The construction of supporting structures requires the use of reliable materials. It is to this list that U-shaped steel channels belong. In the manufacture of profiles, various technologies are used and different types of steel are used. Material is classified according to several characteristics, and their ratio determines such a concept as an assortment of channels. This article is devoted to this topic.

Content [Hide]

What is a channel: features and benefits of the product

Channel is a rolled metal profile with a U-shaped cross-section. It is made from several types of steel, including stainless steel. That is why the characteristics of the assortment of channels include not only weight, size, but also material, as well as production technology. They are made by cold-rolled or hot-rolled methods.

U-shaped profiles have design features. Most types of channels with parallel flange edges, but there are also those where the edges do not have a parallel arrangement with respect to each other, but are made with a certain slope. The main feature of the range of U-shaped profiles is high rigidity with low weight, which determines the widespread use of the material in the construction of structures with high loads.

Due to the main quality, the channels have a number of advantages, including:

- high degree of strength;

- excellent resistance to bending loads;

- the ability to withstand loads of different directions, such as compression or rupture;

- resistance to shock loads that can lead to mechanical damage to the finished structure.

High-quality channels made of high-strength steel, manufactured in accordance with the requirements of GOST, in fact have no weaknesses that can provoke destruction of various types and nature.

Areas of application of metal channels

All of these advantages imply their widespread use in various areas of production and construction, including the automotive industry.It is a necessary component in the manufacture of trucks. It is the channels that play a reinforcing role in the supporting structures.

In large-scale construction, these products are indispensable as transverse supports and floors between floors. Also, a U-shaped profile is used as the main material in the construction of frame structures, the installation of ramps. It is steel channel-shaped beams that withstand high transverse or axial loads and are capable of increasing the strength of the floor several times, when compared with wood material. This is especially true in the construction of slabs with large spans.

Helpful advice! The main condition for the correct choice of material is its compliance with the requirements of Gosstandart, which are indicated in special tables of channels. Their use will greatly simplify the solution of the task.

In addition to mechanical engineering and the creation of frames, channels are used as an additional material in other types of transport production, for example, in crane and car building, where they serve as frames and frames. They can also be used in the process of reinforcing reinforced concrete structures.

Types of channels: structural and technological classification criteria

The channel is made from regular hot and cold rolled high carbon steel or high quality carbon steel, stainless steel or low alloy steel.

The main classification is based on the method of production of channels. Based on this principle, products are divided into the following types:

- made of hot rolled steel;

- steel special;

- steel equal flange made by bent method;

- steel bent with unequal shelves.

Channels are subdivided depending on the scope of application. At the same time, they are distinguished:

- a common profile, which has a wide scope of use, meets the requirements of GOST 8240-89;

- special channel, which is used in the engineering industry, the assortment is determined according to GOST 19425-74;

- the special profile used in car building complies with GOST 5267.1-90.

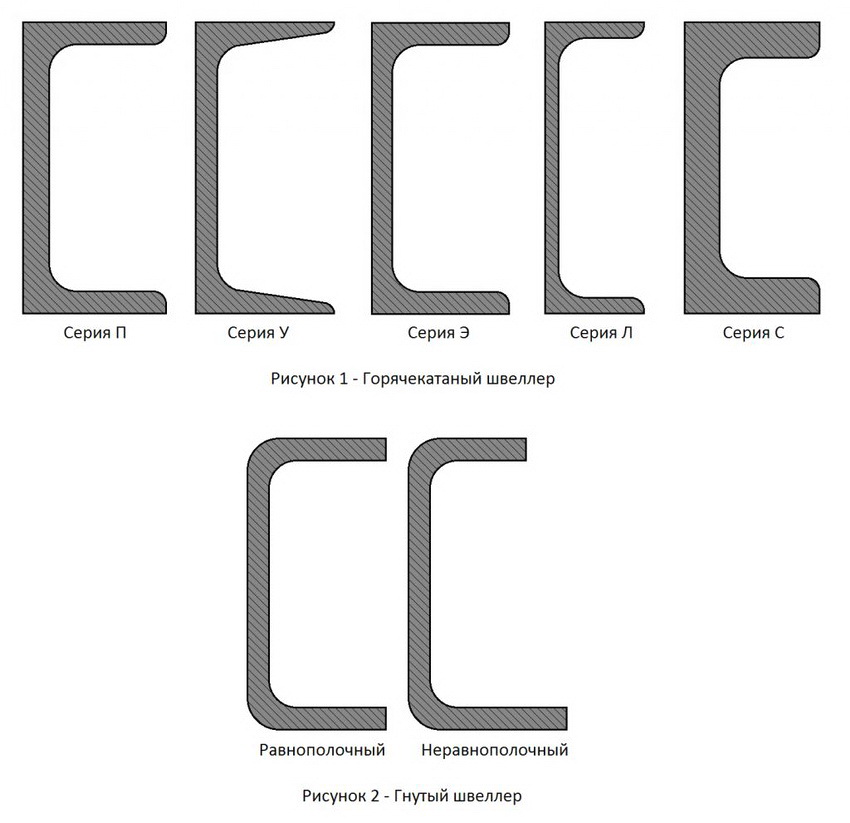

Hot-rolled steel profile that meets GOST 535-88 is subdivided into subspecies:

- Channels with flanges with edge deviations. They are distinguished according to their sizes, which vary from 5 to 40 mm.

- Channel, in which the edges of the shelves differ in a parallel structure, or a U-shaped channel, having the following designations: 5P or 16a P, etc. - up to 40P. The marking is as follows - channel 18P.

If we take into account the size, then channels are of measured and unmeasured length. Dimensional rolled products correspond to the indicators of 11.7 m or 12 m. Unmeasured products are manufactured in sizes from 3 m and more. But the maximum length of any channel is 12 m. That is why the length of the material is often not indicated in the table of the assortment of channels.

Classification of bent channels: assortment according to GOST

In turn, a bent steel channel is classified according to the following criteria:

- equal;

- unequal.

Equal-flange bent profiles comply with GOST 8278-93, they are made on pipe mills. Raw materials in their production are coiled steel of normal quality and carbon structural steel. The shelves in this type of channel have a height of 50 to 400 mm. The width of the product ranges from 32 to 115 mm.

Unequal channels are produced on roll forming machines. Raw materials - cold-rolled and hot-rolled steel of normal or high quality according to GOST 8281-80. They are also classified according to numbers corresponding to the distance (in millimeters) between the shelves.The lengths are the same as for equal channel bars.

The rolling accuracy of the bent section corresponds to the following marking of the channels:

- A - high accuracy;

- B - increased accuracy;

- B is normal accuracy.

Useful advice! The degree of quality of any bent channel (both unequal and equal-flange) is indicated by the accuracy of rolling. High quality characteristics are indicated by markings A and B.

Bent channels are subdivided according to their shape. The designation of the channel with the letter "U" indicates that the inner edges of the shelves have a slope. Marking "P" indicates the parallelism of the edges, "L" - about a light series of profiles with parallel edges of the shelves. The letter "C" is used to designate a special channel.

Main characteristics of the assortment and compliance of channels with GOST

The assortment implies different characteristics of the channels. In particular, the following are taken into account:

- the slope of the inner edges;

- thickness of walls and shelves;

- radius of curvature inside the channel;

- width;

- cross-sectional area;

- the mass of the channel and running meter.

- steel grade on which almost all physical and mechanical qualities depend (hardness, resistance to stress and corrosion).

The widespread use of U-shaped channels in various areas of construction and production has led to the creation of a large number of standards for their manufacture.

A wide range of such profiles has led to the development of a large number of GOSTs and other technical standards. The main condition for high quality is precisely the compliance of the channels with these regulations.

Among the existing standards approved by the State Standard, the following should be mentioned:

- GOST 8240-97. All channels made of steel by the hot-rolled method correspond to it.

- GOST 19425-74. According to this regulation, I-beams and special channels are produced.

- GOST 8278-83. Curved channel, the range includes requirements for equal-flange profiles.

- GOST 8281-80. These are bent products with unequal shelves.

- GOST 5422-73. Hot-rolled steel channels specially manufactured for tractors.

- GOST 5267.0-90. Hot-rolled U-shaped metal rolling for car building.

- GOST 21026-75. Hot-rolled steel profiles with bent trolley shelf.

Different types of rolled metal are produced according to one GOST per channel. For example, a hot-rolled profile with a slope of the edges of the shelves from 4 to 10% is manufactured in accordance with GOST 8240-97. To distinguish it, it is marked with the letter "U" and the corresponding number indicating the distance from shelf to shelf. A channel with parallel edges is also made according to the same GOST.

Channel brand: correspondence to alphabetic and numerical data

To distinguish the types and subspecies of channels, not only the designations of GOST are used, but also marking with letters and numbers, which is called the marking of rolled metal. This is primarily due to the wide range of sizes, different cross-sectional areas and, accordingly, the mass of the channel.

Related article:

I-beam: size table, weight and technical characteristics of profiles

Product weight and specifications. Features of the product design. Formulas for calculating I-beams. Price per running meter of profile.

Profiles produced in accordance with GOST 8240-97 have additional numerical and alphabetic codes. The first number indicates the main characteristic that emphasizes the channel size, determined by the distance between the shelves.

Useful advice! A product is selected taking into account the expected loads on the future structure, the place and the purposes for which the material will be used.

The letter in the marking designates the type of U-shaped product, indicating the structural features and location of the edges.Their decoding is given below:

- "P" - indicates parallelism;

- "Y" - denotes the presence of a slope on the edges;

- "E" - indicates efficiency;

- "L" - means lightness;

- "C" - speaks about the special purpose of the profile.

To determine the remaining parameters of rolled metal of a particular brand, you can use a special table, where the GOST of the channel, dimensions and other data are indicated.

For compactness of information in the tables, special conventions are used:

- h - indicates the height of the walls of the rolled metal (basic value);

- b - indicates the width of the shelves;

- S - determines not the area, but the thickness of the main wall;

- R - indicates the radius of the rounded side of the shelf;

- t - indicates the thickness of the shelves;

- r - defines the total radius of curvature of the shelves.

“Hot-rolled steel channels. Range "- GOST 8240 97: document description

The main difference between a hot-rolled channel and a bent channel is that it is produced by the hot-rolled method. It is made according to several GOSTs, in accordance with the requests of a particular industry. The range of channels GOST 8240 97 was approved by Gosstandart back in 1997 and subsequently approved by almost all post-Soviet countries. On April 5, 2001, by the decree of the State Committee of the Russian Federation for Standardization and Metrology, the document was put into effect on the territory of Russia.

As a direct Gosstandart in the Russian Federation, it began to operate with some changes from the beginning of 2002 to replace the current GOST 8240 89 “Hot-rolled steel channels. Range ". The document indicates all the quality characteristics of rolled metal building materials produced by the hot-rolled method.

The current document indicates the field of application of products, establishes an assortment of hot-rolled steel channels with a height of 5-40 cm and a shelf width of 32-115 mm. GOST includes various parameters of shapes and sizes, dividing products into different series:

- with a slope of the edges inside;

- with the edges of the shelves located in parallel;

- economical models with parallel edges;

- lightweight products with parallel shelf edges.

Each specific series, in accordance with the dimensions and qualities of the steel from which the rolled metal is produced, provides its own expanded table of the assortment of channels GOST 8240-97. In total, the document contains 7 tables, thanks to which you can choose the most suitable material for construction.

Each type of channel has its own table of state standards, which indicates the main characteristics of the material

Channel bars 10P, 12P and 10U, corresponding to GOST 8240-97

In the list of products that meet the requirements of GOST 8240-97, the most popular are channels with dimensions of 10 and 12 cm. All of them are produced by hot rolling. In this case, the number of rolls depends on the initial dimensions of the workpiece and on the required accuracy of the product. The workpiece is subjected to a temperature treatment reaching 1250 ° C.

Useful advice! Considering that the dimensions in millimeters are indicated in the GOST tables, it is often possible to find the marking of the type of channel 120, although this indicator indicates a n-shaped rolled metal with marking 12P or 12U.

Channel 10P has the following characteristics:

- running meter weight is 8.59 kg;

- 1 ton accommodates 116.4 m channel;

- the height of the profile corresponds to its main dimension and is equal to 100 mm;

- channel width - 46 mm;

- profile walls are 4.5 mm thick;

- the thickness of the channel shelves reaches 7 mm.

Channel 10U, like 10P, has similar indicators of a nominal height of 100 mm, a weight of a running meter of 8.59 kg, a width of 46 mm and a thickness of 4.5 mm. One ton of material contains 116.4 m.The differences lie in the characteristics of the rounded shelves. In particular, the radius of the rounded side of the shelf is 7 mm, and the radius of the curvature of the shelves is no more than 3 mm.

Considering the differences in the basic size, that is, in the height of the rolled metal, the 12P channel has significant differences in parameters. Its characteristics are as follows:

- running meter weight is 10.40 kg;

- 1 ton accommodates 96.15 m of the channel;

- product height - 120 mm;

- channel width - 52 mm;

- profile walls are 4.8 mm thick;

- the thickness of the channel flanges should not exceed 7.8 mm.

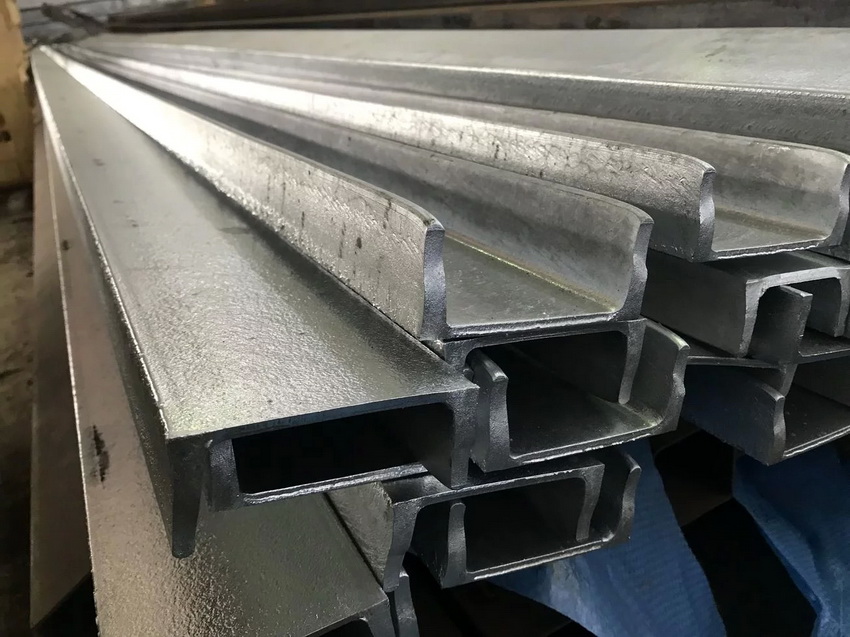

Range of channels: I-beams and other forms of rolled metal

Analyzing the topic of the range of rolled metal products, mention should be made of such a variety as an I-beam channel. Actually, the shape of the product does not correspond to the general characteristics of products that have a U-shape, since this profile looks like an I-beam. In cross-section, the product resembles the letter "H" in shape. A photo of an I-beam channel clearly demonstrates its difference from an ordinary profile.

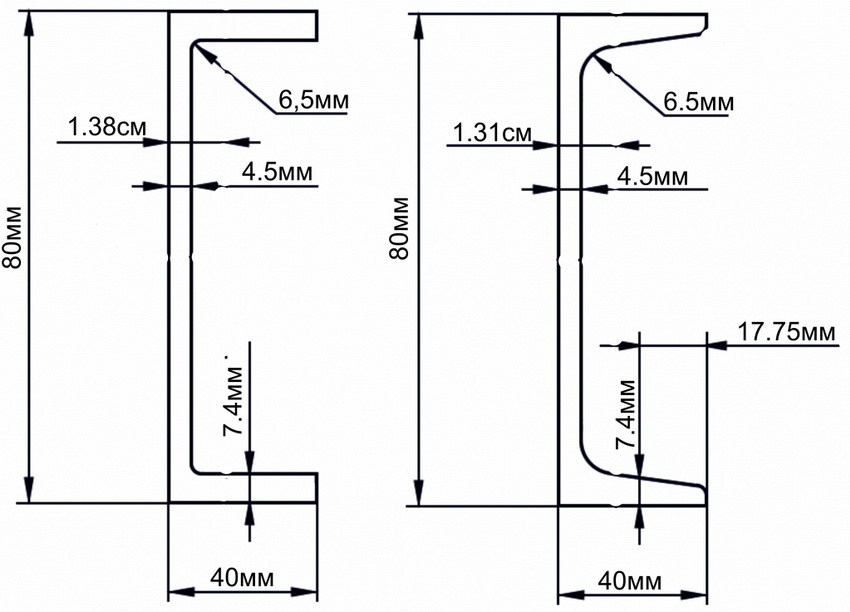

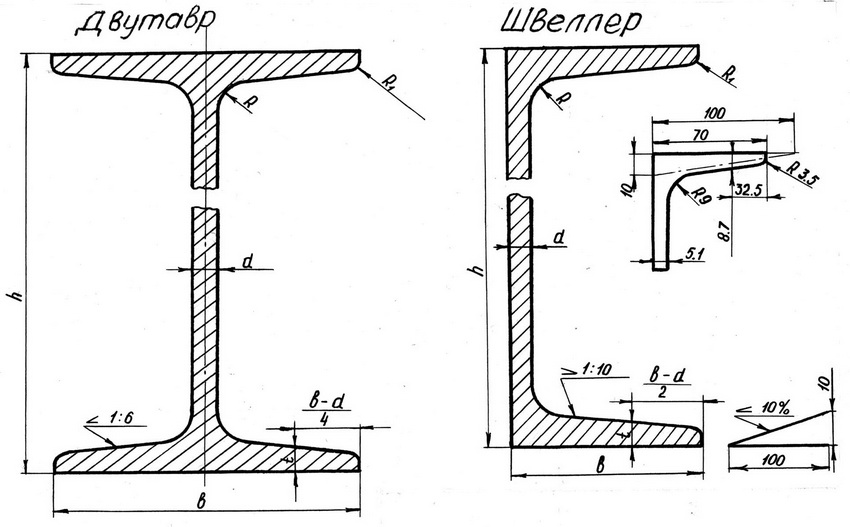

Drawing with typical dimensions I-beam and an ordinary channel

Such products are very popular in various areas of construction, since their use can significantly reduce weight and load on the structure. In addition, the H-beam is highly durable. I-beams, like ordinary channels, are produced by hot-rolled or welded methods. The bending technique is not applicable in this case. Welding is used in the manufacture of large parts or taking into account the individual characteristics of the construction site.

For the production of steel beams, low-alloy (C255) or carbon steel C345 (09G2S) is used. They are made by hot or cold rolling, and beams are welded using special welded equipment. Product strength control is carried out using ultrasound.

The production of rolled H-shaped beams is carried out in accordance with a special GOST. Gosstandart distinguishes between individual types of beams. The main classification is the division of products into hot-rolled and special products. The first type is I-beams with inclined flange edges. They are regulated by GOST 8239, which provides for an angle of inclination with limiting values of 6-12%.

Uniform standards for the manufacture of channels allow you to choose the most suitable type of material for any design

Another type of channels is characterized by parallel edges of the shelves, they are made according to GOST 26020. The height of such products ranges from 100 to 1000 mm, and the width of the shelves can vary from 55 to 400 mm. Such n-shaped beams are divided into normal, columnar or products with wide shelves.

When choosing a material for construction, it is important to consider standard sizes, which imply assortment of rolled metal products... Based on the requirements of Gosstandart, the design process is greatly simplified, since thanks to the calculations, it is possible to determine the exact number of required channels, calculate the permissible load and save on the purchase of unnecessary materials.