Long-burning pyrolysis boilers with a water circuit are an excellent alternative source of energy in private houses in conditions of frequent gas supply interruptions. Firewood is the oldest type of fuel that people use to heat their homes for thousands of years. In the 21st century, the pyrolysis method of generating heat was born from the technology of obtaining charcoal.

Content [Hide]

What is pyrolysis and what is its effectiveness

Medieval Europeans, as a result of long centuries of burning firewood, found that this energy can be used more rationally if you put charcoal instead of firewood in the stove. It was produced by burning ordinary wood without sufficient oxygen. To do this, they dug special holes in the ground, where this whole process took place, later called pyrolysis.

Such pits did an excellent job of producing charcoal, but the energy that was released during these processes was wasted without any benefit. It is worth saying that the amount of energy released was very decent. Therefore, modern technologies have not bypassed such a gift from nature. Pyrolysis boilers with a long burning with a water circuit were created, which were able to harness this heat, which was previously wasted. Today they are successfully used, not only as auxiliary sources of heating, but also as the main ones. This is not surprising, because in addition to ordinary firewood, you can load other, more modern and efficient wood-based fuel into them.

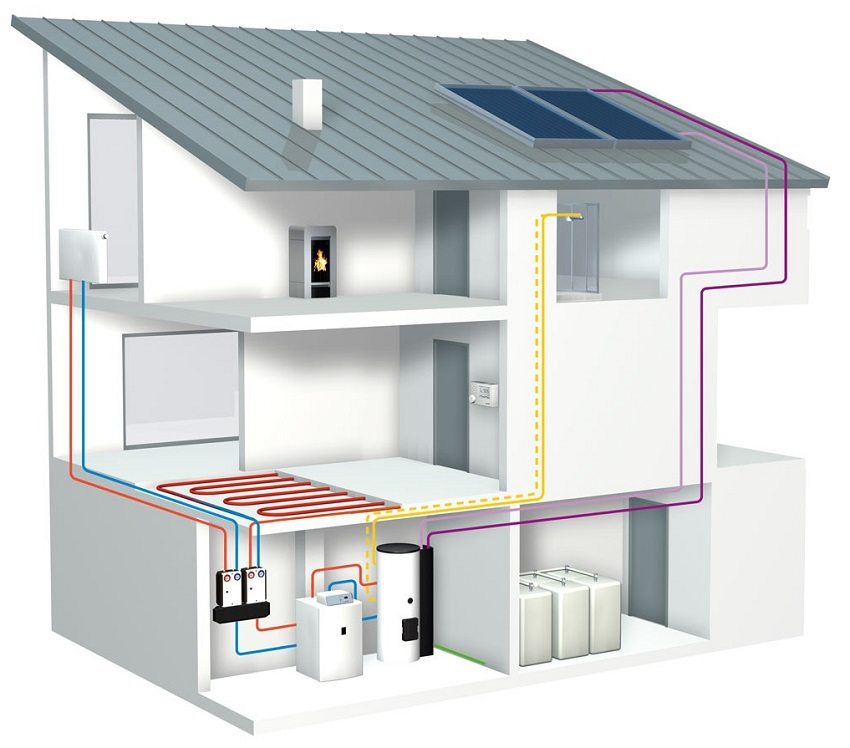

Long burning pyrolysis boilers with a water circuit

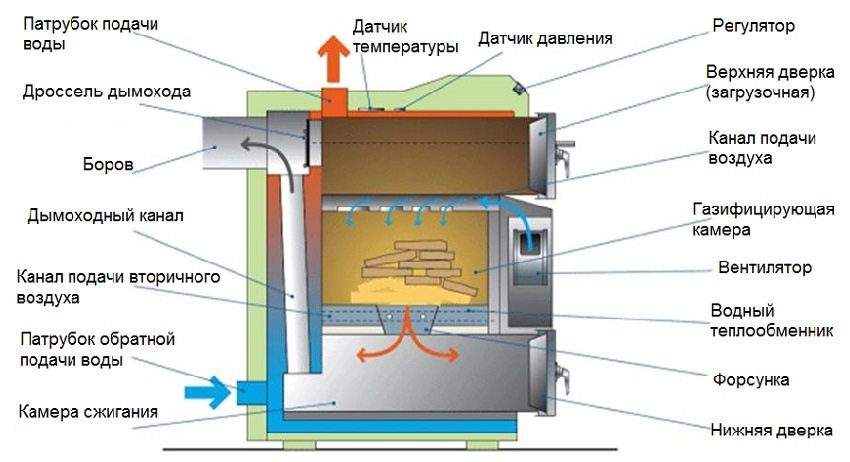

Outwardly, these boilers are not much different from ordinary metal stoves. They have the same loading door leading to the primary combustion chamber. Ordinary firewood, as well as briquettes from sawdust or peat, are placed in it. The invention of the last few years, pellets, is also used for this purpose. They are highly compressed carpentry waste. Everything is used, from tree bark to peat and dried manure.

Helpful advice! It is best to use pellet pellets as fuel. This fuel is small and can be automatically fed into the boiler combustion chamber.

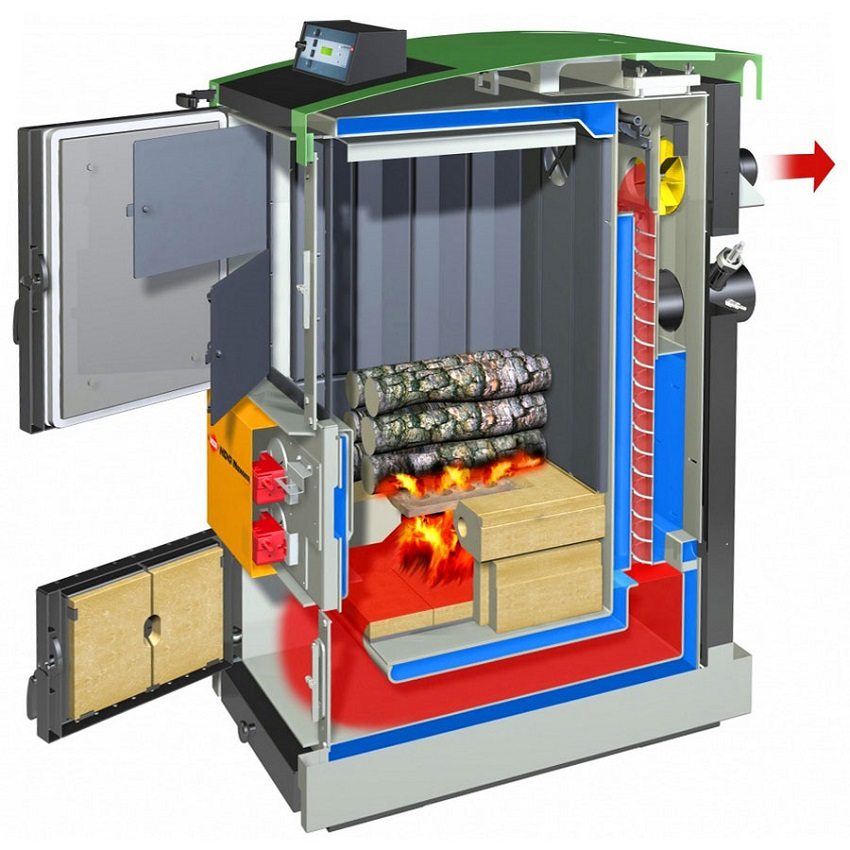

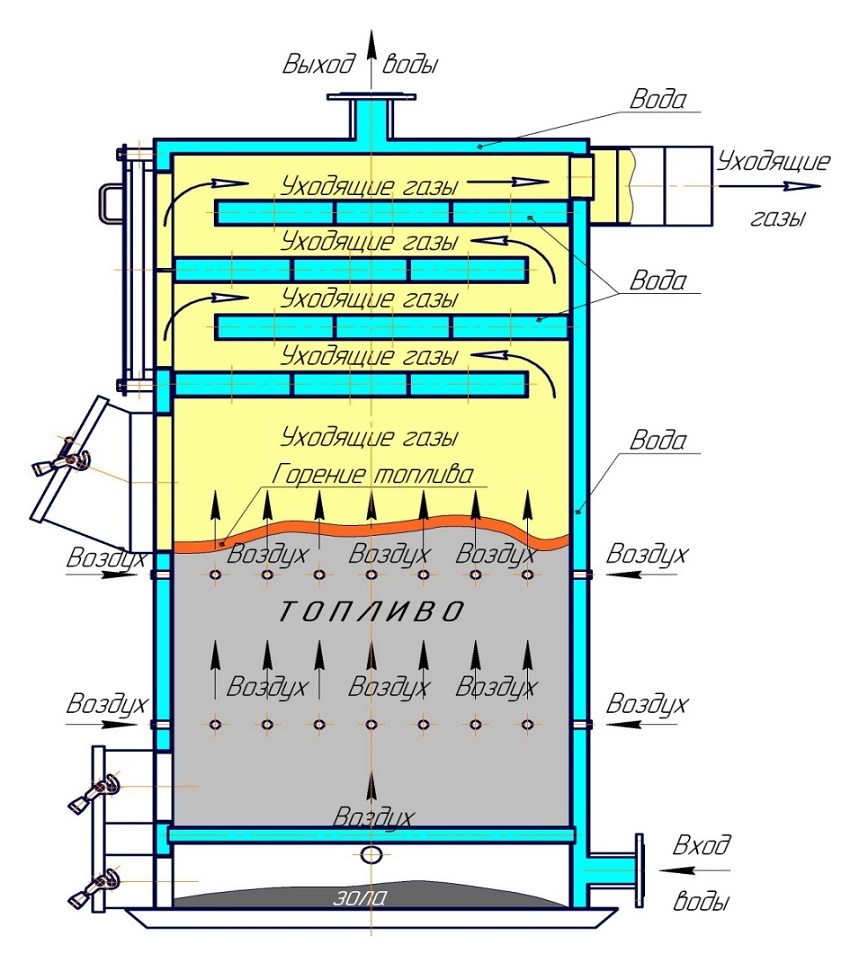

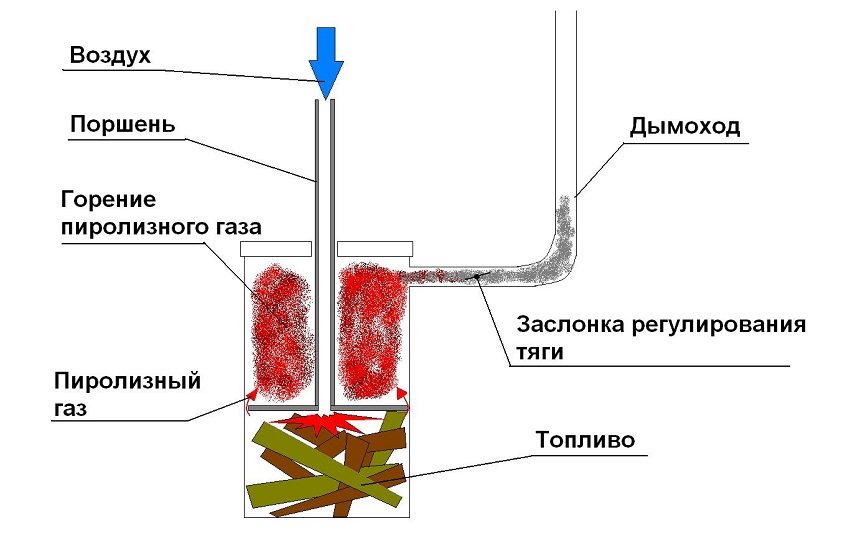

Modern long burning boiler with a hopper for pellet granules

At the bottom of the combustion chamber there is a grate, which looks like a very heavy cast iron grate. It is necessary to supply air for fuel.The loaded wood is set on fire and waited until it is completely ignited by the primary air flow. As soon as the boiler enters the mode, the air access to the primary chamber is practically stopped, as a result of which the combustion stops. The fuel only begins to smolder, releasing pyrolysis gas. It has a very high flammability, but since there is little air, it does not flare up.

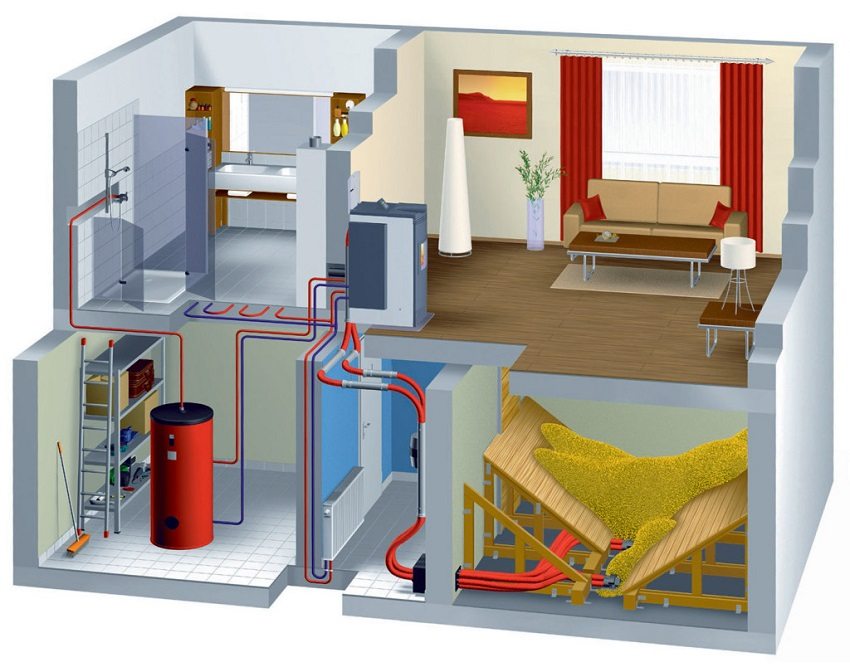

Heating system diagram of a private house using solid fuel boiler

Then, by gravity or forcibly, this gaseous volatile organic mixture is fed into the secondary chamber, which, in fact, is the main working part of the long-burning pyrolysis boiler. It is directly connected to the water circuit of the heating system. The gas entering this chamber has a temperature of about 300 degrees and therefore flares up when oxygen is supplied without delay. A sufficient amount of air is supplied to the secondary chamber for combustion. During combustion, pyrolysis gas releases much more energy than simple firewood, therefore, the heating of the coolant in the system occurs very quickly.

Placement example solid fuel boiler with automatic feeding of pellets from a storage bin in the basement of a private house

An important point is that a portion of firewood placed in the firebox is consumed very slowly, which allows you to heat the room with a very small amount of it for a long time.

Helpful advice! It is recommended to use very well dried substances and firewood as fuel for gas generators. After all, 1 kg of firewood, which contains 20% moisture, emits 4 kW / hour. energy, and containing 25% moisture, is already only 3 kW / h.

Advantages and disadvantages of pyrolysis gas boilers

Long-burning pyrolysis boilers with a water circuit are appreciated for their advantages over direct combustion furnaces. Some of them can be listed:

- complete combustion of fuel without accumulation of soot. In addition to saving firewood, this property is of much greater benefit. Complete combustion means that only carbon dioxide and ordinary water are emitted as waste. Neither one nor the other is of great harm to people and nature in general. This cannot be said about the partial combustion of firewood. Harmful toxic substances formed during incomplete decomposition of organic matter enter the atmosphere, causing undesirable consequences, not to mention fetid pungent smoke;

- due to complete combustion, any organic solid fuel can be used in gas generators. In fact, it can be any organic substance capable of an active oxidation reaction, that is, combustion. Such boilers can be installed in garment and leather factories, wood processing enterprises, and agricultural enterprises. This completely solves the problem of waste disposal;

- high savings in fuel costs, as long-burning pyrolysis boilers with a water circuit have such names due to the fact that from one wood bookmark the working process can last at least 12 hours. Simple oven or a boiler, maximum capable of burning for 4 hours;

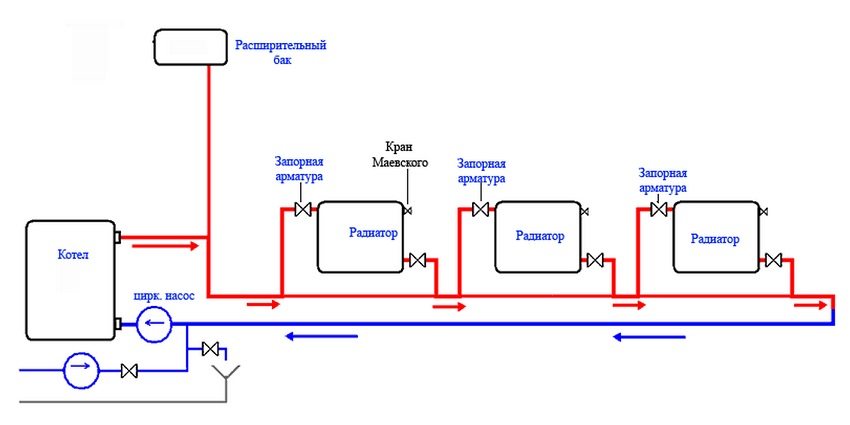

Connection diagram solid fuel boiler to the home heating system

- the issue of regulating the combustion process and heating the coolant has been completely resolved. Due to the fact that gaseous fuel burns in the working chamber, its flow is easily regulated, as well as the intensity of combustion. This allows you to fully automate the operation of the boiler, no worse than an electric or gas one.

Long-burning pyrolysis boilers with a water circuit also have disadvantages that you should inquire about when purchasing this technique:

- the cost of gas generators is much higher than that of other types of heating technology. However, this pays off over time, thanks to the fuel economy;

- the fuel must be perfectly dry. Already 20% humidity is a serious obstacle to combustion. The boiler will simply stop working after air restriction;

- due to the fact that the design of almost all models provides for the use of fans for air injection, their operation requires the presence of electricity, which does not allow the use of this technique in dachas that do not have power supply.

Useful advice! Reviews of the owners of long-burning pyrolysis boilers indicate that sometimes they stop due to the fact that water from the return pipe of the system enters the boiler circuit, which is very cold. To avoid this, it is necessary to solder a bypass circuit from the supply pipe into the system. A conventional three-way valve is used here. Then hot water will mix with chilled water, the boiler will not turn off.

Reviews of the owners of long burning pyrolysis boilers

If you ask a question, you can find on the forums and blogs a lot of reviews from the owners of long-burning pyrolysis boilers. Here is some of them:

Last year I installed a gas generator at my dacha. Near the sawmill, where there is always a huge amount of sawdust bark and knots. Take it - I don't want to. Now I'm not overjoyed. I don't spend at all on fuel. He brought a cart of waste, which he took for free. I don’t know when I’ll use it.

Sergey Vasiliev, Omsk.

Recently acquired solid fuel boiler, a friend advised. At first I did not understand why I did it, where to get and store firewood. And then I learned that you can use pellet granules. Bought some bags. I'm drowning - I don't know grief.

Nikolay Pavlov, Tver.

Long burning pyrolysis boilers - environmentally friendly and energy efficient due to the complete combustion of solid fuel

My husband recently brought a wonderful oven that runs on ordinary wood. I scolded him for a long time. She said that we have a gas pipeline and gas boiler... Why do we still need this stove. He said that I would understand everything later and connected this device to the system, leaving the gas as well. Once a gas pipeline broke in the village. The workers corrected the accident for three days. The neighbors bought up all the electric heaters, and my husband just shrugged his shoulders and melted his stove. Now I realized that I was wrong.

Olga Meyser, Golyshmanovo village, Tyumen region

Reviews of the owners of long-burning pyrolysis boilers reveal all the positive qualities of the device. You can really use this device with great benefit for yourself. As an alternative heat source, it can completely solve the problem of a temporary lack of gas. For those who have the opportunity to use waste from various industries, this is just a godsend.