Very often, when performing finishing work, it is necessary to carry out diagonal cutting of the material with high accuracy. For these purposes, a special tool should be used. It is the miter saw with a broach that is able to accurately and quickly cut the product at any inclination and angle. The features of choosing a tool and its main advantages are described in detail in this article.

Content [Hide]

What is a wood miter saw. Purpose of the tool

A miter, pendulum saw for wood and metal, or an angle cutter is a stationary cutting-off highly specialized tool that is used to cut materials at a certain angle. This possibility is provided by a turntable and a movable working part with a disc over the bed. The miter saw can cut narrow pieces of wood like slats, bars and planks. It can also be used for sawing hardboard, laminate and OSB. The tool copes well with cutting plastic, aluminum profiles and polyurethane moldings.

Due to its high speed, precision and ease of operation, the miter saw has a wide range of applications. It is used for joinery, assembly and finishing work related to the use of wood products. The tool is indispensable in furniture manufacturing workshops, where it is necessary to perform accurate and high-quality sawing of products.

There are universal tools that carry out trimming for metal. Thanks to a special disc, a tool is used to cut metal products from steel, iron and cast profiles. Such end saws for metal are widely used in enterprises that manufacture window frames from metal-plastic profiles.

Important! A diamond or abrasive wheel must not be mounted on the tool instead of a saw blade.

The technical documentation of each specific model indicates the limit parameters of the product that the tool can handle. Small miter saws cut products up to 60 mm thick. The medium-sized tool will handle workpieces with a thickness of 70-80 mm. Large-sized saws are used for processing products with a thickness of 100 mm or more.

Important! Miter saws must not be used for processing stone, ceramics and ferrous metals.

Sliding miter saw: design features of the tool

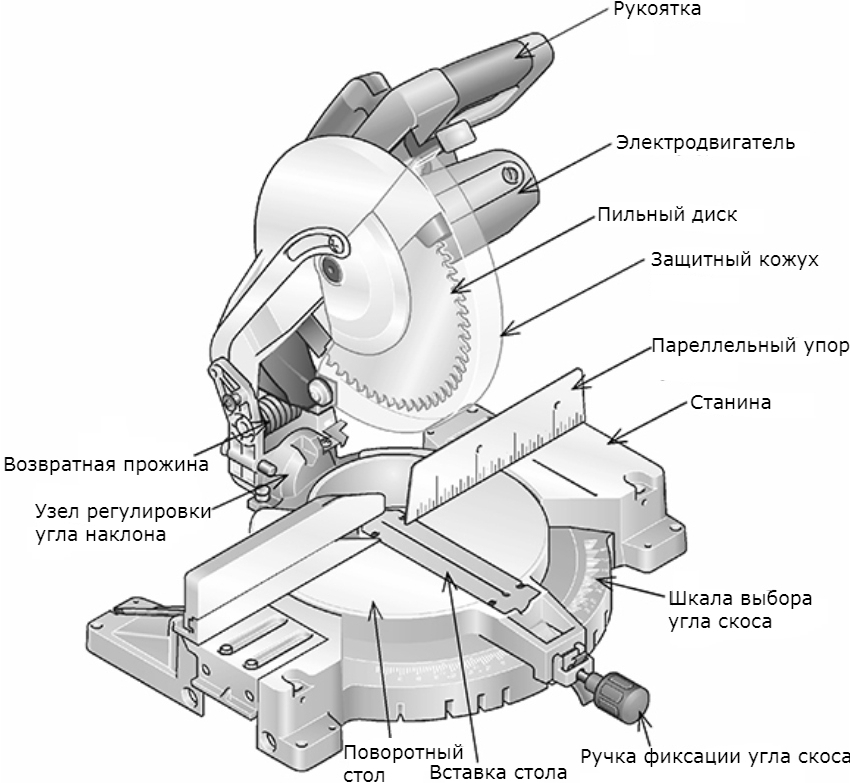

The miter saw for wood has a fairly simple design, which includes a saw blade, a motor with a gearbox, a base and a handle with a start button. The saw motor can be commutator or asynchronous. The first option carries out a greater number of revolutions, does not require regular maintenance, but only requires a periodic change of brushes. And the second is much quieter and more durable. In the classic design of the device, the motor is located to the right of the disc. However, there are improved models where it is located at the back, which increases the viewing angle during cutting, thereby making it more convenient to work.

The rotation of the saw blade is carried out by the operation of the motor, which transfers the gear or belt drive through the gearbox. During operation in the first gear, the possibility of slipping of the product is excluded, even at high engine loads. The second gear provides less noise and reduces disc vibration. And this has a positive effect on the quality of work and on the service life of the tool. However, in such devices, the belt quickly wears out, which can also come off during a sharp change in speed. There are more reliable and durable models that are distinguished by direct transmission. However, their torque is significantly lower than its counterparts.

To expand the capabilities of a conventional miter saw, a broaching mechanism can be built into it. In this case, a regular saw turns into a wood trimmer. In such models, the functional module is installed on two rails that are parallel to each other. This design allows the saw blade to move freely during cutting, allowing you to cut wider workpieces.

The functional module is fixed to the base. This base is a movable round part that can move when the angle and stop are set. The miter saw bed is usually made of magnesium or aluminum alloys. The design of the saw includes a protective cover that is put on the circle when the device is idle to avoid injury.

Stand, saw table and additional stops

One of the main and complex elements of a wood angle cutter is a saw table. On one side, a stand is attached to it, on the other side, a disc moves above the neck. On saws with a broach, the neck is much longer. At the end of the device there is a clamping handle, which serves to fix the table relative to the base, and a push lock used to quickly adjust the most common angles.

On the table and stand there are angular scales on which the angles of rotation and tilt are indicated. The table can be rotated in both directions from 0 to 45 degrees. And securely fixed in the selected direction using a special groove with a latch.

The stand can be immovable or tilted to the left by 45 degrees. A tool with a tilt of the rack to the right is extremely rare, due to the need to significantly complicate the design of the saw.In addition to the basic graduations, several special ones can be provided, which make it possible to choose the optimal angle for cutting skirting boards and moldings.

For reliable fixation of workpieces of any size, built-in clamps and various stops are used. When working with long products, using folding or pull-out stands that are located on both sides of the bed, you can expand the dimensions of the base. These additional stops are usually included with the miter saw. They are represented by U-shaped steel rods bent up to the level of the table.

There are more complex base designs with cast supports, which are fixed relative to the support with thumbscrews. Many manufacturers equip miter saws, the price of which will not be much higher than classical tools, with separate stands or special tables. They can be located at a certain distance from the tool, depending on the length of the products.

Basic and additional trimming options

All devices are equipped with a soft start, which allows you to block the mechanism during wheel replacement, and accordingly stop the engine. All miter saw models are protected against electric breakdown of the housing.

The classic version of miter saws does not include electronic components. However, there are models, usually metal miter saws, which are equipped with an electronic speed control function. Thanks to this function, more precise control over the work process is provided. It also becomes possible to set up equipment for cutting various materials.

Useful advice! For cutting hard wood, it is advisable to use a saw with an electronic engine speed control.

New models are released, in which it is possible to set a certain stable speed. This is useful when you need to complete several workpieces in a short time. After all, with strong pressure, the speed of the device decreases. At this time, thanks to the electronic controller, a certain speed range is set, which allows you to get a smooth and fast cut.

Another useful but expensive feature that increases the cost of the instrument is laser aiming. It can be powered from the mains or battery. In the first case, a switch is located near the handle on the tool body. The beam creates a cutting line, which is especially valuable for an inexperienced craftsman who has not developed intuitive skills to cut with a miter saw. The trimmer can also be equipped with powerful LED lighting behind the blade. When you turn it on, the shadow from the disc falls on the workpiece, forming a kind of backlight.

The tool generates large amounts of wood dust and sawdust. In order to exclude their spread throughout the room, some models are equipped with a nozzle for connecting a vacuum cleaner, through which debris is removed directly from the place of its formation. In modern models, the table top is expanded by 50 cm or more, which allows you to work with long products such as laminate.

The main criteria for choosing a miter saw for wood with a broach

Before choosing a miter saw, you should study its basic parameters. The main criterion is the purpose of the tool. If the use of the saw is planned in rather rare cases for domestic purposes, then it is enough to buy a miter saw with a standard set of functions.For frequent use of the tool for cutting workpieces of various widths, it is advisable to purchase a universal miter saw with a broach, which expands the range of capabilities of the tool. It is the broaching function that is used to work with material of a rather large thickness and allows you to increase the cutting width, which is not very large in conventional models, which in turn expands the functional range of the tool.

Useful advice!In the case of a single or rare use of the tool, you can make a mobile and collapsible miter saw with your own hands from an ordinary grinder and improvised tools and materials.

The saw table can be purchased as a set with a miter saw, which not only makes it convenient to work with the tool, but also increases the level of safety, since the mounts are specially designed and adjusted to a specific model

The next criterion is the safety of the device. Despite the cost of the tool in its design, a protective cover and an option to block accidental starting of the device should be provided. When choosing a tool, it is necessary to take into account its dimensions and weight. It must be mobile and ergonomic in order to work with the saw as comfortable and easy as possible in certain conditions. For work at heights, it is advisable to use a small and light tool that does not necessarily have less power than a large, heavy miter saw.

Important! Professional models are more powerful, which is reflected in the weight and dimensions of the device.

The width and depth of the cut determine the purpose of the tool, namely, indicates what can be processed on it. For high-quality work, you should choose a saw blade with a diameter of at least 20 cm. The larger this figure, the easier it is to work with the tool. When choosing a specific model, one should take into account the quality of the material from which the swivel block and bed are made.

Choosing a miter saw blade

The quality of the cut depends on the characteristics of the miter saw and the cutting part. Saw blades are distinguished:

- by the shape of the teeth;

- along the outer diameter;

- along the mounting hole.

The bore or inner diameter of the disc is usually 3 cm. The outer diameter can be 21, 25 or 30 mm. This indicator is indicated in the characteristic of the tool and on the face of the disc. When choosing the parameters of the cutting product, you should pay attention to the engine for which a specific standard size of the disc is selected. Large discs are not advisable for powerful motors. As a result, you can get a poor-quality and sloppy cut.

Related article:

Homemade machines and accessories for the home workshop

Descriptions and technologies for the manufacture of useful structures for the arrangement of a garage workshop, recommendations.

The larger the value of the outer diameter, the more teeth are located on it, and therefore, the less the load on each of them. This suggests that larger drives have a longer service life. It is advisable to use discs with a small number of teeth for longitudinal cuts, with a maximum - for transverse. The surface of any disc is marked with its markings, maximum rotation speed, direction of rotation and compatibility with the tool.

Saw blade must be selected based on the power of the tool

Useful advice! For high-quality and durable operation of the disc, the proportionality of its size and thickness must be observed. Otherwise, frequent breakdowns of the part are inevitable.

Wood Miter Saw Blade Teeth Design

The quality of processing of products is influenced by the size, sharpening, geometry and material of manufacture of the teeth of the disk. The smaller the size of the teeth, the better and more accurate the cut is.This is especially important for laminate and lacquered or painted wood. For coarse cutting, discs with a small number of large teeth can be used. They are used for cutting plywood and softwood.

For processing plastics and composites, it is better to choose discs with trapezoidal teeth or with "triple chip" brazing. For hard woods, it is advisable to use products with tungsten carbide or cobalt alloy carbide teeth. For cutting chipboard, plywood and veneer, ATV-brazed discs are preferable.

Helpful advice! To obtain a high quality cut in wood products of valuable species, use combined discs, where several beveled teeth alternate with one cleaned one.

The geometry of the teeth indicates the nature of the cut. Depending on this, a distinction is made between discs for longitudinal, cross cuts or for finishing and neat processing. Some discs for long-term use have thin cuts and smooth lines, which compensate for thermal deformation of the wheel and reduce the noise level during tool operation. The surface of the teeth should be smooth without jagging and the edge should be sharp enough. Discs are made of heat-treated steel with composite overlays.

Power and speed

When choosing a saw, you should pay attention to its power and the frequency of rotation of the cutting part of the tool. These parameters are closely related. The higher the power of the device, the higher the rpm of the dusty disc.

The service life of more powerful devices is slightly higher than that of analogs with a lower indicator. The standard power value is 1.6 kW. This value is sufficient for any kind of task. However, many modern models have a capacity of 1.8 kW. But this directly increases the weight of the unit and complicates the work with the tool. In addition, powerful models require proper wiring so that when the saw is operating, there are no short circuits and there are no power outages.

The number of revolutions that the blade makes affects the cut quality. The higher the value, the neater and cleaner it will be. Modern models have a built-in function for adjusting the number of revolutions, which is convenient for processing a specific type of material.

The service life of professional models of miter saws is slightly longer than that of household devices

Rating of miter saws from well-known manufacturers

One of the important parameters when choosing a miter saw is the brand name. Units from different manufacturers may have the same characteristics and differ significantly from each other. This is due to the fact that each manufacturer uses different materials, their own technologies and assembly options. Depending on this, the price of trimming can vary significantly.

Also, the fame and vocation of the manufacturer affects the cost of the tool. It happens so that professional models of little-known brands will cost on a par with the simple execution of equipment by a famous brand. Also, the price of a saw blade from a well-known manufacturer can be equal to the cost of an inexpensive miter saw.

When choosing a tool, it should be borne in mind that on budget models, a simple disc is usually installed, designed for working with softwood. Universal disks are used on high-end devices. Hardwood, plastic and metal blades are usually purchased separately. Budget models can be used as training devices for work where high precision and quality of cutting are not required. They are suitable for building a house or building a fence.

When the device is faced with a serious task that requires high accuracy and level of performance, then it is better to purchase a more expensive miter saw. For continuous operation, you should give preference to high-quality professional equipment.

Among the well-known manufacturers of miter saws, the following brands can be distinguished:

- Bosch;

- Makita;

- Metabo;

- Hitachi;

- DeWalt.

Makita cross-cut: an overview of tools of different classes

The first in the ranking of miter saw manufacturers is Makita. Construction tools from a world-renowned manufacturer are characterized by a high degree of safety and high quality workmanship in every detail. Due to the presence of a traction function in most of the brand's models, it became possible to independently select the cutting width.

At the base of the tool there are two rods, on which a surface is installed for placing the working unit. An example of such a small table with a basic set is the budget model Makita LS 0714. The tool can perform bevel, inclined and combined cuts at an angle of up to 45 degrees. to the right. The motor power is 1 kW. The cost of a miter saw is about 25 thousand rubles.

Among the professional miter saws, the Makita LS 1216 model can be distinguished. This is the best tool for carpentry workshops, which is designed for working on wood and plastic, where high cutting quality is required. This is achieved thanks to double guide rails that allow the saw to move evenly for a smooth cut. The engine power is 1.65 kW. The tool is capable of cutting up to 107 mm deep and 363 mm wide, which is the maximum for a device of this class. The installation cost is on average 45 thousand rubles.

The disadvantages of a miter saw can be attributed to the rather large weight, which complicates the use of the tool as a portable one. It is better to use it as a stationary machine. The saw does not include a laser pointer and illumination, but they can be purchased separately. There is also no way to adjust the number of revolutions.

Among the best universal miter saws is the professional Makita LF 1000 model. Its design is complemented by special folding stands that greatly simplify the work with the tool and expand the range of its capabilities. This tool is used to rip, cross, bevel and miter cuts in wood, aluminum and plastic. The engine power is 1.65 kW. It generates high torque, which allows it to handle hard materials. The model is also equipped with a speed control function, which allows high-quality cutting of material of any hardness. The price of the instrument is on average 53 thousand rubles.

Bosch Miter Saws

The Bosch company has established itself as one of the leaders in the production of high-quality specialized tools. The miter saws of the world brand are equipped with a special circle, a bed, thanks to which you can adjust the cutting angle yourself. The most reliable and durable are the beds made of pure aluminum and magnesium alloy. Such circles not only provide a safe and comfortable cut, but also have a low weight, which makes the saw mobile and easy to use.

The best Bosch trimmer in the category of budget tools is considered the Bosch PCM 7. This is a good option for a novice craftsman or for infrequently performing simple tasks. The working unit can be fixed on the table, which makes the work easier, making the cut more accurate and precise. The engine power is 1.1 kW. The model is equipped with a laser for a more precise cut. The miter saw has a small diameter disc, which limits its range of possibilities. You can buy trimming for only 11.5 thousand rubles.

The Bosch PCM miter saw model belongs to the household series, but at the same time has a fairly high power

As a professional device, you can choose the Bosch GCM 8 SJL Professional miter saw. The model is equipped with a large number of settings, which allows you to set the required parameters to perform a quick and high-quality cut of wood and plastic products, which are decoratively coated. The engine power is 1.6 kW. There is no speed control function. A laser pointer is provided in the design for precise cutting. The tool is equipped with a reliable dust extraction system. The cost of the saw is 32 thousand rubles.

Miter saws Metabo

Miter saws manufactured by Metabo have a unique feature. Here there is the possibility of arbitrary tilt and rotation of the disc. This allows you to perform work in hard-to-reach places without worrying about the quality of its performance. This opportunity is carried out thanks to a special regulator, which is located near the desktop. Some models of this brand are equipped with special projectors that create a shadow from the disc. This function allows you to cut as accurately as possible.

One of the most popular models from the German manufacturer is the Мetabo KGS 305 miter saw. The tool is equipped with a broach, a reliable support platform, a powerful 2 kW motor, and convenient levers for adjustment. The disc with a diameter of 305 mm ensures high performance of the device The maximum tilt angle reaches 47 degrees, the swing angle is 60 degrees. The tool is capable of performing high-quality and accurate cutting of products of any hardness. It is able to cope even with a wooden beam 100x100 mm. You can buy a miter saw with a broach for 26 thousand rubles.

Another equally popular model with a broach is the Metabo KGS 216 M miter saw. The tool is ideal for a novice craftsman and belongs to the category of amateur devices. The miter saw is equipped with a bright LED and laser guide. The power of the brush motor is 1.2 kW. The maximum kerf is achieved at an angle of 45 degrees. and is equal to 205 mm. The price of the device is 19 thousand rubles.

Miter saws for metal and wood DeWalt

The professional range of miter saws is produced by DeWalt. Models of this brand are characterized by the presence of a unique XPC system, which allows projecting the shadow from the disc onto the product, which ensures accurate and high-quality cutting of any material.

One of the most popular models is the DeWalt DWS 780 professional cut-off saw for wood and metal. Rigid and stable design makes work convenient and safe. Thanks to the large disc with a diameter of 305 mm, it is possible to work with wide workpieces. The engine power is 1.65 kW. The belt drive ensures a quieter saw operation. The device has the function of adjusting the speed, which allows high-quality cutting of products of any hardness. The maximum cutting accuracy is ensured by the built-in illumination, which is not clogged with dust compared to a laser pointer. The cost of the instrument is 53 thousand rubles.

Another combination saw for metal and wood is the DeWalt DW 717 XPS model. The design of the tool is thought out to the smallest detail. Here you can set not only the cutting angle, but also set the required depth with millimeter precision. This is especially important for furniture manufacturers and builders, where precise work on the processing of products is required. The motor power is 1.65 kW, which is most suitable for cutting hardwood, plastic and aluminum.To create a better cut, the device has a system for controlling the rotation speed. The model is equipped with a cooling function that affects the entire power unit. The price of a miter saw is 52 thousand rubles.

Other manufacturers of wood and metal trims

Interskol miter saws from a Russian manufacturer are characterized by a simple design, which consists of a base, a saw blade, a motor and a handle with a start button. To cut at a certain angle, you just need to turn the blade or table. The disc can turn both to the right and to the left.

A popular budget model is the Interskol PTK-216/1100 P miter saw, which is designed for efficient processing of workpieces from different materials. The 216 mm saw blade allows you to make difficult cuts up to 45 degrees. round trip. The maximum cutting depth is 58 mm and the width is 133 mm. Thanks to the engine power of 1.1 kW and the disc speed of 5000 rpm. an even and neat cut is created. For added safety, the device is equipped with a braking system. The price of the saw is about 11 thousand rubles.

Interskol PTK-216/1100 P miter saw model is capable of performing complex cuts at an angle of up to 45 degrees. round trip

Another popular electric saw for metal and wood is the universal model Interskol PTK 250/1500 with a power of 1.7 kW and a saw blade size of 255 mm. Thanks to the wide upper work table, the tool can be converted into a circular saw for cutting workpieces up to 40 mm thick. The tool can perform not only through cuts, but also blind cuts. The cost of the saw is 16.5 thousand rubles.

Miter saws from the Chinese manufacturer Hitachi are distinguished by high accuracy of cross-cutting wood products at a given angle up to 45-47 degrees. The tool is widely used in the production of window frames, installation of platbands and baseboards.

The most popular classic model is the Hitachi C10FCH2 miter saw. When trimming panels, skirting boards and profiles, it simultaneously trims the edges of the products. The saw is equipped with a laser pointer and electronic control system for cutting speed, which allows you to get a neat and even cut. For bevel, combination and corner cuts, the saw blade can only be tilted to the left up to 48 degrees. the table can be rotated in both directions up to 52 degrees. You can buy the tool for 12 thousand rubles.

Important!This model is not used for metal work.

The Hitachi C10FCH2 miter saw is used in the manufacture of window structures, as well as the installation of platbands and skirting boards

Another budget option is the PIT miter saw. The tool has a fairly simple design and is easy to use. When making preliminary settings, the saw will cut similar parts at an angle of up to 45 degrees. in minutes. The cost of the instrument usually does not exceed 9 thousand rubles.

Choosing a miter saw is a very serious and responsible undertaking. To choose a quality tool at an affordable price, you first need to decide what tasks it will perform. After that, you should carefully study the characteristics of the selected option and only then make a final decision.