Very often, when arranging the yard of a private house or garden, swing... Such structures are made of wood, car tires and other materials at hand. But in order to achieve a really high-quality result, use drawings and photos of a garden swing made of metal with your own hands: the dimensions and performance characteristics of these products allow you to use them for a long time.

Content [Hide]

- 1 Do-it-yourself garden swing classification made of metal: photos and features

- 2 Drawings and photos of a garden swing with your own hands made of metal: dimensions and technology

- 2.1 A brief classification of a garden swing made of metal

- 2.2 Do-it-yourself swing technology from a profile pipe

- 2.3 List of required tools and materials

- 2.4 Drawings and photos of a swing with your own hands made of metal: the preparatory stage

- 2.5 DIY assembly according to drawings of a swing from a profile pipe: frame part

- 2.6 Assembly technology of wooden swing seat

- 2.7 Making a visor for a structure

- 2.8 The final stage of construction

Do-it-yourself garden swing classification made of metal: photos and features

Various materials are used for the construction of metal structures. Therefore, there are so many design solutions. This is evidenced by numerous photos of do-it-yourself garden swing made of metal, which can be found on the Internet.

For the manufacture of structures, the following material options are used:

- metal corners;

- square profiles;

- I-beams (steel beams);

- pipes (round profile);

- brands (aluminum profiles).

Note! Based on these elements, with equal success, both benches family type, and small baby rocking chairs.

Before you start planning and developing drawings of garden swing with your own hands made of metal, you need to decide on the type of future design. To do this, you can study the ready-made systems offered by modern industry.

How to make a garden swing with your own hands from metal: photos and examples of products

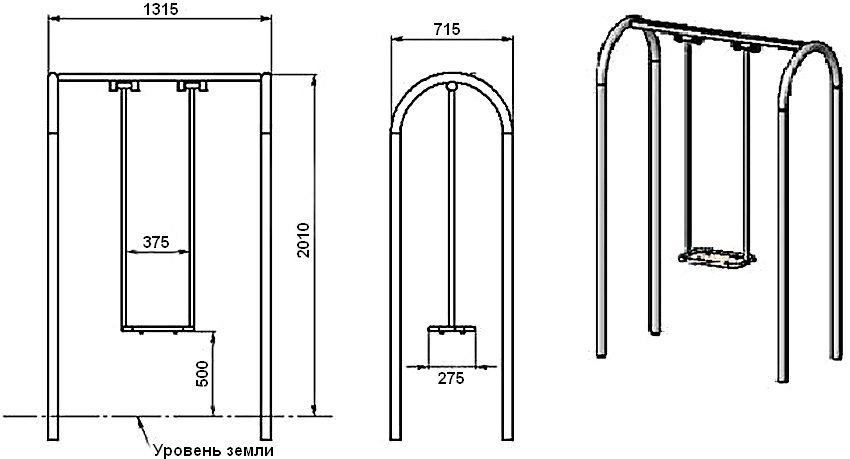

If you are puzzling over how to make a do-it-yourself swing for children, take factory-made options as an example.Such products have a correctly calculated design and are represented by a large number of interesting design solutions. You just need to create a similar swing from scrap materials.

Baby swingsuspended from a metal frame on chains

Product classification from manufacturers:

- freestanding garden constructions. This type of product can be installed anywhere you deem suitable, since it does not require additional support or suspensions. This type of swing can be not only metal, but also wooden;

- sofa swing that can be used by both adults and children. In the second case, the product allows several skiers to sit on the bench at the same time. The constructions are comfortable and safe, equipped with a comfortable backrest. For the period of heavy rains or in winter, the swing can be easily removed, since its structure has a block structure. Products can be metal or wood;

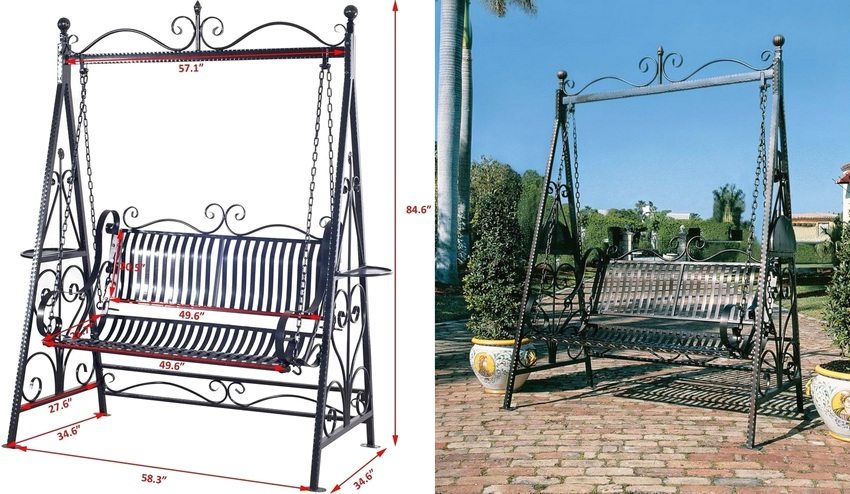

Factory Garden swing metal, installed in the garden of a private house

Photo of a garden swing with your own hands, created by forging

Swings of this type are made mainly for installation in the territories of country houses. To create these products, you will need skills in handling a welding machine and metal, or you can hire an assistant. In this case, the swing is more durable and powerful than other options for metal structures. In addition, you get an original product that can become an interesting decorative addition to the landscape and exterior of the house.

Metal products made by forging are expensive. But it is justified by its excellent decorative characteristics.

Useful advice! Use similar designs to maintain the overall design of your home and surrounding area, with fences, window bars, street lamps, benches, balconies, stair railings, canopies, or gazebos built with this technology. To achieve unity in design, use the same or similar pattern on all the listed items by forging.

Characteristics of a garden swing with your own hands made of metal

Metal structures have the largest number of advantages over products based on other materials. That is why on the Internet there are so many photos and drawings of children's swing with their own hands made of metal.

Technical and operational characteristics of metal-based swing:

- long service life is one of the main benefits. The metal is not susceptible to the destructive effects of such factors as, for example, decay processes. Breakage due to drying out is also excluded;

Wicker swing-cocoon with a metal frame will become an unusual decoration of the yard of a private house

- practicality - environmental influences that are destructive for buildings (ultraviolet radiation, rain and other types of precipitation) cannot affect the strength characteristics of the material;

- reliability - due to the increased strength of the metal and its durability, the resulting structures are very strong;

- budget - the metal in the purchase has a lower cost than high-quality wood (low-quality wood cannot provide the strength of the product, therefore it is not used to create a swing);

- a variety of modifications - the assortment of modern swing, which can be purchased or made independently, is extremely wide, which allows you to choose a design that fully meets individual preferences.

Cons of homemade metal swing

Despite the external attractiveness of metal products, by themselves they will not be able to harmoniously fit into the landscape of a summer cottage, as is the case with a swing made of wood. This will require stylistically supporting their design by adding similar elements to the exterior of the house or garden.

Note! Metal structures can be done by hand, however, you need to study welding technology and get the appropriate skills, as well as purchase or rent the necessary equipment.

One of the positive characteristics of the material, namely the hardness of the metal and its strong structure, can also be considered a disadvantage. On the one hand, a strong and solid swing is what you need for a summer residence, on the other hand, it can cause serious injuries that a person can receive as a result of a blow. Compared to wood, which is soft in nature, metal is many times more dangerous.

Related article:

Do-it-yourself swing for a summer residence: photos and step-by-step instructions. Recommendations for the manufacture of swings for children and adults at their summer cottage. The use of materials at hand to create structures.

Metal products are subject to corrosion. Rust can lead to gradual deterioration, so the durability of a structure can only be ensured with proper care. To prevent the occurrence of corrosion, it is sufficient to cover the metal with a layer of a paint composition intended for metal surfaces and outdoor conditions in a timely manner.

Drawings and photos of a garden swing with your own hands made of metal: dimensions and technology

DIY garden swings can have a different type of frame. Based on this feature, the following design options are distinguished:

- collapsible;

- welded.

Welded swing types require the use of a welding machine and other special equipment. As a result, you will get a strong and rigid support part, which will allow you to operate the structure for many years without any health risks.

If you do not know how to handle a welding machine, choose a swing with a collapsible design. The principle of assembling the frame consists in twisting all elements of the product with bolts and nuts. Anyone can do this work.

Note! Over time, in hand-made metal garden swings, the threads at the joints under weight and other loads gradually loosen up. As a result, backlash (free space) appears. It can provoke the destruction of the structure, as a result of which it is possible for a person to get injured. To prevent this, secure the elements with grovers and locknuts. Do not forget to regularly tighten the joints with a key.

A brief classification of a garden swing made of metal

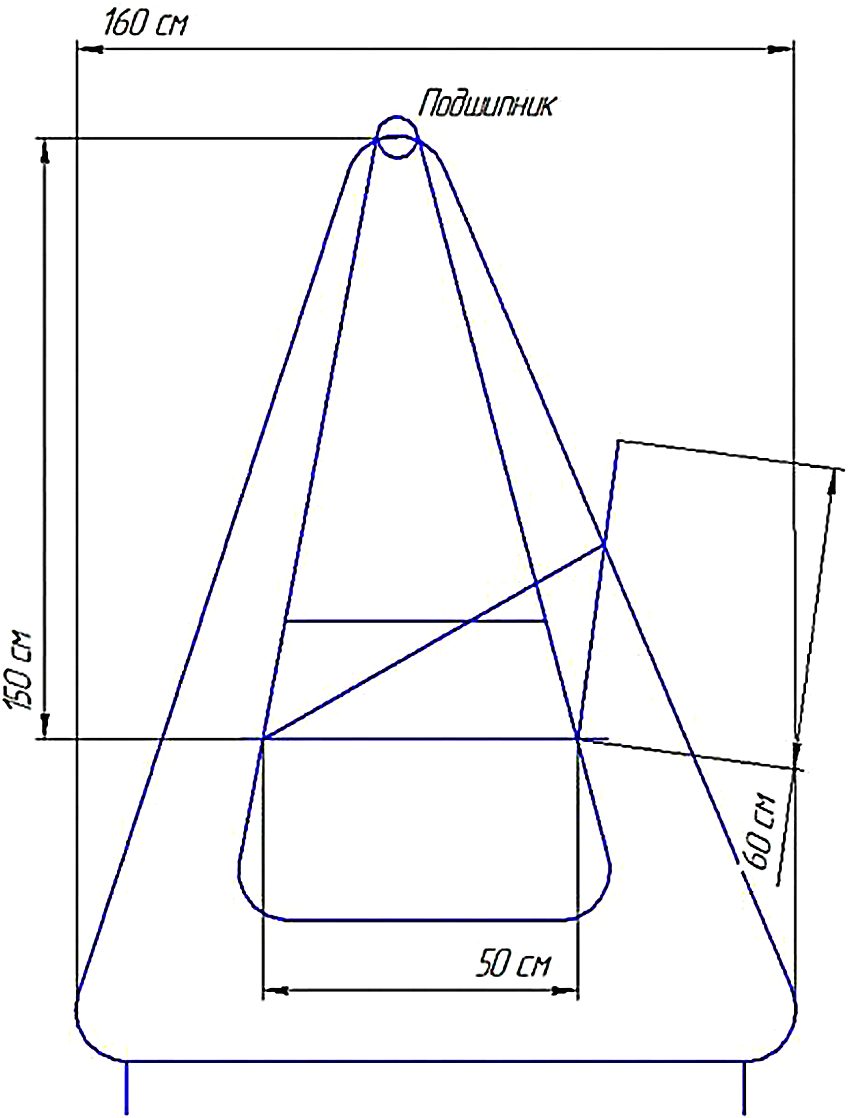

The easiest way is to create a structure according to ready-made drawings of a garden swing with your own hands from metal.Considering the diagrams, you can see that the configuration of the supports is different.

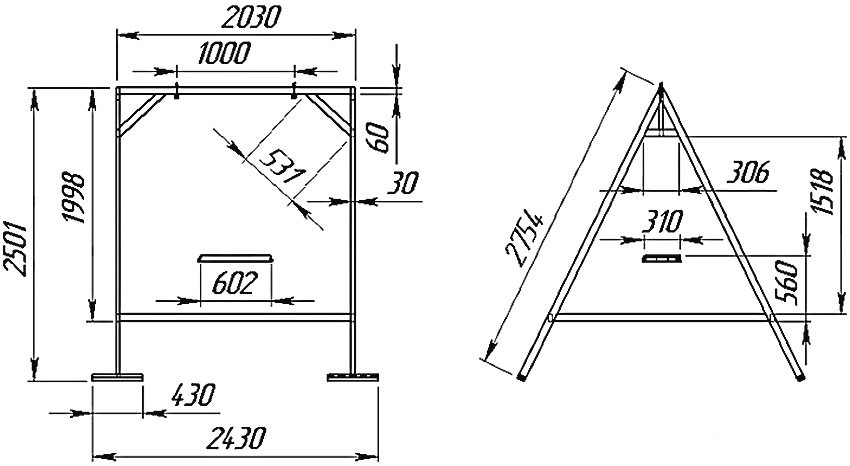

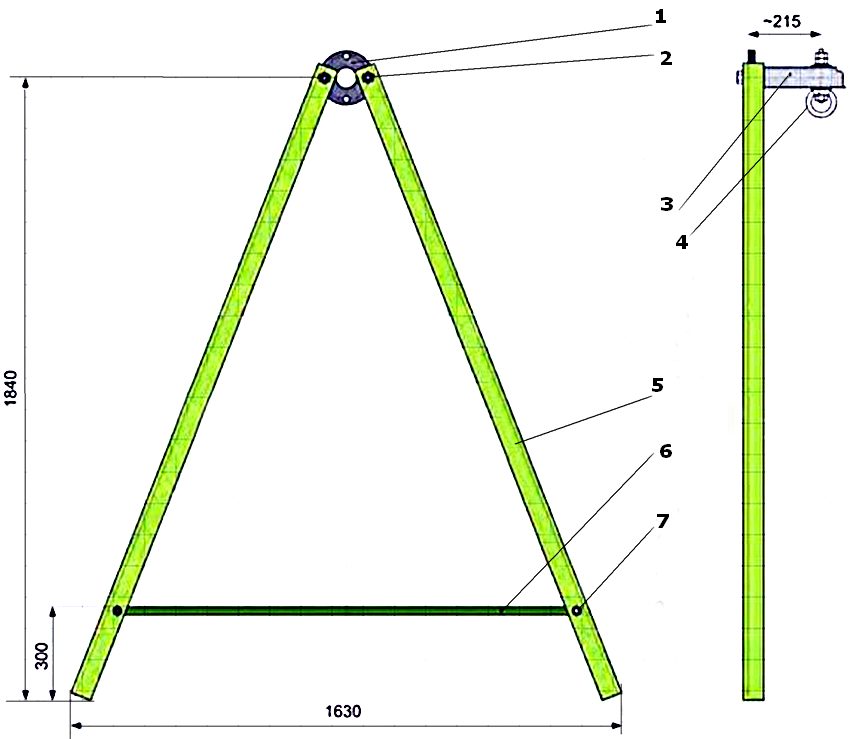

The A-shaped frame base consists of two crossbars, which are interconnected at the top. There is a jumper in the middle of their height. It is designed to increase the rigidity of the structure. There are supports without a lintel, which are L-shaped.

Another type of support is elements with a crossbar that form a U-shaped base. Creating such a structure takes less effort, but the swing is less stable. Their operation will be long-term and safe if the base supports are placed in deep holes in the ground and well concreted.

In addition, all metal products can be divided into two groups:

- stationary - the supporting part of the swing is reliably concreted;

- portable - fixed with anchor bolts or bent reinforcement, which is hammered into the soil.

Do-it-yourself swing technology from a profile pipe

Hanging swings are considered the most common design options. They are comfortable, practical and comfortable. Equip the product with a canopy to protect it from direct sunlight. Thanks to this, the seat will not overheat, and the riding process will become even more comfortable.

To make a canopy for a children's swing made of metal with your own hands, you can use textiles, tarpaulin, wood with soft tiles in the form of a roof. But the most suitable material is cellular polycarbonate. The polycarbonate sheets are transparent, so it won't be dark under the canopy. At the same time, they perfectly scatter direct sunlight.

List of required tools and materials

Before making a garden swing with your own hands, make sure you have the appropriate tools:

- grinders;

- building level and tape measure;

- welding machine and protective equipment (for working with the machine);

- electric drill;

- a set of drills designed to work with metal and wood surfaces;

Mobile hanging swing chair with metal frame

- screwdriver;

- a set of wrenches;

- self-tapping screws designed to fix polycarbonate sheet.

For work, you will also need to purchase materials, namely:

- metal profile (pipes and corner);

- boards or blocks of wood for assembling the seat;

- bolts equipped with semi-countersunk heads (for seat assembly);

- washers and nuts for bolts (for seat assembly);

- fastening elements made of stainless steel or galvanized (carabiners, bearing hangers, eyebolts, chains);

- long length anchors or bent reinforcing bars (for fixing the structure to the base);

- a sheet of cellular polycarbonate (canopy roof);

- protective agents for the frame (primer with anti-corrosion properties and paint composition for metal surfaces);

- protective agents for the wood from which the seat will be created (stain, varnish composition, a set of brushes for surface treatment).

The choice of designs when creating a swing from metal with your own hands is extensive and limited only by your imagination

Drawings and photos of a swing with your own hands made of metal: the preparatory stage

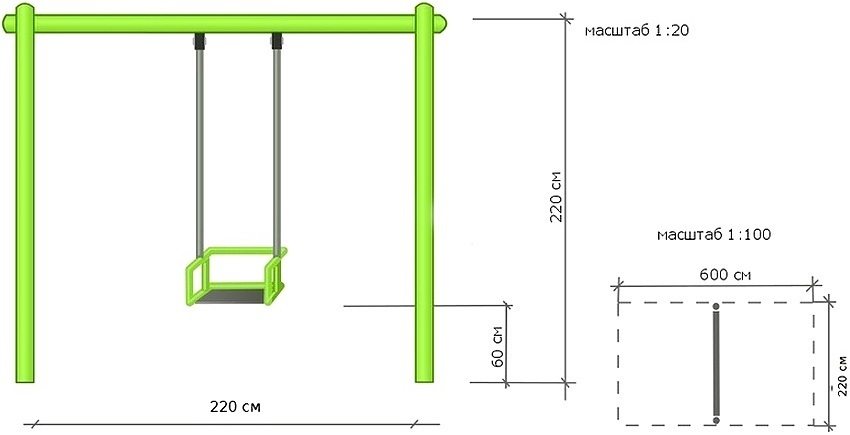

At this stage, the area for mounting the swing is selected, the dimensions of the structure are determined. The optimum size of the hanging bench is 1.5 m. This is enough for two people to sit on the swing or one to lie down.

Useful advice! Be sure to create a gap between the rack structure and the side of the bench.The minimum size is 300 mm.

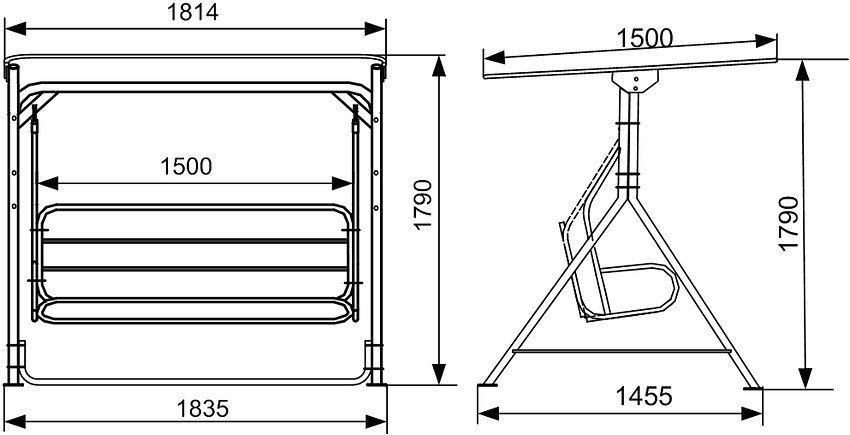

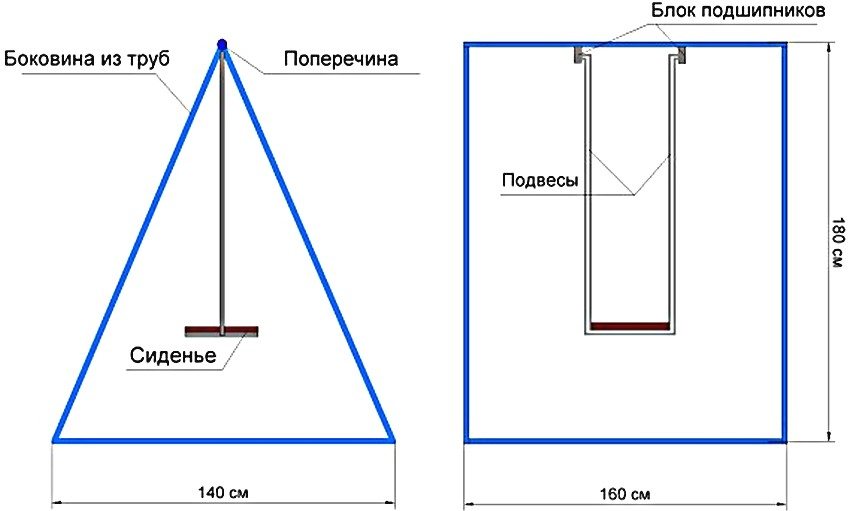

According to the drawings of a garden swing with your own hands from a profile, the structure consists of the following elements:

- rectangular support frame at the base;

- sidewalls made of a pair of pipes, welded together;

- horizontally located crossbar for hanging the bench.

This information will help with further assembly. Thanks to this structure, the structure acquires the required level of rigidity. By choosing the right base width, you can build a very stable product. Take the rule as a basis for your work: the greater the angle that is at the apex of the triangle between the base and the sides, the more stable the structure will be.

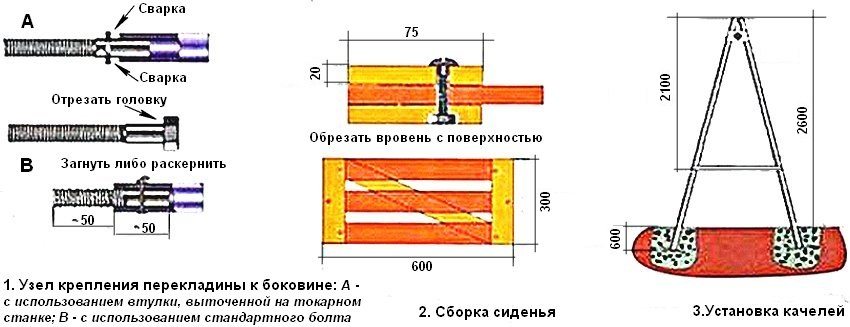

Diagram of a swing frame made of metal with A-shaped posts: 1 - flange; 2 - nut; 3 - crossbar; 4 - eye nut; 5 - support frame support; 6 - frame brace; 7 - bolt

General dimensional parameters are calculated on an individual basis. The indicators regarding the polycarbonate visor and the hanging bench are adjusted for them. Experts recommend that it is mandatory to prepare drawings indicating all the dimensional parameters of the structure, so that it is more convenient to work with the material. Subsequently, this will save you from mistakes and save time.

The sizes of various mobile swing chairs made of metal. Similar designs can be made with your own hands

DIY assembly according to drawings of a swing from a profile pipe: frame part

It is recommended to start assembling the frame from the side parts. To do this, based on the drawings, you need to mark the pipes and cut them with a grinder. Check the dimensional accuracy before assembly. All four sidewall elements must be similar to each other. They must be connected in pairs using the welding method. As a result, you should have two identical L-shaped parts.

Further, the sharp end, located at the top of each of the parts, is sawn off at one level. This procedure is performed so that a small support area can be formed to secure the horizontal bar.

Useful advice! Use a pre-prepared template for work.

The width of the support frame (short side) should be sized according to the distance that is formed between the twin pipes of the side parts of the structure. The welding machine welded the sidewalls to the rectangular support frame, and then the horizontal crossbar (over the side posts).

All stages of the assembly of the frame part must strictly obey the laws of geometry: the side posts are of a vertical type of arrangement, the horizontal crossbar (beam), designed for hanging the bench, runs parallel to the base. Use the building level to control assembly parameters.

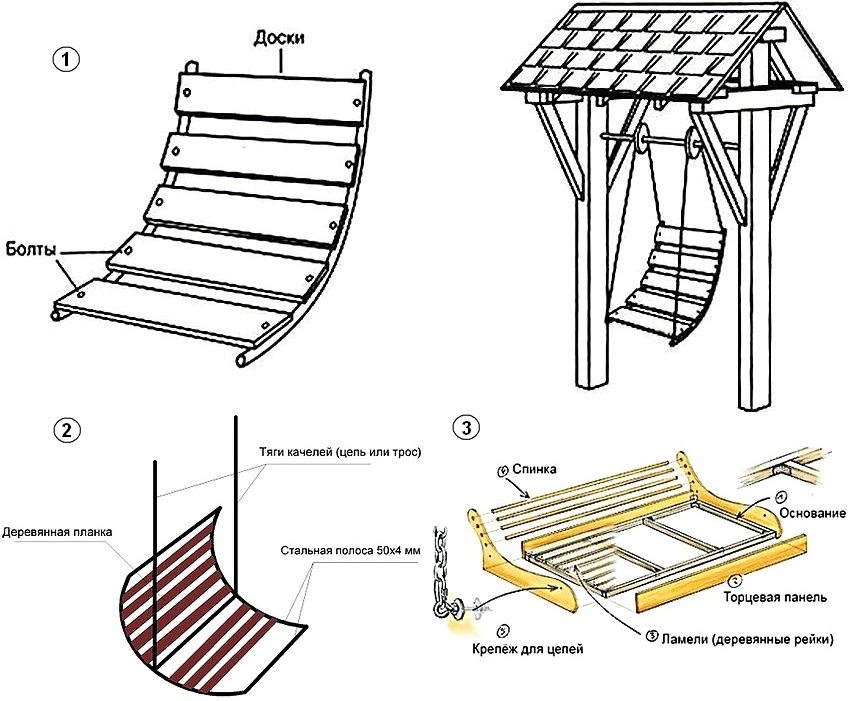

Assembly technology of wooden swing seat

Assembling the bench is an important construction step. Especially if you create a children's swing made of metal according to drawings with your own hands. At the base of the seat, there should be a frame base made of steel corner. To obtain bench with a comfortable backrest, position it at a certain angle in relation to the seat. The optimum angle is 120 °.

To make a correct bend of the corner, cut a triangle (60 °) on one shelf.The frame for the seat is made of a rectangular metal profile using a welding method. The side parts should be connected along the edge zones using horizontal jumpers. The connection zone should also be in the place where the structure bends.

Helpful advice! Optionally, you can improve the structure by adding armrests to the seat. They will enhance comfort and safety.

Whether you are creating a DIY swing design for children or making a product for adults, the back and seat should be completely smooth. For these purposes, suitable wooden bars or boards, carefully processed with sandpaper (first coarse grain, then fine).

The boards are cut to the required size and attached to the frame through pre-drilled holes with bolts so that their heads are recessed. Before the final assembly of the structure, wooden elements are treated with an antiseptic and varnishing composition, and metal elements - with a primer and paint.

Eye bolts are mounted in the corners of the frame part of the bench. The chains will be attached to the lugs of these bolts with carabiners or threaded couplings. To hang the bench, you will also need to install eyebolts at the corners of the product or over the edges of the seat.

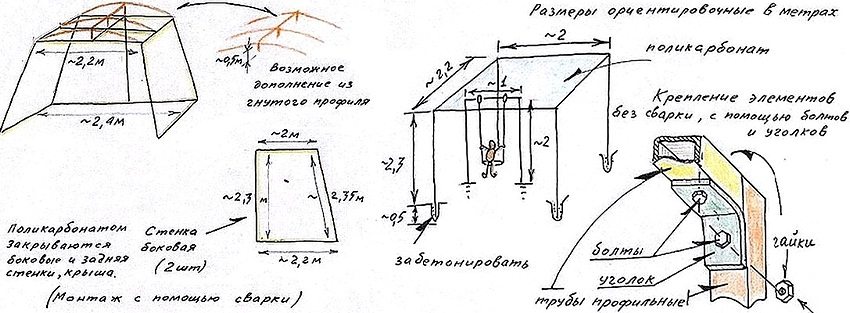

Making a visor for a structure

The visor manufacturing process is optional. But if you create a do-it-yourself swing design for children, you should think about comfort and protection from the scorching sun, as well as precipitation.

To do this, you need to make a rectangular structure, which will be based on a metal frame, reinforced with jumpers. A sheet of cellular polycarbonate is fixed on top of the structure. Installation of the visor is carried out at a slight angle, due to which the precipitation will flow down freely.

To complete the frame part of the visor, take several metal profiles with a small square section. All these elements are fastened by welding, after which the visor can be attached to the upper frame part of the swing. This is also done using a welding machine.

When all the assembly work is completed, the structure is subject to final processing. The surface of the swing is covered with a primer, after which it is painted in any color you like.

The final stage of construction

When the paint is completely dry, a polycarbonate sheet is attached to the visor frame. To do this, use self-tapping screws with sealing washers.

Helpful advice! Cover the end part of the sheets with a polymer profile. It will protect the hollow polycarbonate structure from insects and dust, preserve its beauty and accuracy.

A wide range of colors is one of the advantages of polycarbonate. You can choose the color of the visor to match the color of the swing, or, conversely, make it contrasting. Moreover, the color of the material has a direct impact on the level of dispersion of sunlight.

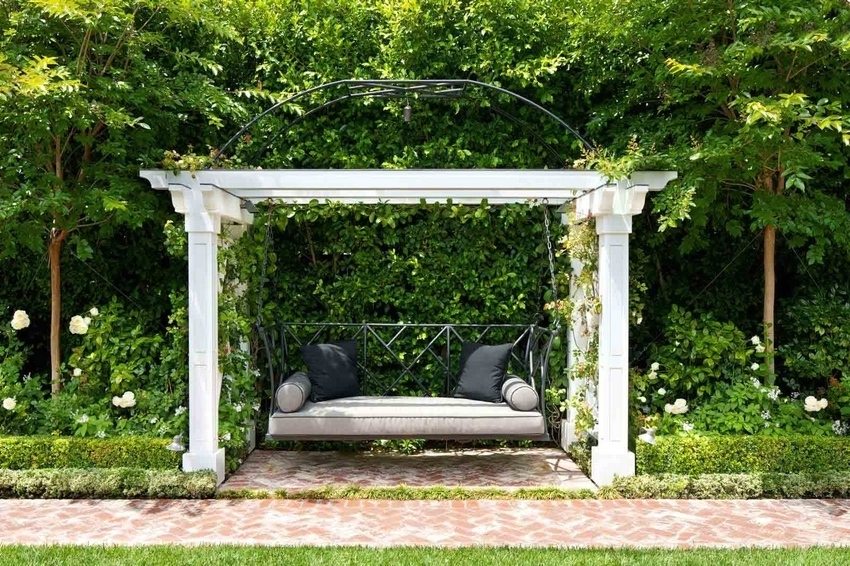

A wooden one acts as a basis for hanging a metal swing pergola

The finished product must be securely fixed on a concrete site. If the structure is being erected on high-density ground, several clamps made of reinforcing bars can be used to secure the frame. First, the ends of the clamps should be sharpened, which will make it possible to drive the rods 0.5 m deep into the ground without any problems.

It is better to use anchor bolts as fasteners on a concrete site. They are pre-installed in appropriate locations.After tightening the nuts, cut off the excess thread with a grinder. This completes the construction of the structure.