For the construction of most complex objects from solidifying raw materials, galvanized basalt masonry mesh is used. This material is a classic reinforcing lattice that protects the building from destruction. This mesh is used not only in monolithic buildings, but also in structures made of bricks, asphalt concrete and other materials. In this article, you will learn about the features, advantages and methods of laying the lattice.

Content [Hide]

- 1 Masonry mesh: dimensions and type of building material

- 2 Basalt masonry mesh: the scope of the material

- 3 Positive characteristics of basalt mesh

- 4 Comparative characteristics of basalt and steel mesh

- 5 Basalt mesh for reinforcement: material dimensions

- 6 Reinforcement of aerated concrete using basalt masonry mesh

- 7 Brick masonry mesh: features of work

- 8 Construction basalt masonry mesh 50x50x4: price per 1 m2

- 9 Masonry basalt mesh: material features

Masonry mesh: dimensions and type of building material

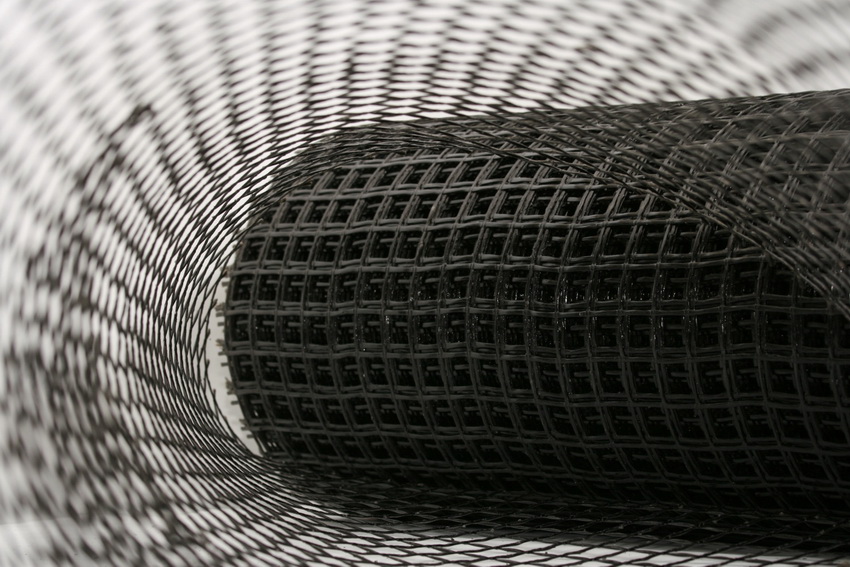

There are several types of this material. The product is classified according to the type of coating and purpose. In addition to the classic metal mesh, gratings made of polymer materials are often used, for example, composite masonry mesh.

There are such types of this product:

- galvanized metal mesh;

- monolithic fiberglass lattice;

- composite mesh;

- basalt lattice.

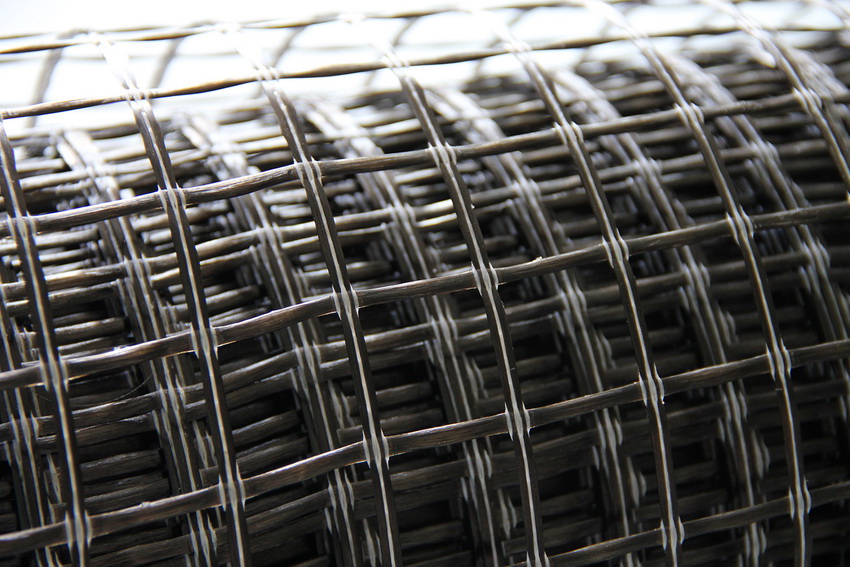

Reinforcing mesh is the most durable, therefore it is successfully used for the construction of walls and foundations made of bricks, as well as for laying walls made of aerated concrete, slag and foam blocks. In addition, this material is often used in frame structures, namely for arranging greenhouses and other outbuildings.

The metal grill has high strength. The disadvantage is susceptibility to corrosion in an aggressive environment, for example, under the influence of glue for connecting blocks. The price of the product depends on the size, coating and thickness of the rods.

The most modern material for masonry mesh is plastic. It is used to strengthen brick and reinforced concrete structures. Also, plastic masonry mesh is used for the restoration of old buildings, especially in the case when it is risky to make the structure heavier.

The advantage of the plastic grill is weight. Thanks to its low weight, this mesh is suitable for block and hollow brick structures. Among all types, this material has the lowest mechanical strength. Therefore, it cannot be used to strengthen load-bearing walls. Fiberglass mesh is suitable for reinforcing walls that do not experience serious stress.

The production of masonry mesh is carried out on an industrial scale by extrusion. The essence of the method consists in blowing or extruding plastic through small-diameter molds. After that, the material is cut into rods of the required length. Then the product is cooled and laminated.

Helpful advice! The plastic mesh is recommended for a variety of decorative screeds and plasters.

A composite lattice is made in this way: the reinforcing bars are first cut and then connected together using a welding machine. This product is very similar in structure to the reinforcement mesh, but the composite mesh is much lighter. This can reduce the load on the supporting parts of the structure.

The manufacturing method for composite gratings can vary from manufacturer to manufacturer. Therefore, many manufacturing companies offer their customers a unique product. Various equipment is used for production, with which you can adjust the quality and size of the finished product.

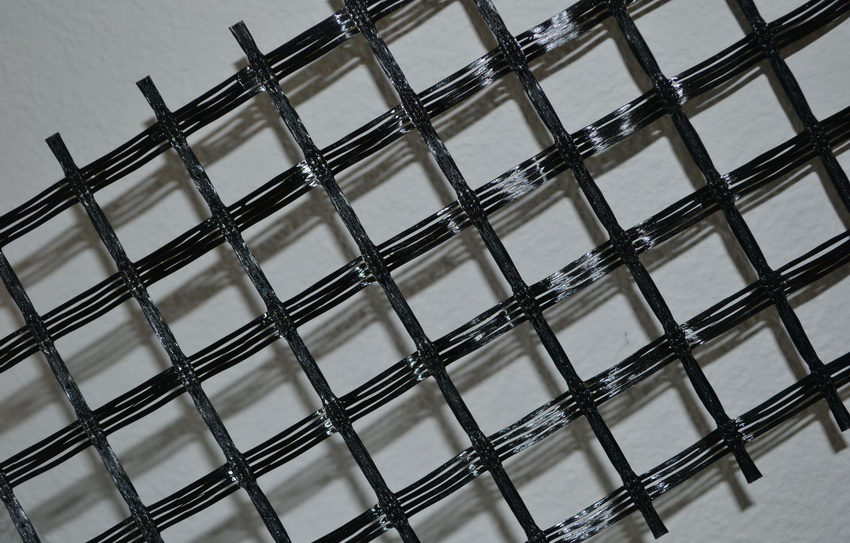

Basalt mesh is made from fibers. This material is much cheaper than masonry fiberglass mesh.

Basalt masonry mesh: the scope of the material

Currently, the basalt grating is in great demand among builders. This popularity is due to the wide range of applications of the material and many advantages: mechanical strength, weight, resistance to corrosion and aggressive environments. Most often in construction, a 50x50x3 masonry mesh with a diameter of 4 mm is used. For decoration, a material with smaller cells is used.

For the production of this reinforcing fabric, continuous basalt-based fiber is used. The uniqueness of this product is that it is impregnated with a special substance. Since basalt is a very durable raw material, the result is a material that is reliable, highly durable and capable of withstanding significant loads.

Basalt fiber mesh is especially resistant to the negative influence of such factors:

- temperature drops;

- high pressure;

- unfavorable environment.

The material is used to reinforce masonry from large bricks and stones. Basalt masonry mesh is used for expanded clay blocks, foam blocks and gas blocks, as well as for ligamentous types of work based on cement-sand mortar at all stages of construction.

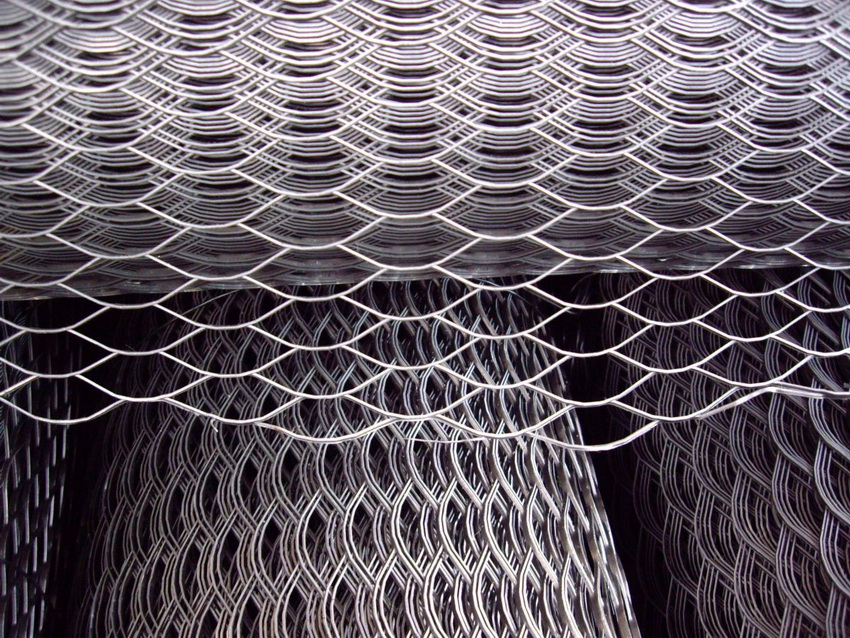

Basalt fibers are used to make meshes, rods for reinforcement, woven and roll materials. Basalt masonry grating is widely used in road construction. It is actively included in the asphalt road at airfields and dirt roads. This reduces the risk of cracking of the roadway and asphalt pavements, and also significantly extends their service life, even under heavy loads.

Positive characteristics of basalt mesh

It is worth noting the advantages of masonry basalt mesh:

- reduces the appearance of cracks on the surface, and also produces a strengthening effect;

- provides resistance to moisture, corrosion, sudden temperature changes;

- basalt rods have a long service life;

- material is resistant to aggressive environment;

- wide scope of use;

- can be used for stone buildings;

- protects concrete structures from cracking.

Reinforcing mesh protects the masonry from destruction and cracks, and also ensures the stability of the building

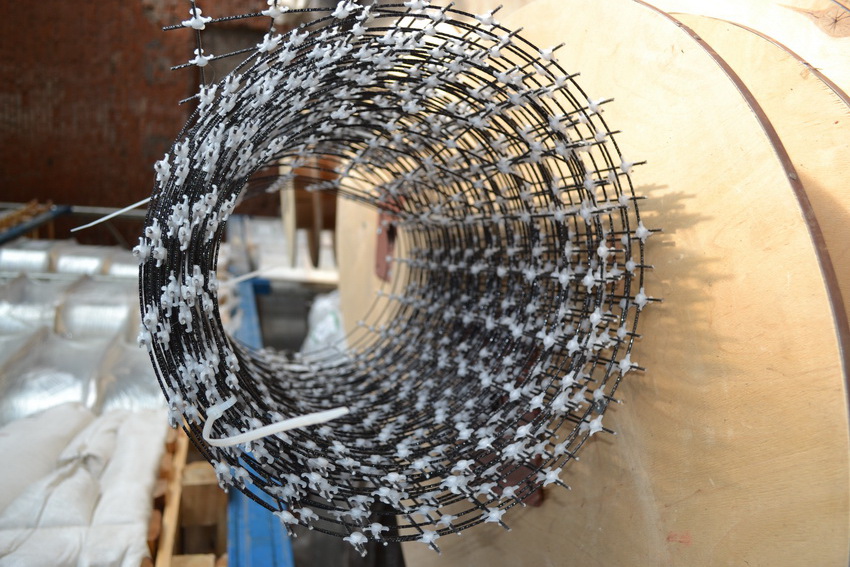

Basalt mesh appeared as an excellent replacement for steel reinforcing structures.In the places of welding, the metal oxidizes and after a while begins to rust, which means that it quickly collapses under the action of corrosion, and defects and cracks appear on the walls. The basalt fiber grid does not oxidize.

Basalt masonry mesh 50x50x4 weighs significantly less than metal of the same size. Due to the large mass of the steel grating, installation difficulties arise, and the sharp iron rods require special care when working with them.

Due to the elasticity of the basalt mesh, it became possible to reinforce structures of any complexity. It is almost impossible to get injured on this material. And the weight does not create problems with transportation and does not load the overall structure of the building.

A significant advantage of this product is its low cost. Therefore, it will not be difficult to buy a masonry basalt mesh even in small quantities.

Helpful advice! Any block buildings require reinforcement, since the building shrinks in the second or third month after the work is completed. Reinforcement with basalt mesh will increase the load-bearing capacity of the walls, as well as prevent cracking.

Comparative characteristics of basalt and steel mesh

If we carry out a comparative analysis of different types of masonry mesh, then, as a result, we can come to the conclusion that the basalt material is superior in its qualities to the metal mesh, as well as products made of fiberglass polymer.

- basalt material has low heat conductivity. Steel mesh, on the other hand, has a high thermal conductivity, 100 times higher than that of basalt. Because of this, cold bridges are formed inside the walls, which cause a number of problems associated with the operation and leading to the fragility of the building. The minimum thermal conductivity for basalt gratings is only 0.44 W per sq. m;

- basalt fiber rods are distinguished by better elongation and ability to withstand a high breaking load (50 kN / m) than a lattice made of steel elements of the same diameter. The 100x100 masonry mesh has the highest tension in the longitudinal and transverse directions;

- the weight of a masonry mesh 100x100x4 1 m2 made of steel is about 2 kg, and the weight of a masonry mesh made of basalt is 300 grams;

- basalt grating, unlike steel grating, is resistant to most aggressive solutions used during construction. Such a mesh does not collapse under their influence and does not rust;

- basalt fiber material is much better able to withstand a large number of prolonged temperature drops, and the metal grate begins to deteriorate from a couple of dozen temperature jumps;

- the basalt fiber reinforcing material can be easily and evenly laid on the wall, and also quite simply cut with ordinary scissors. The mesh unfolds and folds without problems. This reduces the likelihood of injury during construction, and it is much easier and more convenient to work with such material;

Reinforcement of masonry gives strength to the walls and allows you to combine different types of material

- the cost of basalt masonry grating is lower than the price of a metal product;

- Basalt mesh is much wider than steel mesh. They can be used for walls made of stone, brick and foam blocks. Also, basalt products perfectly reinforce walls, preventing cracks;

- As a result of the research, it became known that the reinforcement made with the help of basalt masonry lattice is much stronger than after reinforcement with other materials.

Related article:

Why do you need a grid for facade walls?

Why is it necessary to use a grid for plastering the walls of the facade, its main types, principles of choice, areas of application, methods of plastering, application options, advice.

As for the mesh made of plastic polymer, it is not used for masonry and walls with high loads. The strength of the basalt grating makes it possible to use the material to strengthen the road surface. Fiberglass rods can only be interconnected using a special sleeve. In addition, if necessary, only the basalt mesh can be bent in the desired direction if the masonry requires it.

Basalt mesh for reinforcement: material dimensions

The quality of metal gratings for strengthening concrete and building materials based on it must comply with GOST RF 23279-85. This standard only applies to steel bar welded products. Fiberglass and basalt masonry nets are not subject to GOST. Their technical characteristics are regulated by STO 294248809.

According to these documents, the masonry mesh has the following dimensions: 75x25, 75x25, 25x25, 25x12.5, 16x16, 10x10. The diameter of the reinforcement materials ranges from 3 to 6 mm.

The dimensions and dimensions of the masonry grate depend on the type of product:

- For filling a smooth wall, a masonry basalt mesh in rolls with a width of 1 meter is used.

- To give additional strength and rigidity to the corners of any type, as well as the seams, serpyanka is used. This material is produced in spools with a width of 4.5 to 20 cm.

The strength of the mesh depends on the size of the mesh: the smaller it is, the stronger the material. Therefore, the stretching of the 50x50x4 masonry mesh is less than that of the canvas, which has parameters 100x100x4.

Manufacturers provide the buyer with a wide selection of canvas in various sizes. The most popular are the following dimensions of the masonry mesh: 50x50, 100x100. Also on sale there is a basalt material with dimensions 152x150x4. What size mesh to choose for strengthening - this decision depends on the main masonry material and the number of floors in the building.

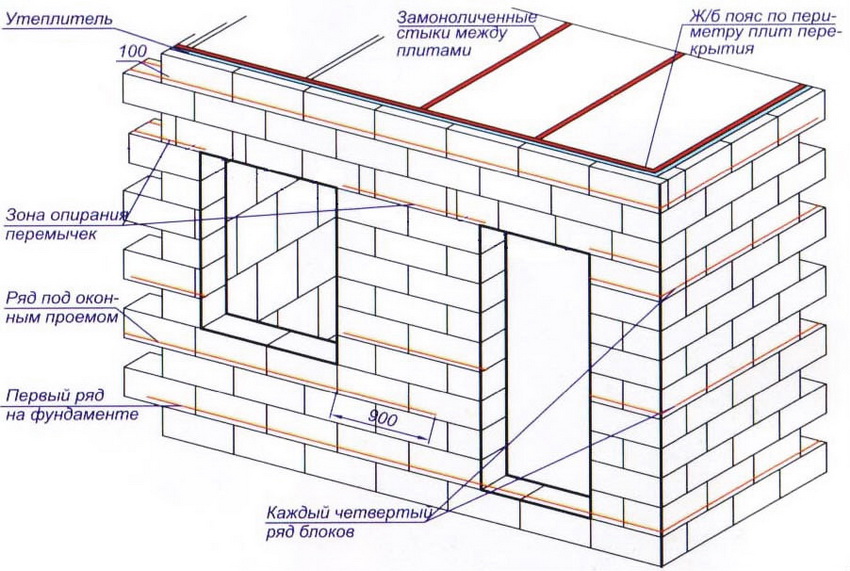

Reinforcement of aerated concrete using basalt masonry mesh

The use of masonry mesh in the construction of buildings made of aerated concrete can increase the strength of the structure and prevent cracking of the walls after shrinkage of the blocks.

Shrinkage of gas blocks occurs within 2-3 months after the construction of the house due to exposure to temperature changes and drying of materials. This process is accompanied by serious loads, which will help to eliminate high-quality basalt mesh.

It is important to determine the optimal pitch of the lattice. It directly depends on the technology of building the wall. Experienced craftsmen advise laying the mesh through 3-4 rows of the gas block.

In the case of reinforcing rows of aerated concrete blocks with simultaneous laying of facing bricks, it is recommended to lay the basalt product through three rows. This solution is also suitable for strengthening walls from two aerated blocks, and for reinforcing walls from one row of blocks, the step can be increased to 4 rows.

The step depends on the strength class of the aerated concrete blocks. For material of class B2.0 and below, the mesh must be laid more often, for class 2.5 and above - less often. Laying should start from the zero row, that is, immediately from the base.

Helpful advice! Shrinkage is typical not only for aerated concrete blocks, but also for walls made of expanded clay blocks and cinder blocks.

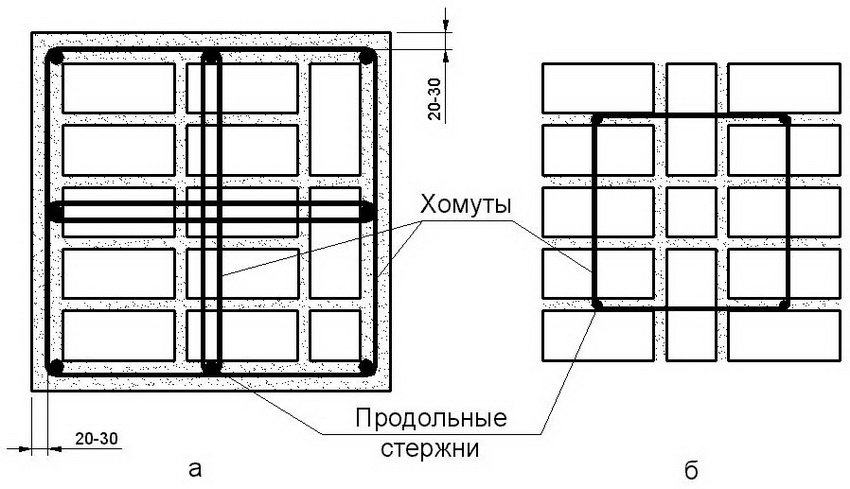

Brick masonry mesh: features of work

Basalt grating for facing bricks is laid in three ways:

- perpendicular;

- parallel;

- longitudinal.

Usually, a reinforcing mesh for brickwork is installed in a transverse way.Although this method somewhat increases the time required to complete the reinforcement works and the financial costs of construction, it is fully justified. Such a wall after reinforcement becomes 50% stronger in terms of support functions.

The size of the cells and the thickness of the mesh depends on the size of the planned load on the wall.

Depending on the planned loads, it is important to choose the appropriate type of product, and then the following manipulations should be performed:

- The mesh must be planted with an adhesive solution on the formed row of bricks.

- The material is covered with a layer of masonry mortar so that the grating is completely underneath.

- Bricks are being laid, while it is necessary to constantly monitor the immersion of the mesh in the mortar according to the level.

Helpful advice! For each type of bricks, there is a special technology for laying basalt mesh for strengthening. For example, for sand-lime bricks, you need to lay a grid in every fifth row, for a double - in every fourth, and for ceramic - in every third.

Longitudinal reinforcement of masonry: a - external arrangement of rods, b - internal arrangement of rods

Construction basalt masonry mesh 50x50x4: price per 1 m2

Basalt masonry mesh is a versatile modern material that is confidently replacing the classic reinforcing mesh from the market. This product is capable of withstanding significant loads, and its weight is much less than the mass of a metal grill of the same size. In addition, basalt material is versatile, which means that it is suitable for reinforcing walls built of any material.

It is profitable to buy a basalt mesh, since the material is not only reliable, but also cheaper than a metal mesh by more than 30%. The cost of the masonry mesh is formed depending on the thickness of the rods and the cell parameters. Also, the price depends on the manufacturer. It is cheaper to buy a basalt masonry mesh, the cost of which varies from 70 to 150 rubles / sq. m. The price of basalt masonry 25x25 starts at 90 rubles / sq. m, but usually stores sell this material immediately in rolls of 0.37 / 0.63 / 1/2 / 4x50 m. Many sellers practice price reductions for wholesale buyers.

64-90 rubles / sq. m. - the approximate price of a masonry mesh is 50x50x3, the weight of 1 m2 does not exceed 300 grams, the strength of the model is 50 kN / m. The size of such a product is 4x50 m. The price per m2 of 50x50x4 masonry mesh with a strength of 100 kN / m is in the range from 120 to 160 rubles. per sq. m. Basalt material for reinforcement with a thickness of 5 mm will cost 190 rubles. per sq. m.

Basalt mesh with cells of 50x50x4 mm is the most common material for reinforcing masonry from various materials

The cost of a mesh with a cell 100x100, having a rod thickness of 3 mm and a strength of 50 kN / m, averages 70-90 rubles. per sq. m.

The price of a 100x100x4 masonry mesh with a strength of 100 kN / m starts from 125-140 rubles / sq. m. For comparison, a metal masonry mesh 100x100x4 has a price several times higher - about 200 rubles. per sq. m. Material for sale in rolls 1/2 / 4x50 m.

Masonry basalt mesh: material features

The smaller the cells in the basalt masonry lattice, the stronger the reinforcing belt will be. But such a buying principle is not always profitable, because small material is more expensive. Therefore, at the design stage of the building, the bearing load of the structure is calculated and the required strength of the reinforcement is calculated. In accordance with the results obtained, the type of mesh is determined.

Recently, the difference between prices for a mesh with cells of different sizes is not very large, so the choice of a basalt masonry mesh 100x100x4 is unlikely to help save money.

Each individual piece of mesh must be docked. This is best done with an overlap of at least 3-5 cells.It is important to ensure that the mesh does not deform during installation, as this can reduce the load-bearing capacity of the building.

Reinforcement is an important and irreplaceable stage during the construction of any building, so you cannot save on it. Basalt masonry mesh is the best option for this task, since this material has many advantages, including low price and good quality.