The grinder, or angle grinder (angle grinder), is a very popular tool that is versatile. It is used in the majority of construction work. Many people are interested in the question of whether it is possible to saw a tree with its help. To process this material, you need to choose the right wood disk for the grinder. There are many types of attachments, differing in characteristics and purpose.

Content [Hide]

- 1 Varieties of discs for a grinder: the most suitable circles for wood

- 2 Chain saw blades for wood: application advantages

- 3 Cutting disc for wood for a grinder: features

- 4 Grinding disc for wood grinder: characteristics

- 5 Grinding and polishing discs for wood on the grinder

- 6 Safety rules when working with a grinder for wood

Varieties of discs for a grinder: the most suitable circles for wood

The assortment of attachments for this tool is quite wide. Products are classified by purpose, depending on which 3 main groups of circles for angle grinders can be distinguished:

- sawing;

- diamond-coated;

- abrasive.

Sawing. Similar to standard saws, but made from different materials. The most common option is tungsten carbide discs. They are not suitable for working with wood.

Diamond coated. This group of grinder circles is the most extensive. The high popularity of diamond-coated tips is due to a wide range of applications. With the help of such circles, you can process metal parts, as well as elements of stone and concrete. Such disks are not used for wood.

Note! The use of angle grinders requires compliance with some rules. One of them claims that you cannot use circles with a larger diameter than indicated in the device's passport.

Abrasive. They are characterized by high versatility. Abrasive discs are used not only for cutting, but also for grinding and polishing surfaces. Products from this group are also used for wood processing.

These products are differentiated according to one more criterion - dimensions. The modern market provides a wide range of products, the sizes of which vary from 115 to 230 mm. The 115 mm grinder wood disc is the most compact and is used for fast and accurate cutting of material.It is worth noting that the largest discs are not suitable for working on wood surfaces.

Types of wood discs for angle grinders: design options

Many experts do not recommend using a grinder for cutting and processing wood. This is due to the principle of operation of the device and the characteristics of the material itself. However, the variety of disks for angle grinders is growing every year. They can be divided into several types according to the peculiarities of work.

Circular saws. Such circles for wood grinders are used, as a rule, for more technological equipment, but many install them on angle grinders. They are divided into two types: large diameter with solders and more compact ones without solders.

Chain. Ideal for working with wood materials. Many people are interested in the question of whether it is possible to cut a tree with a grinder. There is no definite answer to it, however, chain products are maximally adapted for this purpose. In this case, the edge of the circle is equipped with a chain on which the teeth are located. This design has many advantages. This nozzle is most often used for smooth cutting of the board. With it, you can process other materials: chipboard, fiberboard, plywood.

Saws with few teeth. This type of circles was specially invented in order to ensure maximum human safety when working with wood. Compact products belonging to this group have 3 teeth, and larger ones - 4. This group also includes cutting discs for a 125 mm wood grinder. Such products do an excellent job with their functions. They can be used to cut wood along and across the grain. In addition to standard functions, such discs are used to organize grooves in workpieces.

Segmental (material - tungsten carbide). Such products have appeared relatively recently, but have already gained immense popularity. A distinctive feature of such products is the absence of teeth. The edge of the disc consists of segments that are characterized by high strength.

Helpful information! Using the segment nozzle, you can work with wood of any strength and toughness. It is distinguished by high safety and is able to withstand even metal inclusions present in some workpieces (screws, nails, etc.).

Chain saw blades for wood: application benefits

In this case, the saw blade is made using a chain from a chainsaw. This nozzle is the most suitable for working with wood, as it has the highest efficiency. A wood chain disc for a grinder is also considered the safest. The use of this accessory significantly reduces the likelihood of injury if the tool becomes jammed.

If the disc during operation hits a solid element of the tree (for example, a knot), then the chain does not break. This happens by turning the base. Such nozzles are very popular when it is necessary to clean the tree trunk from bark and knots.

Saw blades for wood for angle grinders with a chain are used for all sorts of work. With their help, you can remove tree branches, as well as cut boards of small thickness. The functionality of the chain products allows them to be used as peeling tools. They do an excellent job of removing bark.

With the help of a saw wheel, you can make an even cut of parquet boards, plywood, fiberboard, chipboard, as well as ordinary unedged and edged wooden products. It is important to remember that the thickness of the material that will be processed with such a nozzle should be no more than 4 cm.Otherwise, the device is likely to overheat.

Cutting disc for wood for a grinder: features

For the manufacture of such products, a special material is used - tungsten carbide. This is due to the following: when working with a grinder, there is a possibility that it will break out of your hands, so the material of the circle must have high strength characteristics. The use of tungsten carbide can significantly increase the safety of work, but the cost of such products is quite high.

Discs of this type can have a different arrangement of teeth. A variety of types of products on this basis allows you to choose the most suitable nozzle for a specific situation. The shape and frequency of the teeth are also very important. The most common wheel size for woodworking is 125 mm. If you decide to choose the most versatile version of a cutting saw blade for wood for a 125 mm grinder, then it is recommended to purchase a product with beveled teeth.

Helpful information! Wheels that have straight teeth are best for working in soft woods. Softwood boards are also processed using such attachments.

These products may have teeth that resemble a trapezoid in shape. They have a wider usability range and are used to cut medium density boards. The following materials can be cut with this wheel:

- Fiberboard;

- Chipboard;

- USB plates;

- fibreboard.

Saw blades for wood for this type of grinder have some design features that are determined by their purpose. For example, during operation, products easily overheat, so they have special slots that can be empty or filled with copper. This measure allows you to compensate for the thermal expansion of the metal that occurs at high speed. The width of such slots can vary, but not more than 2 mm. As for their depth, it does not exceed 20 mm.

Grinding disc for wood for a grinder: characteristics

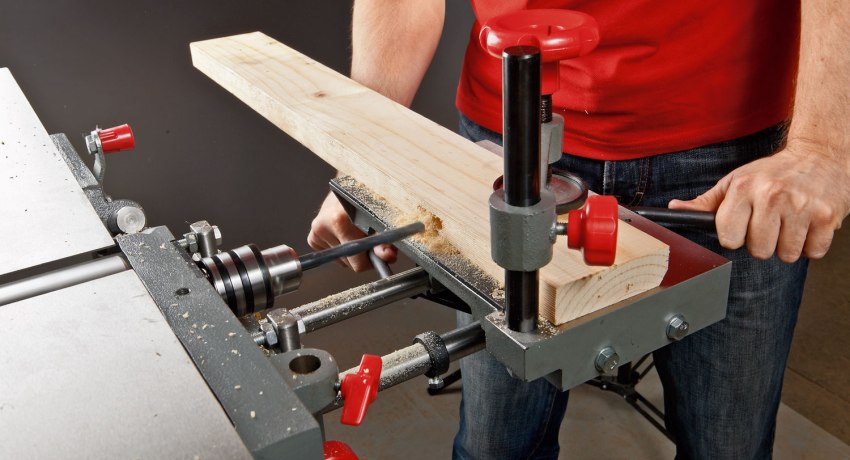

With the help of a grinder, you can not only cut and saw off wooden parts, but also carry out roughing work of varying degrees of complexity. The modern market offers a wide range of such attachments. They are classified according to several indicators: shape, design and purpose.

Grinding discs are used to remove bark from logs or boards. Thanks to them, you can easily remove excess wood from the end surface of the board. They may have special thorns or chips.

Grinding discs for wood for the grinder are also used to level the surface of the boards. Such circles are equipped with special spikes that are placed on a flat surface. This function is very useful, as it allows you to polish the boards from which the flooring is constructed.

On sale you can find roughing products consisting of twisted wire. They are called corsets. Such attachments for a grinder for woodworking are distinguished of two types, depending on the peculiarities of their structure. The first option provides for a base in the form of a glass, to which the wire is attached. The second type is a disc with a wire fixed at the edge.

Corsets are used to remove paint and varnish materials from wooden surfaces. It is important to note that these nozzles are most often used to remove paint and rust from metal pipes.

Note! For wooden parts, you need to choose a thinner wire that will not damage the workpiece itself. These products are suitable for different types of wood.

Wood roughing discs equipped with wire coils are also used for brushing. This event allows you to give wood an unusual look, artificially aging it. However, with a grinder with a wire stripping nozzle, only small amounts of wood can be processed. Therefore, this element is not recommended for industrial brushing.

Grinding and polishing discs for wood on a grinder

Grinding and polishing of wood is carried out using special attachments that are used for the grinder. Such products include a metal base on which the grinding wheel is fixed. Fastening is usually done with Velcro.

Related article:

DIY wood lathe: tips for making and using

Device. How to make a bed, a handguard, a headstock and a tailstock. Drive selection. Types of homemade machines and the rules for their use.

To use such a wood accessory for a grinder, you must fix it with a key (open-end) on the tool shaft. Quite often, it is implemented complete with a special adapter element, thanks to which it becomes possible to quickly attach to the drill chuck. In turn, polishing requires the use of a more gentle material. Therefore, nozzles of this type are equipped with felt discs. They are also fixed with Velcro.

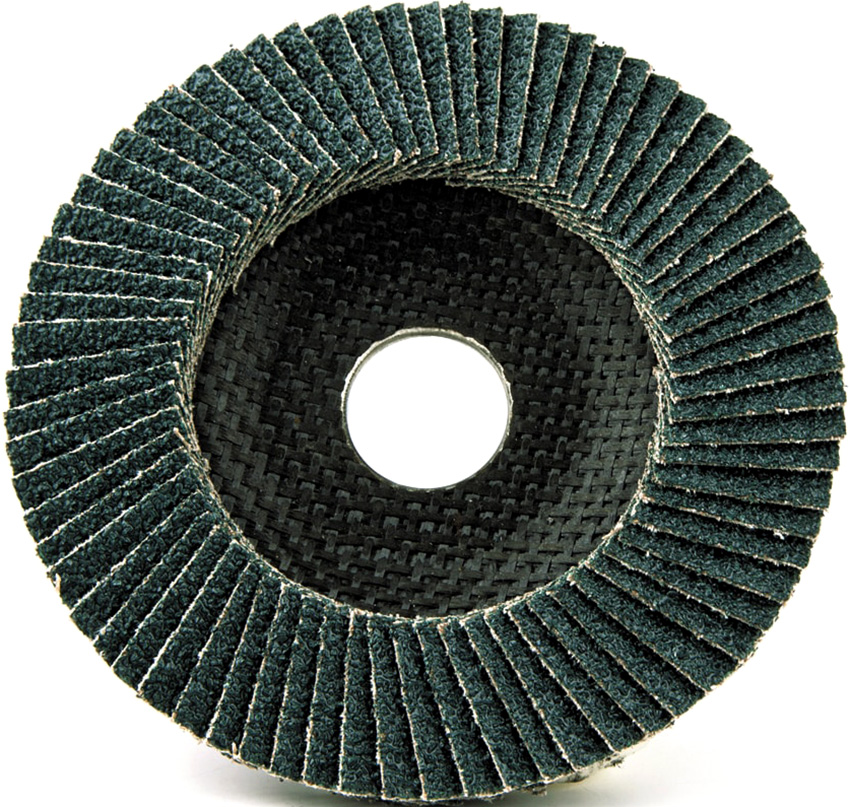

Another option for a grinder grinding wheel is a petal. Its design fully lives up to its name. It consists of a large number of sandpaper petals closely spaced to each other. If desired, you can select the desired paper grain, which allows you to process wood materials of different degrees of density.

Although the grinder is not considered the preferred tool for woodworking, grinding attachments are very common. It is worth noting that grinding in this way is not suitable for smooth surface treatment, since even the most gentle options for angle grinders leave small scratches on the wood. If you decide to perform this process as efficiently as possible, then experts recommend purchasing a special device - a grinder. It is customary to use angle grinders for materials that will subsequently be painted with paint.

Grinding wheels for grinder for wood: coarse grinding

Grinding wheels that are used for angle grinders differ in material of manufacture, shape and operational purpose. The process of wood processing itself, as a rule, takes place in two stages. First of all, a rough grinding is performed, after which the material is subjected to finishing. For rough polishing, several types of nozzles are used:

- roughing;

- corsets;

- end circles.

Grinding wood with a grinder using a roughing product is most often used to remove a layer of old paint. Sometimes this type of nozzle is used to remove varnish if it cannot be removed manually. Such circles can have a different relief, on the features of which it depends on how efficiently the product will function.

The bristles are used for sanding different types of wood. Products that belong to this group are classified according to their design, the direction of the wire bundles and their diameter. Depending on the stiffness, they are also divided into types.If necessary, it is possible to select the right tool, corresponding to one or another variant of grinding.

Helpful information! For coarse processing, a larger diameter wire is used.

End discs for grinding wood on a grinder are used in the case when it is necessary to adjust the size of the part from the end. Often, such products are used for the usual leveling of the side surface with uneven cuts. The operating principle of the end bit is similar to that of a file. The difference in this case is the high efficiency of angle grinders.

The use of grinding attachments greatly simplifies the processing of wood blanks. Such products allow for the restoration of old furniture by removing paint and varnish compounds from its surface.

Grinding discs for grinder: flap wheels

After rough finishing, a fine finish may be required. Of course, if the wood is to be painted in the future, there is no need to bring its surface to a perfectly smooth state. However, in most cases, finishing is necessary. To perform grinding, you can use a common attachment - a flap wheel.

The design of the petal disc model, as mentioned above, includes sheets of sandpaper that are trapezoidal. Their grain size is selected depending on the type of wood and the specifics of the work. This type of wood grinding disc is one of the most common. It provides gentle material handling and a high degree of safety. It is almost impossible to get injured using this disc.

The size of the abrasive coating on the petals determines the efficiency and speed of wood processing, as well as its appearance. For maximum smoothness, it is customary to use fine-grained products. Experts recommend using several such grinding wheels for wood at once. This will make it possible to quickly carry out rough cleaning, and then finish the work with soft petals, bringing the workpiece to the desired degree of smoothness.

The use of such a nozzle requires a certain skill from a person. Therefore, it is recommended to practice on wooden parts before using the flap wheel.

Grinding wheel for grinder: soft processing and polishing

For soft grinding, special discs are used, which appeared on the market not so long ago - just a few years ago. Such circles are characterized by a high degree of functionality and can have various grain sizes.

Helpful information! Unlike petal nozzles, abrasive particles are fixed with Velcro on the surface of the disc, and not on its end.

Grinding disc for this type of wood grinder has one advantage - ease of replacement. This procedure is carried out without removing or disassembling the main nozzle, so it is quite convenient to use such discs. Sticky tips can be easily purchased on the construction market or ordered online. Choosing the right grain size is not a problem in this case. With the help of such devices, you can bring the wooden surface to the desired state.

The polishing that is done after sanding can be done using special felt wheels. These attachments provide maximum surface smoothness that is difficult to achieve with other tools. A large number of turns of angle grinder promotes uniform polishing of wood.

Felt disks on the grinder include wool (tightly pressed), which can have different characteristics (depending on the need). On the modern market, you can find nozzle options of various composition:

- fine-haired;

- semi-coarse-haired;

- coarse-haired.

Wood processing attachments are of high efficiency and quality. The alternating use of these discs can achieve incredible results. The woody surface after using them can be compared to a mirror.

Safety rules when working with a grinder for wood

The use of angle grinders for wood processing requires a serious approach. Incorrect work with the grinder can lead to injury, therefore, before using it, experts advise you to pay attention to some rules for using the device. For example, before replacing one nozzle with another, you need to disconnect the angle grinder from the network. How to change a disc on a grinder? To answer this question, you need to define the kind of circle. Some products are installed without removing the main nozzle. However, in most cases it is necessary to unscrew the flange holding the element.

Note! In no case should you remove the casing, which is used for protection, from the grinder. If the circle breaks, this element will protect your face and other parts of the body from injury from shrapnel.

Processing of wood material using angle grinders must be carried out with protective gloves. Sawing and cutting discs for wood are best used on medium (in terms of power) devices. This is explained quite simply: if the saw jams, then you have a high chance of holding the tool in your hands. This will be much more difficult with a powerful device.

For cutting logs and boards, it is recommended to use attachments that have fine teeth. The smaller their dimensions, the less effort will be required to cut. Among other things, the likelihood of hard wood fibers meeting the disc is reduced.

Any grinder must be equipped with a speed regulator, which must be set to the minimum position. When working with cut-off discs for grinders it is very important to maintain a right angle. Otherwise, the cutting process will be uneven, and the device itself may jam.

LBM can be used for wood processing, however, before starting operation, you should study the technical features of various attachments. Products that are used for grinding and polishing are safe and easy to use. Saw blades for cutting wood material require careful selection. During work, it is necessary to follow the safety rules and not deviate from them.