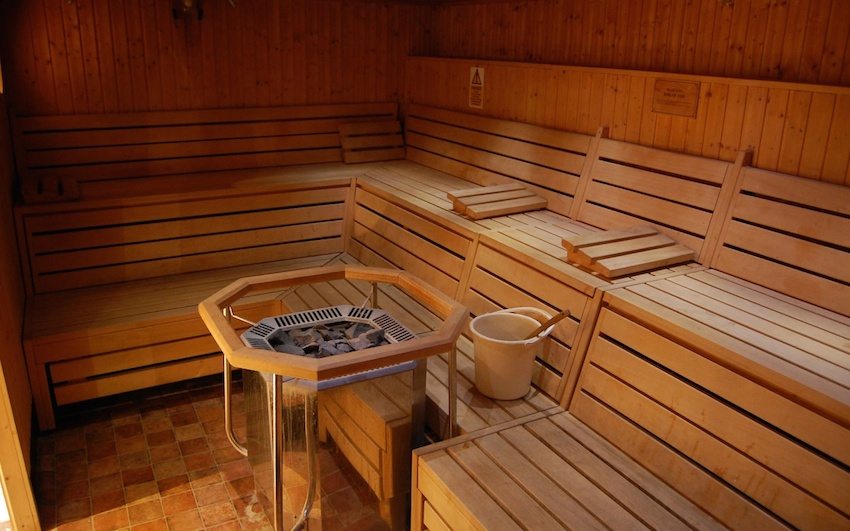

When viewing photo of finishing the bath inside, it is not always possible to understand the sequence of the repair steps. Therefore, it is worth dwelling in more detail on the main points.

Content [Hide]

Bath finishing materials

The main stage in the arrangement baths the choice of material for decoration is considered, which should have a number of advantages:

- resistance to hot air and moisture;

- hygiene;

- lack of toxins released during heat;

- strength and durability;

- excellent external characteristics;

- pleasant texture.

The best option for interior decoration is clapboard. It has excellent medicinal properties, the material is safe and has aesthetic advantages. As raw materials for it, cedar and linden are optimal, larch is also perfect. But pine lining should be used only for decorating a dressing room. The combination of various woods will add a certain zest to the interior of the bathhouse.

Helpful advice! In order to get a high-quality and original finish, it is undesirable to use the same wood in different rooms.

Rules for finishing floors in the bath

Traditionally, in a modern bath, the interior decoration, the photo of which you liked, is started from the floor. For a steam room, it is more expedient to raise it a little. It is desirable to do this in order to protect the room from unnecessary drafts, providing better heat conservation. The flooring is done with tiles, although edged and grooved boards are quite suitable.

Steam room shelf manufactured without the use of metal nails

The temperature on the floor surface does not exceed 30 ° C, so the draft level can be concrete, earthen or clay. The basic rule is to organize the fastest possible removal of water from the premises. In order to ensure the safety of movement, it is required to cover such a sub-floor with a covering made of cork, possibly a fiber mat, a boardwalk. A tile or polished board is also perfect.

Related article:

Ventilation in the bath with your own hands: how to do it right. Why do you need ventilation in the bath, how to make ventilation in the bath yourself, the principles of the device, diagrams, instructions, photos, video materials.

The process of arranging the floor with wood is quite simple. First, the logs are laid, then the boards are laid. Lags are placed on brick posts that are located on a rough base.

The selected size of the lag varies from 20 × 20 to 25 × 25 cm with an installation step of approximately one meter, since the floor will not experience significant loads. For flooring, an edged, preferably grooved board is used. The wood used should have a thickness of about 30 cm. All material should be treated with an antiseptic agent in advance, which will protect against the growth of fungus and the spread of mold.

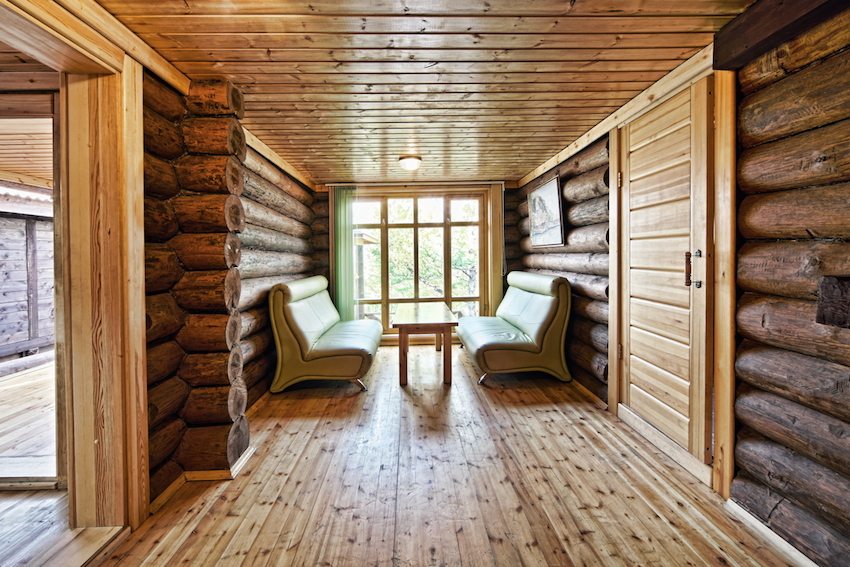

Interior baths with a spacious lounge

If tiles are chosen for arranging the floor, then the installation process is as follows. The floor screed is pre-made, and the surface should become perfectly flat. Fasten the tiles with special glue. To process the seams, a moisture-resistant grout is used to protect the material from mold.

Subsequently, it is necessary to lay low shields or wooden gratings on such a floor covering, which then, after each bath procedure, will have to be taken out to dry. This is to prevent slipping on wet surfaces.

Helpful advice! The floor in the bath is necessarily made with a slight slope, then the water will drain well over it, and not stagnate.

Photos of finishing the bath inside and stages of work

The popularity of the wall paneling is explained by the fact that with its help two tasks are solved simultaneously - wall decoration and room insulation.

This material is made from wood and is the ideal cladding panel. Walls decorated with clapboard look nice. In addition, visually, the boards level any surface. This is the best option for wall decoration, as it provides excellent ventilation all other building materials. The lining allows the walls to "breathe" freely, it does not allow the appearance of condensation, and therefore mold.

The lime board is considered the most optimal. The finishing technology with this material is simple. Initially, the lining is brought into the steam room, where the material adapts to the microclimate of the room. If the walls have drops, they are aligned with slats.

The joints and crevices are carefully caulked. The work begins by assembling the battens made of battens. They are attached to the walls at a half-meter distance. Initially, the most extreme bars are nailed in order to then fix a thread on them, which will serve as a guide for securing the remaining rails.

Although, if there is a flat surface of the walls, the crate can be omitted. In such a situation, the cladding material is fixed directly to the walls. However, this option for interior decoration with wood will be strong, beautiful and durable, only with perfectly flat walls.

Fastening the lining

After completing the preparatory stage, they begin the process of finishing the bath inside - the photo will help navigate the sequence of actions. It is necessary to select suitable fasteners made of materials that are not dangerous to moisture and high temperatures. Forget about traditional nails right away, as they will quickly corrode, the walls will deteriorate with rust stains. And when the temperature rises in the steam room, touching the nails is dangerous - they can burn the skin.

The lining is cut immediately to size, focusing on the height baths, then fix it to a previously prepared lattice (or directly to the walls) with special brackets. If necessary, the width of the lining can be slightly trimmed at the corner joints.

Lounge in bath, the place where the most time is spent

For the finishing of the steam room, high-quality wood should be used that can withstand high temperatures and high humidity.

All actions must be carried out using a level to obtain a perfectly flat structure. After making the frame, it is covered with an antiseptic. You should also process the lining, but even before you start installing it on the frame. Material placement starts from the corner. Nails, staples and clamps are used as fixators. The material that was used to decorate the surface of the walls can also be used to decorate the ceiling.

It is necessary to understand that the maximum temperature is kept under the ceiling, which is why it is necessary to choose lining for this surface from rocks in which there is a small amount of resins, otherwise their drops can burn the skin when falling. The finishing of the place where the stove will stand must be made of non-combustible materials - tiles, bricks.

Helpful advice! It is not recommended to choose spruce or pine for the steam room. It is better to beat the dressing room with this material.

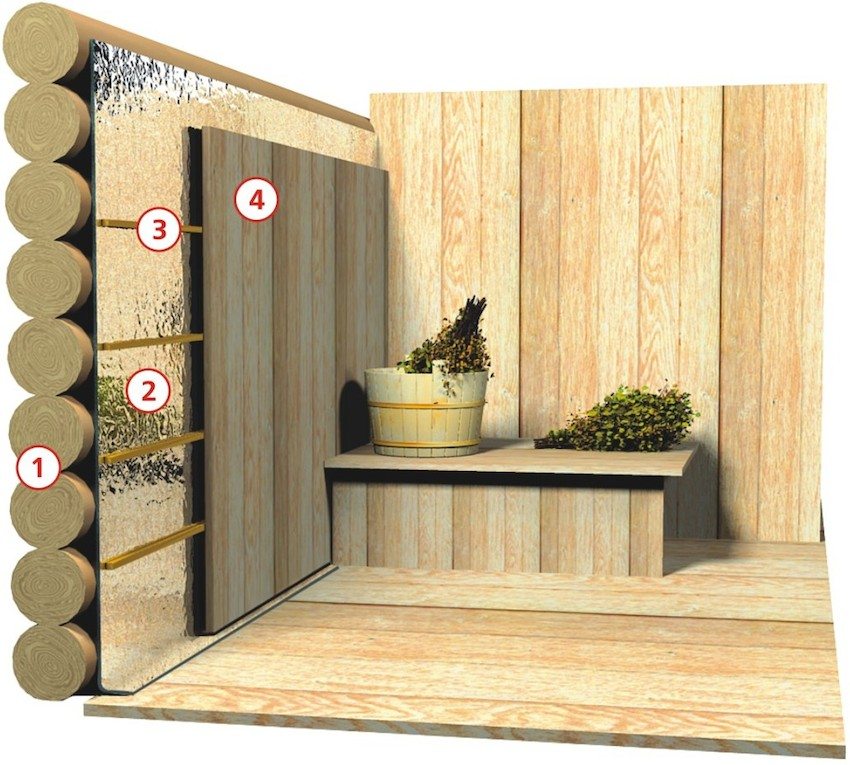

Warming and insulation of walls

The interior decoration of the bath also implies a solution to the issue of room insulation. Sometimes experts recommend using mineral insulation. It fits under the crate, but in this matter everything will depend on the type of load-bearing walls of the building. In the event that the bath is made of stone or concrete blocks, it is better to do without insulation, otherwise after that you will have to solve the problem with poor-quality ventilation.

Among other things, it is necessary to carry out the correct waterproofing of the surfaces. Good waterproofing will protect the material of all supporting structures. The most common material is aluminum foil, as well as vapor barrier film, as its more modern counterpart.

When the interior decoration of the bath is completed, it remains to equip it with furniture and proceed to water procedures. Light steam!