Being in a high-rise building, on the deck of a ship, on board a liner, few people appreciate the strength of the structure - comfort is important. But without a metal base in the form of a frame, sheets, channels, reinforcement, these structures simply would not exist. You cannot do without processed metal products in everyday life: roofing, utility pipes, gratings, etc. The range of rolled metal products is numerous and varied. How to choose a product of the right size will be discussed in the article.

Content [Hide]

- 1 Definition of rolled metal: what includes the range of metal

- 2 Characteristics and features of tubular products

- 3 Manufacturing method and range of sheet steel

- 4 Metal weight tables: which ones exist and how to use them

- 5 How to calculate metal weight without an online calculator

- 6 The range of rolled metal: how to choose metal products

Definition of rolled metal: what includes the range of metal

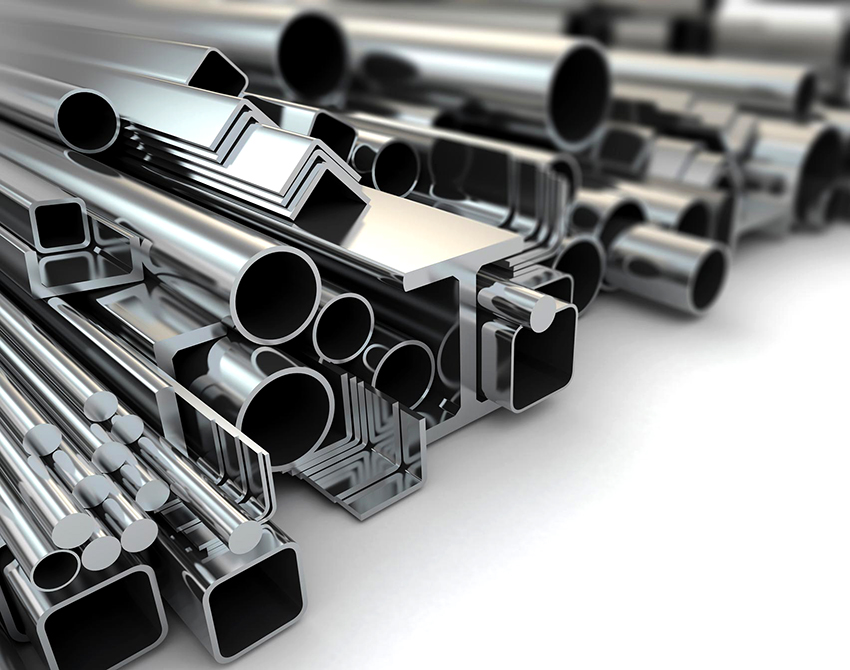

The word "assortment" is of French origin. True, the sound is somewhat distorted (French - assortir), but the essence is identical: to select, sort. Consequently, the assortment is a list of any selected products, grouped by varieties, types. Most often, this concept is used in the metallurgical industry to denote a set of rolled metal products. To understand how the assortment of metal products is formed, it is necessary to understand the question of what is rolled metal.

The range of rolled metal products is formed according to three indicators: size, cross-sectional shape and characteristics

The metal passes through the rolls on a special device (mill) and takes on a certain size and shape. This process is called rolling. There are three ways of rolling:

- hot;

- warm;

- cold.

They differ depending on the presence and degree of thermal effect on the metal. There are several types of rolling mills: tube rolling, sheet, crimping, for special types of rolling, billet.

Based on the above, it is possible to define the range of rolled metal products. The range of rolled metal is a list of rolled profiles, which contains a description of their qualities and sizes. When forming the assortment, three indicators are taken into account:

- sectional shape (profile);

- sizes;

- chemical and physical characteristics.

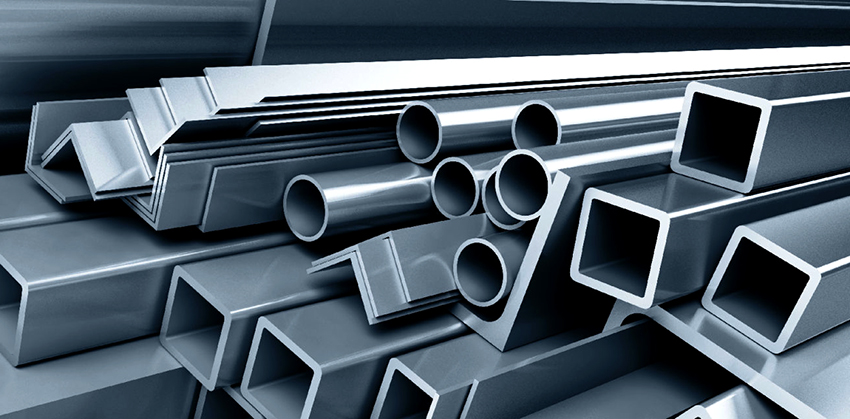

There are three main groups of rolled products assortment:

- sheet hire;

- high-quality and shaped rolled products;

- pipe products.

To summarize information about the types of products and their characteristics, metal rolling reference books are created. It is in them that the consumer can get acquainted with the full list of products and their qualities, choose the desired option.

To get acquainted with the entire list of products, it is necessary to study the metal rolling directory

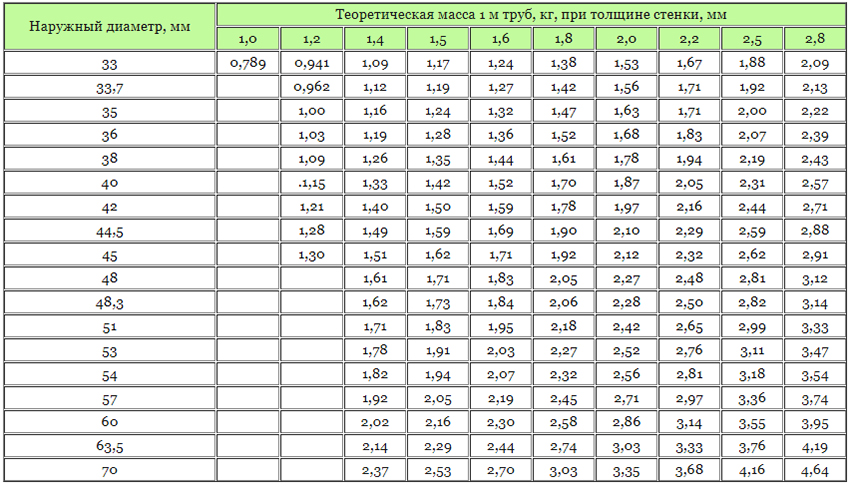

Characteristics and features of tubular products

Pipes are a fairly common category of rolled products. The main characteristics of these products:

- total length;

- wall thickness;

- inner and outer diameters;

- type of material;

- preparation method.

Most of the pipe products are circular, but square and flat pipes are also produced. There are several manufacturing methods:

- rolling;

- pressing;

- casting;

- welding.

Depending on the features of the manufacturing process, pipes are seamless and welded. Seamless is used to transport gases and liquids under pressure above 1 MPa. Welded pipes are created by rolling up a strip (rolled strip), overlapping and butt-welding, and seam welding. These products are used to move gases and liquids with low pressure through them. Requirements for tubular products are regulated by the following documents:

- GOST 10705-80 - electric-welded pipes;

- GOST 10704-91 - longitudinal seam products;

- GOST 8732-78 - seamless pipes;

- GOST 3262-75 (TU) - water and gas pipelines;

- GOST 8645-68 - rectangular shaped;

- GOST 8639-82 - profile square.

Pipes used in the gas and oil industry, in mechanical engineering, construction. They are used for laying various pipelines, for the manufacture of industrial cylinders and vessels.

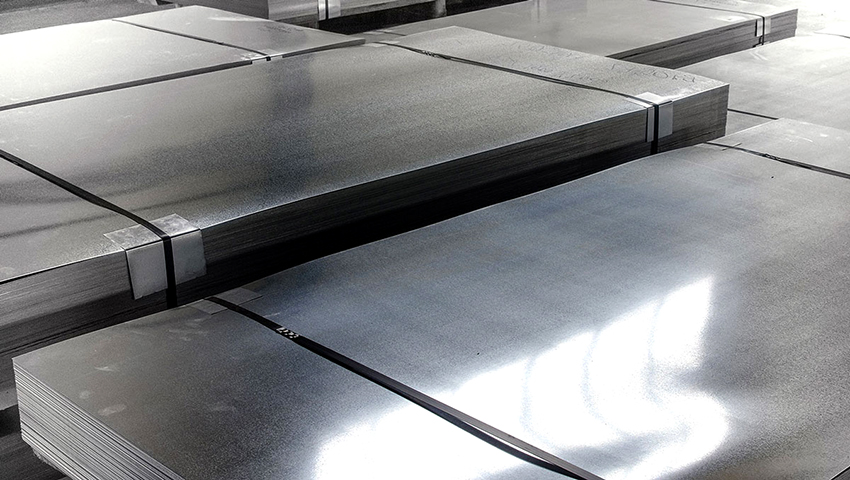

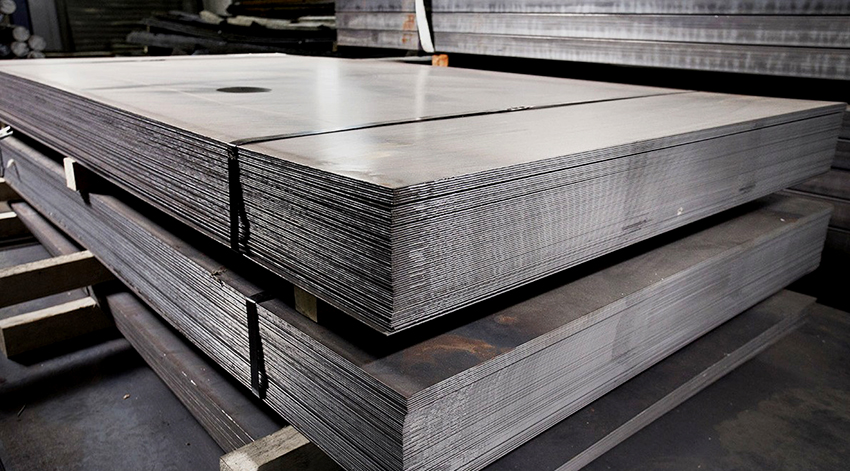

Manufacturing method and range of sheet steel

These products are manufactured by rolling. Supplied as single sheets or in rolls. The edge on these products can be cut, and can keep the shape acquired after processing. The division of these products into types is carried out on the basis of the following characteristics:

- rolling method;

- rolling precision;

- surface quality;

- sheet thickness;

- degree of traction.

Steel sheets are produced by cold-rolled and hot-rolled methods. There are two types of product accuracy - normal and high strength. The degree of traction is divided into deep and normal. The thickness of the sheets varies from 2 to 5 mm. The surface can be corrugated, corrugated or smooth.

Regulatory state documents:

- GOST 19903-74 - assortment of hot-rolled sheet metal products;

- GOST 19904-90 - assortment of cold-rolled sheets;

- GOST 16523-97 - specifications.

Sheet metal is actively used in mechanical engineering and construction. It is used for welding structures, sheathing, making casings, sarcophagi. Can be used as blanks for other products (household appliances, appliances, etc.)

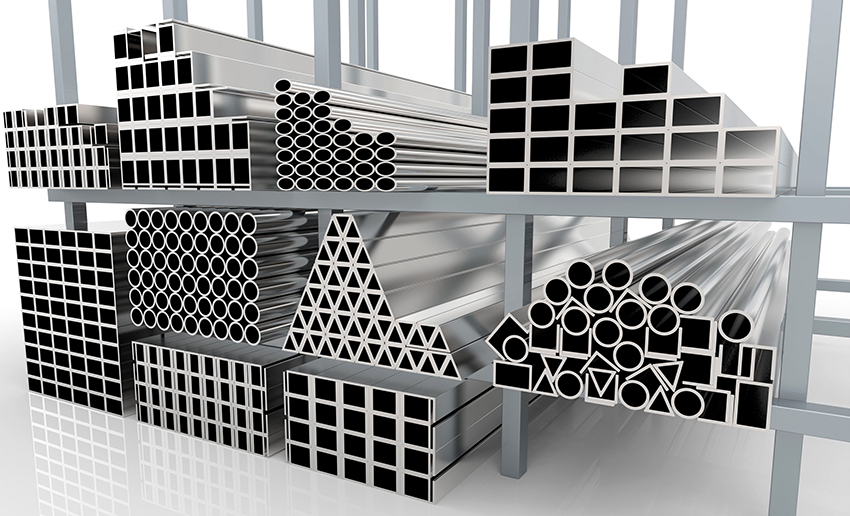

A variety of types and forms of high-quality and shaped products

Sections of rolled metal are standardized products. According to GOST 535-2005, the peculiarity of this type of product is that the diameter of the metal product has one of the geometric shapes: square, hexagon, rectangle or circle. Characteristics defining the assortment:

- profile shape;

- its size;

- method of metal processing.

Depending on the shape, varietal products are divided into the following types:

- simple;

- shaped;

- special.

Simple forms include:

- Circle - hot-rolled steel with a round profile, which is used for the manufacture of fittings, wire, gratings, decorative elements, monolithic structures. Regulated by the provisions of GOST 5751-82.

- Square - hot-rolled products with a square profile. It can be small and large, used in various industrial sectors for welded structures. Produced in accordance with GOST 2591-88.

- Hexagon. Used as blanks for other products, such as bolts.

- A strip is a high strength sheet used for reinforced concrete products in mechanical engineering.

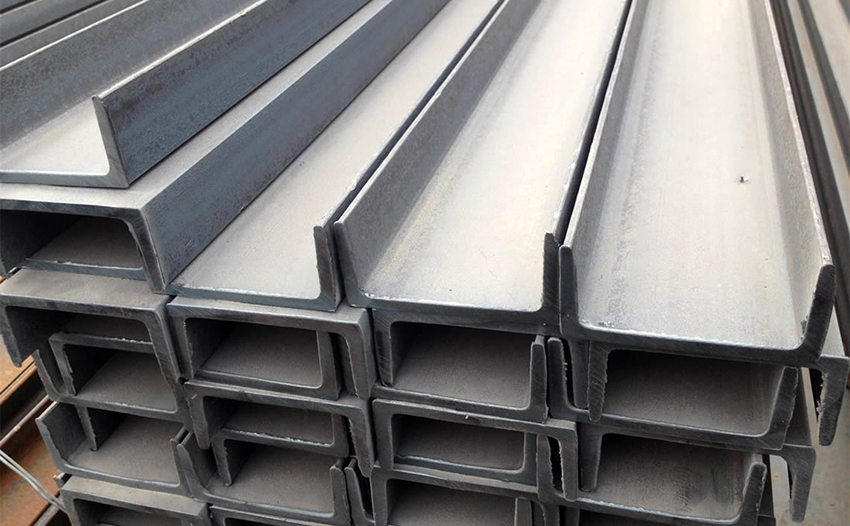

Products related to shaped products are channels and beams. The beams are in the form of a bar. They are used in construction when it is necessary to make a solid frame. Channel bars are U-shaped products characterized by rounded corners. Used to create floors.

Special forms of rolled products are wheels and round fittings. Wheels are used in mechanical engineering, fittings are used to strengthen structures.

Armature A400 and A500C: general characteristics and differences

One of the varieties of rolled metal products used for various industrial purposes is fittings. It is a metal rod with a circular cross-section with a ribbed surface. This product is produced in the form of segments of a certain length or in coils. There is also a rebar with a smooth surface.

Reinforcement comes with a smooth and ribbed surface, is produced in the form of separate sections or in a coil

GOST for fittings 5781-82 regulates technical conditions. GOST 10884-94 was created for hardened fittings. The main area of application is construction. This type of rolled metal is used for reinforcing reinforced concrete products and creating frames. The full range of fittings is divided into VI classes. The most popular types of products (A400 and A500C) belong to class A III. The armature has a profile with two ribs and a transverse protrusion.

In many respects, the characteristics of the A400 and A500C fittings are identical, which determines their belonging to the same class. But the differences in the chemical composition, namely, a smaller amount of carbon and a larger amount of alloying additives, give the A500C type a greater degree of flexibility, which contributes to the formation of a more durable seam when using arc welding. The letter "C" denotes the possibility of using this type of welding.

Related article:

Assortment of corners in regulatory documents: GOSTs, product characteristics

What are GOSTs for? Varieties of steel corners: equal and unequal. Popular product sizes. Steel angle weight.

In construction, reinforcement of I-IV classes is often used. For the foundation, the diameter of this metal product must be at least 10 mm. In mine construction, for the reinforcement of bridges, underground structures, products of the V-VI classes are used. The class table contains an assortment of A500C reinforcement for strengthening reinforced concrete structures.

Important! When replacing A400 with A500C, due to the possibility of using electric arc welding and improving the quality of joints, the consumption of reinforcement decreases and the strength of the concrete structure increases.

I-beam (I-beam): welded and hot rolled

I-beam refers to the high-quality rolled metal products. It has an H-shaped profile, straight and inclined face positions. Products with straight edges are divided into types:

- normal (H);

- wide-shelf (W);

- columnar (K).

Column I-beams are characterized by thick and strong edges and lintels, therefore they are often used for support columns in the construction of bridges, decorative facades of buildings, etc. GOST beams made of carbon and low-carbon steel regulate the following indicators:

- GOST 8239-89 - design and dimensions;

- GOST 535-88 and GOST 19281-89 - technical conditions.

Special beams are controlled by regulatory documents:

- GOST 19425-74 - design and standard sizes;

- GOST 535-88 - specifications.

I-beam produced by hot-rolled method and by welding

The assortment of column I-beams reflects the following characteristics of this type of beams:

- material of manufacture - steel grade;

- strength and mechanical properties;

- sizes;

- heat treatment method;

- type of accuracy class (A - increased; B - normal).

One of the most popular types of this metal product is the I-beam 20. It is carried out in two ways: hot-rolled and by welding.

Important! The welded I-beam is economically profitable: it has a low price (due to the peculiarities of the manufacturing technology) and high technical performance.

Beam sizes 20:

- height (maximum) - 200 mm;

- width - 100 mm;

- profile wall thickness - 5.2 mm;

- lintel thickness - 8.4 mm;

- weight of 1 running meter - 21.04 kg.

The position of the faces of the beam 20 is straight and inclined. This product is actively used in construction for the construction of building frames.

Metal weight tables: which ones exist and how to use them

When purchasing rolled metal products for production or personal needs, it is necessary to determine its quantity. The calculation process is carried out on the basis of data that can be obtained from the tables of rolled metal products. Tables representing the assortment of different types of products for various characteristics (weight, shape, density, etc.) are collected in reference books on metal rolling, textbooks on metal science and other specialized literature.

In addition to printed editions, there are online electronic tables, as well as the computer program "Calculator of rolled metal", with which you can independently calculate the required amount of goods by entering the initial indicators.

This calculation option is more affordable, it does not require additional searches, it is always at hand. Spreadsheets include not only weight, but also technical specifications according to GOST. They are also convenient to use because they are almost always accompanied by a photographic image of the product, which eliminates any mistake in choosing a product.

Important! When buying a rolled metal product, it is imperative to calculate the weight theoretically in order to be able to compare it with the result of practical weighing. This is necessary not only to check the seller's conscientiousness, but also to be sure that the production technology is not violated.

Ferrous weight table: volumetric weight of steel

The most commonly used raw material for rolled metal products is steel. It is an alloy of iron with carbon and other chemical elements. The amount of carbon should not exceed 2.14%. This alloy is subdivided into grades, which, in turn, differ in their composition, physical and mechanical properties. According to its chemical structure, steel is divided into two types:

- doped:

- carbonaceous.

Alloy steel is composed of iron and carbon. Sulfur, phosphorus, manganese, copper and other substances that affect physical and mechanical properties are added to carbon, depending on the grade. One of the most important characteristics of steel is the specific (volumetric) weight (for steel, these values are the same). A specialist in metal processing must know this indicator. This value is determined by the ratio of the weight of a homogeneous body of matter to its volume. The tables show the specific gravity of 1m² of common steel grades in g / cm³.

Important! There are more than 1500 steel grades. Full information about the grade of interest can be found in the metal rolling reference books.

One of the most popular grades is steel 20.The absence in its composition of a significant amount of alloying elements simplifies the production process, and therefore, the cost also decreases. The main characteristics of this steel grade:

- Hardness - this indicator is maintained at the level of 163 MPa. This determines the high wear resistance of products from this metal.

- The density of steel is 20 - 7859 kg / m³.

- Strength and fluidity. These criteria depend on the presence or absence of a heat treatment process.

- Thermal conductivity. The material is characterized by an average coefficient of thermal conductivity: it quickly heats up and removes heat.

Steel 20 is used for the manufacture of high-pressure pipes, fittings, profiles of various cross-sectional shapes. This metal, which has undergone chemical thermal treatment, is used for the production of products requiring high strength.

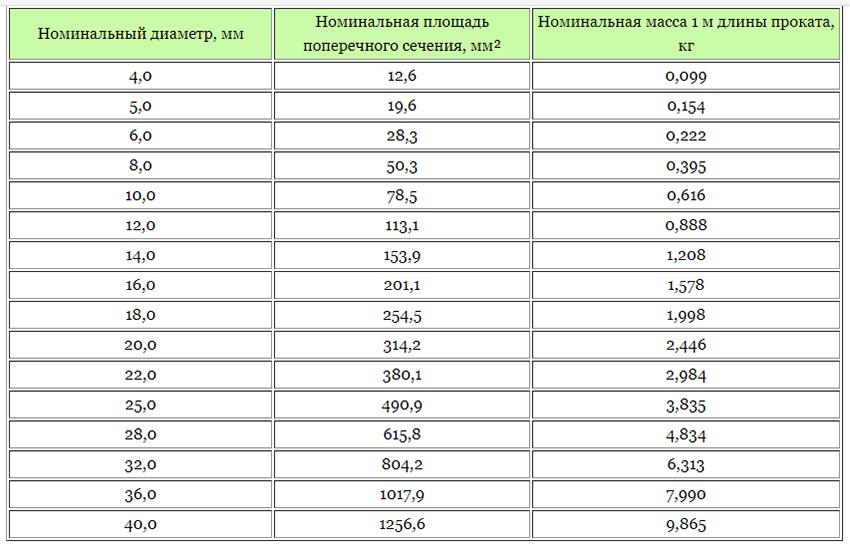

Rolled metal weight table: weight of steel reinforcement

The weight of the reinforcement is a very important value, necessary in the implementation of calculations for the concreting process. Knowing the weight of 1 m of reinforcement, you can determine how much of this metal product is needed for a certain volume of concrete, that is, find out the concreting coefficient. In order to calculate when buying how much the reinforcement weighs, you need to sum up the total length of the rods and multiply by the specific weight, that is, by the mass of 1 linear meter. The tables show the weight of 1 m of reinforcement depending on the diameter.

We calculate the weight of the reinforcement 8 mm using the data in the table. The batch of the required purchase is 15 rods of 6 m each. We calculate the total number of meters: 15 x 6 = 90 m. According to the table, the weight of 1 m of linear reinforcement with a diameter of 8 mm is 0.395 kg / m. 0.395 x 90 = 35.55 kg. The number of meters per ton is also calculated quite simply: you need to divide 1000 kg by the weight of 1 m of reinforcement.

Rolled metal weight table: I-beam

The functional purpose of I-beams - holding, ensuring the strength of large building structures - makes high demands on the correctness of calculations. The first quantity you need to know when starting to design a structure is the weight of the beam. The following tables will help to calculate the required amount of this metal product based on the weight of 1 linear meter:

- The weight of 1 m of a running I-beam with an inclined position of the edges (GOST 8239-89).

- Weight of 1 m of a running beam with parallel edges (GOST 26020-83).

- Weight of 1 m running beam with parallel edges (GOST 26020-83).

- Weight of 1 m running beam with a column with parallel edges (GOST 26020-83).

- Normal beam weight (STO ASChM 20-93).

- The weight of the wide-flange beam (STO ASChM 20-93).

- Column beam weight (STO ASChM 20-93).

How to calculate metal weight without an online calculator

Sometimes situations arise when it is necessary to make an approximate calculation of the weight of the metal, without resorting to online help, using a telephone calculator and tape measure. To calculate the weight of a product, you need to multiply the specific gravity by the volume. Determination of the specific gravity does not cause problems. The volume is harder to figure out. In this case, you need to take the Gulden principle as a basis: the cross-sectional area is multiplied by the height. These values can be determined by direct measurement.

In order to calculate the weight of the product, it is necessary to multiply its volume by the specific gravity

Formulas for calculating the weight of the most popular rolled metal products.

Calculation of pipe weight - M = (D - s) * s * 0.02466:

- M is the mass of one running meter of the pipe, kg;

- D is the outer diameter of the calculated pipe, mm;

- s - pipe wall thickness, mm;

- 0.02466 - coefficient at steel density 7.850 g / cm³.

Calculation of the weight of a sheet of metal - M = S * 7.85:

- M is the mass of the steel sheet, kg;

- S is the area of the calculated sheet, m2;

- 7.85 - weight of a sheet with a thickness of 1 mm and an area of 1 m², kg.

Reinforcement weight calculation - M = (0.02466 * D²) / 4:

- M - mass of 1 running meter fittings, kg;

- D - circle diameter, mm;

- 0.02466 - coefficient for steel density 7.850 g / cm².

Important! Calculation using these formulas gives more accurate results than a special online calculator, since the values of the quantities in the second case are rounded.

The range of rolled metal: how to choose metal products

The number of enterprises engaged in the production of rolled metal is quite large. Products are in demand not only by industry, but also by individuals. Therefore, the issue of quality is quite relevant. The suggested tips can help when buying rolled metal products:

- A close study of the market for this product will help identify a trusted firm. It is necessary to pay attention to the duration of the existence of the enterprise, the vastness of the regions of supply, the range of products and reviews.

- The quality of the purchased products must be documented. If the characteristics are only voiced or there is only a descriptive option, you should refuse to purchase such a product.

- A visual inspection is required. The presence of rust, cracks, traces of welding indicates serious shortcomings that may be associated with a violation of the manufacturing technology of rolled metal.

- An important point that characterizes the level of the enterprise's work is product packaging and delivery. Negligence, lack of additional services should alert. Therefore, you need to take a closer look at the trading company.

The purchase of rolled metal products is a responsible and rather troublesome process. You need to be confident in chemical and technical criteria, and quantitative indicators should be calculated in order to know how much to buy and how to transport it.