The operating conditions of the baths differ from those with which most buildings have to deal. Therefore, the issue of high-quality steam and heat insulation should be given special attention. Consider how to insulate the ceiling, floor, walls in the bath and which technology to give preference to in order to create a suitable microclimate and minimize heat loss, saving our own efforts and resources.

Ceiling insulation in a bath is one of the most important aspects of construction, which allows you to protect the building from the aggressive effects of temperatures, steam and moisture

Content [Hide]

- 1 Why is it necessary to insulate the ceiling in the bath: structural features

- 2 Ceiling insulation in a bath with a cold roof, depending on the characteristics of the roof

- 3 How to insulate the ceiling in a bath: the best thermal insulation materials

- 3.1 Do-it-yourself sauna ceiling insulation: advantages and disadvantages of mineral wool

- 3.2 Insulation of the ceiling in a bath with expanded clay: features of use

- 3.3 Is it worth doing the insulation of the ceiling from the inside with foam

- 3.4 Using ecowool as a heater for a bath

- 3.5 Thermal insulation of the sauna inside with a mixture of cement and sawdust

- 4 Features of arrangement of vapor barrier and waterproofing layers

- 5 Do-it-yourself flooring ceiling insulation: step-by-step instructions

- 6 Do-it-yourself warming of a false ceiling: step by step instructions

- 7 Do-it-yourself sauna ceiling insulation without an attic: the nuances of work

- 8 2 options for warming the floor in the bath with your own hands: instructions for work

- 9 Thermal insulation of a bath outside and inside: features of wall insulation

- 10 Thermal insulation of a bath from block bricks inside: video instruction

Why is it necessary to insulate the ceiling in the bath: structural features

A bath is a room that is periodically heated in order to take health procedures. Inside the premises, a special microclimate is formed, characterized by high temperature and humidity. Of course, this cannot but affect those building materials that have to be exposed to such an impact.

The arrangement of the bath requires special attention in terms of hydro, steam and thermal insulation

In addition, you have to reckon with the costs associated with the use of a particular amount of fuel. If the building has a tendency to cool quickly, a large amount of fuel will be required to maintain the appropriate temperature. And given the fact that, according to the laws of physics, warm air is lighter than cold air, it is the roof of the bathhouse that requires insulation, through which there is a significant loss of heat.

But on the way to erecting a barrier to keep warm air indoors, there is another aspect that should be paid special attention to all bath owners. High humidity becomes a source of a large amount of condensation, which, if the roof is not properly insulated, can accumulate. This often causes the destruction of wooden building elements.

Interesting fact! High humidity is a favorable environment for the growth and development of various microorganisms: fungi, mold and bacteria. Poorly thought out steam and heat insulation can cause their appearance and reproduction.

Materials for warming and insulating a bath are selected depending on the type and size of the building

Ceiling insulation in a bath with a cold roof, depending on the characteristics of the roof

The roof of the bath can be represented by one of two types: having an attic space and without it. In the first case, the air layer itself creates a fairly effective barrier, which has a positive effect on the building's ability to retain heat. But this does not mean at all that the presence of an attic completely eliminates the need for insulation work.

If the bathhouse does not provide for an attic or an attic, then high-quality thermal insulation is almost a prerequisite for the further use of the building for its intended purpose.

Regardless of what type of room you are faced with, the first and extremely important step is to provide a vapor barrier. For this, such affordable materials as aluminum foil, high-density cardboard, which are pre-impregnated with linseed oil or wax paper, are perfect.

Before laying the thermal insulation layer, you should take care of reliable vapor barrier of the roof. baths

Useful advice!If work is being carried out to insulate the ceiling in a bathhouse, where there is an attic room, then it is recommended to coat the ceiling boards from the side of the roof with a layer of clay of about 2-3 cm.

How to insulate the ceiling in a bath: the best thermal insulation materials

In the process of kindling the sauna, the temperature and humidity in the room reach extremely high levels. Therefore, special requirements are imposed on the building materials that are used in the process of arranging this room, namely, they must be resistant to such effects and at the same time not emit hazardous substances when heated.

In addition, it is not recommended that the weight of the insulation be too heavy. It is preferable to make a choice in favor of lightweight material, simple and convenient both in transportation and installation. And of course, we must not forget about such a characteristic as fire resistance, which is important for such a room as a bath.

There is a wide variety of heaters and insulators for buildings on the modern market, so it is quite easy to choose high-quality material based on their required characteristics and financial capabilities

Do-it-yourself sauna ceiling insulation: advantages and disadvantages of mineral wool

Mineral wool is by far the most popular option among them all. It is often used for insulating not only baths and garages, but also for residential buildings. By itself, it is a fibrous material that has excellent thermal insulation characteristics and can be presented in one of three types:

- glass wool;

- stone wool;

- slag wool.

But if the first option is familiar to almost everyone, then not everyone saw the other two. Rock wool is a material derived primarily from basalt, although it is sometimes made from other rock melts as well. Slag wool is very similar to cinder blocks, for the production of which blast furnace slags are used.

Mineral wool is characterized by significant resistance to high temperatures, and also has excellent heat and sound insulation properties

In addition to the fact that mineral wool has a low thermal conductivity, which makes it possible to use it for thermal insulation of ceilings and walls, it has another significant advantage. Unlike other materials, it cannot serve as a breeding ground for microorganisms: fungi, mold, small insects or rodents, which is very useful for summer cottages.

As for other characteristics, mineral wool is not prone to fire and does not react in any way to temperature changes: it does not deform or shrink. Light weight and convenient packaging (usually in the form of rolls or rectangular plates) make it easy and convenient to work with the material, even alone.

Of course, this material also has drawbacks that one way or another will have to be reckoned with:

- mineral wool is able to absorb moisture;

- it contains phenols, which can potentially pose a danger to human health.

Both of these disadvantages can be neutralized during the installation process, providing the insulation with high-quality steam and waterproofing, completely eliminating the risk of contact of the mineral wool with air under the ceiling. This is especially true for warm and humid air that is concentrated indoors.

Useful advice! Despite the fact that, subject to all the rules for installing mineral wool, it does not pose a real threat to health, during its installation, care must be taken and protective equipment must be used, since its small fibers can irritate the skin and eyes.

Insulation of the ceiling in a bath with expanded clay: features of use

Expanded clay are small pebbles that consist of clay and have a porous structure. If all factors are taken into account, then expanded clay can be called the most suitable material for insulating the ceiling in a bath. Of course, if the building has an attic space and there is a possibility of using it.

Distinctive features of expanded clay as insulation are the high hydrophobicity of the material, as well as resistance to the development of microorganisms and fungi

The advantages of such a choice can be confidently attributed to the following aspects:

- expanded clay is completely safe: it does not support combustion, it is environmentally friendly and even in the event of a fire will not emit hazardous substances into the atmosphere;

- over time, as well as under the influence of external factors, expanded clay does not deteriorate and does not decompose;

- the cost of the material is quite low;

- bacteria and fungi do not consider expanded clay an attractive environment for life.

In addition, expanded clay is superior to mineral wool in its ability not to absorb moisture. And although the need to equip steam and waterproofing layers remains, the risk of moisture accumulation inside the insulation layer is much less. It should also be noted that the service life of expanded clay is one of the longest when compared with other materials.

Is it worth doing the insulation of the ceiling from the inside with foam

At a certain period, polystyrene was the leader among thermal insulation materials, which were used to insulate not only baths, but also residential buildings. But with the advent of alternative options, its significant disadvantages became noticeable. So, for example, in the event of a fire, the foam burns well, while also emitting toxic smoke that can harm human health.

In addition, the foam is not too resistant to external factors, collapsing under the influence of high temperatures, which is inevitable if it is used in a bath.

For these reasons, we can conclude that foam is far from the most suitable material for this purpose and it is better to give preference to another material that is more stable and suitable in terms of characteristics.

Many builders prefer to insulate the ceiling of baths with foam with a thermal layer, rather than foam

Using ecowool as insulation for a bath

Another material that is popular among heaters and is often used, including for baths and garages, is ecowool. This fibrous material is made from cellulose, adding special additives to it, designed to provide protection against insects, bacteria and rodents. In addition, they make ecowool resistant to fire.

Related article:

Construction of a bath in the country: video instructions and tips for creating a building

Video review of the technology for creating a bath with your own hands, the main stages of building a building, requirements and tips. Common types of baths.

The advantages of this material include environmental friendliness, as well as low weight and the ability to fill even the smallest gaps and gaps, which is very convenient when it comes to working with an uneven surface. It does not emit any toxic substances, so, like expanded clay, it is completely safe for human health.

But there is also a significant drawback: the efficiency of using ecowool is directly related to the presence of ventilation, as well as a high-quality waterproofing layer, which is designed to remove moisture. This is due to the fact that ecowool itself is very prone to absorbing condensate, which negatively affects its thermal insulation characteristics.

Ecowool, as an environmentally friendly material, is used for insulation and insulation of walls, floors and ceilings

There are two ways to apply this heat insulator to walls, the so-called "dry" and "wet". The main difference and, at the same time, the complexity of the second option is the need to use special equipment for this, the rental of which will cause rather high prices for ceiling insulation in this way.

Thermal insulation of the sauna inside with a mixture of cement and sawdust

This method can be confidently called the oldest among all those described, since these materials were used for insulation long before such thermal insulation materials as foam and mineral wool appeared on the market at all.

Interesting fact! Usually, cement and sawdust are used to create a suitable mixture. Although it is quite acceptable to replace these components with clay and straw.

First of all, a dry mixture is prepared, which includes sawdust, lime and cement in a ratio of 10/1/1, respectively. After mixing all the dry components, add 1.5 parts of water to them, pouring it in gradually and stirring thoroughly so that the solution is homogeneous. After that, it remains only to lay the mixture on the surface and level it to an even layer.

You can insulate the bath from the inside using inexpensive materials such as cement and sawdust, mixing them in the correct proportion

Experts recommend using sawdust to create such a mixture, which has been previously dried for several months, or even better for a whole year.

If all recommendations and technologies are followed, as a result, you can get high-quality, environmentally friendly material. Although we have to admit that in terms of thermal insulation characteristics, it is still inferior to mineral wool and even expanded clay. So, perhaps its only advantage is its low cost, which nevertheless entails quite a lot of hassle.

Features of arrangement of vapor barrier and waterproofing layers

The presence of a vapor barrier is not a whim, but a real necessity. Especially when it comes to premises such as a bathhouse, where hot air is an integral part of using the premises as intended. Rising in the form of steam, moisture can have a destructive effect on the insulation and contribute to the appearance of mold and mildew on the wooden elements of the bath frame.

In order to avoid problems that can arise from the accumulation of moisture on the ceiling and walls, special films and coating materials are used, for example, anti-condensation membranes. When choosing a suitable material, it is advisable to purchase one that has a foil layer.

Useful advice! When installing a vapor barrier film, it is very important to pay attention to its integrity. It is necessary to prevent the appearance of breaks, as this will greatly affect the technical characteristics of the coating.

To ensure waterproofing, special films are used, which can be purchased at hardware stores. Sometimes the most common polyethylene of sufficient density or cheap roofing felt is used.

To protect the bath frame from moisture, it is recommended to use a waterproofing membrane that can be mounted in contact with the insulation without losing its properties

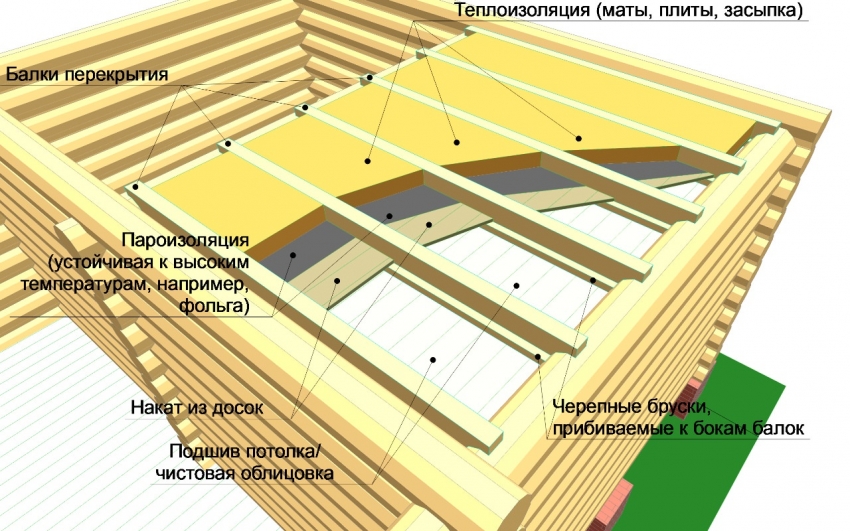

Do-it-yourself flooring ceiling insulation: step by step instructions

A flat ceiling is a great option for buildings that are used seasonally and have a small footprint. But in such a design there is not a lot of space for bulk insulation. In addition, such a ceiling is also unable to withstand a large weight. Therefore, the choice of material should be approached more responsibly.

In order to have enough space for laying the insulation, the floor ceiling must be placed slightly below the height of the walls. And after that, you can proceed to the phased work according to the following instructions:

- First of all, it is necessary to install the vapor barrier layer from the attic side. In this case, the side on which the foil is located should face down. The material is laid with an overlap of about 10-15 cm, and in order to ensure tightness, you also need to glue the joints with tape.

- The selected thermal insulation material is laid on top. In this case, mineral wool or expanded clay is best suited, since the floor ceiling is not designed for heavy loads.

- A layer of waterproofing material is placed on top, which is suitable as roofing material or plastic film. Laying must be done with an overlap, and the seams are carefully glued with tape.

- The final layer should consist of sheets of plywood or planks, which will provide reliable protection for the previous layers.

The plank ceiling is easy to use, in particular, in terms of insulation. If necessary, the layers of insulators can be replaced with little effort

This is a simple method that is relevant if you do not plan to spend too much money and time on it. If the bath area is large enough or it is necessary to use the space under the roof for storage, then this option will not be very suitable due to its fragility. In this case, it is better to give preference to a false ceiling.

Do-it-yourself warming of a false ceiling: step by step instructions

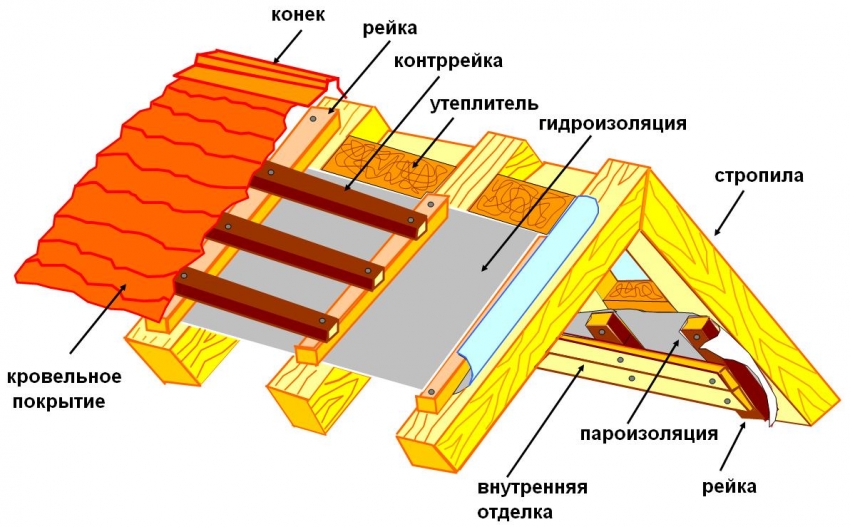

The design of the false ceiling provides for fastening to the upper part of the wall not the flooring itself, but the support beams, for which a wooden beam or several boards spliced together are most often used. Above and below, a ceiling is attached to the beams, which also serves as the floor of the attic. Well, in the middle between the upper and lower layers, a layer of insulating material is laid, as well as hydro and vapor insulators.

The installation process may differ slightly depending on what kind of insulation was chosen, however, in general, the technology remains the same. In the case of using mineral wool for this purpose, the procedure is as follows:

- the first is a layer of waterproofing material, which is attached to the upper surface of the beams using a furniture stapler. As in all other cases, the overlaps must be at least 10 cm, and the joints are additionally glued;

- boards or plywood are laid on top of the waterproofing, thus providing the structure with strength and reliability;

- mineral wool of suitable thickness is placed in the gaps between the beams based on the following standards: 150-180 mm for regions with a temperate climate, 200-250 mm for regions characterized by severe frosts. As with waterproofing material, the connection of two separate parts of the material must be overlapped;

- the vapor barrier film is attached to the floor joists from the bottom side. At the same time, it is highly recommended that its edges are attached to the upper part of the walls. Since this is a very delicate material, it is important to work with it carefully, avoiding damage and tears;

- perpendicular to the beams, wooden slats are attached on top of the vapor barrier material;

- the final stage - fastening the lining with screws or nails to these slats.

Such an insulated ceiling is very durable and capable of withstanding serious loads, so that the attic space can be used for arranging an attic or as a storage for various accessories.

The final layer of insulation of the ceiling of the bath is the installation of a vapor barrier film, with which you need to work quite carefully

Do-it-yourself sauna ceiling insulation without an attic: the nuances of work

The technology of warming a wooden or panel bath, in the case of a complete absence of an attic space, has some differences from those that were considered earlier. In this case, it is necessary to fix the vapor barrier material, and then attach the insulation itself. Already on it, the fastening of the beam and the final layer - ceiling boards is carried out.

Particular attention should be paid to the junction of the insulation and the pipe. First of all, this is necessary to ensure compliance with fire safety standards. The indentation stipulated by the rules must be at least 200 mm. Naturally, it is impossible to simply leave a hole, and therefore a simple box is mounted, consisting of rafter legs. Its main role is to separate the insulation and the pipe.

Useful advice!The inside of the box can also be filled with thermal insulation material. True, it must be fire resistant and not subject to high temperatures. For example, stone wool is suitable for this.

Before laying the layers of insulation and insulation, it is recommended to treat the wooden ceiling with special means to exclude the possibility of the development of harmful bacteria and fungi

Another important task facing the owner who insulates the ceiling of a bathhouse without an attic is to completely eliminate the risk of condensation. Therefore, all steam and waterproofing materials must be of high quality and fixed in strict accordance with the rules and regulations.

2 options for warming the floor in the bath with your own hands: instructions for work

Of course, when carrying out work on the insulation of a brick bath or a building made of wood, laying the insulation material only on the ceiling will not be enough. Therefore, it is worth taking care that the room has a warm floor. Consider how the work is carried out, depending on what materials you have to deal with.

Option 1. Thermal insulation of a wooden floor in a bath

In order to make the floor in the bath warmer and reduce heat loss, use the same materials as in the case of ceiling installation. Often they use the method of floor insulation in the bath with expanded clay, mineral wool, ecowool.

Warming and insulation of the wooden floor in the bath is carried out without fail in accordance with the technologies and recommendations of specialists

Useful advice!One of the most effective ways to keep warm in a room is to install a bath on screw piles. In this case, floor insulation will not be required so urgently due to the presence of an additional air cushion under the building.

The insulation procedure begins with the dismantling of all elements that may interfere with the work. Skirting boards and floorboards are removed. After that, all remaining wooden elements are thoroughly examined and checked for damage. If found, the damaged elements are replaced with new ones. It is imperative to carry out treatment with antiseptics, which will protect against rodents, insects and fungi.

Using small-sized blocks, the lower edges of the log are built up to create a reliable support for the rough covering. Using cheap lumber, a rough covering is mounted, leaving gaps of about a centimeter between the logs and the boards. The subfloor boards should not be laid too tightly, as the wood tends to expand when the air humidity rises, which can lead to deformation of the coating in case of too dense laying.

It is imperative to lay a vapor barrier layer, especially if the ground levels are located in close proximity to the surface. The vapor barrier should cover the entire surface, including the logs. If the groundwater is located high, then glassine or roofing felt is best, and for a low groundwater level, a vapor barrier membrane.

The fastening of the material for the vapor barrier must be carried out in such a way that it also captures the lower edges of the wall, by about 15 cm. It is most convenient to fasten the material to the logs using a construction stapler, gluing each joint with tape.

The heat insulator is placed between the logs so that about 2 cm of air cushion remains on top. This will allow natural ventilation.

Useful advice! If the thickness of the heat insulator is so large that it is impossible to leave free space, then a crate can be placed on top of the material with a step of about 40 cm.

To eliminate the risk of moisture ingress, another waterproofing layer is placed on top. It is preferable to use a membrane material for this purpose. If there is a need to install a batten, then the membrane should be laid under it. Finally, the floorboards and skirting boards are attached. All protruding edges of the materials are cut off.

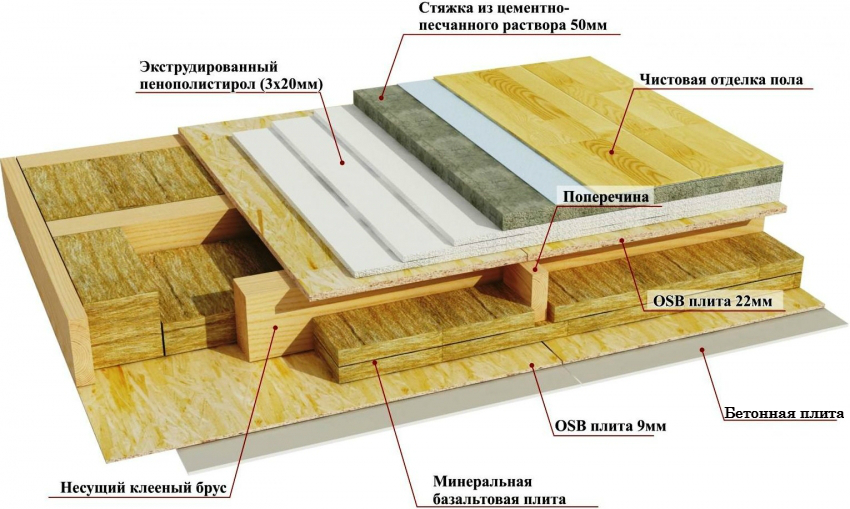

Option 2. Description of the technology of insulation of the concrete floor with expanded polystyrene

The procedure for warming the concrete floor in the bath is carried out in a slightly different way. This must be done after the completion of the rough work:

- A layer of waterproofing material is laid on top of the rough screed. Unlike a wooden floor, in this case, it is allowed to use ordinary high-strength polyethylene. At the same time, the approach to the walls should be at least 5 cm. The material is laid on the surface, and the excess is cut off. If the polyethylene was originally in a roll, its parts must be laid with an overlap of 10 cm, gluing the joints with tape.

- After that, the thermal insulation material is laid. Expanded polystyrene is best suited for this, since it has all the characteristics necessary for this. To attach the sheets to the surface, you can use special glue and self-tapping screws, and in some cases they make a crate.

- A reinforcing mesh is laid on top and another screed is made, the thickness of which should be at least 2 cm.

- When the reinforcing screed is completely dry, you can start leveling the floor. For this, special self-leveling mixtures are on sale. It is only important that its layer is at least 5-8 cm above the level of the insulation.

Useful advice! In the process of pouring, be sure to level the mixture with a needle roller.This will get rid of excess air bubbles and make the coating as even and smooth as possible.

Thermal insulation of a bath outside and inside: features of wall insulation

The first thing you should pay attention to when planning work on the insulation of the walls of the bath - from the inside or outside, you want to place an insulating layer. Both options are acceptable, however, the first is used extremely rarely for a number of reasons:

- insulation from the inside of garages, baths and houses of modest size is an irrational use of the small space that is available. Obviously, laying all the necessary layers will reduce the room, which in some cases is not ergonomic;

- the humidity in the bath is so high that even if all the necessary conditions are met and the steam and heat insulation layers are installed, it is almost impossible to guarantee that the heat insulator will not be exposed to moisture sooner or later;

- warming the walls in the bath from the inside with your own hands allows you to keep warm inside the room, but is not able to protect the walls from freezing from the outside. This temperature difference is often detrimental to the condition of the building.

Depending on the size and type of structure of the bath, insulation and insulation can be carried out both from the inside and from the outside, or from both sides.

Consider the features of wall insulation, depending on the material that was used for the construction of the building.

Features of insulation in a wooden bath: a steam room from a log house

At first glance, it may seem that log buildings do not really need thermal insulation, since the wall looks quite sealed, and the wood does a good job of keeping heat. But in fact, the problem lies in the fact that the timber is highly susceptible to shrinkage and cracks form over time. It is they who become the main sources of cold.

The most effective way to close the gaps that form is to lay insulation between the logs during the construction phase. Then, using a hammer and caulk, all the remaining, even the smallest gaps, are clogged and treated with a sealant.

Interesting fact!To this day, lovers of environmentally friendly materials continue to use plants such as moss or cuckoo flax to fill cracks in the walls.

Thermal insulation baths from a bar occurs even at the construction stage, when a mezhventsovy insulation is laid between the logs

Do-it-yourself sauna insulation from the inside: brick, block and frame buildings

Perhaps one of the most labor-consuming processes is the insulation from the inside of the bath from expanded clay concrete blocks, bricks or other materials, to which it is not so easy to mount, and you also have to carefully choose the material, taking into account its weight and size.

For example, if we are talking about the insulation of a frame structure, which is not able to withstand serious loads, it is simply impossible to do without careful preliminary calculations. As an expensive but ideal option for this purpose, you can consider spraying PPU... This method can be used both for insulating a bath from foam blocks from the inside, and for buildings made of almost any material.

In some cases, extruded polystyrene foam boards are used. For internal insulation, this is not a very suitable option, since it takes up a significant amount of space, but for external cladding, there is no better solution.

In the case of a small bath area, in order to save space, you can consider the option of PPU spraying as insulation of the building

Useful advice! Warming by spraying polyurethane foam must be carried out by professionals and in compliance with all technological requirements and standards. Also, the availability of high-quality specialized equipment is required.

Thermal insulation of a bath from block bricks inside: video instruction

There are many different ways to insulate the floor, ceiling and walls of a bath, using various materials and technologies. You can find out more about one of these methods by reading the detailed video instruction on insulating a brick wall from the inside. Moreover, this technology can be used not only for baths. According to this instruction, you can also carry out the insulation of the garage from the inside with your own hands.