Recently, many Russian regions have been equipping them by erecting low-rise buildings. The project of a house from foam blocks and its turnkey implementation is an offer for families with an average income, this is an excellent alternative to other building materials. Planning and construction are being carried out at an accelerated pace, which allows the customer to quickly move into their own home.

Foam concrete houses - it is fast and profitable, warm and reliable

Content [Hide]

- 1 Acquaintance with available materials: projects of houses from foam blocks with a layout

- 2 Why is it profitable to order turnkey foam block house projects

- 3 Projects of one-story houses from foam blocks with a layout: from foundation to roof

- 4 Choosing a roof for a project of a house made of foam blocks for individual building

- 5 The main advantages of custom-made foam block houses

- 6 Material as an economic component of a foam block house project up to 100 thousand rubles.

- 7 Other factors affecting the price of designing a foam block house

Acquaintance with available materials: projects of houses from foam blocks with a layout

Building the old fashioned way is painstaking and unprofitable. Thanks to the use of innovative materials, modern technologies in a short time make it possible:

- in the winter, purchase a plot and choose a project of a one-story house from turnkey foam blocks;

- lay the foundation in the spring;

- start and complete construction during the warm season;

- perform roofing and finishing works in autumn;

- move into your own house by winter and celebrate a housewarming.

It is worth considering that, on average, foam block houses are built from six months to one and a half years. Some are inclined to believe that your own house should be made of timber or bricks. Environmentally friendly and affordable building materials are not always available in your region, and the price of a ready-made house (turnkey) often alarms citizens in need of their own housing.

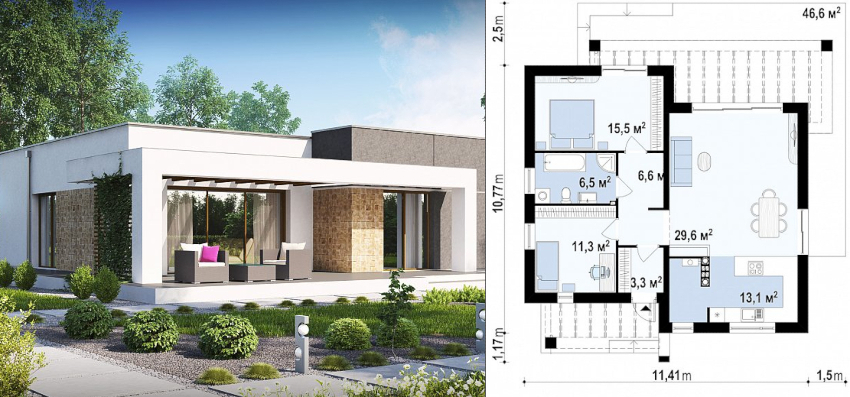

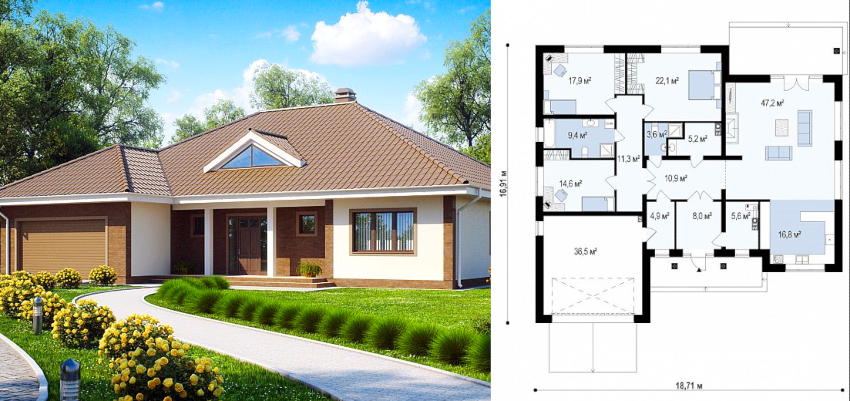

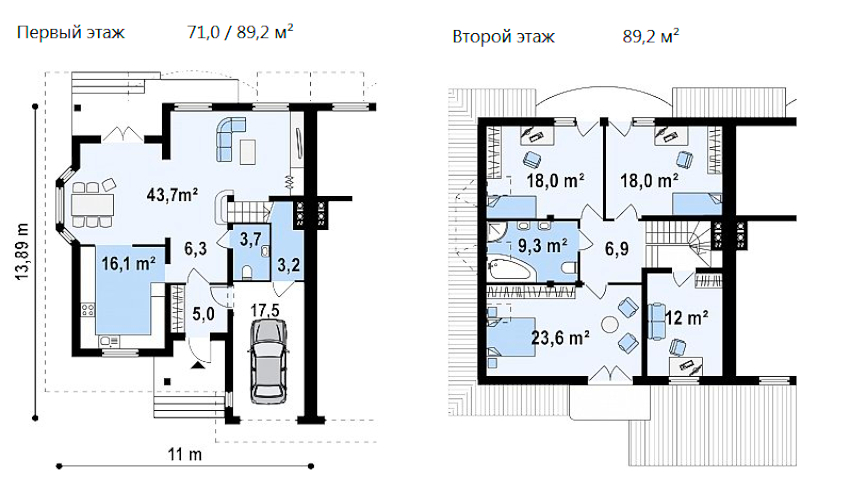

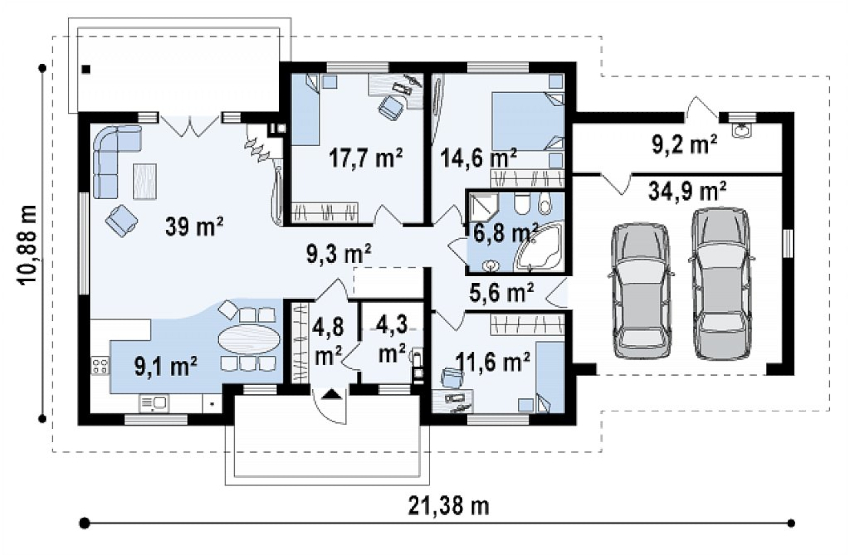

A solid building can be built on the basis of any material, for example, in the form of a panel, cast or frame cottage. Separately, it is worth considering the option of a solid two-story house made of 8x8 foam blocks - projects with a ready-made layout provide great stylistic possibilities for decorating the original interior design.

Foam concrete is a material with a porous cellular structure, designed in the form of blocks. It is characterized by strength and low cost, has a lot of excellent performance, including thermal insulation properties. This is the best option for building a small country house, which will cost almost half the price of traditional buildings.

Although foam blocks are made of ordinary concrete, walls made of such material are warmer, less damp, building a house is relatively cheap. This is another argument in favor of the fact that it is worth paying attention to the finished projects of houses from foam blocks offered by construction companies in different regions.

Why is it profitable to order turnkey foam block house projects

Today, not everyone can afford to participate in the process of building their own home. The "turnkey" concept means the implementation of all stages by a private construction company, such as creating a project, building a house from foam blocks, finishing work.

Some firms have experience in the construction of cottages, summer cottages and houses from different materials. Others have a narrow specialization, for example, they work only with foam concrete. This relatively inexpensive material attracts middle-income customers.

The high strength of foamed concrete and a long service life (up to 70 years) give it the opportunity to take its rightful place in the construction market. It should be noted that in the free access there are free projects of houses from foam blocks, allowing you to evaluate their aesthetics and get acquainted with their cost. Having chosen the option you like the most, it is quite possible to order it "turnkey" in your region.

Note! Dowels and brackets are difficult to attach to a porous foam concrete wall. It is important to consider this during interior design and heating arrangement. Heavy cast iron batteries on holders are a bad option for a foam block house (projects and work prices compensate for such restrictions).

The speed of building a house is quite high, since the very format of the foam blocks is thought out in such a way as to optimize the masonry process. Even builders who do not have high qualifications can cope with this material, in contrast to brick cladding, which requires special skills. This significantly reduces the cost of work.

Foam concrete houses are fast and profitable, warm and reliable. As a rule, the turnkey implementation of a two-storey house made of foam blocks depends on various factors. This is almost always done twice as fast as building a brick house of a similar format. Upon completion of all construction stages, the customer only needs to move to a ready-to-use cottage or house. Therefore, the personal involvement of the client often begins and ends at the same time - at the stage of choosing a turnkey project.

Projects of houses from foam blocks with a layout: the main stages

The creation of any building begins with design, without which it is impossible to make an estimate of the future costs. Before starting the construction of a building, you will need to draw up or borrow on the Internet a plan of a house from a foam block (quite often these are one-story economy-class buildings). Such plans may have drawbacks, but they are often used by those with some experience in construction. You can make some changes to the project that will allow you to realize the personal wishes and preferences of the future owner of the house.

Useful advice! With a limited budget, it is recommended to use a typical project of a 6 by 6 house from a foam block, since individual development is expensive - from 25 thousand rubles (depending on the region).

If there is a ready-made (typical) project, it can be adapted to suit your capabilities and tied to the area. Next, prepare all the necessary documentation, which includes:

- certificate of ownership of the land plot;

- master plan of the site with adjoining communications;

- calculations of building structures;

- floor plans;

- drawings of the foundation, facade, individual units and structures;

- wiring of internal communications, including heating;

- estimate and specification of building materials;

- After the approval of the documentation, they begin to build houses from foam blocks, projects and prices must be agreed in advance.

Projects of one-story houses from foam blocks with a layout: from foundation to roof

When choosing a foundation, you should familiarize yourself with its main varieties, but the final decision must still be made by specialists. This takes into account the properties of soils, terrain and number of storeys of the building.

When laying the foundation, it is important to remember about waterproofing and holes for communications.

It is no secret that local authorities often give soil that is not suitable for other purposes for individual construction. Usually it is not suitable for the construction of multi-apartment high-rises and heavy private cottages, consisting of 2-3 floors. This also needs to be taken into account when choosing a house project from foam blocks 10 by 10 m or a larger structure made of heavy materials.

Upon completion of engineering and geological work (drilling, soil sampling), it is possible to determine which foundation will be preferred:

- Slab (applicable on heterogeneous, unstable and weak subsiding soils) is suitable for small summer cottages if other support is impossible. It is inexpensive.

- Cast (with formwork) and tape are the most common types of foundations practiced in most of the European territory of the country. Suitable for 6x6 foam block house projects.

- The columnar foundation is also referred to as budgetary foundations used in individual construction. It should be used on solid soils unless significant displacement due to frost heaving threatens.

- Shallow columnar - the most inexpensive foundation, which, on the contrary, is recommended for frost heaving caused by deep soil freezing.

- A shallow strip foundation is slightly more expensive, suitable for saline and swampy soils. It is used for light individual building.

Screw piles are used for most types of soil (except rocky and stony). It is worth considering that it is they who are often recommended by architects who develop projects for houses from 10x10 m foam blocks.

Useful advice! Carrying out an independent laying of the foundation of a house according to a standard project, it is important to remember about the obligatory organization of waterproofing and the creation of technological holes necessary for carrying out communications.

The choice of walls corresponding to the project of a one-story house from foam blocks

Brickwork often looks more attractive. But walls made of foam blocks, lined with decorative plaster, siding or facade paint, can be built faster, easier and easier. Low specific weight and convenient block format contribute to fast work:

- 200x300x600 mm;

- 100x200x600 mm.

With regard to the finish, you can afford various options by choosing a material that will be cheaper and more attractive than a terracotta brick wall. Aesthetic foam block masonry is a good solution. This is confirmed by photos showing projects of houses and cottages from foam blocks.

Informative! A cube of this material weighs no more than 630 kg. It is almost twice lighter than concrete and three times lighter than brickwork, which makes foam blocks indispensable for the construction of light buildings on unstable soils.

The advantage of this material also lies in the fact that the various parameters of foamed concrete blocks allow them to be adjusted to a specific project. Usually their sizes vary within:

- width - 200, 250 and 300 mm;

- height - 90, 120, 140, 180 and 300 mm;

- length - 300, 400, 500 and 600 mm.

For additional insulation of the building, the foam block can be combined with another budget analogue. More often it is wood concrete, consisting of sawdust (chopped straw, shavings) and cement.

Note! It is worth agreeing on the possibility of using sawdust concrete and other materials at the stage of discussing projects of country houses made of foam blocks.

Whatever the format and material of cast blocks, technological standards must be observed:

- walls of two- or three-story houses made of foam blocks, projects with an attic are reinforced with reinforced belts and concrete columns, which can be hidden under ceilings between floors;

- a one-story building is reinforced only with a belt under floor slabs;

- between the foundation and the first row of foam concrete there should be 2 layers of waterproofing;

- every 4 rows, the masonry is supplemented with reinforcement or special mesh.

The porosity and relatively low strength of the foam block walls do not give this material a chance to be in demand in multi-storey construction. However, it is precisely its financial affordability that allows low-income families to acquire their own one-story or two-story housing. In economy class buildings, the block can only be used on the top floor, while the bottom is made of denser reinforced concrete slabs.

Choosing a roof for a project of a house made of foam blocks for individual building

Typically, the construction of such a house lasts no more than one and a half years, including the installation of the roof. The degree of complexity of its construction depends on the chosen form.

When choosing the shape of the roof, you need to take into account its windage, especially in places where strong winds often blow

The main constructive options for roofs:

- hip (4 slopes in the form of a trapezoid);

- half-hip;

- tent;

- conical;

- single slope;

- gable;

- tambourine;

- vaulted;

- broken line;

- flat;

- multi-gable;

- combined;

- attic (no attic).

The slope ranges from 30 ° to 45 ° depending on the expected amount of precipitation during snowy winters in the region. When choosing a shape, the windage of the roof is also taken into account, which is especially important in places where strong winds often blow. Competent specialists, in order to minimize the possible consequences of the disaster, help to determine all the parameters, laying them in the cost of projects of one-story houses from foam blocks (up to 100 thousand rubles).

Related article:

Flat roof house projects: the best ideas for construction and decoration

Features of laying each layer of the roof. Arrangement options: the best ideas for decorating a space.

As roofing materials are usually chosen:

- euroruberoid (flat roofs);

- metal tiles;

- professional flooring;

- ondulin;

- slate;

- folded metals.

Low prices for building materials make it possible to choose any base, roof and topcoat of a house project from a foam block 9 by 9 m (or other area).

Useful advice! If you have to spend money on creating an individual project, the specialist will tell you how to save on other components. However, hydro and noise insulation, insulation method, heating and all communications must be performed flawlessly.

The main advantages of custom-made foam block houses

Foam blocks are a profitable material from available raw materials, consisting of a mixture of sand and cement. Its cellular structure and its properties determine the price segment of buildings made of this material.

Such structures have a number of positive characteristics:

- environmentally friendly material obtained from natural raw materials can be recommended even for people with respiratory diseases and allergy sufferers;

- high fire safety, projects of houses from 6x8 m foam blocks (as well as other sizes) are considered in all cases, since there is no likelihood of fire;

- the walls are laid out of a material that "breathes", that is, it has the ability to absorb excess moisture from the air and give it away in case of excessive dryness;

- the material favors the preservation of a healthy microclimate, the walls are resistant to dampness and mold;

- the low weight of the foam blocks simplifies its transportation, and also allows laying without the use of improvised devices;

- wall masonry can be made from denser materials at the lower level and from light materials - above;

- blocks do not change geometric dimensions, since they are characterized by resistance to deformation under conditions of reinforcement;

- insects, rodents do not start in the blocks, they are not exposed to the negative effects of microflora;

- the material has improved thermal insulation indicators (compared to walls made of cast concrete and reinforced concrete slabs), which allows saving on heating in winter (about 25-30%);

- the small thickness of the internal walls (1 stone) is quite sufficient for summer cottages and houses, which additionally increases their usable area;

- the porous material has high sound insulation properties (up to 60 dB), due to which many sound waves and ultrasonic vibrations are blocked;

- blocks can be easily cut or processed in another way, giving them the desired shape, which simplifies the laying of communications.

Note! Europeans, known for their practicality, have long "discovered" this material, which resembles pumice stone or hard foam rubber. Foam concrete enjoys well-deserved attention, displacing more expensive materials.

Such buildings have few disadvantages. The house is not particularly durable. However, in the absence of very strong mechanical influences, this drawback does not in any way affect the reliability of the building. It is undesirable to hang cast-iron radiators and other heavy structures on the walls. It makes sense to give up expensive buildings and opt for beautiful projects of houses from foam blocks up to 150 thousand rubles.

Material as an economic component of a foam block house project up to 100 thousand rubles.

A small country house or a two-story cottage made of foam concrete can be an excellent alternative to buildings made of other materials, which will cost several times more. Many builders prefer foam blocks when building their own homes.

A well-built and tiled block house will look like a reliable fortress that can stand for 70-80 years. It is possible to build a small summer cottage (subject to a finished foundation with shrinkage) in record time - in 3-4 months. This factor is also taken into account when they decide to complete the postponed "unfinished" in the forgotten dacha cooperatives or nearby villages.

Wall blocks can be laid by hand. Outside observers would not even guess that the two-story cottage is being built from inexpensive, environmentally friendly and lightweight material, the structure of which resembles porous pumice. This is clearly demonstrated by photos of foam block house projects.

The foam block is not the best alternative to masonry or masonry when it comes to reliability. However, affordability remains an important argument in favor of inexpensive construction with environmentally friendly materials. In terms of the level of thermal insulation, a building made of foamed concrete (with additives and polymers) is much more profitable than stone and brick houses that need significant insulation.

Let's compare "related" materials in terms of cost (in rubles):

- foam concrete - from 12,500;

- expanded clay concrete - from 11 300;

- sand cement (blocks) - 10 200;

- aerated concrete - from 14,000;

- ceramic blocks (and other dense materials) - from 16,000.

As mentioned earlier, these materials are excellently assembled during installation, which is cost-effective when erecting walls from residues. The cost of installation from blocks will cost one and a half times less than the price of facing brick masonry:

- The cost of brickwork is approximately 6,300 rubles. (3800 rub.- material + 2500 rubles. - masonry).

- The price of installing a foam block is 4200 rubles. (2700 rubles - material + 1500 rubles - masonry).

A simple process can be mastered by anyone who has at least a little practice in summer cottage construction. A self-taught master can use a ready-made house project from an 8 x 8 m foam block (or other area), independently realizing the dream of his own house. This is another argument in favor of the economic benefits of such projects.

Other factors affecting the price of designing a foam block house

The portfolio of any construction organization contains many facts indicating the successful implementation of the project of a foam block house: prices, photos, reviews. Experienced developers are increasingly turning to this material to grow their middle-income client base. There are many “quick” designs currently available to build a house in a season.

The customer is often offered a version of the building in a certain style, for example, an ivy-covered house reminiscent of "good old England", a Provence-style cottage or a chalet-style mountain house. Working with designers, the client gets the opportunity to calculate in advance the cost of the selected house project from 7x7 m foam blocks (and other sizes).

Not only foundation laying, wall construction and roof assembly are taken into account, but also other costs:

- external insulation and facade decoration;

- internal plastering (starting and finishing);

- wall insulation around the perimeter;

- installation of door frames (entrance and interior);

- installation of windows: if the house is located close to the highway or railway track, then to improve sound insulation, you can install plastic structures with double glazing;

- connection of external communications, including gas, electricity and water;

- organization of the heating system (choice of a boiler and a method of connecting radiators);

- finishing work on interior design.

Useful advice! Having significantly saved on building a house, you can afford modern lighting design or special interior designs made in any style. This should also be reflected in the design of a 6 by 8 m foam block house (or other format).

Regardless of what kind of building the family dreams of: a large country cottage worth up to 2 million rubles. or about a small cottage with an attic at a price of up to 500 thousand - you need to approach the process of choosing a project with maximum responsibility. Currently, foam concrete is one of the most popular materials used in construction.