The fashion for building sustainable housing has predictably returned the popularity of wooden houses to their former popularity. This natural material has undeniable advantages: it is economical, durable, aesthetic, has a low thermal conductivity and allows you to create a very special microclimate in the room. However, mold, mildew and moisture can negate all of these benefits. A way out of the situation will be a vapor barrier for the walls of a wooden house.

Content [Hide]

Why do you need a vapor barrier for the walls of a wooden house

One of the distinguishing features of the tree is its ability to "breathe". In simple wooden houses built in the old fashioned way, this was enough to ensure sufficient circulation of steam between the interior and the street.

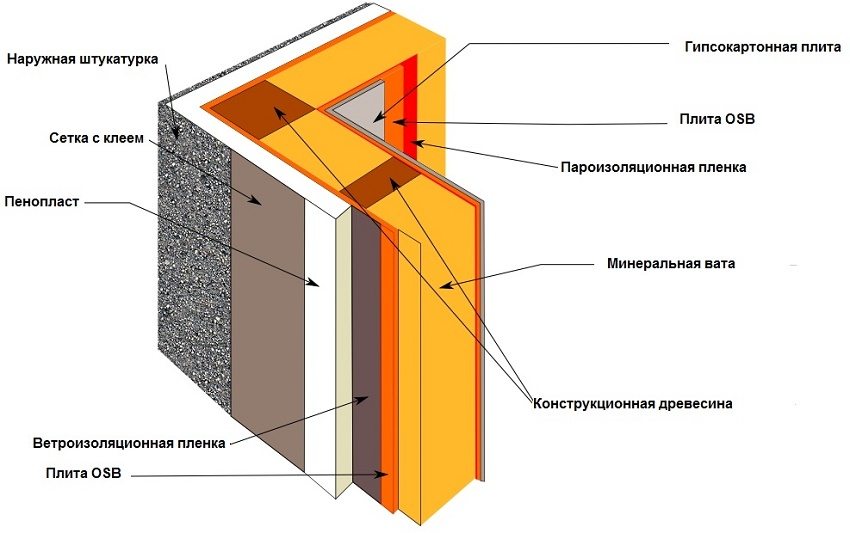

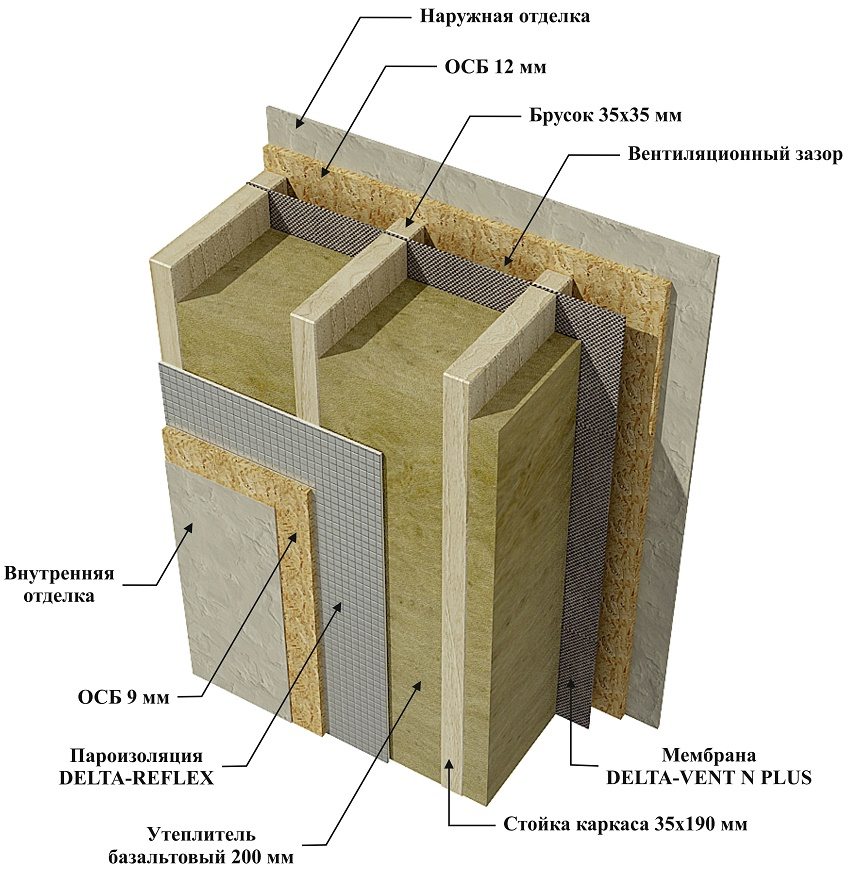

In modern houses, an important role is played not only by environmental friendliness, cost and beauty, but also by compliance with energy saving standards. Because of this, an ordinary wooden wall has turned, in fact, into a multi-layer cake made of timber, insulation, waterproofing materials and finishing.

This layering prevents free steam circulation. As a result, it accumulates in the insulation, deforming it and reducing the thermal insulation characteristics, and condensate gradually destroys the tree, provoking the formation of mold and mildew, changing the shape of the logs, provoking the development of cracks and breaking the tightness of the joints. Thus, it became necessary to add another layer to the wall cake - layer vapor barrier.

However, even in modern wooden house vapor barrier is not always required. A carriage, semi-carriage, chopped with an ax or hand-sawn timber due to its inherent natural high humidity can dry for many years, not allowing you to go to interior work. In this case, the installation of a vapor barrier makes it possible to significantly save construction time, protecting the material from decay and fungus, and the insulation from the accumulation of moisture.

Useful advice! Glued or rounded timber loses most of the moisture even at the production stage, standard factory dimensions and grooves allow you to achieve significant tightness when installing walls, which allows you not to use vapor barrier.

It is also worth paying attention to the material used as insulation. For example, mineral wool, one of the most common thermal insulation materials, absorbing moisture, gradually begins to settle, deforms, and its protective properties decrease. This implies the mandatory use of a vapor barrier layer. Unlike mineral wool, the foam is laid in such a way that the joints become airtight, and the vapor barrier material itself is completely impervious to moisture.

The main types of materials used for the vapor barrier of a wooden house

The choice of material for vapor barrier walls depends on many factors: on how the house is planned to be insulated - outside or inside, on the condition of the building, on financial capabilities, on the type of insulation.

Reinforced film has a high density

The most democratic type of vapor barrier is a polyethylene (better reinforced) film. It is affordable, but not strong or durable. Its main disadvantage is complete air and moisture resistance, which leads to the accumulation of moisture on the surface and significantly reduces its vapor barrier properties.

Useful advice! Polypropylene film is free from some of the disadvantages inherent in polyethylene film. It is stronger and contains cellulose fibers that prevent condensation.

Laminated plastic foil with aluminum coating or aluminum foil (more than 0.02 mm thick) not only provides vapor barrier, but also reflects heat into the house, ensuring optimal energy savings.

Related article:

Insulation for the walls of the house outside for siding: choose the material and method of installation... The choice of the type of insulation. Features of materials, their advantages and disadvantages. The main stages of installation.

Foil-clad polymers (foamed polyprofen and penofol) and fiberglass combine the vapor and heat insulation characteristics.

For the vapor barrier of the walls of a wooden house outside, roofing material is also often used, and the choice is to be made of bituminous, with a double-sided coating.

The diffusion membrane has excellent performance characteristics. This breathable durable material can have several layers, it is one-sided and two-sided and additionally provides hydro and thermal insulation. Its disadvantages include the high cost. In addition, it is not suitable for vapor barrier exterior walls.

Important! Vapor barrier should not be confused with waterproofing. Waterproofing prevents water from entering, while vapor barrier prevents condensation from forming and promotes normal air circulation.

Recently, vapor barrier for the walls of wooden houses is gaining popularity isospan - high-quality vapor-permeable membranes and films with different strength and density. Simple and clear instructions contained in the instructions for the use of isostan vapor barrier make it easy to install them even for an inexperienced builder.

Features of installation of vapor barrier for the walls of a wooden house

Vapor barrier is an important stage in house insulation work. The technology of its installation depends on whether it is an external or internal insulation of the house, which, in turn, depends on the state of the building, the type of logs, etc. So, if it is necessary to insulate an old wooden house and improve its appearance, the insulation is mounted outside. If the house is new or the stage of external finishing is completed, the house is insulated from the inside.

Vapor barrier complements the properties of the insulation and extends the service life of the entire structure

Installation of vapor barrier for external insulation of a wooden house

When laying the vapor barrier on the outer wall of a house made of round logs, you can leave no ventilation gaps.Their role is to fill the voids at the junction of the logs themselves. If the house is erected from a smooth square or rectangular bar, then it is impossible to lay the vapor barrier layer directly on the tree. This will disrupt the steam circulation. On the logs, it is necessary to fill rails with a thickness of 2.5 cm in increments of 1 m. And only after that you can lay the vapor barrier material, fixing it with a construction stapler.

Then the lathing is installed, on which the thermal insulation is laid, the waterproofing film is pulled on top, and finally, they move on to the external finishing.

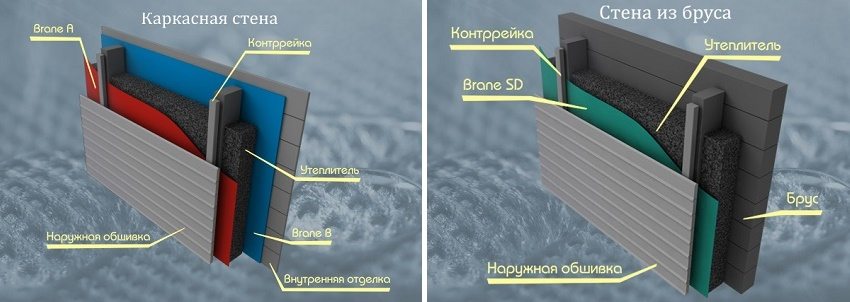

This option allows you to maintain a special indoor climate due to the fact that the tree inside the house is not hidden under the decoration. It is suitable not only for log cabins but also for frame houses, differs in sufficient simplicity, which allows you to carry out vapor barrier of walls outside a wooden house with your own hands.

However, there are also certain disadvantages. The wood must dry completely, which can take more than one year. Therefore, this option is not very suitable for new buildings. In addition, the joints must be treated with a sealant, the grooves must be drilled on both sides, and only hydrophobized materials can be used as insulation. The service life of such a structure does not differ in durability.

Installation of vapor barrier for internal insulation of a wooden house

There is also a way to install a vapor barrier for the walls of a wooden house from the inside. For this, the walls are thoroughly cleaned and treated with an antiseptic compound. A crate of slats is installed on top. Insulation is laid between the slats, and a vapor barrier layer is mounted on top of it. It is attached with staples or nails with wide heads.

If a diffusion membrane is used as a vapor barrier, it is laid directly on the insulation. Otherwise, it is necessary to leave a distance of about 5 cm between the thermal insulation and the vapor barrier. The film must be well stretched, otherwise its protective properties will decrease. The cladding is attached to the vapor barrier, and the finishing interior is already applied to it. The distance between the sheathing and the film should not be less than 3 cm, otherwise free circulation will be impaired, and moisture accumulated on the film will not evaporate.

General rules for arranging vapor barrier for the walls of a wooden house

There are several general rules that allow you to correctly select the required material and carry out its installation.

To prevent moisture ingress, the film is fixed with an overlap of at least 2 cm. It can be laid in several layers, but the total vapor barrier layer should not exceed 4 mm. The joints must be sealed with a special self-adhesive tape. If foil was used for vapor barrier, metallized tape is used.

It is also very important to figure out which side to lay the vapor barrier on. In other words, determine which side of the vapor barrier for the walls of a wooden house is internal and which is external. For example, the film must be laid with the lighter side to the insulation. Likewise, the smooth side of the vapor barrier always fits into the insulation, and the fleecy side outwards. The shiny side of the vapor barrier, which includes a layer of aluminum, is always laid inside. When insulating external walls, the smooth side of the material should be adjacent to the wall, and the rough side should always face the street.

Thus, we found out how important it is to prevent the formation of mildew, mold and excessive moisture in a wooden house.Vapor barrier for walls, subject to proper arrangement, will not only extend the service life of the building, but also will not spoil its aesthetic appearance.