A special place in the dacha reality is given to greenhouses. Every gardener seeks to get an excellent harvest, and even ahead of time. Modern greenhouses made of polycarbonate have an aesthetic appearance, are resistant to mechanical stress, are easy to maintain, and a special protective ultraviolet film protects plants from the negative effects of solar radiation. An excellent solution is a polycarbonate greenhouse with your own hands from a profile. Structural drawings can be found online or developed independently.

Content [Hide]

- 1 Choosing polycarbonate for the greenhouse

- 2 Profile types for polycarbonate greenhouse frame

- 3 DIY polycarbonate greenhouse from a profile. Drawings and diagrams of structures

- 4 Do-it-yourself foundation for a greenhouse from a profile

- 5 DIY installation of a greenhouse from a profile

- 6 Greenhouse heating

Choosing polycarbonate for the greenhouse

Polycarbonate is a modern building material with high strength characteristics and very attractive decorative properties. A wealth of colors and a wide variety of sizes allow you to use it in construction, embodying any idea.

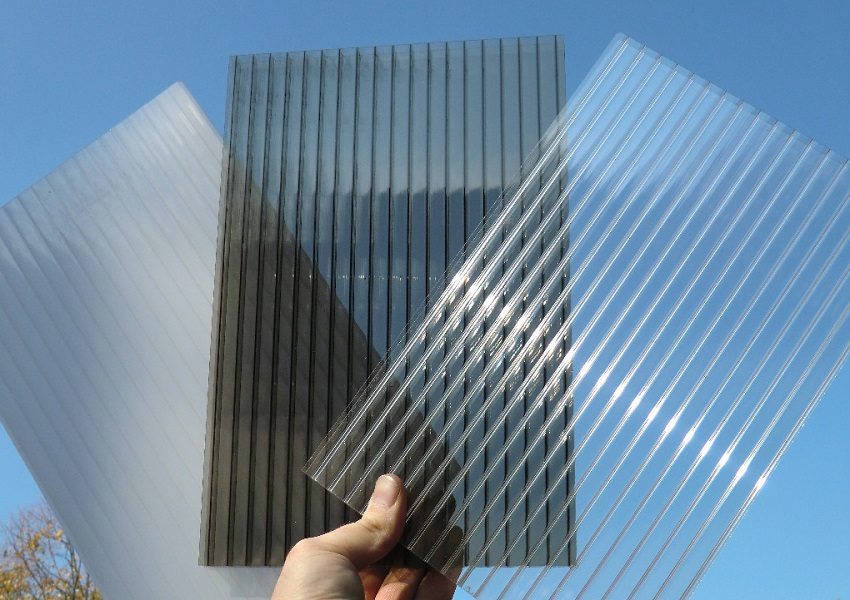

By their structure, polycarbonate sheets are divided into solid or honeycomb. Which polycarbonate sheets are best for a greenhouse? Reviews indicate that it is cellular polycarbonate that is popular for the construction of greenhouse structures. And this is quite reasonable, given a number of main advantages:

- high strength - multilayer sheets, interconnected by stiffening ribs at different angles, represent a structure in the form of honeycombs filled with air;

- stability, impact resistance, durability, the ability to withstand strong gusts of wind and the severity of the snow cover;

- due to the lightness and plasticity, a polycarbonate structure can be given any shape without deteriorating the properties of the material;

- resistance to large temperature extremes - withstands from -35 to + 60 ° C;

- high light transmittance (92%), UV-protected sunlight scattering allows this material to be used for greenhouses;

- layering gives an excellent thermal insulation effect;

- light weight (15 times lighter than glass), ease of installation and processing (cutting, drilling);

- has a dust-repellent property, easy to clean;

- non-flammable - in direct contact with fire, it can melt without emitting harmful substances;

- the price for a polycarbonate sheet for a greenhouse does not exceed the cost of glass of a similar size.

In order for a finished greenhouse made of polycarbonate sheets to serve as long as possible, it is necessary to follow simple procedures for its care: do not use abrasive detergents containing chlorine and alkali to clean the sheets.

Useful advice! To avoid the formation of mold or mildew in the greenhouse, make sure that the entrance to it is always closed. Do not allow moisture, precipitation and insects to enter the structure.

In winter, it is recommended to clean the surface of the polycarbonate from the ice crust to prevent deformation of the sheets.

Profile types for polycarbonate greenhouse frame

The strength and stability of the greenhouse structure directly depends on the material from which its frame is made. You can make greenhouses from a profile with your own hands using various types of material. A galvanized, aluminum and plastic profile is used for the frame of structures. It is also possible to manufacture the base of the greenhouse from a PVC profile, a wooden beam, a metal corner and a profile pipe.

Metallic profile. Greenhouse frames made of such a profile are distinguished by their strength, durability and resistance to heavy loads. The main requirement for such structures is the mandatory treatment of the metal surface with an anti-corrosion compound. The frame from a metal profile can be assembled independently or purchased in the form of ready-made factory structures.

Wooden bar. Wooden blocks lend themselves well to processing, are easy to install, polycarbonate sheets are easily attached to them. Wood is an environmentally friendly material, wood structures "breathe". If any of the parts is out of order (broken or rotted), it can be easily replaced with another. Assembling and disassembling such a frame will not be difficult. Among the shortcomings, vulnerability to the external environment is noted, which can be solved by treating wood with special impregnating compounds.

Aluminum profile. For a greenhouse, such a profile is quite relevant. Aluminum does not corrode and rust under the influence of external factors. Due to the square shape of the cross-section, the frame made of aluminum profile does not bend, provides the structure with ideal stability in all weather conditions (snow drifts, wind, etc.).

PVC profile. Frameworks greenhouses made of plastic pipes durable, safe, modern and attractive. Polyvinyl chloride greenhouse structures are the most airtight and easy to maintain. The disadvantage of such frames is the rather high price of a profile for a greenhouse.

Polypropylene pipes. This frame is easy to assemble due to the flexibility of the material. It is this property of pipes that allows you to give the frame any desired shape. The design is robust and can withstand various loads. For such a greenhouse, you do not need to arrange a foundation, but simply install it on a prepared site.

You can get acquainted with the technology of mounting various types of frame by watching the video of assembling a polycarbonate greenhouse with your own hands on the network.

DIY polycarbonate greenhouse from a profile. Drawings and diagrams of structures

If you are going to build a polycarbonate greenhouse with your own hands from a profile, first of all you need to decide on the shape of the future structure, its dimensions and the place where it will be installed, the necessary materials. It is recommended to choose a place on the site that is not obscured by the shadow of buildings and tree crowns.

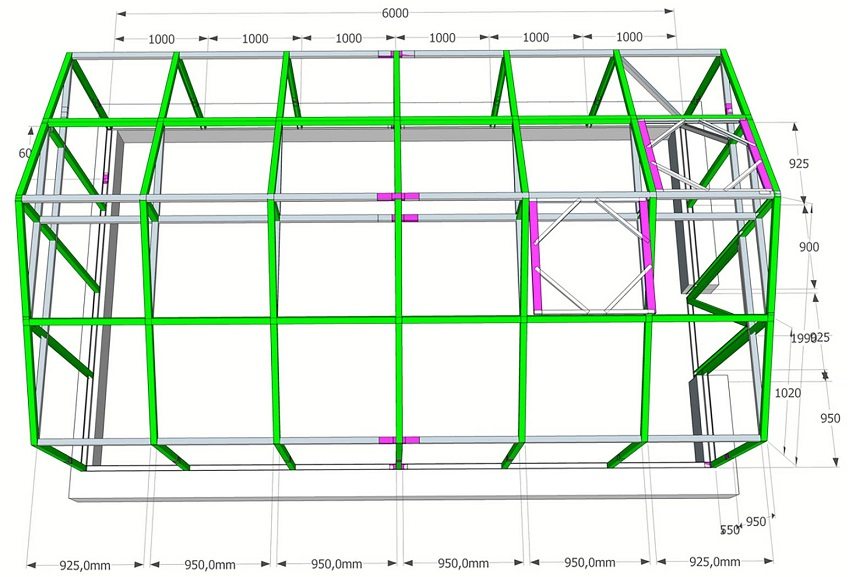

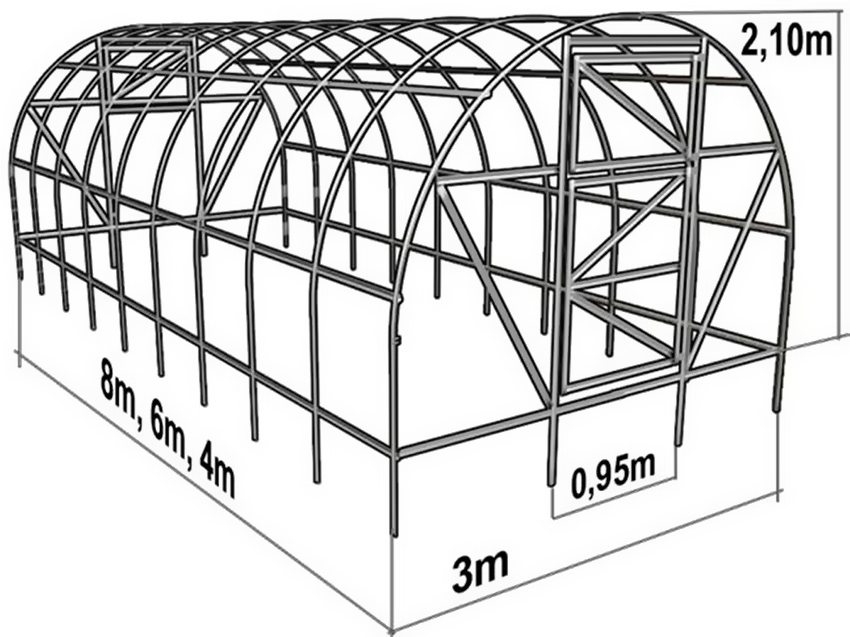

Having decided on the size and shape of the greenhouse, you should make the necessary calculations and prepare drawings.A do-it-yourself polycarbonate greenhouse from a profile (construction drawings are available on the Internet) in shape can be made in several versions:

- a structure, one of the sides of which is the wall of an existing structure - this option is used when funds for building a greenhouse are limited;

- construction with a pitched and gable roof;

- arched shape of the greenhouse - the roof of this design has the shape of an arch; in winter, snow does not linger on such a roof, which prevents possible deformation.

The video "DIY polycarbonate greenhouse" will help to mark the merits of this or that form of construction.

Having chosen the shape of the structure, they begin to develop drawings of a polycarbonate greenhouse with their own hands from a profile. They display all dimensions: height, length, width of the structure, the distance between the frame posts. The scheme provides for the presence of window and door openings, roof parameters and other necessary data.

In addition, the drawings should show the layout inside the greenhouse: the lines where the paths for moving around the greenhouse will be located, the marking of the beds and their fencing.

Do-it-yourself foundation for a greenhouse from a profile

The foundation for a greenhouse from a profile can be made in several versions: tape, brick, stone. You can also use a foundation made of timber, however, the service life of this option does not exceed five years, since the tree is prone to rotting. A wooden foundation is suitable for temporary greenhouse structures.

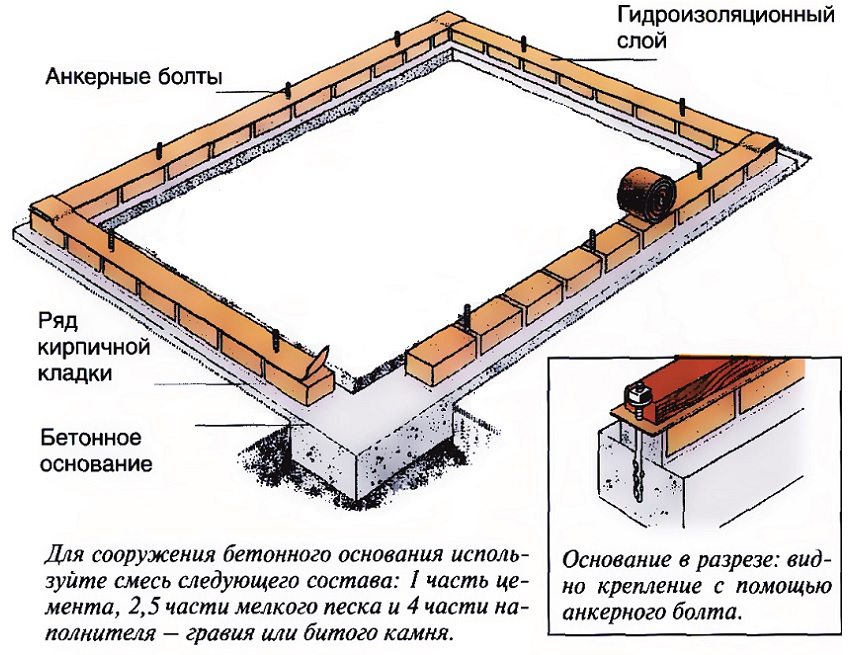

The brick foundation will last long enough, but the costs of its construction will be significant. For the construction of such a base, a waterproofing pad is made to prevent the negative effect of soils. For brickwork, a solution of cement with sand is used.

An excellent solution for a polycarbonate greenhouse is a stone foundation. Natural stone is laid with a mortar of clay and sand in a one to one ratio. Working with a stone of various shapes requires some skills, therefore, specialists can be invited to perform such a task.

A fairly common option for a greenhouse is a strip foundation. The reliability and durability of such a foundation is beyond doubt. For its device, a sand cushion is created, a plank formwork is assembled and poured with a solution to a depth of about half a meter. The width is 30-40 cm.

Useful advice! At the stage of arranging the strip foundation, you can immediately provide for the filling of fences for the beds inside the future greenhouse.

When the foundation for the greenhouse is ready, they begin to strap it. For this, as a rule, a profile pipe or a metal corner is used. The harness is attached to the foundation by means of anchor bolts. The main requirement is a high-quality coating of the metal surface of the pipes with paint to protect against corrosion.

DIY installation of a greenhouse from a profile

You can make greenhouses from a profile with your own hands using various materials. A galvanized, aluminum and plastic profile is used for the frame of structures. It is also possible to manufacture the frame structure from a wooden bar. Many people make a greenhouse frame with their own hands from a drywall profile.

The advantages of a frame made of galvanized profiles for greenhouses are the lightness of the material, ease of installation, the ability to perform work by one person and sufficient structural strength. The question of the cost of such material also remains important. The price of a galvanized profile for greenhouses varies from 75 to 190 rubles per 1 meter. (with a width of 100 mm) depending on the thickness of the metal.

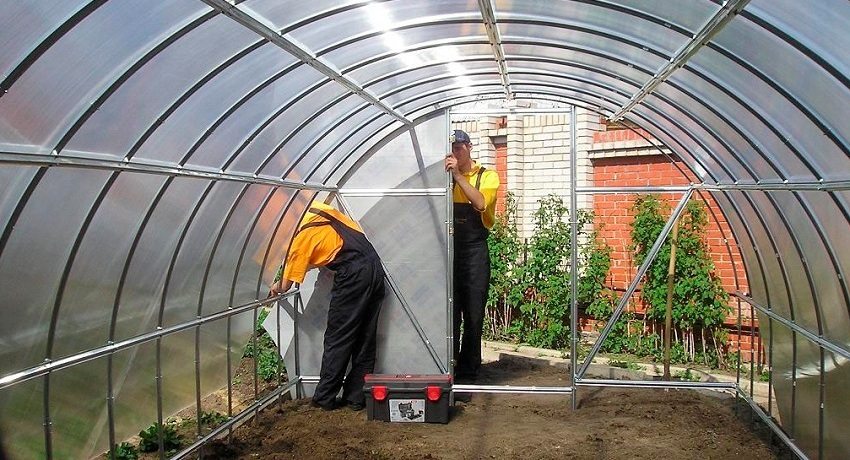

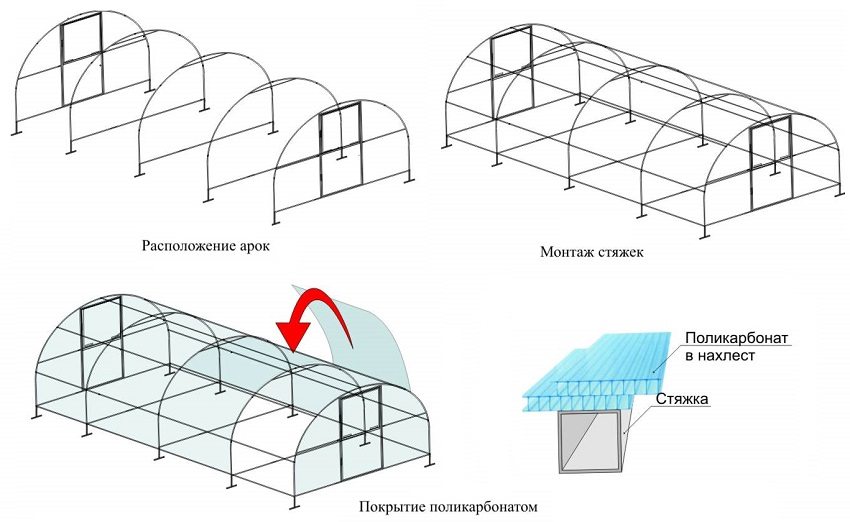

When starting to assemble the frame, you first need to make blanks of elements according to the dimensions indicated in the drawing. First of all, a profile is attached to the foundation with the help of anchors, which will serve as the base for the entire frame of the greenhouse. You can assemble the frame in different ways. But the most acceptable method is when arched structures are assembled on a horizontal surface, which are subsequently fixed to the base and horizontally tied. In the end parts of the greenhouse structure, doors and windows are equipped according to the drawings. The presence of windows and vents will provide good ventilation of the greenhouse.

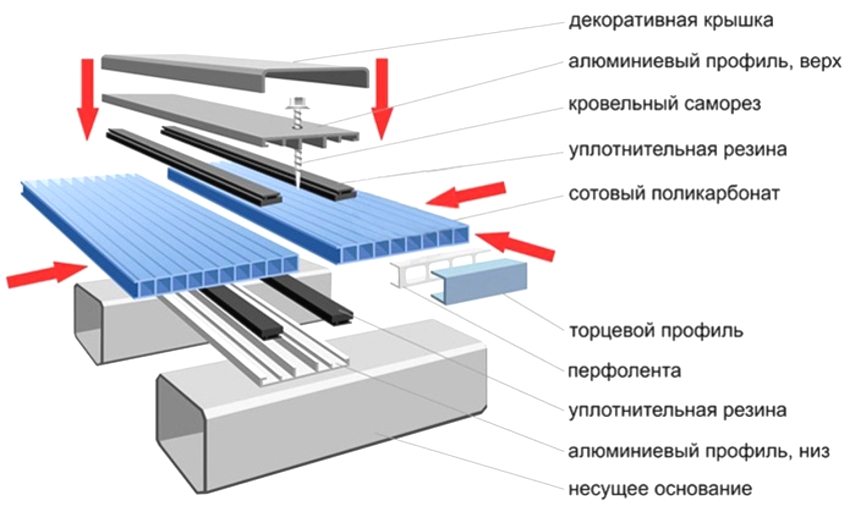

Installation of polycarbonate sheets on the greenhouse frame of an arched structure from an aluminum profile

For the construction of a greenhouse from a drywall profile, arched structures are not used. Therefore, they choose the form of a greenhouse with a gable or gable roof.

Related article:

Polycarbonate porch canopy. Photos and design features. Material properties. Types of polycarbonate. Visor design options - interesting ideas and photos. Features of installation.

The finished frame is covered with polycarbonate sheets. They start with the roof sheathing, then finish the walls. Windows and doors are sewn up last. The polycarbonate is positioned so that the channels inside the material are vertical or nearly vertical so that condensation that forms inside the plastic can flow down. The sheets are screwed to the frame using thermal washers. These washers are available in a variety of colors. The main thing is that the length of the mounting leg exceeds the thickness of the sheet and the rubber gasket of the washer.

Useful advice! The diameter of the hole in the polycarbonate sheet should be slightly larger than the diameter of the screw. This will allow the material to retain a sufficient degree of freedom to avoid deformation due to temperature extremes.

Polycarbonate sheets are stacked end-to-end. A special connecting profile is installed in the connecting lines. A video of installing a polycarbonate greenhouse with your own hands will help you to understand in detail the assembly methods.

Greenhouse heating

In early spring and autumn, when the air and soil are still cold, there is no hope for a good harvest. To grow fruits and vegetables at such a time, it is necessary to provide high-quality heating of the greenhouse.

Well-thought-out heating of the greenhouse will ensure harvesting much earlier than its ripening time in the open field

There are various ways to heat greenhouses, among which you should choose the most suitable option:

- stove heating - this option provides for the construction of a stove or barbecue. Firewood, coal and other energy sources are suitable for such heating. An important point with this heating method is the organization of good ventilation of the greenhouse. However, with such heating, the heat inside the building is distributed unevenly. An alternative is the installation of "Buleryan", the main advantage of which is significant energy savings;

- electric heating - it can be convectors, heaters, heating elements, heat guns, etc. With this heating method, the greenhouse heats up evenly, but the soil does not receive adequate heat. It is possible to warm up the air in the greenhouse evenly throughout the entire volume with the help of heat fans. The disadvantage of this method is excessive air drying. Infrared heating of greenhouses is often used. The advantage of this method is the possibility of directional heating. Considering that for infrared heating not only the air heats up, but the whole structure, this method excludes a sharp temperature drop;

- water heating - with this method, uniform heating of air and soil is possible. With all its advantages, significant disadvantages are the high cost, installation of the pipe system by professional specialists and the implementation of constant monitoring. Water is supplied to the system from a boiler and can be heated using electricity, coal or wood;

- gas heating - for heating in this way, a complex of gas burners is used, which are installed throughout the greenhouse. The operation of such a heating system provides for high-quality ventilation and air flow.

For the development of the project and installation of water heating of the greenhouse, it is better to contact the specialists

It is possible to independently establish a stable, reliable and aesthetically attractive greenhouse structure provided that the developed drawings and design diagrams are strictly followed. A properly installed greenhouse will last for many years, providing you with the maximum yield.