A wrought iron gate is a construction that not only fulfills its direct functions, but also has artistic value. With the right choice, they become a real decoration of the site. The variety of solutions is so wide that people often have a question about which design to give preference to. In order not to be mistaken, it is recommended to study several aspects that allow you to choose the right forged gate: photo, product types and installation features.

Content [Hide]

- 1 The main features of a forged gate: photos and characteristics

- 2 Advantages of doors with forged elements

- 3 What other advantages do forged structures have?

- 4 Varieties of forged metal gates: photos and characteristics

- 5 What are the doors depending on the opening method?

- 6 Stylistic and design options: a photo of a beautiful gate

- 7 A variety of colors when choosing a forged gate

- 8 Tips for choosing a wrought iron gate for your home

- 9 The cost and features of the choice of wrought iron gates for the house

- 10 DIY cold forging: advantages of the method

- 11 Installation of forged gate supports for the house: photo of the process

- 12 Gate installation algorithm and tips for installing them

The main features of a forged gate: photos and characteristics

Forged structures harmoniously combine qualities such as functionality and aesthetics. They can be assembled from a variety of materials. However, regardless of what components are included in such a fence, all structures have high strength and do an excellent job with protective functions.

Buying or assembling forged gates by yourself is first of all a chance to show your taste. The variety of patterns contributes to the great popularity of these designs. Each person can choose a drawing they like and order a product or try to make it on their own. Photos of beautiful wrought-iron gates make it possible to visually assess their advantages.

Note! Before you buy a forged structure, you need to remember that it will require the construction of reliable supporting elements. This is due to the fact that such gates are made of metal and are heavy.

Forged constructions have a wide variety of patterns

The mass of such structures is, perhaps, their main disadvantage. This also complicates their own production. Mistakes made in the design of an inexpensive forged gate are fraught with serious consequences, therefore, to prevent them, you need to know how the sketch is drawn up.The drawing of a future metal structure must contain the following elements:

- frame;

- fixing products;

- decorative details;

- awnings;

- locking devices.

In addition to the mandatory image of all elements, it is also required to indicate their sizes in the diagram. The choice of the geometric shape of the doors depends on the financial capabilities of the owners and their personal preferences. For example, you can choose regular rectangular sashes, the organization of which is not difficult. Curly elements are reflected in the final cost of the gate.

Advantages of doors with forged elements

Today, there are many types of forged structures that differ in their structure. All of them are united by the fact that they have certain advantages and disadvantages. Consider the advantages of forged products.

First of all, it should be noted that such fences are highly versatile. They look beautiful in combination with any stylistic design of suburban areas. They are often combined with various materials. Photos of the gates made of corrugated board with forging elements, as well as polycarbonate fences allow you to evaluate their advantages. Such structures look presentable and, moreover, protect the site from prying eyes.

Another advantage of such products is that they do not need special care. The variety of different solutions, designed in different styles, allows you to easily find the desired option that will be combined with the characteristics of a particular site. It is recommended to pay attention to the photo of the iron gate with different pattern options. Before purchasing this design, you need to decide on the desired type of entry.

Note! In order to emphasize the originality of your site, you can order a gate according to an individual sketch. In this case, you yourself can choose a pattern, color, as well as additional elements that will be used in the assembly of such a product.

In addition to simple drawings, there is a possibility that the gate will be decorated with complex elements. Metal flowers, birds and a wide variety of other options - all this can be done on such a fence. However, this will certainly affect the cost of custom-made forged gates.

What other advantages do forged structures have?

One of the main advantages of such gates is their long service life. In this respect, they are vastly superior to conventional fencing. This is achieved due to the fact that they are made of high quality metal. This material is highly durable. But all metal elements must be protected from destructive corrosive effects, otherwise such products will not last long.

Today you can find combined structures that consist of forged metal rods and screen materials. Forged gates with polycarbonate are very popular. This material is easy to install and has high technical characteristics, and also has a wide color spectrum.

Such products are suitable for almost any weather conditions, therefore, in regions with a harsh climate, their purchase is the most rational. To protect against rusting, forged elements, as a rule, are treated with special anti-corrosion agents at the production stage. But this does not mean that the finished structure will not need additional protection after it is put into operation.

When purchasing auxiliary security equipment, which include video cameras and motion sensors, you can increase the protective qualities of the gate. Forging is highly environmentally friendly and does not emit substances harmful to human health. Therefore, such elements are used not only in outdoor conditions, but also as decorations for pieces of furniture, as well as independent decorative elements of the interior.

Varieties of forged metal gates: photos and characteristics

There are several points on which such designs are differentiated. The first factor in classifying these products into types is their purpose. According to their operational accessories, gates are:

- to block the road;

- arched;

- to organize the passage through the fence;

- to protect entry-exit.

All of the above types of gates are quite common. The second feature, according to which forged structures are subdivided, is the type of sash opening. Depending on this, there are four types of similar products:

Related article:

Fences and barriers for the house. Photo collection of brilliant ideas

Functions and types of fences. Photos of metal structures. Photo examples of models. Wooden fences. Original and decorative fences.

- swing;

- retractable (single-leaf);

- sliding (double-leaf);

- lifting.

What are the doors depending on the opening method?

According to this indicator, such products are divided into 4 main types.

Swing designs. The most common are the first two types of forged gates, the manufacture of which requires the least effort. The same goes for their installation. Swinging structures have a simple device and do not require special maintenance.

Helpful information! There is no movement mechanism in swing gates. Therefore, they have a more affordable cost when compared with other varieties.

Rollback products. They differ from the previous type in that they include in their design special guide elements equipped with a roller mechanism. Due to the need to purchase these accessories, their cost is higher than that of hinged counterparts. When opening, a wrought-iron sliding gate moves to the side (along the fence). One of the main advantages of such products is that they save a lot of space. Therefore, they are most often purchased for installation in confined spaces.

Sliding structures. Such gates have the same principle of operation as sliding ones. The difference in this case is that they have a different device. Sliding products consist of two sashes that move in different directions when opened.

Preventive maintenance consists of lubricating the hinges and checking individual structural elements for rust. Opening the gates is very simple: two leaves simply disperse in different directions, freeing the road. Such products also have some drawbacks that are worth paying attention to. First of all, it is a high price. However, over time, the costs pay off, since the useful life of these gates is longer than that of their counterparts. The second disadvantage of such structures is the complexity of assembly and installation.

Lifting gates. The most original version. A special mechanism is installed on such products. During opening, such gates rise and enter the building, freeing the passage.This design has several drawbacks. Special conditions are required for its installation. The disadvantage in this case is the high price of forged gates. Retractable options are the most acceptable if it is necessary to organize travel in confined spaces.

The cost of forged gates is influenced not only by their type, but also by the size of the figured elements, as well as their number. Large patterns are easier to manufacture than small ones. Forged sliding gates can be made from a conventional design. Thanks to special accessories, it is not difficult to create such a device. An automatic system that controls the movement of individual leaves is a very convenient solution. With it, you can remotely change the position of the gate.

Sliding doors are equipped with a roller mechanism, due to which the structure moves to the side when opened

What degree of openness can a forged gate have: photo

Modern fences can be completely closed, protecting the site from the views of passers-by. There are other gate options that are in no less demand. Depending on the degree of openness, such designs are subdivided into the following types:

- deaf;

- transparent;

- solid.

Deaf constructions. Such gates can be found everywhere. They not only consist of forged parts, but also contain insert elements. Various materials are used to organize continuous shielding, but the most popular is ordinary corrugated board. Another common option is to use polycarbonate, which is affordable and has a wide range of colors.

Note! When creating a picture of a forged gate, it is necessary not only to note the number and dimensions of individual figured elements, but also to take into account the surface relief.

Transparent fences. Still, the most common option today is a gate that includes iron bars and forging elements. The degree of openness in this case is maximum. If necessary, additional shielding can be added to this design. In order to answer the question of how much forged gates cost, one should focus on the material from which they are made, as well as on its quantity.

Solid products. From the name it becomes clear that such gates consist of a continuous metal sheet. Of course, and in this case they contain forged patterns. This design is very similar to an ordinary solid fence, but it looks more impressive.

The basis for forged structures is most often metal. Photos of metal gates allow you to assess how presentable they are. Sometimes there are gates made of wood and containing metal forging.

Stylistic and design options: a photo of a beautiful gate

Previously, structures that contained forging elements were quite expensive. Therefore, only the owners of expensive estates could afford them. Today, with the right choice and calculation of the material, such a product can become a decoration of any site.

When choosing a design style, you need to focus on the design of the house and the area adjacent to it. The gate production technology today practically does not differ from the previous production methods. The master uses the same blacksmith tools as before and carries out metal processing, taking into account the sketches that were selected by the customer. Thus, various elements of artistic gate forging are produced.

The gates, as a rule, are made in the general style with a fence. However, there are exceptions. Some designs contain complex (in terms of execution) ornaments and paintings. Today, these fences are made in the following styles:

- classicism;

- Gothic;

- baroque;

- rococo;

- modern;

- minimalism.

Pictures of the gate allow you to appreciate the variety of stylistic solutions and highlight the options you like. It doesn't matter in what style this design will be executed, but it should fit into the overall idea. The combination of a gate with a plot, landscape elements and a fence is a sign of good taste.

A variety of colors when choosing a forged gate

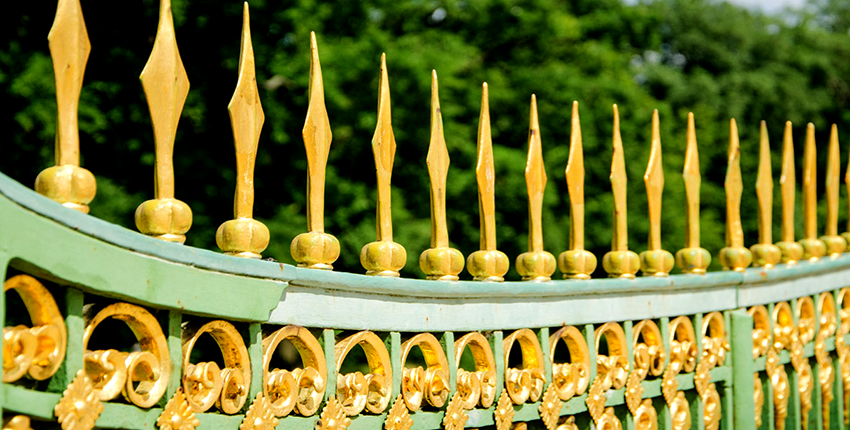

The forged construction can be made in various colors. The choice of shade is a serious task, since it depends on it whether the gate will be combined with other elements of the fence. It is also worth paying attention to the architectural features of residential and utility buildings located on the site. Photos of beautiful wrought-iron gates, which are combined with the general style, allow you to understand the principles of their choice.

Helpful information! The classic option is to use a black design with gilding elements.

It is necessary to select the color for the gate based on the architectural features of the building

Gold and silver components in the design look elegant and effective. Such gates are universal, as they fit almost any design. In addition to black, other dark shades are actively used (dark blue, burgundy, etc.). If the design of the site is close to modernism, then you can paint the structure white.

Black gates can be completed with multi-colored polycarbonate. Photos of forged gates with such shielding allow you to assess the feasibility of a particular shade.

Professional designers have identified several rules that should be followed when choosing the color of the forged structure. For example, the color of the fence should match the shade in which the roof of the residential building is made. The material used for the supports also affects the color. Brown and beige tones are best combined with stone pillars. The patterns on the gates often have an independent color, which should also be in harmony with the color of the structure.

Products painted in light colors are most often used when it is necessary to visually increase the area of a small area. And also it is worth paying attention to the facade of a residential building: if it is light in color, then the fence and the gate should contrast with it.

Blue shades are not so common, but they can create the effect of merging the fence with the surrounding space. Despite all these rules, the main factor that influences the choice of color is your taste.

Tips for choosing a wrought iron gate for your home

It is very important that the design matches the design of the site and the buildings located on it. Still, the main selection criterion is the functionality of the gate. The individual needs of the owner must be fully satisfied, otherwise it makes no sense to use this design option.

It is always recommended to pay attention to the features of this or that type of product: swing, lifting and forged sliding gates. Prices for these designs can vary greatly. Experts do not recommend purchasing the cheapest options, since their quality is often very low.

If such a design is bought in order to emphasize the individuality of the site, then you need to pay attention to products that have an original design. But in any case, do not forget that they must be combined with the environment. The most beautiful gates are those that are made according to individual sketches.

The door material must be suitable for the climatic conditions of a particular region. If the weather conditions in your climatic zone involve high temperature fluctuations, then it is recommended to buy fences made of galvanized steel. Such material is characterized by increased resistance to moisture and other unfavorable factors that can reduce the operational life of the metal.

Note! In order to save money, you can order a design made of aluminum. However, in this case, it should be taken into account that this material is extremely unreliable and has low strength. Aluminum gates and railings are only suitable for decorative purposes.

When choosing sliding gates, special attention should be paid to the sliding roller mechanism. It must be made of durable metal and resistant to corrosive effects. Otherwise, such a mechanism will not last long and will cause breakage of the sliding wrought-iron gates. Photos of sliding systems show their advantages over conventional designs.

The cost and features of the choice of wrought iron gates for the house

Pricing takes place depending on the material of manufacture, the complexity of the pattern and the amount of metal spent. A square meter of simple construction can cost only 2,000 rubles. At the same time, the price of a gate with an original pattern and relief reaches 20,000-50,000 rubles.

The height of this type of door varies from 1.5 to 3 m. If necessary, you can place an individual order, which will indicate non-standard dimensions. However, the original design will cost more than the standard options produced in factories.

It is worth noting that products that have a low height are the best suited for decorating with artistic forging. In turn, large gates are purchased to ensure the highest degree of security. Photos and prices of wrought iron gates can be easily found on the Internet. Each of the types of this design has its own characteristics, so when choosing the required variety, you need to take into account all the pros and cons.

When choosing a gate, you need to take into account the opening options, the size of the leaves and the type of locking mechanism

Combined options provide protection from prying eyes. However, when choosing them, you must take into account the combination of materials. Decking is best suited for shielding such structures. Photos of forged doors with such a continuous coating clearly demonstrate the advantages of this combination.

An important factor when choosing a gate is its functionality. In this case, the dimensions of the doors, opening options, types of locking mechanism, as well as the presence of a wicket are taken into account. Forged sliding gates with a beautiful pattern require careful calculations and organization of an accurate sketch. The same applies to other variants equipped with a roller sliding mechanism. Simple designs are less functional and therefore easier to choose.

DIY cold forging: advantages of the method

Self-execution of forged gates can significantly save finances. However, such a process requires special knowledge and skills in this area.For a person who has never had to deal with forging before, it will be very difficult to master the principles of the process and implement them on their own.

Helpful information! If it is quite problematic to completely make a forged gate with your own hands, then you can save money by making their individual parts. For example, some masters perform some of the large elements on their own. Thereafter, the large metal products are assembled and supplemented with smaller finished components.

In order to carry out the cold formation of the gate, it is necessary to study the basic rules of work. It is important to remember that after bending, metal rods acquire increased rigidity. Therefore, it is much more difficult to correct the wrong bend than to redo it. For the production of curly elements, you need to purchase special equipment, and each part requires a separate device. Forming is carried out by means of such devices as a snail, whip, etc. All work is carried out in accordance with the project.

The design of the future forged structure also includes stiffeners, their location and the distance between them. At the stage of organizing the plan, you should decide on the option for fixing the products and the place in which the gate will be located. It is recommended to entrust the drawing up of a diagram of such a complex structure to specialists.

Self-made designs certainly save money, but their production takes a lot of time and effort. If you decide to make such a product yourself, then the best option in this case would be to combine factory parts with gate elements with your own hands. Photos, which show the processes of performing individual components for the fence, will help to do this work correctly.

If you are not confident in your own abilities, then you should not experiment. It is best to order forged gates in such a situation. And you can save on their installation by completing all the stages of installation yourself.

DIY hot forging: features of the method

Hot forging differs from the cold method. To carry it out, you need to have professional equipment that is not cheap. Thus, this method is not preferable for self-production of the gate. However, other devices can be used to heat the metal rods. For example, welding equipment would be a suitable option in this case. In any case, all work must be done according to the sketch of a forged gate.

A cheap way to heat metal rods to the desired temperature is with a gas burner (household). This method is used for rods with a diameter not exceeding 14 mm. More voluminous metal products require a different approach. At home, a rail is used as an anvil for forging metal. It must be turned over, since the lower platform is wider, which means it will be more convenient to work on it.

Note! The time for making a forged gate with your own hands depends entirely on the complexity of the project. For example, it may take less than one day to produce simple variants. Complex designs, consisting of a large number of small parts, are produced from one week to several months.

To add aesthetics to your designs, you can purchase decorative fittings. Many manufacturers produce individual elements that decorate fences and gates. Among them are hinges, locking devices, latches and figured products.

Depending on the complexity of the work, it can take from one day to several months to manufacture one structure.

For self-production of gates from scratch, you will need to purchase some equipment. At home is more preferable cold forging... The hot method requires a burner. Thus, when making doors with forging elements with your own hands, you should focus on personal capabilities.

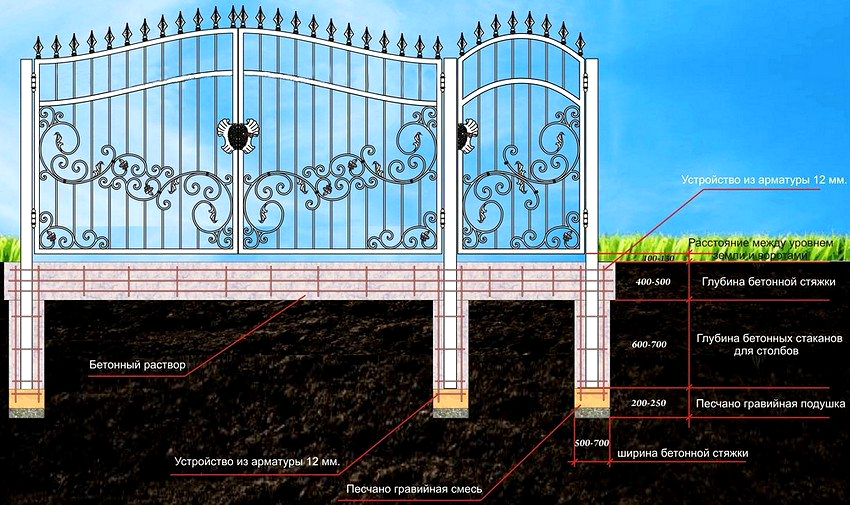

Installation of forged gate supports for the house: photo of the process

Before you start developing a sketch of future gates, you need to decide on their type. For this, all individual factors are taken into account: the type of fence, the reliability of the support racks, the design of the site and the buildings located within it.

Installation of such a structure is a laborious undertaking that must be approached with all seriousness. It is recommended to entrust the installation of forged gates to qualified craftsmen who have professional knowledge and skills. Otherwise, there is a high probability of making mistakes that reduce the technical characteristics of the structure, as well as its operational life.

Before starting the direct installation of forged doors, prepare an opening for installation. A competently mounted opening will allow you to position the gate evenly, which is very important, as this will affect their future work. In the event of an error, it is likely that the structure lock will often jam.

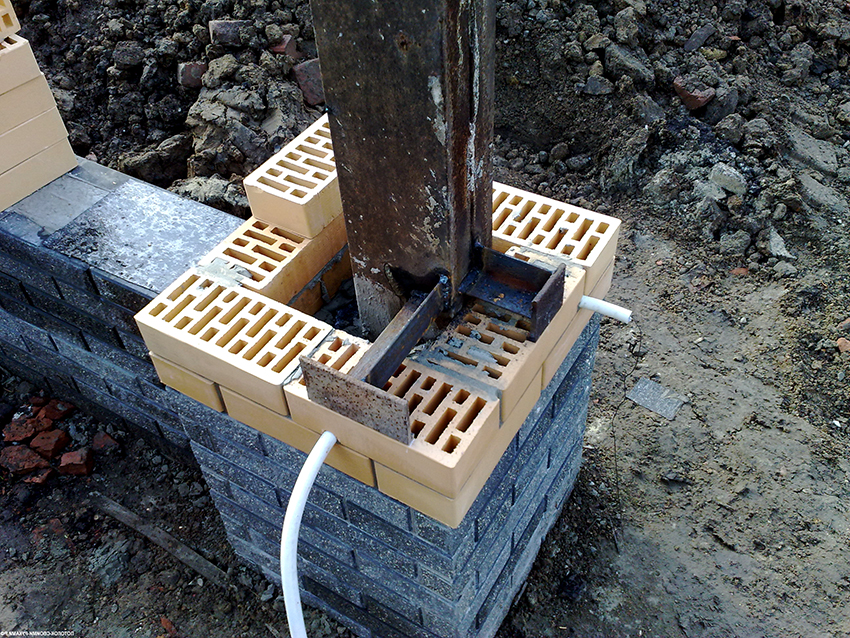

Forged gates have a high mass, therefore it is recommended to make supports in the form of strong pillars with brickwork

Since forged gates have a large mass, the supports under them must be strong and reliable. The best option in this case is the organization of strong pillars with brickwork. Each support must have a base represented by a bar that provides the necessary stability.

Such a pipe is dug into the ground and fixed with cement mortar. To prepare the composition, cement, sand and water are used. The ratio of the components in this case is 1: 1: 1. The rod must be deepened into the ground by at least 1 m. When choosing the depth, one must be guided by the weight of the future structure for which the support is mounted. It is also worth noting that the pipe for the core of the support must have thick walls, otherwise it simply will not withstand the pressure exerted on it.

Gate installation algorithm and tips for installing them

It is recommended to pay attention to the photo of a wrought iron gate. Pictures explain in detail all the stages of installation and allow you to cope with this task, avoiding mistakes. After the foundation for the support hardens, you can start organizing the brickwork. In this case, the cement mortar must be made thicker. For laying bricks, a special device is used - a trowel.

Note! If you plan to install forged gates with corrugated board, then you need to calculate the facing material in advance. Experts recommend adding 15-20% of the stock to the final figure, which will cover the possible marriage that occurs in the process of work.

It is important to remember that at the fixing points of the gate on the brickwork, a metal tire must be stretched. This is a must-have event that cannot be ignored. After that, you can proceed with the direct installation of the gate. The fixing elements are mounted first. Further, sashes are installed on them. For a deeper understanding of this process, it is recommended to search the Internet and watch the training video.

Forged elements for gates can be welded to the structure in advance or this process can be performed after its installation on the supports.It all depends on the number of components and their dimensions. Installation work in this case is complex. The possibility of making a mistake by an inexperienced specialist is very high, so you need to soberly assess your own capabilities. If you nevertheless decide to carry out the installation of the forged structure yourself, then you will need to purchase the following tools for work:

- grinder;

- welding equipment;

- drill;

- fixing elements;

- trowel;

- building level;

- measuring tape.

Before starting the installation, be sure to study the photo of the forged gate. The installation price depends on many factors, such as the type of doors, their size, soil conditions, etc.

In order to avoid mistakes when installing the gate, it is recommended to carefully study the process algorithm

Before you buy a forged gate, you need to choose a suitable (for specific conditions) design. Self-assembly requires adherence to the order of actions and care. Do not forget that the finished structure requires preventive checks, which include processing the hinges and applying protective compounds. Proper maintenance can extend the life of the installed fence.