A garden bench should not be viewed solely as a common piece of furniture used for relaxation. This type of furniture can be a spectacular decoration for a summer cottage. A do-it-yourself bench made of wood can become a key component of the whole composition, emphasizing the beauty and benefits of landscape design in your garden or yard. At the same time, an important place is given to style, materials and the location of the future product.

Content [Hide]

- 1 DIY photo of wooden benches: drawings and recommendations

- 2 Products from scrap materials: do-it-yourself benches and benches from pallets

- 3 Do-it-yourself photo of wooden benches: creating combined products

- 4 DIY drawing of a bench made of wood and a description of the manufacturing process

- 5 Recommendations for decorating benches and benches

DIY photo of wooden benches: drawings and recommendations

Wood is the most suitable material for creating furniture items. It has beneficial properties:

- absorbs warmth;

- has a noble appearance;

- easily lends itself to any type of processing.

Note! Do-it-yourself benches or wooden benches can be created on the basis of any type of wood. The only requirement for the material is that the raw material must be well dried.

Do not take into work a tree with external defects. The exception is some products, the design of which allows the presence of cracks. Knots and burrs will have to be removed in any case.

A number of requirements are also put forward for the structures themselves:

- safety - ensured by several points: correct design calculation, selection of materials and fasteners corresponding to weight loads, careful assembly. Not least is the quality of materials and fittings;

Eco-style wooden bench located on private house terrace

- durability and durability - since these products are designed for outdoor use, the raw materials used for their manufacture should not have serious defects and damage. In addition, it is desirable that the material be resistant to the negative effects of climatic and weather fluctuations;

- ergonomics - the design you develop should be comfortable. In most cases, this type of product is created specifically for relaxation, therefore it is recommended to use drawings of structures with a back to create a bench with your own hands from wood.

Wooden bench with back and armrests in the courtyard of a country house

DIY design and photo of wooden benches and benches for a gazebo and garden

The choice of design determines the direction of all subsequent work. The design of the future product will certainly have an impact on the landscape, the design style of the space where the garden furniture will be installed. Therefore, the choice of a project should be approached thoroughly. For inspiration, you can use a photo of the benches for the gazebo with your own hands, which you can find on the Internet or on the pages of magazines on gardening and gardening.

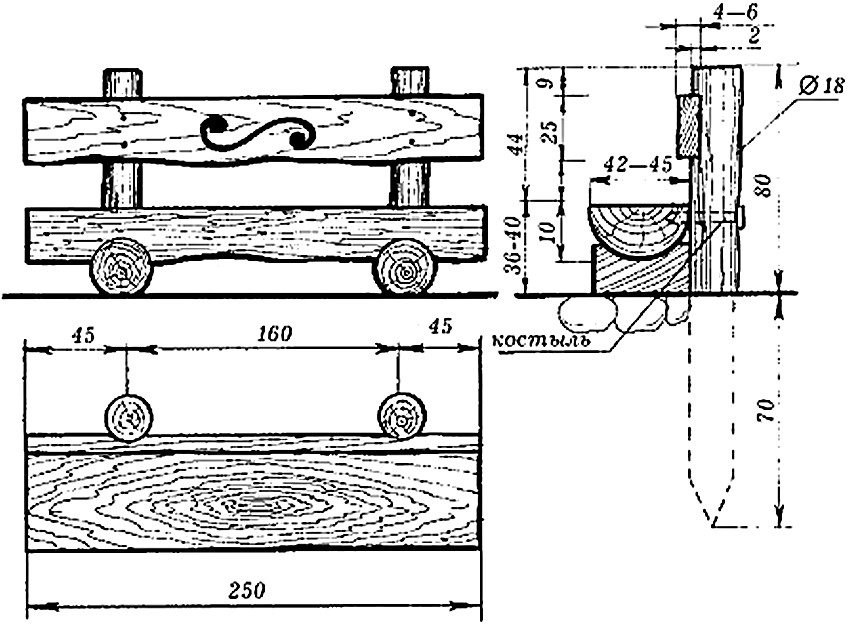

The simplest design on two supports is suitable not only for a gazebo, but also for a veranda or terrace. The supporting part is assembled from boards. All leg elements must be the same size. Boards are stacked in pairs, and each next floor of the structure should have a perpendicular arrangement with respect to the previous one. The seat can be made of timber. You choose the length, the main thing is that the structure does not bend.

Useful advice! These types of structures can be made long by adding additional supports. This allows you to install a long bench along the outside wall of the house or inside a gazebo.

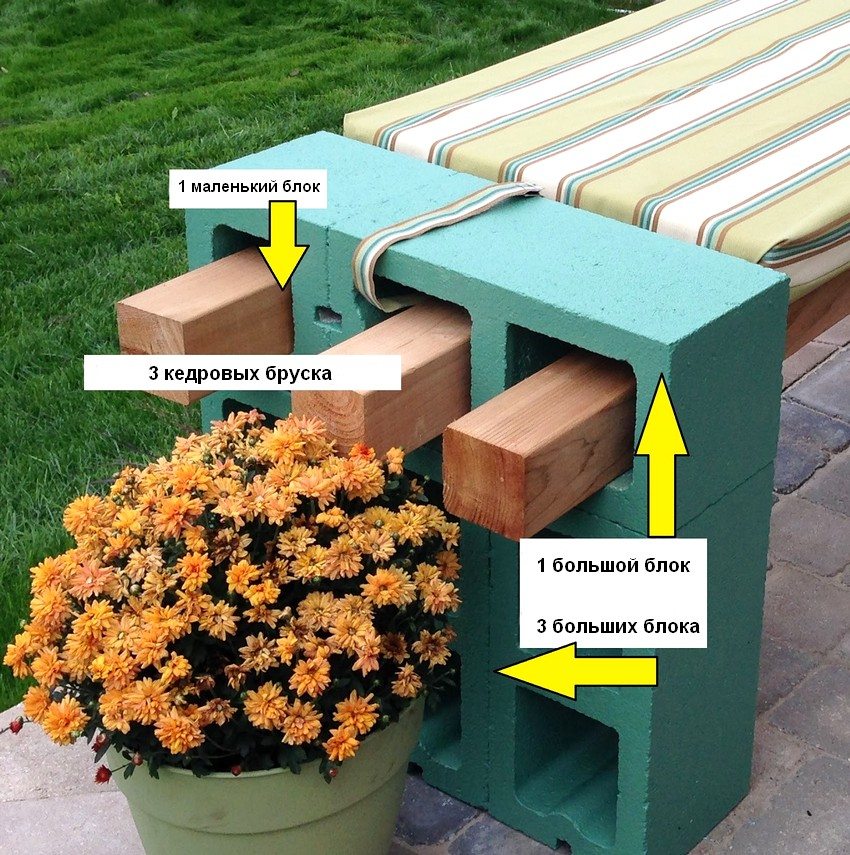

A wooden plank support can be made more durable and reliable by replacing it with a hollow building block. In this case, the seat bars will be fixed in the holes of the supports. Remember to pre-round the edges on the wood to make it more comfortable to sit.

Wooden bench is made in the same style as the rest garden furniture

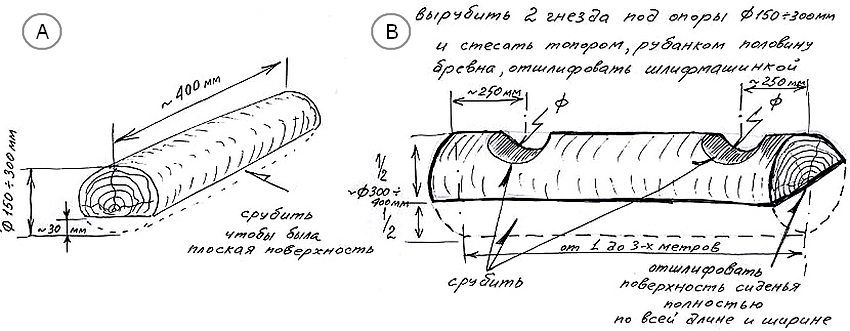

Do-it-yourself log benches and benches: photos, design solutions

Buying lumber is more expensive than using available tools. Creating a bench from a log with your own hands is the most budgetary way to organize a cozy recreation area at a summer cottage. To do this, you can use a long fallen tree trunk that takes up space in your area, as long as the wood is not too deteriorated or damaged by insects.

Prepare the necessary tools:

- grinder;

- wheels for grinderintended for cutting wood;

- ax;

- chainsaw;

- a sander or sandpaper with coarse and fine grains.

To make a bench, you need to cut 2 pieces of the same length from a tree. As a result, you will get 2 thick stumps of the same height. They will be used as supports. From the core of the remaining trunk, cut a thick and long board. It will become the seat of the future design. The width of the board should match the diameter of the supporting parts.

To secure the seat to the support, cut grooves at the top of each stump. The design will be considered correct only if board the seat will fit snugly into the grooves and will be held in them by gravity. For greater security, nails or pin connections can be used.

Useful advice! The seat board must be well sanded. Support stumps can also be freed from the bark and sanded or, on the contrary, left intact if you want to achieve a distinctive appearance.

Recommendations for making a bench from a log with your own hands

To make a bench from a felled tree, you need a chainsaw. The main material of construction will be a barrel with a large diameter. The minimum length is 1 m.

The technology for creating a product looks like this:

- markings are applied to the log with a pencil or marker so that the material is divided in two. But the cut will not be carried out in the middle, but with a slight offset to one side from the center of the log. As a result, you should get 2 parts unequal in size. The smaller one will be used to make the back, the larger one will serve as a seat;

- after cutting the log in two, the surface of the manufactured parts should be leveled at the place of the cut so that flat planes are obtained. Irregularities are carefully removed with a chainsaw;

- flip the seat piece face down. Find the highest point of the circle and mark out in the form of two lines connecting to each other. You should have a triangle with a rounded base and equal sides, the top of which is directed towards the plane of the seat. In this case, the height of the triangle should be small so that the structure does not fall apart. To put it simply, you will need to cut a kind of small “piece of cake” closer to the edge of the circle. The cut-out element must be one-piece, it will run along the entire length of the seat. This is done in order to subsequently perform a type of attachment called a dovetail;

- the resulting element should be halved in length. The back of the seat (its back) will rest on these parts, therefore, in the appropriate places, you need to make triangular cutouts that match in size and shape with the supporting elements;

- to create a strong stop, similar notches must be made in the side of the seat. The recesses on the back and seat should be mirrored. The ends of the triangular supports will be inserted here.

Useful advice! The design is rather crude. After assembly, you can modify it: give the seat and back a figured shape, grind, decorate the product with carvings.

Set the bench on legs made from thick stumps. The same groove method can be used here.

Related article:

Do-it-yourself garden swing made of wood: photos and drawings, dimensions and recommendations for manufacturing. Popular technologies for creating structures for recreation, the advantages of wooden products.

Products from scrap materials: do-it-yourself benches and benches from pallets

At first glance, it may seem that creating even the simplest bench will require a significant investment of your time and effort. In fact, almost any materials at hand can be used to equip the territory of the summer cottage. To understand this, just look at the photo of pallet benches with your own hands.

You do not need to have specialized knowledge or have skills in handling woodworking tools to create such a structure in your yard. It is enough to be patient and have 3-4 unnecessary wood pallets on hand.

The tool required for work can be found in almost every home:

- small power saw (usually used for cutting branches in the garden or leveling bushes);

- electric screwdriver;

From pallets, you can effortlessly create a beautiful and functional garden furniture

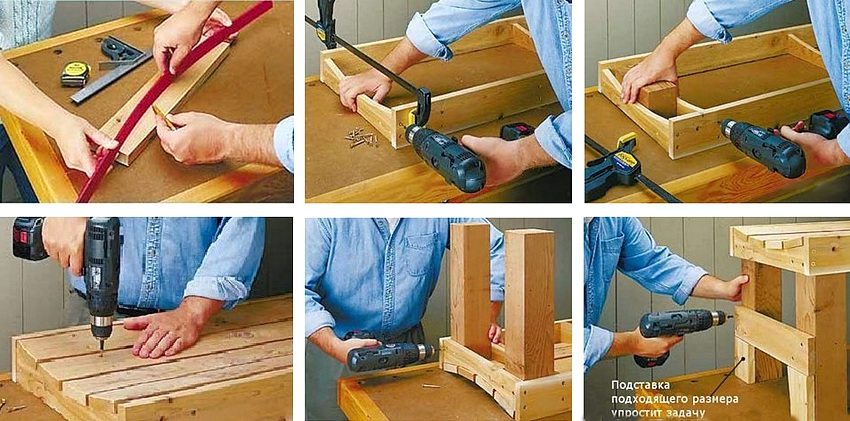

DIY wooden bench: photo and assembly of pallet structures

The design is so simple in execution that drawings are not needed to make a wooden bench from pallets with your own hands. For this, it is enough to use your imagination.

Note! Some pallets are subject to sawing in order to obtain additional elements for the assembly of the structure.

The simplest version of the product is created on the basis of two pallets, fixed to each other at right angles. As a result, the lower pallet will be a seat, and the upper one can be used as a backrest. The pallets can be trimmed slightly to make the structure more neat and harmonious. Fixation is carried out using a screwdriver and self-tapping screws.

The side area can be reinforced with additional planks that connect the backrest and seat at an angle. Use the remaining pallet trimmings after the main structure has been cut to create these parts.

Similarly, you can create a bench by removing the back from the structure and adding legs to it. Use nails or screws for these purposes.

Do-it-yourself photo of wooden benches: creating combined products

The combination of textures, colors and materials is welcome in modern design. If you are still thinking about how to make benches for your summer cottage with your own hands, be sure to use this method. As a result, you can get state-of-the-art designs with minimal effort.

If you take metal products as an example, in this case you will be dealing not only with advantages, but also with disadvantages. Such structures are durable and this is their main benefit.

disadvantages metal benches:

- high cost;

- heavy construction and bulkiness;

- the surface of the material overheats too much in the summer and becomes very cold in cloudy weather, which negates all comfort.

All these shortcomings are easily compensated for by making a combined bench with your own hands: photos of successful combinations are not limited to one or more variations. There are many effective solutions that can be easily implemented.

The use of metal to create the structural supports has a significant advantage. The legs of products, made entirely of wood, are constantly damp when in contact with the ground and grass. Mold and mildew begin to develop in them, which contributes to a decrease in the service life of the product. Metal is not afraid of such operating conditions.

Ideas for creating DIY wood and metal benches

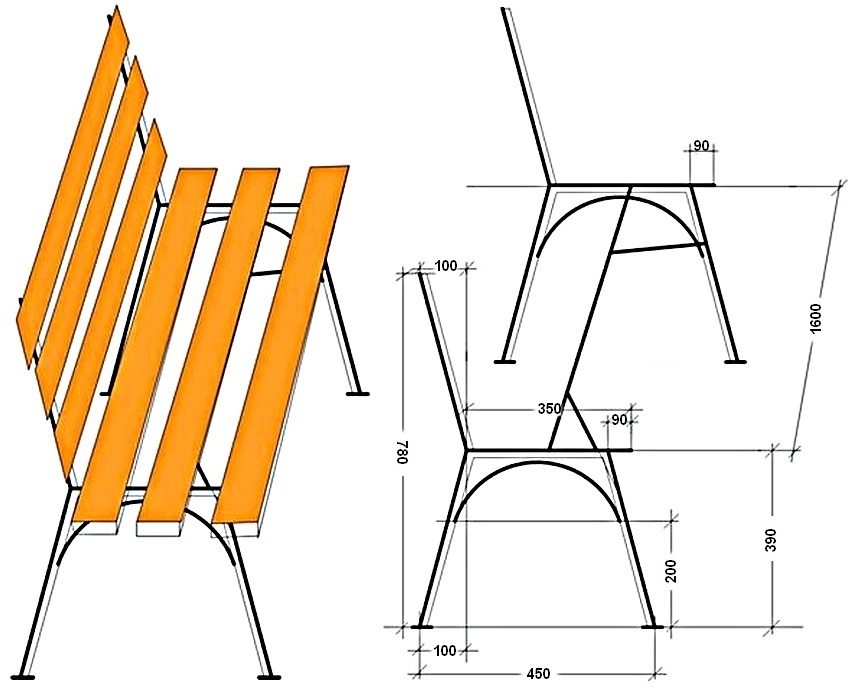

The simplest project involves the creation of a bench, where the supporting part is made of metal, and the material for the back and seat is wood. To do this, you need to weld two rectangles or squares from a profile pipe. Better if it is a square profile.

Jumpers must be welded from the inside of the rectangles. A seat made of boards will be installed on them. Fixation is carried out due to the weight of the seated people. The construction is obtained:

- reliable;

- practical;

- stylish;

- functional;

- durable.

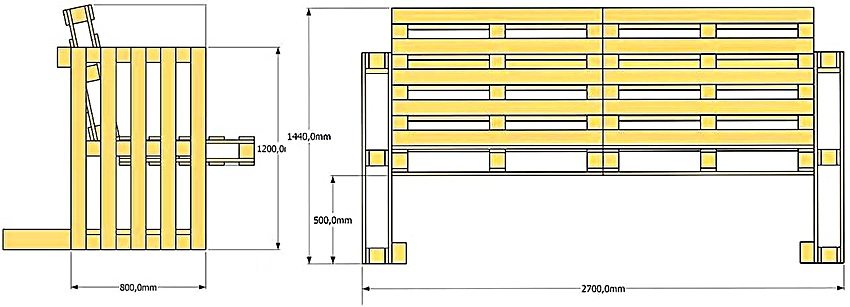

You can create a more complex structure by equipping it with a backrest and armrests. In this case, a frame base in the form of a frame with jumpers and supporting parts for fixing the seat and armrests is created from profiled square-section tubes. By increasing the width of the seat, you can create a comfortable sofa with soft cushions.

This idea can be used to organize an entire patio in the yard or on a flat roof of a cottage. Create your furniture composition, consisting of a table and two large benches or several single seats.

For the table, use a similar set of materials: a profiled pipe (frame) and wooden boards (table top). When installing wooden elements, be sure to leave a small gap (3-4 mm). Since wood is subject to deformation changes under the influence of moisture and climatic conditions, this gap is necessary in order to compensate for its expansion. Otherwise, the details of the backrest, seat and table top will warp.

DIY wooden bench on a concrete base: step by step instructions

Concrete, along with metal, has a long service life. It is completely invulnerable to weather conditions, therefore it is considered one of the most durable materials. Having dealt with the technology of creating simple benches from wood, it will not be difficult for you to make a bench from the same material, only on a concrete base.

Note! The design is very simple and does not require significant financial investments.

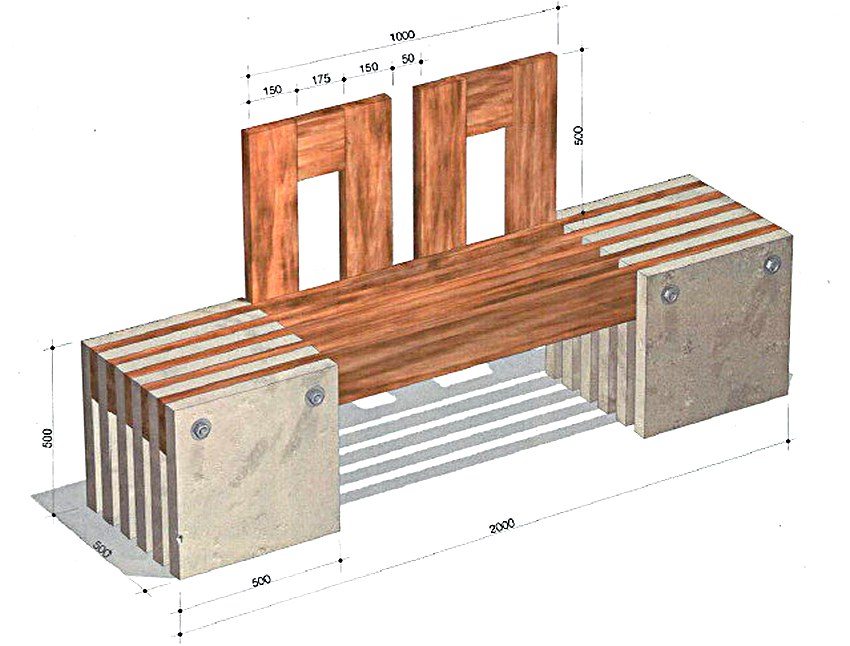

Figure: 1-1. Diagram of the device of a garden bench made of wood and concrete slabs with mounting dimensions

First, you need to prepare parts for further assembly. The wooden elements of the bench will be made on the basis of planks with a section of 15x3.8 cm. They need to be cut in a special way so that as a result you get a set of ready-made parts for assembly.

Dimension table for cutting boards:

| Wooden part length, cm | Number of parts, pcs. |

| 200 | 5 |

| 65 | 4 |

| 17,5 | 2 |

In addition, square concrete slabs will be needed to form the base:

- thickness - 5 cm;

- length - 50 cm;

- width - 50 cm.

The required number of concrete parts is 12 pcs.

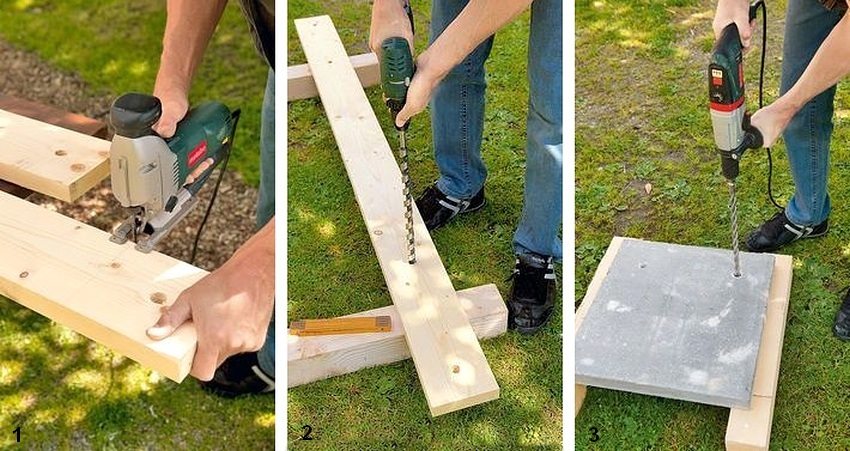

Figure: 1-2. The procedure for making a garden bench from wood and concrete slabs: 1 - preparation of wooden parts; 2 - marking the boards, drilling holes in them; 3 - marking concrete slabs, drilling holes in slabs

Planks 200 cm long should be marked for making holes. For this, two marks are put (with an indent from the end of 10 cm and 40 cm). On the other hand, a similar marking is applied. After all the boards (200 cm) have been marked with a drill with a diameter of 1.8 cm, holes are made in them at the indicated points.

Figure: 1-3. The procedure for making a garden bench from wood and concrete slabs: 4 - preparation of backrest parts for assembly; 5 - applying glue

Holes for fasteners should also be made in concrete slabs. In this case, an indent of 7.5 cm is taken from the upper edge, and 10 cm from the left and right ends. Draw the lines and find the point of their intersection. It will be considered a control marking for making holes. For this procedure, you will need a drill designed for working with concrete surfaces.

Figure: 1-4. The procedure for making a garden bench from wood and concrete slabs: 6 - collecting the back; 7 - coating of wooden parts with an antiseptic solution

Assembling a wooden bench with your own hands: the initial stage

To increase the service life, wood elements must be treated with antiseptic agents.

After the material has completely dried, you can start assembling the back:

- make marks on one of the long boards (200 cm), while stepping back from the edge of 50 cm.This is where the edge line of the concrete slabs will be placed;

- indent 15 cm from the previously made marks (50 cm), moving further towards the center of the board. This is the fixing zone for the first boards;

Figure: 1-5. The procedure for making a garden bench from wood and concrete slabs: 8 - assembly of the main part; 9 - insertion and fastening of threaded rods

- indent 17.5 cm from the fixing zone of the first boards in the same direction. This area will be located between the boards from which the back is made;

- make two more marks (15 cm each) with a gap of 5 cm (the distance between the backrest elements).

Useful advice! All the indicated markup is clearly visible on the diagram (Fig. 1-1), with this stage you should not have any special problems. Use blueprints to guide and control your actions during the construction process.

Treat the 15 cm long zones with wood glue. The previously prepared boards (65 cm) must be attached to this area. Install self-tapping screws to strengthen the strength of the fasteners. In a similar way, boards 17.5 cm long are installed in the sections corresponding to them along the length.

To ensure a good adhesion of the adhesive, clamp the pieces (17.5 cm) until the compound is completely dry. Further, the entire back should be treated with an antiseptic composition. Varnish will help to increase the level of durability of wooden parts and their decorative properties. Cover the wood with compound.

Assembly of the structure: installation of the frame part of the product

It is recommended to start assembling the frame part of the product from both sides simultaneously. This will eliminate the skew and the need to redo the work. The assembly scheme involves the alternate installation of a long board and a concrete slab. The elements are connected through the holes using 4 threaded rods M16 (two rods on each side of the bench). The required length of the fastener is 55 cm.

Use M16 washers and nuts to secure the rods. To eliminate unevenness, twisting should be carried out simultaneously on each side.

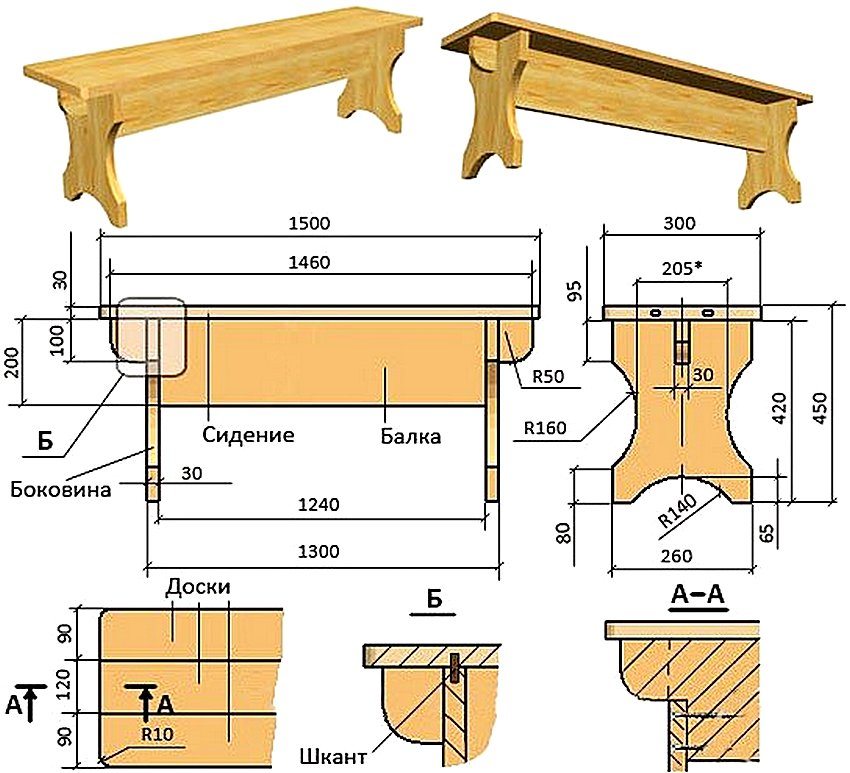

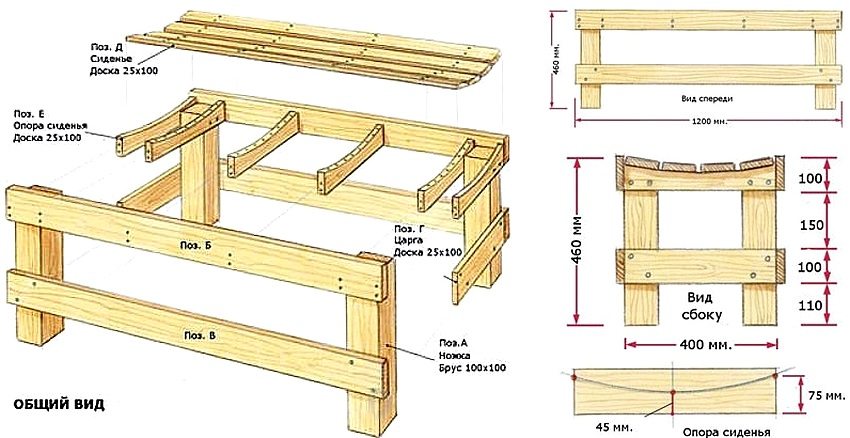

DIY drawing of a bench made of wood and a description of the manufacturing process

This project looks like an ordinary bench. The only nuance that distinguishes this bench from more primitive designs is the concave seat.

Dimensional table for the manufacture of parts according to drawings:

| Item position | Part name | Quantity, pcs. | Dimensions, cm |

| A | Support | 4 | 10x10x44 |

| B | Tsarga (front upper) | 2 | 2.5x10x120 |

| IN | Tsarga (front lower) | 2 | 2.5x10x120 |

| D | Tsarga (side lower) | 2 | 2.5x10x40 |

| D | Board (for seat) | 4 | 2.5x10x120 |

| E | Support (for seat boards) | 6 | 2.5x10x40 |

DIY wood bench: how to make the correct assembly of the seat

Before proceeding with the assembly, you should prepare all the parts for work. Saw the timber and boards to the length indicated in the table so that you get blanks.

The most difficult stage of building a bench is the formation of the support parts for the seat. It is necessary to strictly follow the recommendations for applying the markings in order to make the correct structural elements. To do this, at the edges, make two marks with an indent of 7.5 cm from the bottom of the workpiece. Mark one more point in the center, only now the marking is done with an indent of 4.5 cm.

Useful advice! For a precise and accurate cut, use a flexible plastic ruler when connecting the marking points. An electric jigsaw will help you make a controlled cut, which you then need to process with sandpaper.

Now that all the details of the structure have been prepared, you can proceed to the direct assembly. The support elements for the seat must be attached to the two side rails (upper).This must be done in such a way that one part is obtained from each edge and one more is placed in the center.

Then, with an indent from the edge (by the width of the leg), the supports are installed. During the assembly process, self-tapping screws must be used to fix the parts. On top of the resulting base, it is necessary to fix the boards that form the seat. To make it comfortable to sit on the bench without fear of injury or spoil your clothes, the caps of the screws should be drowned in the wood.

The final stage of creating a structure

Next, the legs are mounted. They are fixed to the seat supports. The drawers (lower) will help to increase the stability of the legs. These items are installed last.

At the last stage of manufacturing the structure, the product is refined and finished. Recessed screw caps can be masked with wood polish. It is necessary to choose a mixture that is suitable in shade and add small sawdust to it. This composition fills the voids that were formed after screwing the screws. The dried surface is treated with fine-grain sandpaper and then covered with a protective antiseptic and varnish.

Recommendations for decorating benches and benches

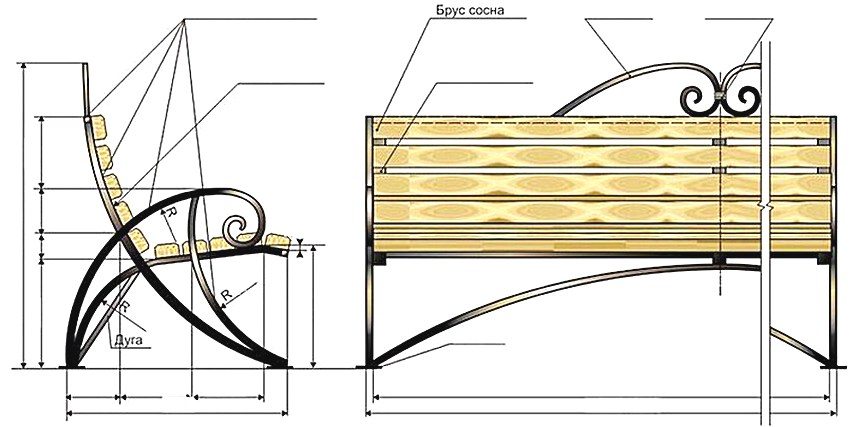

There are many interesting designs and spectacular material combinations.

Using such decorative elements will only improve the bench:

- forged patterns (decoration of metal surfaces);

- glass, pebbles and pieces of ceramic tiles (creating mosaics on concrete and wood surfaces);

- inlay with wire and decorative elements (mounted into wood by plunging);

- patterns obtained by burning;

- carved patterns.

Useful advice! If you want to give the wood a special color, use a colored varnish or pre-treat the surface with a stain.

A wooden bench painted in a cheerful yellow color harmoniously fits into the overall design of the recreation area

There are two technologies for burning patterns on wood:

- Pyrography - the main working tool is a "hot pencil". All patterns are made by hand. The exclusive backrest of the bench can be ordered individually at a furniture factory, where the patterns will be laser cut.

- Pyrotyping is a stamp application of patterns using temperature.

The easiest way to decorate a structure is to add a voluminous decor, making a single composition from corners, layouts, rosettes and bas-reliefs. Elements can be wood, metal, composite, etc. By combining different textures, you can achieve a unique design.