100 | 2,366 | 2,180 |

| 2 | M150 | 2,360 | 2,181 |

| 3 | M200 | 2,362 | 2,182 |

| 4 | M300 | 2,358 | 2,183 |

| 5 | M400 | 2,350 | 2,170 |

| 6 | M500 | 2,355 | 2,180 |

As you can see, the weight of concrete depends on many factors. Therefore, no one can calculate the exact value up to 1 kg. It is quite enough for the necessary calculations to use approximate figures to determine the weight of the future structure.