The bathhouse is a primordially Russian structure, rooted far in history. This is a special place where not only the washing of the body takes place, but also the cleansing of the soul. The construction of a bath is a laborious activity consisting of a number of stages performed in a certain sequence, which is the key to obtaining a reliable and warm structure. All the intricacies of building a building can be found in this article.

Content [Hide]

- 1 How to choose the right place for building a bath

- 2 Do-it-yourself design and internal layout of the bathhouse

- 3 What material to build a bath with your own hands

- 4 Bath construction: choosing a foundation for the construction

- 5 Do-it-yourself steam room construction: step by step instructions

- 6 How to build a bath yourself: interior decoration

- 7 Organization of water supply and sewerage during the construction of wooden baths

- 8 Which stove to choose for a bath: types of designs

- 9 How to build a bathhouse: video instructions for erecting a structure from a log house

How to choose the right place for building a bath

The choice of a place for construction precedes the construction of any building on the site. The rules for placing a bath are strictly regulated by the requirements of current regulations, which indicate the distance from the building to other buildings both on its own territory and in relation to neighboring areas. Compliance with the latter condition will eliminate the occurrence of claims from neighbors in the event that they experience some kind of discomfort. How much to retreat from the neighbors' fence during the construction of a bath? The standard value is 1-3 m.

The first step is whether you need a permit to build a bath. If the building is located in a summer cottage and will be used for personal purposes, the document for it need not be drawn up.

First, it is worth deciding how the bath will be located relative to the house. It can be a separate structure or be attached to the house, being under the same roof with it.

Useful advice! If there is no desire to engage in the construction of the structure with your own hands, you can order the construction of a turnkey bath. The price will primarily depend on the size and type of building.

It is better to erect a free-standing bath in an elevated area, which will contribute to the formation of a spontaneous flow of waste water during its operation. It should be located as far away from other buildings as possible. This approach will make it possible to secure buildings in the event of a fire. It is best to place it in a backyard where the building will be in relative seclusion.

A good solution would be to choose an area near a natural or artificial reservoir. However, it should be borne in mind that it is necessary to exclude the possibility of flooding the site during spring or autumn floods. Therefore, the distance to the source should be at least 20 m.

Useful advice! The entrance to the bathhouse should be located on the south side, which will exclude the accumulation of a large amount of snow near it, and the windows - from the south-west, as this will provide natural illumination of the room with the sun's rays before sunset.

Do-it-yourself design and internal layout of the bathhouse

After choosing a place for construction, a bath project is created, where the features of the structural design of the structure, its dimensions, internal layout, communication equipment are determined, the material for the construction is selected. The estimated cost of work is also calculated here. The bath construction project can be completed independently, which will significantly save money, or you can use the services of specialists.

There are various types of structures. The answer to the question of how much it costs to build a bathhouse will depend on this criterion. A full-fledged building is represented by a free-standing structure, which has a steam room, a washing room and a recreation area. Such a bath can be one- or two-story, it can have additional rooms, where they often equip a billiard room or a bedroom.

The bathhouse can be built-in, located under the same roof with the house. This option will save space on the site. The recreation room can be combined with the living room, and the sink is often used as a full bathroom. With this solution, it is enough to allocate space inside the house for a steam room.

The bathhouse can be attached to the house, having one common wall with it. This option requires a permit to build a bath. The budget solution will be the arrangement of a bath-trailer. The structure can be installed directly on the ground or located on a low-power foundation. In such a compact structure, only a steam room and a washing room are located, there is no rest room.

When determining the dimensions of the future structure, it is worth being guided by the size of the free area and the recommendation, which assumes that about 5 m2 of territory is required for one person. When planning the interior space, it is worthwhile to provide for the minimum composition of the premises, which includes the dressing room, steam room and washing room. If space permits, it is worth allocating space for a rest room.

Useful advice! If possible, it is recommended to equip the sauna (next to the steam room) with a pool of a suitable configuration that matches the design of the room.

What material to build a bath with your own hands

Choosing which material is better to build a bath from, you should give preference to natural wood. It is an environmentally friendly, natural product of natural origin. The material does not lose its original qualities over a long period. Due to the fact that wood is able to "breathe", constant air exchange and natural thermal insulation are provided.

The wooden walls of the building are a kind of moisture regulator.In the case of regular use of the bath, the interior environment does not have time to dry, so the room has a light, pleasant smell of wood.

Wood can be presented in different designs. The most demanded option is profiled timber. Each element has clearly defined dimensions, thanks to which the structure will have an attractive appearance, clear neat lines, which is clearly demonstrated in the photo of the baths with your own hands. On opposite sides, the bars are equipped with a spike and a groove, which contributes to quick and easy installation of products, ensuring high reliability of fixation.

Useful advice! When choosing wooden elements for construction, you should pay attention to the absence of blue spots on the surface of the products, indicating that the material is rotting from the inside.

Such a connection also ensures uniform shrinkage of the entire structure, which will help maintain the geometry of the structure throughout the entire period of operation. The profiled timber bath is distinguished by its high thermal performance and minimum airflow.

You can do the construction of a bath with your own hands from a glued-type bar. The product consists of individual wooden lamellas that have been thoroughly dried. In the amount of 3-5 pcs. they stick together to form a single piece.

The material is characterized by a minimum amount of moisture, is not prone to cracking, shrinkage, damage by microorganisms, insects and rodents. It has high strength. Each element is equipped with a tongue-and-groove system to facilitate and speed up the installation process. Glued material, in contrast to profiled timber, has a higher cost.

What kind of timber to build a bath from: other options for wood elements

You can build a bathhouse with your own hands from a rounded beam, which is distinguished by high sound and heat insulation qualities. The elements have a regular cylindrical shape, a smooth, even surface and the same diameter, which facilitates easy installation, providing a reliable and tight connection. The building will have a low level of thermal conductivity, good air exchange, and an attractive appearance. This type of timber is characterized by the greatest weight, therefore it requires the arrangement of a reliable foundation.

You can build a bath yourself from logs. The chopped structure will have a distinctive appearance, demonstrating unity with nature. When building a bath from logs, it is important to keep the fibers straight. Therefore, curved elements are not suitable for such purposes. Such a building will not last long. All cracks and gaps after the completion of construction must be drilled.

Important! In order for the structure to please the eyes of the owners for a long time, wooden products must be treated with special impregnations to protect the wood from adverse harmful factors.

The best type of log that is ideal for building a bath is rounded material. Such products have smooth, even side walls, which is achieved due to the removal of the bark and the top layer on sizing machines. The logs are equipped with grooves, which makes it possible to overlap them, ensuring a reliable connection of the elements. However, at the end of the work, you should wait about a year for the structure to shrink, after which you can refine the bath for further operation.

The construction of frame baths is gaining popularity. In this case, it will be possible to save on the foundation, since the structure will be lightweight. A frame technology bath is built quickly and easily.A competent approach to construction is the key to a reliable structure that will retain heat well.

What baths are built from, in addition to wood: types of building material

What are baths made of besides wood materials? The structure can be built from bricks. The material is characterized by good heat and sound insulation qualities, environmental friendliness, fire resistance, and a long period of operation. However, a large amount of fuel will be required to heat such a structure. The disadvantages also include the high moisture absorption of the material.

When building a brick bath, you will need equipment of a reliable and solid foundation. For such a structure, you can use exclusively red brick, which is distinguished by its high cost.

When building a brick bath, it is necessary to use several masonry options. The most rational solution is the well laying of the material, which allows you to lay insulation inside the wall. A suitable option is also the construction of a thin wall with finishing of the outer part, while high-quality insulation is required.

Important! When building a bath, you should not use continuous brickwork, which will lead to overspending of material and will allow the structure to be operated exclusively in the summer.

What blocks are better for building a bathhouse? The ideal solution is to use foam concrete. A structure made of such a material will have low thermal conductivity, increased moisture resistance, and a long period of operation. The construction of a foam block bath is carried out on the principle of brickwork. To fix the elements, special glue is used, which eliminates the formation of cold bridges and improves the insulating parameters.

Useful advice! Low-density aerated concrete blocks can be used for the construction of small structures, and high-density aerated concrete blocks.

A budget bath with your own hands can be built from cinder blocks. The work is carried out in a short period of time. However, this option requires the organization of additional insulation.

Bath construction: choosing a foundation for the construction

The choice of the type of foundation for the bath is carried out based on the dimensions of the structure and the characteristics of the soil. As a rule, preference is given to a strip or columnar base, the choice of which also affects the price of building a bath.

The foundation for a bath from a bar is often chosen of a columnar type. It consists of free-standing supports. The pillars are made of brick, reinforced concrete, rubble stone, wooden frame or concrete. Supports should be erected at the corners of the structure and under its walls at a distance of 1.5-2 m from each other. The optimal value of the cross-section of the supports is 60x60 cm.

Related article:

Bath with an attic: delightful projects with a comfortable space under the roof

Features and benefits of building an attic floor. Project development, planning examples. Average prices for turnkey solutions.

Under the supports, holes are made with a depth below the freezing value of the soil by 15-20 cm. A cushion of sand and gravel is placed on the bottom. The foundation should protrude 20-30 cm above ground level. From above, the base is covered with a waterproofing material. For this, roofing material is often used.

Important! When using wooden logs to erect poles, each element should be coated with bituminous mastic and covered with a layer of roofing material before immersion in the hole.

When deciding on what to put a bath with an overall and heavy structure, it is worth giving preference to a strip foundation.The cost of its construction significantly exceeds the cost of a columnar base, since it is equipped around the perimeter of the future structure. To do this, a pit 40-50 cm deep is pulled out. A sand layer 10-15 cm thick is laid on the bottom to protect the base from seasonal soil displacement. Next, the side walls and the bottom are strengthened with a waterproofing material in the form of roofing felt.

Formwork is installed along the perimeter of the trench. In the pit, a frame is being laid, created from reinforcing rods with a cross section of at least 12 mm. It is important to ensure ventilation of the base, which is carried out using pieces of plastic pipe with a diameter of 10 cm, which are mounted around the perimeter of the foundation. Next, the trench is poured with concrete. For this, the material of the M200-M400 brand is used, which is determined by the climatic conditions of the area. The concrete solution is prepared using cement, sand and gravel in a ratio of 1: 3: 3.

Useful advice! The finished strip base must stand for 10-14 days before the construction of the bath begins.

The strip foundation can be made in the form of a concrete base, where gravel, crushed stone and broken bricks are used as a filler.

Do-it-yourself steam room construction: step by step instructions

Before you build a bath from a bar, you need to choose the right material. To do this, it is better to choose products from pine or spruce, which grow in the northern regions. To obtain the effect of aromatherapy during the implementation of bath procedures, the structure can be erected from linden, which has a pleasant aroma.

After arranging the foundation, the next stage in the construction of the bath is the laying of the lower crown. For this, the thickest logs with a cross section of at least 150x150 cm are selected, since they will perceive the maximum load. Several layers of waterproofing material are laid on the foundation. Above, monitors with a thickness of 6 cm are installed, which are pre-lubricated with bitumen mastic. Next, wooden logs are mounted in the "paw" method.

The first crown is carefully aligned horizontally. The corner grip should provide a 90 ° angle. After the erection of the flap, further laying of the timber is carried out until the required height of the walls is reached.

When erecting walls, gaps should be provided for future windows and doors. After the completion of construction, openings are made in the designated places with the help of a chainsaw in sizes corresponding to the dimensions of the installed products.

How to build a bath: connecting wooden elements

Considering the question of how to build a bath correctly, one has to decide on the option of connecting wooden elements. The best solution is to fix them with wooden dowels, which can connect three rows at once. Such fastening helps to preserve the shape of the structural elements, which will shrink evenly. Dowels are selected with a diameter of about 30 mm. The length of the product must correspond to 80% of the total depth of the drilled hole.

Useful advice! It is recommended to choose wooden pins from larch or oak.

The pins are located at a distance of 1.5-2 m from each other. In this case, it is important to observe strict symmetry. Their planting is carried out with an interference fit, placing the butt end in the hole by 2-3 cm. This will promote free shrinkage of the logs, which will not loosen up, reducing the strength of the structure.

For this, holes are pre-created in the beams. The last two crowns are not fixed. This is due to the tendency of the wooden structure to shrink. When the process becomes unobtrusive, the upper rims are dismantled before the installation of the ceiling beams.

Insulating material is laid on top of each new crown. In this case, tow, jute or moss is used.

Useful advice! The thermal insulation material is laid with a slight overlap from the outside of the building, which can be used later for caulking.

How to build a bathhouse with your own hands: arranging the roof and floor of the structure

After the shrinkage of the structure, the construction of the bath continues with your own hands. The next step is the installation of the roof. For this, the wooden ceiling beams must be laid over the upper wall trim. Further, using brackets, rafter elements are attached to the fixed beams with a step of about 1 m, forming the shape of the roof.

For a single-pitched structure, the rafters are attached using one external and one internal support, or two external ones. Most often, a gable roof is equipped for a bath. To do this, you should reliably support the rafters on the wall from below, while connecting the upper parts to form a roofing ridge. A wooden lathing is made on top of the rafters. Steam, heat and waterproofing layers are laid on it.

The final stage in the construction of a bath with your own hands is the installation of the selected version of the roofing material (according to a certain technology for performing the work). The ridge must be covered with galvanized sheet metal. For finishing the gables, you can use clapboard, siding or other material.

To equip the floor of the bath, you need to perform the following sequence of actions. Logs are attached to the lower rim, the thickness of which is 5 cm. Their fixation is carried out with the help of nails. To repel water, the elements should be treated with an antiseptic. They are stacked on posts made of bricks on a concrete base, in which a drainage receiver should be provided. Therefore, the floor is made with a slight slope towards the drain. Another layer of boards 25-30 cm thick with a gap of 5 mm for water drainage is mounted on the logs. They are attached with metal screws.

Important! The floor in the bath can be wooden in all rooms, except for the steam room, where the temperature and high humidity will be high, so it is better to lay ceramic tiles here.

You can familiarize yourself with the stages of building a building on the Internet by watching the video "Building baths with your own hands".

How to build a bath yourself: interior decoration

Ceiling decoration can be done in two ways. It can be hemmed from the underside with boards by laying a vapor and heat insulating layer. The second option involves laying the material immediately under the roof. In this case, a vapor barrier material is used in the form of a layer of clay or foil.

Important! For finishing the ceiling, only hardwood is selected, which contains a minimum amount of resins.

The inner walls of the bath can be sheathed with clapboard. For this, hardwood material is used: aspen, linden or alder. It is not recommended to use pine trees for the steam room, as they emit tar when heated.

To allocate separate rooms in the sauna, partitions are being erected with their own hands. For this, special wooden blocks are used. If partitions are installed between the joists, they are attached anywhere to the crossbars. In the case of installation in the direction opposite to the floor beams, a purlin is installed to which the partitions are attached.

Bath partitions can be solid single or double, double with an air gap, full filling or frame-sheathed. For the simplest design, you will need boards 40-50 mm thick and 10-20 cm wide.It is not recommended to use larger elements, which is explained by the tendency of products to deformation changes. To connect the bars, steep spikes of 10-12 cm are used with a step of 1 m. You can also purchase nails without caps 6-8 cm long.

In the steam room, shelves should be made using one of the existing location options. They are mounted in a timber frame to which the boards are attached. All stages of the construction of the facility can be studied by watching the video "Bath with your own hands".

Organization of water supply and sewerage during the construction of wooden baths

Before making a bath with your own hands, you should decide on the organization of water supply. The best option is an artesian well. Its drilling will require significant financial costs. In addition, special filters will need to be installed.

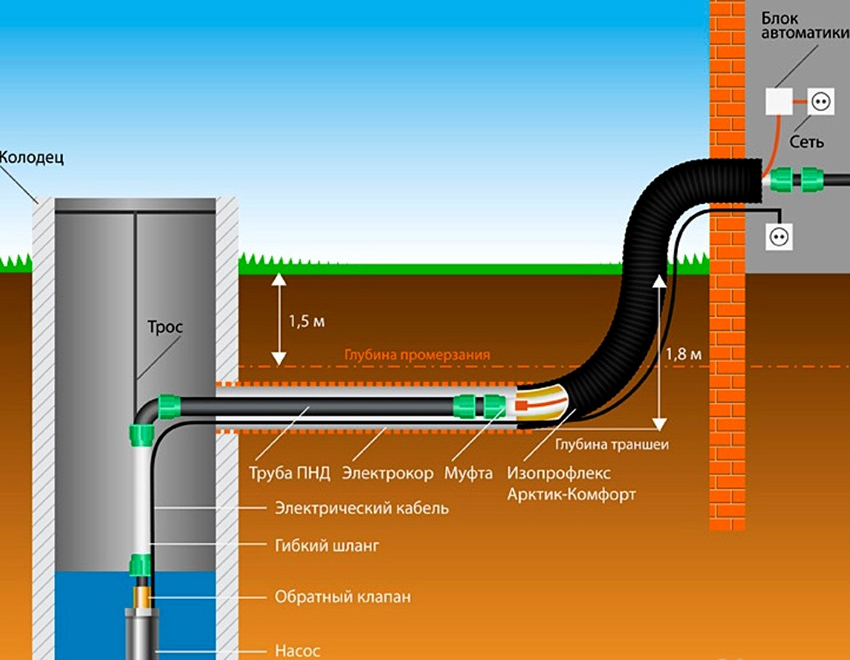

The optimal and less costly solution for organizing water supply to a bath is to create a simple well. Its arrangement is carried out using special rings equipped with a thorn-groove system, with which they reliably adhere to each other. This fixation technology excludes the possibility of horizontal displacement of elements. Metal parts are used to tighten the rings, which ensures a secure connection.

A bottom filter is installed at the bottom of the well, which must be carefully sealed. For this, multi-layer waterproofing using silicone, concrete and liquid glass is suitable. Bituminous mastic is not used in this case.

The water supply is carried out using a submersible pump that descends into the well. From it, through propylene pipes, water distribution is made. A tee must be installed inside the well. It will serve to fix the drain cock and check valve. A sieve filter with a carbon cartridge is installed in front of the pump.

When deciding how to build a bath correctly, one should not forget about the arrangement of the sewage system, which should be thought out at the design stage and during the construction of the foundation. Near the future structure, a drainage well should be dug, where a sewer pipe buried with soil will enter with a certain slope. It drains waste water from the washing compartment.

Which stove to choose for a bath: types of designs

The installation of the stove must be carried out in full compliance with fire safety regulations. All wooden structures must be protected from high temperatures. Heavy ovens should be placed on a special foundation.

The type of oven is selected based on personal preference. There are brick and metal structures. The fuel can be wood, gas or electricity. Combined ovens are also popular.

The best option is considered to be a traditional stone or brick structure that operates on wood. In the first case, exclusively granite is used, which can withstand high temperatures and does not crumble when water gets into it. The construction of such a furnace is a costly undertaking, therefore it is better to build a brick structure with your own hands, which is considered an economically viable option, characterized by good technical and operational properties. The material is fireproof and has low thermal conductivity. The design does not require the use of additional screens, since you can touch the stove without fear of getting burned.

The brick oven can be of various configurations. It consists of a firebox made of refractory material, steel or cast iron grate, ash pan, coil and chimney.

Before building a bath, you should decide on the option of the stove, which is being built at the stage of creating the foundation. The structure should be deepened by 0.5 m, which is necessary to prevent its subsidence or inclination in case of moisture or freezing of the soil. For it, a concrete or rubble concrete base is equipped, which is covered with a layer of waterproofing. For the construction of the furnace, solid ordinary or refractory bricks are used. Masonry is carried out using a mortar of clay and sand.

Important! Silicate or hollow material must not be used.

The disadvantages of a stone oven for a bath include the large weight of the structure. After the end of construction, until the moment of its operation, it will take a significant period of time, during which it must dry well.

Construction of a summer cottage: the feasibility of installing metal furnaces

How does a bath work when using a metal stove? Such a stove provides quick heating of the room with low fuel consumption. It can be presented in two options - cast iron and steel welded structure. The first type of product can be purchased exclusively ready-made.

Metal stoves are solid fuel. They use coal, firewood or peat briquettes as fuel. In the bath, it is recommended to install a metal stove with a firebox lined with refractory bricks, which is characterized by a long period of operation. This option is best suited for coal heating.

Metal furnaces are compact in size. On metal shelves, grates with a stove are laid, which are the bottom of the combustion chamber. The body is equipped with internal cavities for storing stones. Metal structures are open or closed. The stove is equipped with chimneys consisting of drop wells and collecting pipes.

The metal firebox is often lined with bricks. This is necessary in order to protect yourself and the visitors of the bath from burns, since the stove has a hot surface during operation.

Before making a bath with your own hands, you need to decide which version of the metal stove (cold or hot) to install in the room. It is worth considering that the second type of product heats up to a temperature of 100 ° C in a matter of minutes.

Despite the undeniable advantages, metal furnaces have their disadvantages. They provide little heat storage and cool down quickly. To improve operating efficiency, it is necessary to constantly maintain fuel combustion.

Structural design of metal furnaces

When building a bath-sauna, you can choose a closed, open or combined type of metal stove. The first option is advisable to use in small rooms. The design consists of three sections: a chamber for loading fuel, a container with a lid and holes for steam for laying stones, a tank for heating water. Refractory bricks are installed inside and outside the metal stove, which ensures long-term preservation of heat in the steam room. Such a device promotes the production of wet steam.

Important! The closed design of the stove creates a temperature and humidity regime that is most characteristic of a real Russian bath.

The open design has a stone grate. This element fits directly onto the firebox. The device contributes to the production of dry steam, so this stove is purchased by those who like to warm up, and not to steam.

The combined design is equipped with a high box with double latches and grilles. For the normal functioning of the device, there must be several pairs of such elements.Stones are placed in its mouth, from where hot smoke comes out.

The bathhouse is an ideal place where you can fully relax not only your body but also your soul. Bath procedures are very beneficial for health. They help to rejuvenate the body. The best option is a log bath. The construction of the structure is a simple undertaking. It is important to follow the sequence of actions and useful recommendations, thanks to which it will be possible to build a reliable, warm and durable structure. The right decision will also be the construction of a turnkey log bath.