Parking geogrid is a new material for landscaping. The product is very popular due to the fact that it helps to carry out various landscape works. This new development is successfully used for reinforcement, prevention of soil displacement, strengthening of slopes, provides strength, reliability and long-term operation of parking areas. This article contains information about the features and varieties of products, as well as tips and recommendations for the selection and installation of structures.

Geogrid is an innovative modern material designed for arranging parking lots, paths and lawns on the site

Content [Hide]

What is a parking geogrid

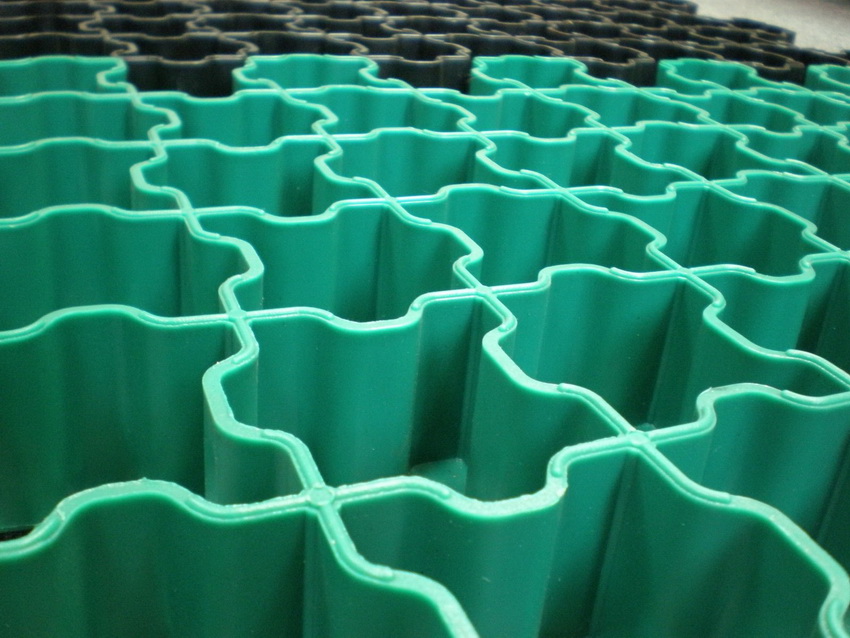

The lawn grating, the cost of which depends on the type and material of manufacture, is a construction product with a honeycomb structure. It is made of geosynthetic polymer or concrete. The size of the cells is in a wide range, which is selected depending on the area of use of the lattice. The length, width and height of the honeycomb are also different - the optimal values are selected based on the total load on the structure.

This polymer building material is used as a covering for sidewalks, parking lots, parking lots and lawns. It also works well as a reinforcing cage for unstable ground. The material is increasingly used instead of paving slabs. The lawn grating is a more economical and environmentally friendly solution.

When stretched, this product creates a stable and durable reinforcing frame, the cells of which can be filled with sand, gravel, soil or other material that is fixed and limited in movement. Using concrete mortar as a filler, you can create a monolithic platform. If you pour marble chips into the honeycomb, then the result will be a decorative path.

The main advantages of the geogrid are the following:

- increased strength of the frame due to the reliable bonding of polymer tapes in a checkerboard pattern;

- obstacle to ground shifts;

- resistance to temperature extremes, moisture and corrosion;

- providing comfortable conditions for plant growth;

- resistance to mechanical stress;

- the ability to pass moisture absorbed into the soil, which eliminates the formation of puddles;

- repetition of the distinctive features of the ground relief;

- immunity to chemical attack, molds and rodents;

- environmental friendliness of the material;

- obstacle to silting up the territory;

- ease and simplicity of installation and dismantling;

- plastic products can be recycled;

- affordable cost.

Thanks to the honeycomb structure and resistance to mechanical stress, the load is evenly distributed over the entire area of the roadway. Geogrid is able to significantly increase the strength of the car park cover.

Useful advice! Since each type of grille has a different margin of safety, it is recommended to take into account the peculiarities of parking operation when choosing.

Varieties of geogrids: design and material of manufacture

Depending on the design, the honeycomb parking tile can be flat or three-dimensional. The first design option is used for mechanical fixation of the filler, which is poured into the honeycomb. With its high strength in all directions, the flat frame is able to withstand significant dynamic and static influences. It is ideal for heavy-duty concrete parking lots.

The height of the cells is in the range of 5-30 cm. The diagonal has the same values. The size of the product is selected based on the type of filled material, which has a different structure and fractionation, and also depends on the steepness of the slope. The service life of the material is 50 years.

More demanded is the volumetric lawn grating for parking, the price of which is proportional to the size of the product. With the help of this structure, you can strengthen the slopes of hills, swamps, river banks, as well as create barriers to erosion and creeping of soil.

The volumetric geogrid can be fixed by means of various elements. Construction anchors made of steel reinforcement with a diameter of 10-14 mm and a length of 50-110 mm are often used. They are fastened in the stretched position of the product. After filling the cells with material, the anchors are removed. Thus, a lawn path for paths in the country is attached.

For surfaces with heavy soil and steep slopes, it is advisable to use polymer rope and prefabricated anchors. The structure can be attached to the soil surface using load-bearing anchors. The grating walls are connected by means of steel brackets and a stapler.

Lawn parking grill made of polymer material

Today, two types of material are used to create eco-parking: a lawn concrete grating and a plastic honeycomb structure. The second option is made of high-strength plastic in different configurations. The most popular are honeycomb and diamond-shaped cell modifications. The products are available in black and green.

The honeycomb frame has thin walls, so that the product is almost invisible in the area, which improves the aesthetics of the surface. Plastic modules can be easily divided into parts, which is convenient when arranging an area of irregular shape. The product is lightweight, so there is no need to use special equipment during its installation.

Useful advice! Plastic geogrids are not recommended for use on difficult soils, since strong mechanical stress can shorten the service life of the product.

Plastic lawn grates can be light or heavy.The first type is used for the organization of sports grounds, walking paths, golf courses, trade and exhibition centers and parking lots with infrequent traffic. Heavy plastic lawn gratings, the price of which is one and a half times higher than the previous version, are used to strengthen soils, embankments and slopes, when arranging parking lots for buses, trucks, helipads, and light aircraft.

Concrete lawn grating: product features

Such a grid is represented by a stamped concrete block. Stamping is performed by vibration pressing or casting. The dimensions of the concrete geogrid cells are 60x40x10 mm. The holes can be square or diamond-shaped. The structure is installed in the ground at a shallow depth. Drainage is laid under it, which protects the soil from excessive moisture.

The main advantages of a concrete lawn grating:

- resistance to mechanical stress;

- increased strength:

- thick walls of the product are able to withstand constant significant loads;

- long period of operation;

- a wide range of colors allows you to choose the right shade for the landscape design;

- resistance to moisture, temperature extremes and sunlight;

- the material is a good alternative to paving slabs;

- low cost in comparison with plastic counterparts.

The disadvantages include the following indicators:

- significant weight of products, which complicates installation and requires the involvement of special equipment;

- thick walls, which do not provide an opportunity to create a solid lawn, and this worsens the aesthetic appearance of the surface;

- the small size of the honeycomb, which makes it difficult to root lawn grass.

Useful advice! It is recommended to install concrete geogrids on solid soils where it is difficult to achieve full drainage of water after precipitation.

You can buy a concrete lawn lattice in a square or honeycomb shape. The first option is used to create sites with heavy traffic. Such structures can withstand loads of up to 400 tons. Honeycomb concrete gratings are used in the arrangement of bike paths, sidewalks, playgrounds and parking lots for cars.

Criteria for choosing a geogrid for parking

Before buying a geogrid for parking, you should study in detail the characteristics of the product and the appropriateness of its use for a particular case. First of all, you need to decide on the material of manufacture. When choosing a concrete lattice for parking, you do not have to worry about the strength, durability and load-bearing capacity of the structure, which can even withstand rocket carriers and tank tractors. But if a polymer product is preferred, some points should be taken into account here.

In order for the structure to meet the stated operational requirements, it must be made of 100% polyethylene. However, there are two types of material: high pressure HDPE and low pressure LDPE. The first option has good rigidity, but low ductility, especially at low temperatures. The second type is more plastic. The material reacts much less to temperature changes, so it is more preferable for lawn parking.

When choosing material for creating eco-parking, you should take into account the parameter of the carrying capacity of the lawn lattice

Some manufacturers are trying to reduce the cost of production, while making it easier to manufacture, by adding various impurities to the molding composition that degrade the quality of the material.Such lower quality products include a polypropylene grid. The material has a weak resistance to ultraviolet light, which leads to rapid aging of the product. Moreover, such gratings are very fragile, especially at low temperatures.

Related article:

DIY garden paths at low cost

Options for choosing materials and installation features of tracks for each of them. Useful tips to reduce the cost of garden paths.

The next criterion is the carrying capacity of the lawn grating for paths and parking. This indicator depends on the height and wall thickness of the product. The lattice intended for the creation of parking lots must have a height of at least 50 mm. If this value is less, then the product is suitable for a site with a low load. In this case, the wall thickness of the cells must be at least 5 mm. If lawn parking is being installed, the size of the cells should be as large as possible, as this will promote successful rooting of the grass.

Review of foreign and domestic manufacturers of lawn gratings: product prices

Today you can buy a lawn grating for parking, both foreign and domestic.

Among concrete structures, one can single out the products of the Russian North-West Road Company, which are manufactured by vibrocompression. The products are used in the arrangement of yards, sidewalks, parks, and strengthening of slopes. The size of the modules is 840x420x90 mm. The price for 1 m² of material is 450 rubles. No less famous is the Meba lawn lattice from the Melikonpolar company. The products are manufactured in the size 596x396x80 mm. Material cost - 650 rubles / m².

The Erfolg plastic lawn grating from the German company is very popular among buyers. The product has the following characteristics:

- module size - 400x600x40 mm;

- the weight of one element is 900 g;

- maximum load - 80 t / m²;

- operating temperature range - from -50 to 60 ° С;

- deformation under load - about 0.1 mm.

You can buy a lawn lattice from a German manufacturer in the range of 550-700 rubles / m².

An equally well-known German company is Funke Kunststoffe, which produces certified plastic products from recycled materials - polypropylene / hydropropylene. The modules are produced in dimensions 330x330x38 and 640x330x38 mm, they are attached to each other using the hook-eye method. Products have a green tint. The cost of a geogrid is 500 rubles / m² on average.

Lawn grating Geo Lawn is made of high pressure polyethylene. The size of the honeycomb modules is 640x395x50 mm. The construction can withstand loads up to 270 tons. Available in black and green. The price of 1 m2 of the product is 450 rubles.

The Super lawn grating from the Ukrainian manufacturer is in good demand. Products are manufactured in sizes 630x430x50 mm, made of polyethylene. Withstand a load of up to 250 tons. The cost of 1 m² is 400 rubles.

How to make parking in the country with your own hands

In an effort to create an aesthetic, convenient, reliable and durable parking in the country, you should opt for a geogrid, with the help of which the foundation for the entrance and parking of vehicles is strengthened. Using different fillers, you can create a site that will harmoniously blend with the landscape of the local area or the suburban area itself.

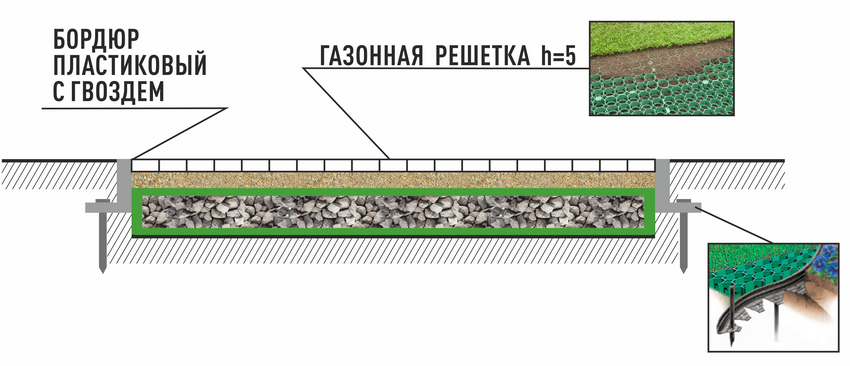

The device of the lawn grate begins with the preparation of the base. The strength and durability of the future coating will depend on the quality of this process. The substrate for the geogrid consists of several layers: sand and gravel cushions, leveling layer.Next, the grate is installed directly, the cells of which are filled with soil with lawn grass.

If the parking is intended for parking cars, the thickness of the sand cushion should be 10-20 cm, gravel - 20-30 cm, leveling base - 2-3 cm. These values vary depending on the type of soil. For hard rocks, the thickness of the base layers can be reduced, and for weak rocks, it can be increased.

Useful advice! To separate the base layers from each other, it is recommended to use a geotextile polymer material, which is capable of holding sand and soil, while allowing water and air to pass through. This material has high drainage properties.

The sequence of laying the lawn lattice: do-it-yourself eco-parking

The first stage is the implementation of the marking of the territory based on the number of vehicles that will be located on it and their dimensions. There should be a place for maneuvering, check-in and check-out. Also at this stage, the size of the lawn grate is taken into account. This is especially true for bulky products.

Next, they begin to remove the soil. The depth of the pit depends on the thickness of the underlying base and the height of the structure. The bottom of the pit should be carefully tamped. Then a sand layer is made, which is also compacted. Geotextiles are laid on top of the pillow. The next stage is the formation of a gravel layer, which is also covered with polymer geotextile. Then a leveling layer is formed. For this, sand is used. The result should be a flat, compacted area.

The features of installing a lawn grill depend on its type. Sections of the concrete lawn grating for parking are staggered to increase structural strength, and are tapped with a mallet to create a level surface. In the same way, modular polymer structures are installed, which are attached to each other using lock joints.

Volumetric gratings with their longitudinal side are fixed in the ground by means of anchors with a step of 1 m. Then the grating should be stretched to the required size and fixed with anchors. Each subsequent strip is mounted in the same way. The elements are connected with each other using latches.

Important! The lawn grating must completely cover the entire area of the future green parking lot.

Creation of lawn tiles and further maintenance of the parking lot

After laying the lawn grate, the lawn is arranged. To do this, a fertile soil mixture with fertilizer is poured into each cell in two stages. The first layer fills 2/3 of the comb height, compacted and watered abundantly with water. Then the upper layer is formed, the soil of which can be mixed in advance with the seeds of the lawn grass. Upon completion of work, the soil is watered abundantly with water.

For green parking, it is recommended to use low-growing perennial grasses that grow in a lack of light, such as red fescue, pasture ryegrass or bluegrass.

Useful advice! Do not use the parking lot until the grass cushion has formed.

Ecoparking does not need special care. As the grass grows up, you need to mow, periodically feed and water. The site must be cleared of debris and unnecessary growth. If gaps appear in the cells, add soil to them and sow grass seeds.

In order for the product to last longer, you need to purchase material that can withstand with a margin all vehicles that will be located in the parking lot.Otherwise, if individual elements are damaged due to excessive load, it will become necessary to equip the site again.

In places with high humidity, you can create an unpaved green parking. In this case, the lawn grate for parking is chosen exclusively of a volumetric type. It is immediately filled 2/3 with gravel or crushed stone. Then it is covered with a soil base mixed with grass seeds. Such parking, in comparison with lawn, is more resistant to loads. This option eliminates the formation of uneven ground.

Geogrid for parking, the price of which starts from 400 rubles / m², is an innovative material that is widely used in private housing construction. Parking for vehicles, paths or slopes, decorated with the use of such products, will become a real decoration of the garden area, which will simultaneously increase the level of comfort and make it possible to implement original design ideas.