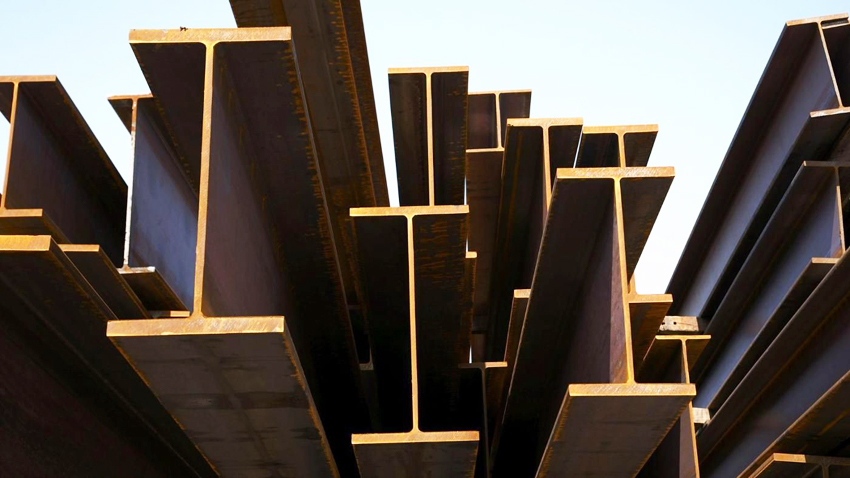

Today, I-beams are very popular in construction and other industries, which are distinguished by their unique strength and reliability. The product is capable of withstanding a load that is several times higher than the value typical for structures with a square, round or rectangular section. The assortment of I-beams is distinguished by a wide range of types, and each product is made in accordance with the current standards.

Content [Hide]

- 1 I-beams regulated by GOST: characteristics and design features

- 2 Variants of manufacturing profiles according to GOST I-beam

- 3 Construction parameters according to the range of I-beams

- 4 Assortment of I-beams: range of materials of manufacture and sectional shape

- 5 Requirements of GOST 26020-83: assortment of hot-rolled steel I-beams

- 6 Requirements of GOST 8239-89: assortment of hot-rolled steel I-beam

- 7 Calculation of an I-beam to determine the bearing capacity of a product

- 8 Domestic manufacturers of I-beams: product prices

- 9 Characteristics of I-beams: features of wooden products

I-beams regulated by GOST: characteristics and design features

What is an I-beam? This design is a metal profile with an H-shaped section. Standard sizes of the product, its shape and maximum permissible deviations in technical parameters are strictly regulated by GOST 26020-83 and GOST 8239-89. The standards indicate the types of I-beams and the order of their marking.

Against the background of other types of rolled metal, for example, a channel, the range of which is standardized by GOST 8240-97, an I-beam (GOST 26020-83 determines the unique shape of the product section) is characterized by the highest degree of specific stiffness and strength. The stress is evenly distributed over the entire area of the beam, which significantly reduces the amount of material used.

If we compare the ultimate tensile strength of the H-shaped profile and a solid bar, the same value is obtained, while the mass of the I-beam is 10 times lower. The strength of adjacently placed products is determined by summing, and those located on top of each other - by increasing by 4 times.

Important! The use of I-beam will make it possible to lighten the mass of the structure, reducing construction costs.

I-beams are widely used in the construction of hydraulic structures, floors of multi-storey buildings, and support structures. This is due to the resistance of products to increased loads and their immunity to mechanical stress. Profiles are quite common in industrial construction.

I-beam is often used in metal frame structures, buildings and structures of industrial and civil construction

Due to the high bearing capacity, which is evenly distributed throughout the entire product, it is advisable to use such structural elements for spans exceeding 7 m in length. An I-beam is indispensable for the construction of overhead passages and bridges, which is associated with the ability of the profiles to perceive increased vertical loads.

Variants of manufacturing profiles according to GOST I-beam

GOSTs for I-beams determine that products can be made in two ways. The first option involves the production of profiles by rolling from billets 3-12 m long, which are processed at a temperature of 1200 ° C. This process is carried out on special machines. The production uses structural steel, which does not contain alloying additives.

This technology contributes to the rapid production of monolithic products. Such elements show increased resistance to various kinds of mechanical stress. The technology makes it possible to use building parts without the use of additional stiffeners.

The unique shape of the product allows to reduce the weight of the structure, while increasing its load-bearing capacity. Shelves that evenly distribute the load eliminate the possibility of skewing of the structure.

The H-shaped profile can also be made of three elements using welding. This technology allows you to get a part with a smaller cross-section in comparison with monolithic structures.

Important! Thanks to the use of elements from various grades of steel, the cost of the welded product can be reduced.

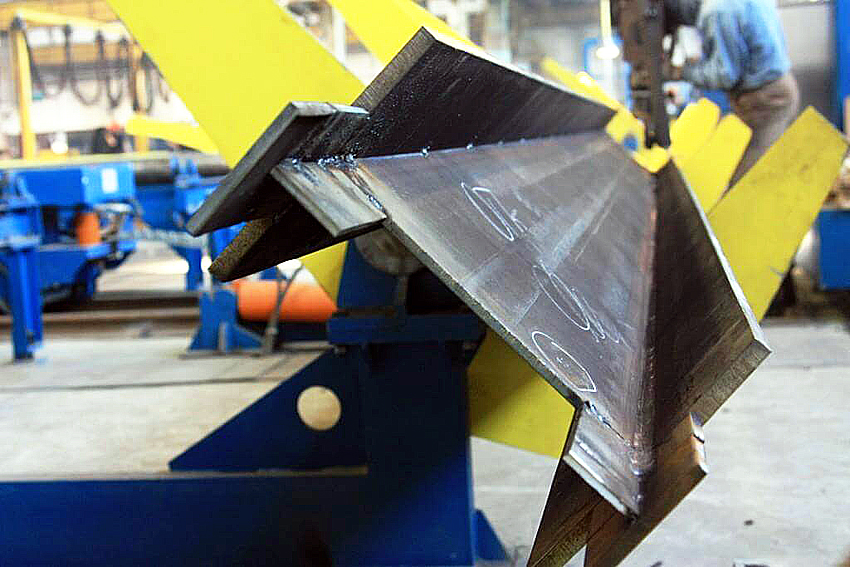

The process of welding an I-beam occurs in the following sequence:

- cutting of steel sheets on CNC machines;

- welding of metal blanks on automated installations using hydraulic clamps;

- editing of structures based on the parameters prescribed by the standard.

Using the method of welded technology, it is possible to obtain I-beams, the price of which per 1 meter depends on their geometric parameters, different widths and thicknesses of the shelves. You can order a product of a certain length with cutouts and holes for fastening in the profile body.

If I-beams are produced on modern equipment, the products are not inferior in their technical characteristics to their hot-rolled counterparts. With outdated equipment and low-carbon steel grades, building elements will be characterized by low performance.

Construction parameters according to the range of I-beams

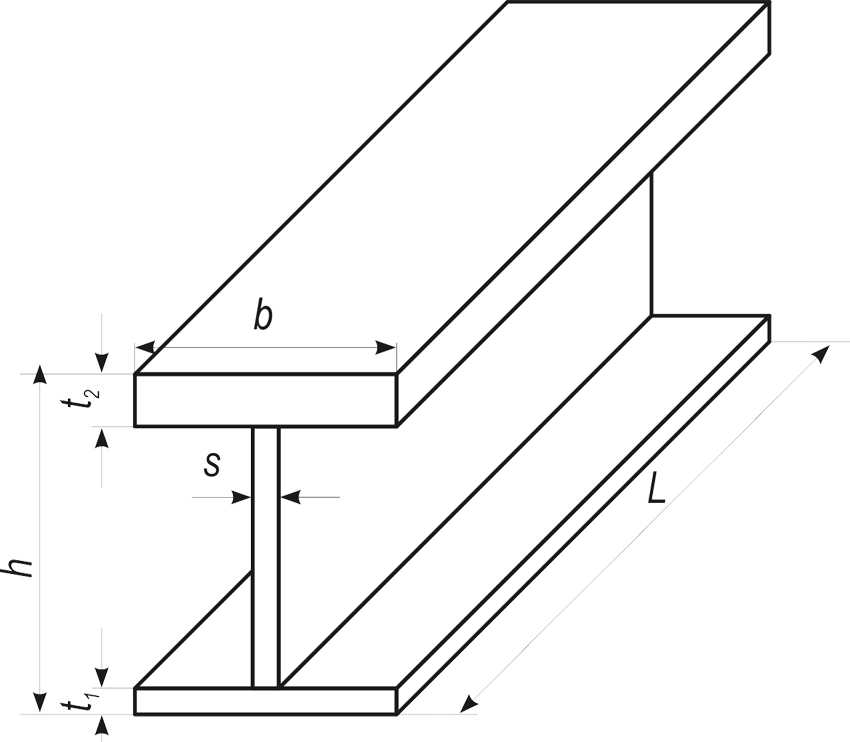

When choosing I-beams for performing a certain kind of tasks, one should take into account their main parameters:

- height - the distance between the flanges of the I-beam;

- width - the size of the gap from the base of the product to the end of the shelf;

- wall thickness, which is calculated based on the base of the product and determines the strength and bearing capacity of the structure;

- the average flange thickness, determined by subtracting the wall thickness from the flange width, dividing the result by 4;

- the radius of the inner curvature, formed by the abutment of the shelves, which takes on the greatest load, which determines the charge of rigidity and strength of the product.

Important! The shelf should not be at right angles to the wall. The radius formed at the joint increases the strength of the product.

The purpose of the beam depends on various parameters, such as height, width, thickness of walls and flanges, radius of internal curvature

To designate I-beams in the design documentation, an inscription is used, drawn up in a certain way. The letter indicates the type of product, which can be normal, columnar or wide-shelf. The letter "D" denotes an additional series of profiles with specified parameters regulated by the standard.

The numerical value in front of the letter corresponds to the height of the I-beam in centimeters. The number after the letter defines the element modification. The higher the number, the thicker and heavier the product. Further, the number of the standard according to which the I-beam is manufactured is indicated. At the end, the material for making the structure is prescribed. For example, beam 35SH1 is a wide-flange I-beam with a height of 350 mm.

Assortment of I-beams: range of materials of manufacture and sectional shape

The current standard defines several types of I-beams with different dimensional characteristics, weight and sectional shape, which is determined by the nomenclature of materials.

H-shaped rolled metal is characterized by a different sectional shape. For a hot-rolled steel I-beam, regulated by GOST 8239-89, the shelves with the wall form an angle of 8-12 °. The product is used as a supporting girder for hoist lines. A normal I-beam (in accordance with GOST 26020-83), designated in the design documentation by the letter "B", is made with parallel flange edges. This simplifies the production process, while at the same time reducing the resistance to deformation of the profile.

The wide-flange I-beam (GOST 26020-83 denotes the product with the marking "Ш") has a 1.5 times increased width of the shelves in comparison with the above types of rolled metal. This has a positive effect on the rigidity, strength and durability of the structure. Thanks to this, it is able to withstand a load 40% more than a normal beam.

Column I-beams in accordance with GOST 26020-83 are designated by the letter "K". Products have a maximum shelf width with increased thickness, which allows you to get a high-strength product. The I-beam is used in the construction of especially critical structures.

To create stairs, floors, supports, farms, bridges and various hydraulic structures, a normal I-beam regulated by GOST 26020-83 is used. Wide flange beams are used in load-bearing floor structures and staircases. In industrial construction, column structures are mainly used.

In accordance with GOST 8239-89 and GOST 26020-83, the assortment of I-beams contains the following nomenclature of materials that are used for the manufacture of I-beams:

- carbon steel of ordinary quality, regulated by GOST 380-2005, can be calm, boiling and semi-stable, characterized by an optimal ratio of strength, technical characteristics and price;

- construction steel, in accordance with GOST 27772-88, is characterized by increased requirements regarding the content of harmful impurities in raw materials;

- aluminum alloy (in accordance with GOST 4784-97) is used to create lightweight profile products, which are characterized by high aesthetic and corrosion properties;

- high-strength steel for bridge building, which meets the requirements of GOST 4784-97, is used in the construction of particularly critical structures and has increased resistance to the influence of cyclic loads.

Requirements of GOST 26020-83: assortment of hot-rolled steel I-beams

This standard specifies hot rolled steel H-shaped sections having parallel edges. The dimensions of the I-beam are strictly regulated by this GOST. The height of the product shelves is in the range of 100-1000 mm, and the width is 55-400 mm.

Unlike the dimensions of the channel made according to GOST 8240-97, the I-beam assortment is characterized by a wide range of thickness values, which is in the range of 100-600 mm. Such I-beams can be normal - they are designated by the marking "B", wide-shelf - "W", columnar - "K" and additional - "D".

Hot-rolled steel I-beam withstands heavy loads, and therefore is used in the construction of multi-storey buildings

The assortment of wide-flange I-beams defines profiles with a height of 193-718 mm, which can be used without additional fastening. Such products are used as a base for laying reinforced concrete slabs or steel sheets.

This type of elements is able to withstand significant loads, therefore it is often used in the construction of multi-storey buildings. T-profiles for lattice structures are made of 50SH1 wide-flange I-beams.

Important! Due to the increased width of the flanges, wide-flange type I-beams have maximum rigidity, which allows them to be used as independent support elements.

Beams are produced in the following lengths: measured, unmeasured, measured with a segment, multiple dimensional, multiple dimensional with a segment from 6 to 24 m. This value is defined as the maximum length of a conditional cut profile with ends perpendicular to the longitudinal axis.

A segment is profiles with a parameter of at least 3 m for products with a linear density of up to 20 kg / m and at least 4 m - with a density higher than 20 kg / m. The standard allows the production of I-beams with a limited length, which is within the off-gauge range, which is most typical for 30SH1 beams.

Related article:

I-beam: size table, weight and technical characteristics of profiles

Design and manufacturing features. Characteristic of I-beams: 12, 14, 16, 18, 20, 24, 25, 30, 36 and 40. Table of sizes and weights.

Requirements of GOST 8239-89: assortment of hot-rolled steel I-beam

The range of steel hot-rolled I-beams with a slope of the inner edges of the shelves by 6-12 ° is regulated by GOST 8239-89. I-beams can be made of high and normal precision by hot rolling, and the method of production is determined based on the scope of the product. This type of profile is characterized by the lowest cost and is suitable for mechanical engineering and the construction of structural elements of a building.

According to GOST 8239-89, I-beams can have a height of 100 to 600 mm. The length of the profiles is in the range of 4-12 m. The longest products are less reliable.

The use of a hot-rolled steel I-beam allows avoiding shifts, shrinkage and cracking during the operation of buildings

The structures are characterized by high strength, reliability, increased resistance to mechanical loads and a long period of operation without violating the geometric characteristics of the product. All the main parameters of the profile: height, width of the shelf, thickness of the shelf and walls, moment of resistance, moment of inertia of the I-beam, radius of inertia are presented in the product range.

Useful advice! The I-beam can be made to individual dimensions, which will affect the cost of the product.

Depending on the position of the edges, the I-beam can be inclined with the marking "Y" or parallel ("P"). Such structures are widely used in the construction of residential and industrial facilities, pavilions, bridges, storage facilities and columns. I-beams with a slope of 10% are intended for the installation of overhead tracks. Structures with a slope of edges of 12% find their application in reinforcement and strengthening of mine shafts.

Calculation of an I-beam to determine the bearing capacity of a product

To minimize costs, lighten the structure, reduce labor and material costs without harming the strength of the structure, the calculation of the I-beam is performed. The initial data for choosing the profile of the product are, according to the bearing capacity, the span length, the design and normal load, the number of I-beams and the design resistance.

The I-beam is calculated in order to select it from the assortment when the construction is being designed

Span length is defined as the distance between the inner edges of short walls. The standard load is taken from the product mix table, the calculated one is calculated by multiplying this value by the beam pitch. The design resistance, which depends on the steel grade, is taken equal to 210 MPa.

The load on an I-beam is determined as follows:

- the total load on the floor is summed up, taking into account the weight of the profile, which is calculated per 1 running meter of the product;

- the obtained value is multiplied by the coefficient of reliability and elasticity of steel;

- the value of the moment of resistance is determined based on the table of calculated values of GOST;

- according to the moment of resistance, the profile number is selected from the I-beam assortment table.

Domestic manufacturers of I-beams: product prices

Today, there are several well-known brand companies on the construction market that specialize in the production of metal structures. The price of metal I-beams depends on the technical parameters of the product, its dimensions and company policy.

The main manufacturer of I-beams in Russia is the Nizhniy Tagil Metallurgical Plant, which produces high-quality certified products that fully comply with applicable standards.

The manufacturer's catalogs contain all types of I-beams with parallel flange edges and products with a slope of the inner edges. The most popular in the construction industry is the 40SH1 beam, which can be bought at a price of 55 thousand rubles. per ton.

The West Siberian Metallurgical Plant offers I-beams with parallel flange edges in accordance with GOST 26020-83. The products are characterized by an optimal price-quality ratio. You can buy a 40B1 beam for only 30 thousand rubles. per ton.

Ariel Metal is a universal supplier of rolled metal products. In the catalogs of the manufacturer, you can see a wide range of products from steel 09G2S, 35GS and 17G1S, as well as aluminum I-beams. GOST 13621-90 regulates aluminum beams of different denominations. The average cost of a ton of a product is within 50 thousand rubles.

The main suppliers of H-beams in the Russian Federation are the company "Ariel Metal", Nizhny Tagil and West Siberian Metallurgical Combines

Characteristics of I-beams: features of wooden products

A novelty in the construction market is a wooden I-beam, which can be used for arranging the frame of a structure, installing interfloor ceilings, installing a rafter system, reconstructing attics and balconies.

The I-beam consists of two planed coniferous beams and an OSB slab located between them. Such a structure is able to withstand a large bending load without deforming the product and without the use of reinforcing auxiliary structures.

The beam does not dry out over time, does not corrode and deformation changes as a result of external factors. To extend the service life, the product does not need special impregnation and painting. The wooden I-beam is characterized by wear resistance, strength and high load capacity.

Useful advice! The use of wooden I-beams when laying the floor allows you not to screed it.

A wooden I-beam is characterized by the ability to withstand heavy loads, an uncomplicated installation process, economic feasibility and a low level of thermal conductivity

The product has a flat and smooth surface, which makes the material ideal for floor and ceiling installations. The laying of structures is carried out without the involvement of special equipment with minimal labor costs and material savings.

Wooden I-beams: the price of a novelty in the construction market

I-beams for floors, roof trusses and building frames are divided into the following series:

- BDK - glued beam;

- BDKU - reinforced glued;

- BDKSH - wide glued;

- SDKU - reinforced wall;

- SDKSH - wide wall.

BDK beam consists of structural elements glued together using synthetic resins under high pressure. The product is used in short spans. The price of an I-beam per running meter of the product is 300 rubles. with an element height of 241 mm. The Glued Reinforced Beam has an increased flange width of 64 mm, sufficient for fastening nails. Can be used on long spans. The price of the product is 320 rubles / lin. m.

The glued wide beam is characterized by a shelf width of 89 mm. Such products are used for structures that are under extremely high stress. You can buy a running meter of a beam for 400 rubles.

A reinforced wall structure, the average price of which is 300 rubles, is used to create the basis of a frame building. The wide wall beam is used for the installation of wall panels. The cost of a running meter of a beam is 390 rubles.

If there is a letter "L" near the marking, this indicates that the product is made of high-strength timber, which gives the I-beam increased strength. The standard length of the product is 6 m. The height can be equal to 457 mm, 406 mm, 356 mm, 302 mm, 241 mm.

Possessing universal parameters, I-beams are widely used in various fields of construction. To obtain the maximum service life of the structure, it is necessary to correctly determine the load, relative to which the type of H-shaped profile is selected according to the product range.