The construction industry offers a wide range of materials for various types of finishing and renovation work. Modern production is progressing every year in the variety of new construction products. Chipboard is one of the most demanded materials. Particleboard: this is what, how this abbreviation stands and what should be taken into account when choosing a material, the presented article will help to find out.

Content [Hide]

Particleboard: what is this?

What is chipboard? This is a chipboard obtained by flat hot pressing of dried shavings, sawdust and wood chips with the addition of synthetic resins, which are used as a binder. Chips, sawmill waste, woodworking and plywood production are used as raw materials for creating the material.

Compared to natural wood, chipboard is devoid of many disadvantages: voids, knots. This material has a homogeneous composition and equal rigidity over the entire area. And the presence in the composition of the product of synthetic resins, such as phenolic and formaldehyde, contributes to the reliable retention of fasteners in its thickness.

Material creation history

The first prototype of chipboard is a building material created in 1887 by Ernest Hubbard from a mixture of sawdust and casein glue. Later in 1918, this material was veneered. At this time, the scientist Freudenberg from Germany patented the ideal formula of the material, where he accurately calculated the ratio of sawdust and binder, which should be no more than 3-10%. In 1935 this data was corrected and the first board was produced using a phenolic binder.

Further appeared moisture resistant chipboard, which included paraffin. In the USSR, the first plate was produced in 1957, which was the beginning of the creation of a powerful domestic production of chipboard at plywood factories.

Application area

Due to its high strength, moisture resistance and lightness for mechanical processing, the material is very popular in the manufacture of furniture, door blocks, for the installation of interior partitions.

Based on the sound insulation and thermal insulation properties of the material, chipboard is often used for the floor.This material allows you to achieve a perfectly flat structure when insulating wooden or concrete floors, while the work costs will be minimal.

The main stages of production

The technological process for the manufacture of chipboard from different manufacturers may differ. This significantly affects the weight of the chipboard sheet, which depends on the type of wood, pressing density and the size of the finished product.

However, any production process for creating a chipboard consists of several main stages, which will be discussed below.

Preparation of raw materials... The raw material is obtained from waste from the woodworking industry, which is crushed to a certain size.

Drying and mechanical selection... The raw material enters the drying chamber, where vortex drying is performed by streams of hot air, which helps to reduce the moisture content of the material by 6-7%. Then the dried raw material is sent to a cyclic unit, where the correct particle size is selected. They move on to the next stage, and the larger ones return to the regrinding stage.

Connecting components... The wood dryer enters the mixer, where it is combined with formaldehyde resins.

Form creation... The pulp is poured onto a conveyor belt in several layers, created by a cold press. Then a hot press joins all layers into a single piece. Then the board is cooled and dried. Here the sheet is cut to the dimensions set by the standard.

Decorative coating... This stage is used to create laminated chipboard. The surface is pre-leveled and carefully sanded. Next, the sheet is laid with the back side on sulphate paper and covered with sulphate and finishing paper. The press creates a laminated chipboard.

Material composition

The uniformity and quality of the final product directly depends on the production equipment on which the web was made, and on the degree of preparation of the raw materials. For the production of chipboard, low-value deciduous and coniferous wood is used, any construction wood waste that must comply with certain geometric requirements.

The raw material should not resemble fine dust and contain sawdust with a square cross-section, which impairs the property of the material to resist bending.

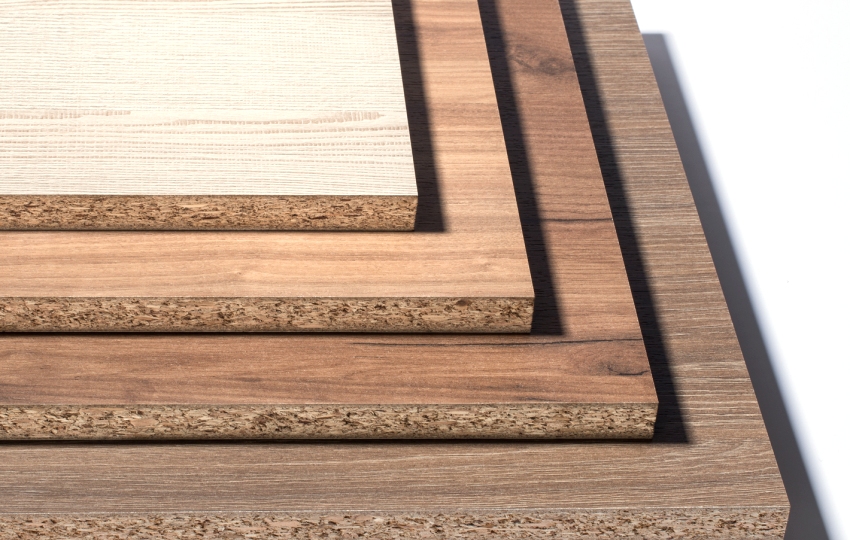

Chipboard construction

Chipboard can be composed of several layers. Depending on this, they are divided into single-layer, three-layer and multi-layer. Multi-layer boards are of the highest quality. Here, coarser chips were used on the inner layers of the material, and small chips on the outer ones. There are chipboards with a unique design - tamburat. The tamburat is designed in the form of a "sandwich", where the upper and lower layers are represented by chipboards of various thicknesses, and in the middle there is cellular cardboard.

Surface treatment method

According to the method of surface treatment of the material, chipboard can be laminated and lined.

Laminated chipboard sheet is obtained as a result of applying a decorative and protective layer to the surface of the material under the action of high temperature (140-210 ° C) and pressure (25-28 MPa).

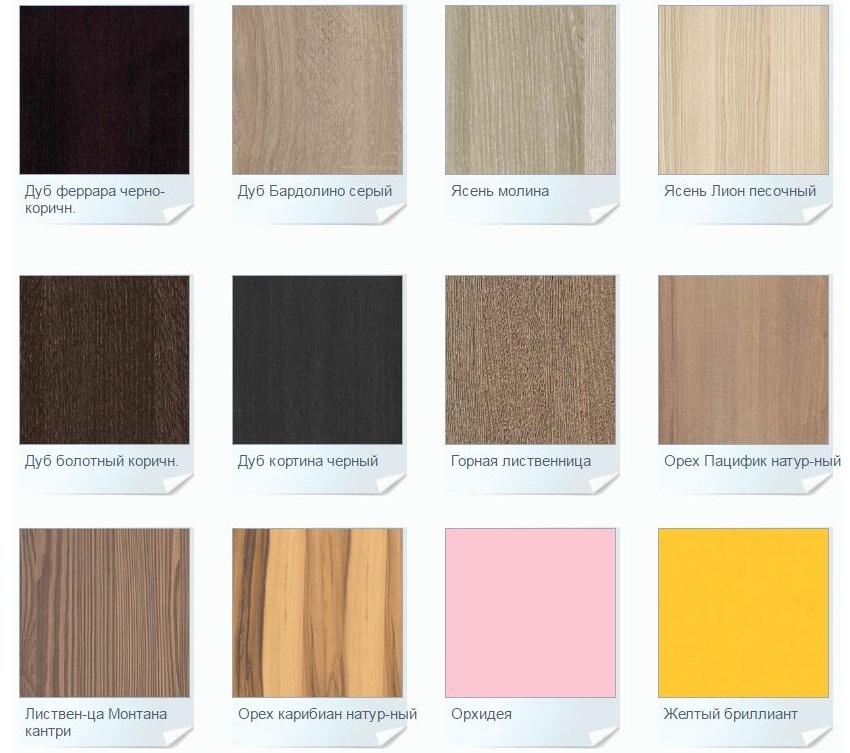

Today the use of laminated chipboard is very popular. Using this material, you can create real masterpieces. Well-known manufacturers, such as the Kronospan holding, are clearly focused on the consumer's request and produce chipboard in a variety of colors. There are several groups into which the general color spectrum of chipboard is assembled:

- plain smooth (yellow, white, blue);

- plain textured (textured white, aluminum);

- woody tones (beech, cherry, alder);

- imitation of rare wood species ("Merano", "Cordoba", "Winchester oak");

- glossy tones;

- veneered tones;

- fancy decors with patterns and designs.

Useful advice! For the manufacture of the front of the furniture, you should use veneered, glossy and fancy colors.

What is DSPC? This is a kind of chipboard, which is obtained by gluing paper-resin films to the surface of the chipboard using an adhesive composition. This is achieved at lower rates compared to laminated chipboard, temperature (20-150 ° C) and pressure (5-7 MPa).

Compared to laminated chipboard, MFC has a lower cost. However, despite the initial presentable appearance, it has a short service life.

The modern industry offers chipboard faced with paper-laminated plastics. These polymeric materials contain parallel layers of filler (veneer, fabric, paper). Such chipboard will have good ductility, mechanical strength, and impact resistance.

Chipboard countertops for the kitchen are made using this technology. The popularity is due to high physical parameters, a wide range of textures that imitate artificial and natural materials, as well as an affordable price.

Building material classification

According to the surface quality of the material, chipboard is divided into three grades.

1st grade... These materials have a perfectly flat, smoothly sanded surface. The presence of even the smallest scratches, chips, undulations, protrusions, depressions, crumbled corners and edges is not allowed here. This web is processed on a special linear sander.

This type of material is used in the manufacture of furniture, as a panel for the subsequent application of veneer, lamination.

2nd grade... This is the rejection of first-class finished material. There may be small scratches, edge chips on the surface. But the total percentage of defects, depending on the dimensions of the sheet, should not exceed 10%. Grade 2 materials may differ in appearance of the outside. They can be with a normal surface, fine-textured and coarse-textured outer layer. The material is used for construction work and in the manufacture of furniture.

3rd grade: unsorted canvas. This is an absolute marriage, where scratches, chips, cracks and other mechanical damage are clearly visible. Materials of this grade can be used for formwork, creating interior partitions. Those. in those places that are hidden from human sight.

Note! For the manufacture of furniture for kitchens and bathrooms, there are chipboards of increased moisture resistance, which include paraffin. Such slabs have a greenish tint on the cut.

Chipboard sheet cost first-class material with a size of 2440x1830 mm and a thickness of 18 mm will be about 800 rubles, respectively, the cost of a square will cost 150 rubles.

Grade 2 material can be purchased much cheaper. The price for a chipboard sheet 18 mm thick and measuring 3500x1750 mm will be within 120 rubles. per square meter.

Chipboard grade

For the production of chipboard, manufacturers adhere to the standard that regulates two main brands of chipboard, differing in physical and mechanical properties.

Grade PA: a high quality product with improved flexural and tensile strength. Unlike П-Б, the material of the П-А grade has a low percentage of swelling, has a lower percentage of roughness of the warping of the plane. Grade PA is exposed to facing.

A quality material must have certain physical and mechanical properties:

- water absorption is 12-88%;

- humidity is within 6-10%;

- the percentage of swelling along the thickness of the material in 24 hours should not exceed 5-30%;

- specific heat is 1.7-1.9 kJ;

- thermal conductivity is in the range of 0.07-0.25 W;

- the thickness of the material ranges from 10 to 38 mm.

Related article:

SIP panels: what is it? Turnkey SIP-panel houses, prices for finished projects

Pros and cons. Projects of houses from SIP panels, house kits. Exterior and interior decoration methods. User reviews.

Material hazard

Particleboard is a relatively harmless material, despite the fact that it contains a certain amount of formaldehyde.

The maximum permissible concentration of formaldehyde for the working area is 0.5 mg / m³, and modern technologies for the production of particleboard allow bringing the content of this indicator closer to 0.02 mg / m³.

It should also be noted that wood that comes from contaminated areas can emit more harmful substances than chipboard.

According to the amount of formaldehyde resins in the chipboard, the material is divided into two types:

- E1 type is the most environmentally friendly. The content of harmful particles in the composition of the material is quite low. European countries are producers of the purest material.

- Type E2. The content of formaldehyde resins in this material is much higher, so it is not recommended to use it to create furniture for children.

Which is better: chipboard or MDF?

The scope of use of chipboard is very extensive. This material is used for the manufacture of furniture, wall cladding (laminated plates), in repair and construction work. But chipboard is not recommended for use in rooms with high humidity. The material has high technical performance, thermal and sound insulation properties.

MDF, like chipboard, is made from wood shavings and sawdust, but smaller fractions. However, the adhesion of the particles takes place using lengin or paraffin, which makes the boards environmentally friendly to use. Due to the presence of paraffin, MDF has increased moisture resistance. The material is used for the manufacture of interior door blocks and structures, furniture parts, for the installation of partitions. However, it is not recommended to use MDF as a flooring, as the boards are vulnerable to mechanical stress.

Chipboard is a versatile building material that can be used in the manufacture of furniture, door panels, tabletops, window sills, flooring. The material has high strength and stiffness. Having opted for chipboard, you can get an easy-to-handle building material for a reasonable price.