Wood is widely used in construction and furniture production. This material is easily susceptible to negative influences from external factors, so it needs additional protection. Of the products on the market, only wood stains retain the texture and beauty of the surface, creating a natural decorative finish. This article describes all the existing types of formulations, their characteristics, advantages and disadvantages.

Content [Hide]

- 1 Features of wood stain: what is it for and what properties it has

- 2 The main types of wood stains: classification of compositions

- 2.1 Characteristics of water-based wood stain

- 2.2 The main advantages of alcohol wood stains

- 2.3 Specificity of wood stains for oil-based wood

- 2.4 Advantages and disadvantages of treating wood with a wax-based stain

- 2.5 Oil-wax wood stains: pros and cons

- 2.6 Characteristics of modern wood stains in the form of gels

- 2.7 Features and benefits of acrylic wood stains

- 3 Which wood stains are better: a list of popular manufacturers and product prices

- 4 How to make wood stain at home

- 5 How to paint a tree with wood stain: options for applying different compositions

Features of wood stain: what is it for and what properties it has

Wood is distinguished by its natural beauty and warmth, environmental friendliness and the ability to create comfort around itself. To preserve all these properties of the material and extend its service life, special tools are used, including stains.

These compositions improve the decorative qualities of wood, as well as provide reliable protection against various pests and the negative effects of environmental factors. Before you start choosing the right option, you need to figure out what a stain is and what is its purpose.

What is wood stain: what is it for and what functions it performs

Stain (stain) is a special product designed for wood processing.Most often, the composition is sold in liquid form, but in rare cases it can be in the form of a dry powder. Mostly dark stain. It is used to give wood a variety of translucent shades. At the same time, the texture of the material and its natural pattern do not change at all, since the product penetrates only into the top layer. The stain enhances the natural beauty of the wood and enhances its attractive sides.

Useful advice! By choosing the right shade of wood stain for pine, you can "turn" this budget material into more expensive types of wood, for example, dark oak or ebony.

This tool allows you not only to change the appearance of the material, but also to protect it from the destructive effects of external factors. It was the multifunctionality of the stain that made it so popular.

Why do you need wood stain? This composition is used in the following cases:

- Toning the material while preserving its texture and woody pattern - the composition raises the fibers of the material without drastically changing its natural pattern.

- Wood bleaching - this property is used in the restoration and restoration of damaged and old products made of wood. Such stains are also used in cases where you want to lighten the shade of the material or prepare its surface for color varnishing.

- Imitation of elite wood species on budget materials.

- Protection of the material from damage by parasites - the antiseptic properties of the stain prevent the development of putrefactive processes (elimination of fungi, bacteria and mold) and the reproduction of insect pests.

- Strengthening the structure of the material.

- Moisture protection of wood - the stain protects the material from the negative effects of moisture, and some types of compositions create a water-repellent layer on the surface (partially).

- Extending the service life of wood products.

- Creating a finish effect using different types of wood by combining shades.

The better to process wood: paint, drying oil, stain or varnish

Stain is used by professionals and do-it-yourselfers as a means to add texture to wood. Getting deep into the material, the composition tints it from the inside. At the same time, the natural pores of the tree are not closed, which helps protect it from destruction and decay, while preserving the natural pattern.

Drying oil has similar properties, however, after processing, a film forms on the surface of the wood. This tool is not able to penetrate deeply into the pores of the material, but it covers them well from the outside. Unlike stain, drying oil cannot be used as an independent finishing agent. It is designed to prepare wood before painting.

Useful advice! If you treat the wood with drying oil before painting, this will not only improve the result, but also reduce the amount of dye required for this procedure.

Wood varnish is very different from wood stain. It forms a stable film on the surface of the material. Moreover, the formation of a protective layer occurs only after the solvent in its composition has completely evaporated. Oil-based varnishes, after drying, form a film on the surface with strength and elasticity. It is quite difficult to remove such a coating even with the help of white spirit.

Like any other finishing option, the varnish will have to be periodically renewed, and for this it is necessary to remove the previous layer. This requires some effort, therefore varnish is used in cases where the effect of atmospheric factors on the wood is too aggressive and it is impractical to use stain.

Paint used as a finish is fairly common. It is used to treat a variety of wood products, from flooring to furniture and window frames. This tool forms a dense opaque film on the treated surface. The paintwork completely hides the natural pattern on the wood. This is what distinguishes paint from stain.

Coloring compounds, unlike wood stain, are not able to give wood a natural shade. After 2-3 years, many types of paint and varnish coatings lose their properties, strength characteristics decrease. During operation, cracks form on the surface, the paint begins to peel off. To update the finish, you will have to completely remove the previous layer.

The main types of wood stains: classification of compositions

There are a huge number of wood stains on sale that are used for processing wood products. The existing types of compositions can be divided into groups according to the following criteria:

- operating conditions (indoors or outdoors);

- base or composition (aqueous and non-aqueous wood stains);

- the effect that the stain creates on the surface of the material after processing;

- price category.

The most important selection criterion is the conditions in which the stain will be used. The composition of the funds that will be used to treat surfaces inside the house should not contain harmful components. The wood in the room is not exposed to the negative effects of atmospheric factors, therefore there is no need to use resistant stains containing toxic substances. For these purposes, water-based solutions are suitable.

The composition of wood stains for outdoor woodwork contains components aimed at improving the performance of the coating. After surface treatment with their help, wood acquires the ability to resist the negative effects of ultraviolet rays and moisture. For external use, wax and oil stains are more suitable.

Important! Water-based wood stains should not be used outdoors. Such formulations are unsuitable for outdoor use.

Water-based wood stains include formulations made on a water and acrylic basis. The category of non-aqueous products includes alcohol, oil and wax stains. In addition, on sale you can find other options for wood stains, for example, rustic, gel, etc. Each type of composition has its own characteristics, advantages and disadvantages that must be taken into account when choosing a protective agent for wood processing.

Characteristics of water-based wood stain

Water-based stains are the most popular and common type of wood compound. These funds can take several forms. The buyer can purchase a solution that is completely ready to use. In addition, powders and concentrates are on sale. They must be diluted in accordance with the instructions immediately before use.

Diluted powder stains must be drained before application. This is done so that pigment particles do not get on the treated surface that have not completely dissolved. If the composition is not filtered, then the surface staining will not be uniform. Powder products are good because on their basis a solution of various concentrations can be prepared, having achieved the required shade (dark or light).

Water-based liquid stain is sold in containers of different sizes. Such formulations are already completely ready for use and do not require additional preparation.On the other hand, they have a small drawback. Liquid stain has a specific shade that cannot be changed.

Advantages of water-based wood stains:

- affordable cost;

- low consumption;

- simple application system that does not require special knowledge and skills;

- ecological cleanliness;

- lack of unpleasant odor and harmful substances.

These compounds are ideal for indoor wood treatment. When buying a water stain, it must be borne in mind that this type of impregnation is not able to radically change the color of the processed material. The solution dyes the wood one tone darker and makes its color more saturated. The composition is applied in several layers.

There is one more feature of water stains, which is reflected in the result of staining. The solution impregnates the wood, while lifting its fibers, which makes it possible to achieve a textured effect. On the one hand, the natural pattern is preserved, on the other hand, the service life of wooden products is reduced.

Useful advice! To extend the life of wood when treated with water stain, the surface of the material should be soaked in plain water before applying it. In this form, the product must be left for a day, then go over it with sandpaper and cover it with stain.

The main advantages of alcohol wood stains

Stains based on alcohol can be either liquid or dry. Ethyl alcohol is used to dilute the powder. The main advantage of such formulations is their fast drying. For this reason, alcohol-based stains are widely used for outdoor work. It is also allowed to process wood indoors, but it must be taken into account that these products have a specific pungent odor. Therefore, when applying the stain, it is imperative to ensure good ventilation in the room.

The quick drying of alcohol stains can be regarded not only as an advantage, but also as a disadvantage. It is quite difficult to evenly distribute the composition over the surface with a brush, so you will have to use a spray gun, which is associated with additional costs.

Alcohol stains have good penetrating ability. They deeply penetrate the wood structure, thereby providing reliable protection of the material from the sun and moisture. The advantages of alcohol-based stains include a huge variety of shades. Despite this, these formulations are not as popular as water-based solutions. The fact is that working with them requires the right equipment, as well as certain skills and experience. In addition, the cost of alcohol stains is much higher.

Specificity of wood stains for oil-based wood

The oil components contained in such stains can be natural (made from linseed oil) or synthetic. In addition, they contain dyes that dissolve in drying oil. If the stain is thick, it can be diluted. For these purposes, drying oil or white spirit is suitable. With their help, you can make solutions of various consistencies in order to achieve the desired shade of wood during processing.

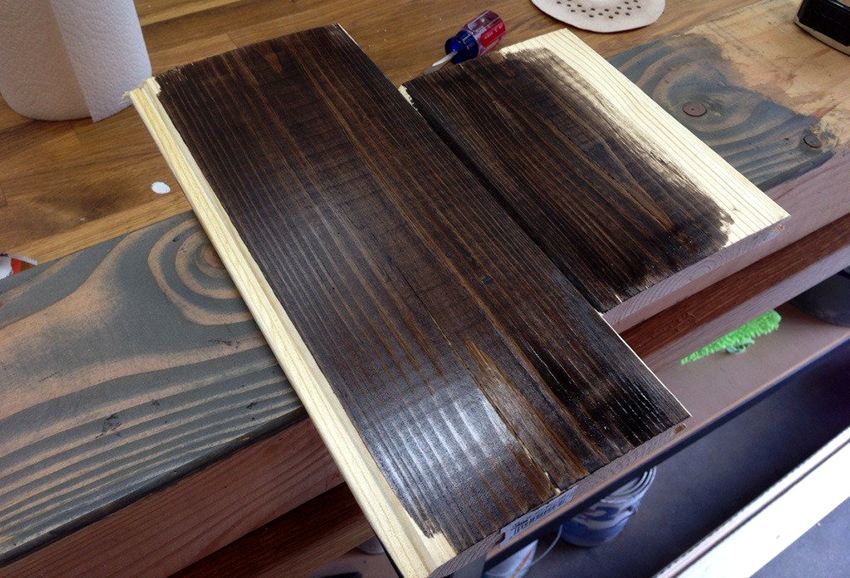

Oil-based stains penetrate deep into the wood, well impregnating its structure. After processing the material, no streaks remain on its surface. To paint wood with an oil-based stain, it is advisable to use a brush. This type of impregnation provides excellent protection against the negative effects of moisture as well as damage from wood-boring insects.

Benefits of oil-based stains:

- environmental friendliness;

- lack of harmful impurities;

- excellent penetrating power;

- the coating retains color fastness for a long time;

- lack of unpleasant odor;

- the treated surface acquires moisture resistant properties.

Useful advice! Experts recommend using oil stains for wood and parquet floors and furniture.

Oil-based solutions are suitable for both indoor and outdoor use, since the coating is not afraid of direct exposure to sunlight and does not fade. To apply the product, you can use any kind of painting tools. Even a beginner can handle such work. Oil stains for wood also have disadvantages. The main disadvantages of these compositions include a very long drying time, as well as their high cost.

Related article:

Acrylic paint for wood: sustainable and decorative surface protection

Characteristics and features of the composition. The scope of the material. Recommendations for the choice of paint. Acrylic staining technology.

Advantages and disadvantages of treating wood with a wax-based stain

Wax-based stains are relatively recent. The composition of these modern products has been significantly improved, thanks to which manufacturers have managed to get rid of many of the disadvantages that classic solutions have.

Wax stains are classified as non-aqueous products. They have poor penetration ability, forming a thin protective film-like layer on the wood surface. Thanks to this feature, wax compositions can be safely used as a decorative coating for outdoor use. They serve as an excellent base for paintwork.

These stains can be applied over other stains. Specialists often use soft wax to treat surfaces that have previously been painted with wood stain. This is done in order to improve the performance of the coating.

Advantages of wax-based stains:

- The ability to mask minor surface defects, such as uneven staining, which was produced earlier.

- Reliable protection of wood from external factors.

- Ecological cleanliness.

- Safety.

Disadvantages of wax stains:

- The compounds are not able to penetrate deeply into the wood structure.

- Stained surfaces must not be overcoated with a two-component acid-cured varnish or polyurethane-based varnish.

- High price.

Note! The protective film is practically impervious, so the wooden surface will not be able to "breathe". Although not all masters note this drawback, it may depend on the brand of wax stain.

Oil-wax wood stains: pros and cons

For the manufacture of oil-wax stains, natural ingredients are used, therefore these compositions are environmentally friendly. Of course, this fact affected the cost of the Beyts, which is quite high. Despite this, wax-based stains are not without their advantages. The advantages of oil-wax formulations are numerous:

- In the process of staining, the wood is not saturated with moisture.

- The composition can be used not only for tinting wood, but also for restoration, since it is able to eliminate minor surface defects.

- Oil-wax compositions can be tinted. By adding a dye to the solution, the shade of the stain is changed.

- When applied, the composition is distributed evenly over the surface, forming a thin protective film layer.

- Stains are resistant to ultraviolet radiation, so the coating retains its original color for a long time.

- Wood treated with oil-wax stain does not need additional varnishing.

Oil-and-wax stains take a long time to dry. This is one of their most significant disadvantages.

Characteristics of modern wood stains in the form of gels

Stain gels have a thick consistency, therefore, special tampons are used to apply them to the surface. These products are ideal for coloring and protecting soft woods. After they dry, the treated surface becomes more durable.

On sale there are stains in the form of gels only from foreign manufacturers. These compositions are suitable for both outdoor and indoor use. They are used for tinting any surfaces. Gel stains are suitable even for the treatment of wooden floors in rooms with high traffic.

Features of stain gels:

- After processing, the surface acquires a rich shade that well emphasizes the natural wood pattern.

- Unlike solutions with a liquid consistency, after processing with a gel stain, there are no smudges on the surface, since this product is evenly distributed.

- Gel stains have excellent hiding power, which is double that of liquid formulations.

- Gel stains do not lift wood grain.

- The product dries very quickly. If you need to apply a second layer of gel stain, you can do this 2 hours after the initial treatment.

Among the disadvantages of gel means for tinting wood is the high cost, as well as a rather limited range, which, by the way, is gradually expanding.

Useful advice! With a gel stain, you can create a realistic imitation of natural wood on a steel surface.

Features and benefits of acrylic wood stains

For the manufacture of acrylic stains, manufacturers use acrylic resins. The product is available in the form of an emulsion, which makes it easier to apply. Getting on the surface of the wood, it penetrates deeply into its structure. Acrylic-based stains have a very wide palette of colors, so buyers have no problems choosing the right shade.

Advantages of acrylic stains:

- Due to the antiseptic properties of the composition, the treated wood is reliably protected from insects, mold and other microorganisms.

- The coating is UV and moisture resistant, protecting the wood from the damaging effects of these factors.

- There are no toxic substances in the composition of acrylic stains, so they are odorless, and besides, these impregnations are fireproof.

- Acrylic solutions do not damage the environment and are completely harmless to human health.

- These emulsions have good adhesion properties, so they can be used to treat any wood surface, including plywood.

- Stains deeply penetrate the wood.

The disadvantages include only the high cost of acrylic stains. High-quality emulsions are expensive.

Which wood stains are better: a list of popular manufacturers and product prices

There is a huge variety of wood stains from different manufacturers on the market, so buyers have a difficult choice. Moreover, the price is not always an indicator of high quality. Many formulations at a reasonable cost can give excellent results and have excellent properties.

Table with prices for wood stains:

| Manufacturer | price, rub. |

| "Novbytkhim" | from 60 |

| "Rainbow" | from 130 |

| Tikkurila Pirtti | from 600 |

| Coswick wood stain | from 1200 |

| Varathane | from 1400 |

| Zar | from 1760 |

Which wood stains are better: the most popular firms

Novbytkhim stains are in high demand among consumers. The water-based formulations produced by this manufacturer do not have an unpleasant odor and, after processing, form a wear-resistant coating on the surface of the wood. These products have a rich palette of colors and can be used for tinting various products:

- skirting boards;

- door leaves;

- platbands;

- railings;

- boards, etc.

Note! Water-based stains manufactured by Novbytkhim can be used in decoupage.

To protect wooden products from mold and mildew, one of the best options is the Rainbow 21 stain. This acrylic stain contains special ingredients. This tool has excellent adhesion properties and can be used for processing various types of wood.

If a certain shade is required, buyers prefer Tikkurila Pirtti wood stain. By adding the appropriate pigment to this colorless composition, any color can be obtained. The manufacturer offers 36 glaze shades.

For a pure natural shade, you can use Varathane Oil Stain. It is made on the basis of transparent soybean oil and is capable of penetrating deep enough into the material.

Coswick Wood Stain alcohol stains are also among the best. With the help of these compounds, you can process the end part of the material when installing parquet floors. Impregnations well mask chips and small scratches, they go well with varnishes.

The quick-drying stain Zar is considered a universal option for indoor and outdoor use. One of the main advantages of this compound is the self-leveling structure. After processing, there are no stains or streaks on the wood.

Other manufacturers are no less in demand on the market: Liberon, Zerwood, Minwax, Vershina, Pinotex Interior, Biotex Universal, Krafor, Belinka, Latek and Herlak.

How to make wood stain at home

Most wood stains are composed of solvent and natural pigment, so you can make your own wood stainer.

Homemade stains are of several types:

- based on herbal ingredients;

- based on synthetic materials;

- food-based.

In addition, chemicals can be used to stain wood at home. For example, slaked lime will enhance the brown color of oak. If you treat a nut with this tool, the wood will acquire a greenish tint.

Useful advice! You can use ordinary hydrogen peroxide to bleach wood.

How to make a plant-based wood stain with your own hands

The pigments contained in plants are suitable for toning wood. If you apply a decoction made from larch bark to the surface, it will acquire a reddish tint. The lighter the wood, the more contrasting and brighter the result will be. Best of all, the shade manifests itself on products made from birch. A golden hue can be obtained with onion peels. This option is only suitable for light wood species.

Walnut shell is a universal toning agent. With its help, you can get different shades. The color depends on the amount of this ingredient in the stain. To begin with, the shell is finely ground to a powder state. Then it is added to boiling water and simmered over the fire for 12 minutes. The resulting broth must be drained and baking soda added to it.

If a dichromate solution is also applied to a surface soaked in a decoction of walnut shells, a reddish tint can be achieved. Treating painted wood with acetic acid will give a grayish color. To obtain a black color, decoctions made from the bark of alder and oak or willow are used. Buckthorn fruits give a golden yellow hue. They must be immature.

A brown tint can be obtained by mixing the following components:

- oak bark;

- alder earrings;

- willow bark;

- walnut shells.

All ingredients are combined in equal proportions. To prepare the stain, they must be soaked in cold water and then brought to a boil. For some time, the broth should simmer over the fire, then soda is added to it, after 10 minutes. it is removed from the stove.

There is another way to make brown stains. For this, a decoction of walnut shells and apple bark is used. If you add alum to it, you can get a richer and darker shade.

How to make your own food and synthetic wood stain

Coloring pigments are also found in food. You can use coffee to give the wood a brown tint. The stain is made on the basis of ground grains and baking soda. The use of instant coffee is allowed. To prepare the stain, it is necessary to firmly weld the grains or granules, and then thoroughly saturate the wood with this agent.

A brown tint can also be obtained with a tea pot. Tea contains theanine. This component gives the wood its natural brown color. Moreover, the saturation of the shade depends on how strong the tea is brewed.

The ebony effect is obtained using vinegar. Metal parts are required to prepare the solution. Small pieces of metal are poured with vinegar, after which they must be left in a dark place for at least 48 hours.

Note! The longer the solution is infused, the richer and darker the stain color will turn out. At the same time, you cannot keep metal parts in vinegar for more than a week, and because of the pungent odor, it is better to process it outdoors.

Dark shades of cherry and brown at home can be obtained using a solution of potassium permanganate. To do this, dilute 50 g of powder in 1 liter of warm water. After 5 min. after processing wood with this solution, its surface is wiped with a soft cloth. To get a richer and darker shade, this procedure must be repeated. Potassium permanganate quickly fade in the sun. If it was used as a wood stain, the surface of the material must be covered with a protective agent.

To give the tree a herbaceous shade, it should be treated with vinegar essence with the addition of copperhead (60 g). Before use, this solution must be boiled for 10 minutes.

How to paint a tree with wood stain: options for applying different compositions

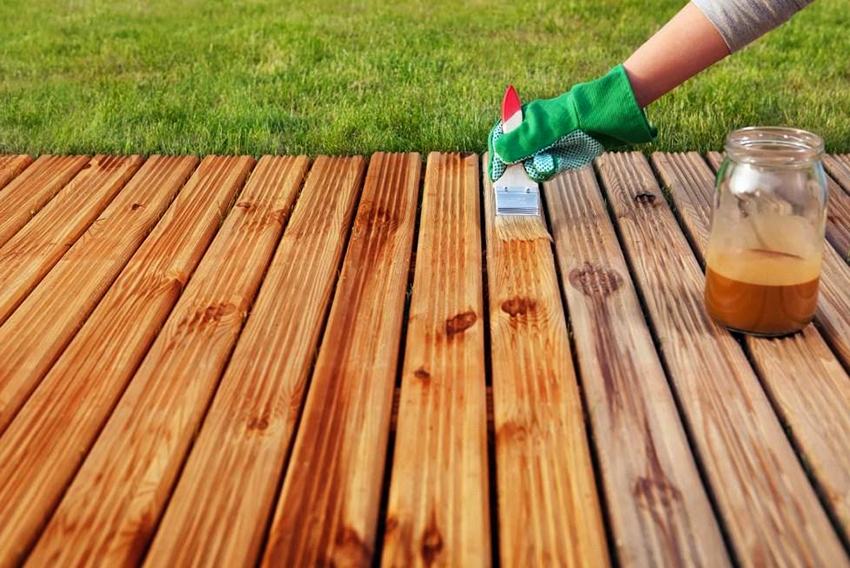

The way the stain is applied depends on its type. Various tools are used for wood processing: foam sponges, fabric tampons, brushes, sprayers (spray gun), paint rollers.

Stain application tool table:

| Stain type | Recommended tool |

| Acrylic | Wide brush with natural bristles |

| Nitromorilac | Spray gun |

| Oil | Lint-free tampons, brush |

| Water | Swabs, synthetic bristle brushes, paint roller |

| Alcohol | Spray gun |

Home craftsmen use two processing options. In the first case, the composition is applied to the surface of the wood in excess, and all excess is removed using tampons. This technique is mainly used when working with water-based stains.It allows you to smooth color transitions, achieve light, even tones, and also eliminates the likelihood of smudges.

If a swab is used as a tool, the composition is applied in a circular motion. Using a brush and a paint roller, the stain is applied longitudinally. Then the excess is removed using tampons. The wiping of the composition is performed along the fibers. After the top layer dries, the second is applied. The procedure is repeated until the desired saturation of the shade is achieved.

The second method, which does not imply subsequent removal of excess, is suitable for applying stains based on oil, acrylic and wax. This will preserve the depth of the shade.

Note! If minor defects appear when using the composition, it is allowed to partially wipe off the excess in those areas where there are errors. This is done only after the main part of the stain has been absorbed.

How to stain wood: the preparatory stage of staining

In order for the staining result to be of high quality, the base must be absolutely clean. New products made of wood do not need additional preparation. Surfaces that have already been in use will have to be worked on, especially if they have been varnished or painted. Before tinting, the old coating must be removed. Special removers will help get rid of the varnish.

In addition, you can use thermal and mechanical methods:

- The painted surface is treated with an organic solvent, after which the old coating is removed with a spatula.

- This method is used when a thick layer of dye needs to be removed. To begin with, the surface is abundantly moistened with a special wash and covered with cellophane. After 24 hours, the bag is removed, the softened paint layer is removed using a grinder, spatula or knife.

- You can also soften the layer of old paint with a building hair dryer or blowtorch. For this, the coating is thoroughly warmed up, and then it is removed with a spatula. If a blowtorch is used to soften the paint, the wood is pre-wetted with water. This will prevent fire.

Remains of old varnish or paint must be removed with sandpaper. If there are defects on the surface, for example, cracks, they should be repaired with putty and cleaned. You also need to get rid of knots and protruding fibers. Before staining coniferous wood, the resin should be removed from the surface. For this, a special composition is used.

Formulations of compositions for resinning softwood:

- Dissolved in water (750 ml) acetone (250 g).

- Caustic soda (50 g) and 1 liter of water.

- Soda ash (60 g) and potassium carbonate (50 g) are dissolved in 1 liter of water.

Any of these solutions are aged for 30 minutes. on the surface of the wood, after which it is washed off, and the material is dried.

Important! If the wood is damp or wet, it must be dried before applying the stain, otherwise it will not be possible to achieve high-quality staining.

How to use the stain at home

First, a test painting is done to determine how many layers of solution will be required to obtain the desired color. The consumption of stain will also depend on this. To do this, you need a small plank made of the same type of wood as the surface to be treated.

Test staining is done in the following order:

- The surface of the board is sanded.

- The workpiece is stained.

- The time required for complete drying of the composition is maintained.

- Another coat of stain is applied.In this case, the board is covered only for 2/3 of its area.

- After complete drying, another layer of stain is applied, but this time the coverage area should not exceed 1/3 of the board.

After the third layer is dry, you can evaluate the appearance of each of the colored areas and decide which shade suits the best.

How many different types of wood stains dry:

| Stain type | Complete drying time, h |

| Alcohol | 0,5 |

| Gel | 2 |

| Acrylic | 4-5 |

| Water | 10-12 |

| Oil | 12-14 |

| Wax | 10-15 |

The consumption of the stain depends on its type. The method of application and the quality of surface preparation are also of great importance.

Useful advice! Even experts are not able to accurately calculate the amount of solution required for staining, especially if you have to process a large area. Therefore, it is advisable to buy a composition with a small margin.

Consumption of different types of stain:

| Stain type | The amount of solution required for processing 1 m², g |

| Alcohol and water | 50-70 |

| Acrylic | 120 |

| Oil | 150 |

How to cover wood with wood stain and varnish: application technology

Before starting work, all areas of the product that will not be processed must be covered with a film. You can use masking tape to protect the edges. The technology depends on the type of stain and the selected tool. This can be spraying, rubbing, applying with a paint roller, swabs or a brush.

Stain application principles:

- The stain is applied exclusively in the direction of the grain on the wood. The removal of surplus is performed in the same way.

- If you want to get a deep saturated shade, the composition can be applied in 2-3 layers.

- If toning is done in one layer, it is advisable to use a small amount of stain. After the coating is dry, the surface of the wood must be sanded and polished to a smooth state.

- After complete drying, the coating is processed with a coarse cloth along the grain or diagonally.

- If the staining area is very large, it is better to divide it into several zones and process them in turn.

- Water stain can be thinned with water, and white spirit is used for oil based stains.

- Do not put too much stain on the tool, this can affect the quality of the staining. In addition, the consumption of the composition will increase.

After the stain dries, all its excess is removed from the surface. This is done with a brush dipped in acetone. For the highest quality result, it is advisable to varnish the tree. This is done with a roller or brush. In hard-to-reach places, the varnish is applied with a sponge. To simplify your work, you can use a spray varnish in a spray can. It is practical and convenient, but the material consumption in this case will be much higher.

Like stain, varnish is applied in 2-3 layers. In this case, the material is applied very thinly so that smudges do not form. The technology itself is very simple and does not require any special knowledge and skills. The main thing is that the stain and varnish are combined with each other, and all actions are as accurate as possible.

Stain, or stain, is an irreplaceable material for wood processing, which is able not only to protect the surface, but also add decorativeness to it. Thanks to the varied assortment of wood stains, choosing the one you need is not difficult.