Concrete flooring is the most popular option for the arrangement of residential and industrial buildings. Over time, the material loses its strength under constant stress. Deformation cracks and depressions form on the surface. To protect the base from damage and extend the period of its operation, impregnations or topping for the concrete floor are used. You can find out about the features, varieties and methods of applying the compositions from the article.

To increase the strength of the coating and make it invulnerable to aggressive external factors will allow topping for a concrete floor

Content [Hide]

- 1 What are concrete floors with a reinforced top layer?

- 2 Varieties of impregnation for concrete floor

- 3 Characteristics of polymer impregnations for concrete floors

- 4 Concrete base impregnation technology

- 5 Topping: This is a modern way to strengthen a concrete base

- 6 Distinctive advantages of concrete topping

- 7 Areas of use of the topping floor

- 8 Floor topping technology

- 9 Features of arranging topping on concrete floors

- 10 How to make a concrete floor with a hardener: dry method of applying the composition

What are concrete floors with a reinforced top layer?

Concrete floor screed is widely used in various facilities. This is due to the high technical and operational qualities of the coating, which is characterized by simple installation technology, reliability, durability and affordable cost. However, the flooring constantly experiences various loads that contribute to the destruction of concrete. Not only moisture penetrates into its structure, but also chemicals that leach the coating.

To increase the strength of the floor and extend the period of its operation, there are special means in the form of impregnations and toppings. These hardeners penetrate the porous structure of concrete, blocking the pores. This protection increases the endurance and durability of the coating, which can withstand more intense stress and stress. At the same time, the concrete floor is sealed, due to which moisture and chemical elements cannot penetrate into its thickness.

The gradual destruction of the concrete pavement is accompanied by the formation of fine particles. The hardener helps to reliably dedust the surface. Salts in its composition bind together, blocking the pathways of dust formation and removal. Dusting the surface gives it hygienic properties, which is especially important for children's and medical institutions.

Concrete floors with a reinforced top layer, which is formed by impregnation or topping, have an aesthetic appearance.This is achieved thanks to a flat and smooth surface that can be tinted in any color. You can use such a concrete floor in a private house, production workshop or public area.

Important! In order to ensure reliable protection of concrete floors using impregnations and toppings, it is important to strictly observe the technology of applying the hardener to the surface.

Varieties of impregnation for concrete floor

Impregnation for concrete base is a liquid composition that has an organic or inorganic base. The latter option is mainly used. Such mineral impregnations contain potassium and sodium compounds, which penetrate deeply into the structure of concrete, causing chemical reactions in its upper layer. This contributes to the neutralization of free components with the creation of additional crystalline insoluble glassy bonds, which provides surface hardening.

Modern mineral impregnations for concrete floors for dust control and the reinforcements are based on lithium polysilicate. They penetrate into the smallest pores. The period of chemical processes is 10-12 days. It is enough to process the surface once without rubbing and washing the floor.

Organic reinforcing and dedusting impregnations for concrete floors are acrylic, polyurethane and epoxy. The first option, which is water-based, is advisable to use for substrates that do not take heavy loads, as well as for screeds intended for flooring. The composition can be used for concretes of grade no less than 200. A concrete surface with acrylic impregnation will have hydrophobic qualities. It is able to withstand high humidity, ensuring high hygiene.

Characteristics of polymer impregnations for concrete floors

Epoxy concrete floor impregnations are the most reliable and durable. They are represented by two-component aqueous compositions based on epoxy resins. Such impregnations are recommended to be installed in food processing shops, refrigerators and freezers, and at medical facilities. The main disadvantage of the formulations is their high cost.

The most popular is the strengthening impregnation for concrete floors "Epoxol", which can be used for residential, public, industrial and warehouse premises. The hardener contains organic solvents, organosilicon modified resin and functional additives.

Polyurethane impregnation is the most widespread. It gives the base additional water-repellent qualities, is more versatile and durable. This composition can be used for low grade concrete. After application, the floor turns into a concrete polymer, which is characterized by impact resistance, dust-free and moisture-proof properties. The main disadvantage is the strong odor, which evaporates after the end of the polymerization process.

Important! The most justified is the use of polyurethane-based impregnation for concrete floors in the garage.

The most popular composition is Protexil. The impregnation for concrete and concrete floors is specially designed for industrial floor surfaces that are subject to serious transport, mechanical loads and are under the influence of an aggressive environment. The composition can be used for both new and old floors.

Concrete base impregnation technology

The first step is to prepare the base before applying polyurethane or epoxy impregnation to the concrete floor. The process takes place with the help of a grinding machine, which removes the top loose layer, cement laitance, traces of oils and dirt. The procedure is necessary to open the pores of the concrete and ensure the penetration of the composition deep into the material.

Depending on the type of impregnation, the composition penetrates into the concrete thickness by 2-8 mm, increasing its branded strength several times.

To apply the impregnation, use a brush, roller or air spray. The composition is poured onto the prepared surface in strips and spread using a brush, squeegee or synthetic winterizer roller with long pile. The impregnation should evenly occupy the entire surface area, excluding the formation of puddles and places where the composition is quickly absorbed into the concrete.

The topping is applied as a top layer to the finished concrete, thus creating a reliable protection for the surface

The technology for applying organic compounds is somewhat different. Such impregnation for a concrete floor from dust is applied in several layers. The first one should stand for 40-60 minutes. Next, a second layer is applied, after 20 minutes, all excess composition must be removed using a squeegee or rag.

Topping: this modern way of strengthening the concrete base

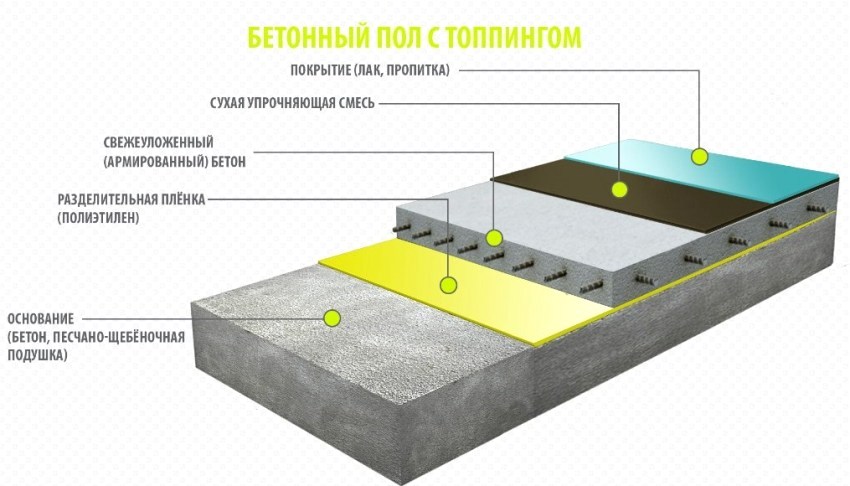

Topping - what is it? The first step is to learn more about this protective coating. This concrete hardener is represented by a durable outer surface, which includes cement, plasticizing additives, fixers and colorants. The first element acts as a connecting link between the aggregates, preventing material delamination.

The rest of the ingredients give the coating durability, impact resistance, crack resistance, resistance to aggressive chemical environments, frost resistance, hygiene, reflective, antistatic and decorative qualities.

Topping is available in liquid and dry state. The first option includes inorganic compounds that dissolve well in water. During the application of the mixture to the floor covering, the composition penetrates into the pores of the concrete, forming durable seals that are resistant to moisture. Dry topping has a powdery state. In the form of small crumbs, the composition crumbles to the surface, followed by tamping and grinding. This option has a lower cost.

Important! The use of dry material involves the formation of seams on the surface.

Distinctive advantages of concrete topping

This method of strengthening the concrete base has replaced iron, when, when installing concrete floors, dry cement was scattered over the screed in a thin layer, followed by trowelling. The topping in the form of a dry or liquid mixture is applied to a fresh or hardened screed, further processed by grinding machines. Thanks to special additives, the surface has an improved structure, and the fine-grained filler gives it texture.

This type of protective coating does not allow moisture to pass through. The topping penetrates deeply into the porous structure of concrete, sealing its pores. The surface does not need special maintenance. Thanks to topping, the service life of the concrete floor is extended. This hardener is also characterized by an acceptable cost. In addition, when arranging a concrete floor, you can use low grades of cement, which is compensated for by an ultra-strong protective layer.

The topping coating exhibits an increased susceptibility to certain chemical components, which contributes to a decrease in surface performance. Such a floor cannot be repaired. If necessary, the surface is dismantled and a new base is laid.However, it should be borne in mind that the period of operation of the floor is at least 15 years, during which it will maintain its operational and decorative qualities.

Areas of use of the topping floor

This technology for strengthening a concrete base is used in warehouses, industrial and production workshops. Such floors, due to their hygiene, are indispensable in the food industry. Due to its frost resistance, concrete floors with topping are the best solution for refrigerators and freezers. The presence of reflective qualities ensures the demand for the hardener at objects with high temperatures.

High wear-resistant qualities make the protective coating indispensable in places with increased vibration and mechanical stress, such as parking lots, shopping and entertainment centers, medical, cultural and educational institutions, pedestrian areas with high traffic. Such an industrial floor screed is widely used in car dealerships, car services, hangars, garages, where the top concrete coating is constantly in contact with gasoline and diesel fuel, slightly alkaline liquids and mineral oils.

Important! Topping cannot be used for premises where acids and alkalis are widely used, for which special impregnations are acceptable.

Topping helps to increase the life of the floors of gyms, sports fields and swimming pools. The coating is widely used today in civilian facilities, which is associated with undemanding care, durability and decorative surface when using colored compounds.

Concrete floor topping: varieties of hardeners

There are three types of concrete hardener: quartz, corundum and metallized. The first option is the most popular and demanded. It also has the most affordable cost. The main filler of the mixture is perlite, which can be combined with coloring pigments. This feature has a positive effect on the technical and operational characteristics of the surface, changing its appearance.

Quartz topping is the best option for substrates that experience moderate stress, which is typical for warehouses, entertainment and shopping centers, educational institutions. Such hardeners are also widely used in the construction of residential buildings.

Important! Quartz topping helps to increase the strength of concrete by 1.5 times.

In corundum toppings, corundum chips act as a filler. This mineral additive has high strength characteristics, increased wear resistance and abrasion resistance. The hardener increases the strength of concrete by 2 times.

Related article:

Detailed description of preparatory work, technology features. Installation of underfloor heating system under laminated flooring.

Corundum toppings are used on sites with large and heavy equipment, as well as in places with heavy traffic of people and vehicles. Such an environment is typical for warehouse-type premises, gyms, special-purpose facilities and grounds.

Important! Corundum topping gives the finish surface a pleasant matte finish.

The main filler of metallized toppings, the price of which is the highest among analogues, is metal shavings. Such mixtures contain a concrete solution in their composition.Thanks to its components, metallized topping is considered the most reliable floor reinforcement, which increases its strength by 2.5 times.

Such topping is used for objects experiencing excessive loads, where massive equipment is installed, heavy equipment moves daily, which are characterized by increased vibration.

In the construction of residential buildings, such a composition is impractical to use due to the high cost and rather complicated application technology.

Floor topping technology

There are several technologies for floor topping. The DTW method involves the application of a dry hardener to a wet concrete base, which can be sprinkled by hand or using special trolleys. Such mechanisms provide a uniform coverage of a large surface area of the powder. The concrete base dries and adheres together with the topping, which guarantees high adhesion.

After the surface has completely dried, the absorbed mixture is rubbed with a special grinding machine. Such a coating is reliable, durable, resistant to various adverse factors and durability.

WTW technology involves the application of liquid topping immediately after the concrete floor is laid. This option of laying the hardener has been used recently and is not yet recognized in popularity, since the application process is rather complicated, laborious and expensive. However, such a coating is characterized by maximum durability and high decorative effect. The surface is perfectly flat, smooth, evenly colored and beautiful.

The WTD method involves the use of dry topping, which is laid on a wet or dry screed. The final stage of the work is a thorough grouting of the surface.

There is a volumetric option for applying topping, which provides hardening of the concrete surface throughout the entire thickness. At the stage of pouring concrete floors, a special plasticizer is mixed into the working solution, due to which the performance of the surface increases.

Important! The volumetric method of applying topping implies the use of cement grade of concrete for a screed not lower than 350 for a concrete base.

Features of arranging topping on concrete floors

The thickness of the screed to be poured is taken into account without fail. If it is placed on an old concrete base, its height should be up to 70 mm. If the topping is applied to a fresh substrate, the screed thickness reaches about 120 mm.

Important! The level of surface drops should be within 4-5 cm.

DIY topping works are carried out at an ambient temperature of at least +10 ° С. If the weather is colder, it is worth organizing additional heating of the room.

Topping is a complex concrete surface treatment technology, therefore, to obtain a good result, the process must be carried out in a strict sequence. Concrete hardeners are available in two states - liquid and dry. Each option is characterized by an individual technology for applying the composition.

The slurry can be applied both to the old base and to the freshly laid screed. The effect will be the same. The process is performed in the following sequence.

The first step is to prepare the concrete base. The old coating is thoroughly cleaned from dirt, debris and dust. In case of cracks and potholes, they should be filled with repair mortar of cement or concrete. The fresh screed must be sanded.

Liquid topping is applied with a roller or spray to the prepared substrate. It is necessary to carefully monitor the absorption of the composition, which depends on the quality of the concrete surface. If the process is fast, the topping is reapplied. The coating thickness is 2-3 mm. The mixture consumption reaches 4-5 l / m².

Liquid topping is characterized by its versatility and fast setting speed. However, such a composition has a higher cost compared to dry mix.

How to make a concrete floor with hardener: dry method of applying the composition

Dry formulations can be purchased in 25 and 50 kg bags. The mixture is applied on a fresh concrete screed 6-7 hours after its laying, if the surface has set to a state where shallow imprints remain on it.

Helpful advice! For laying topping on large areas, it is impractical and ineffective to use the manual method; for this, special grinding machines are used, equipped with a large working disc.

Dry topping works are carried out in the following sequence.

At the first stage, an industrial concrete floor is trowelled using a grinder. The procedure is carried out with the aim of leveling the surface until it is fully set. With the help of a topping trolley, 65% of the total amount of the mixture is evenly distributed on the concrete base from the windows towards the exit. The powder starts to absorb moisture immediately. A crystallization reaction of the composition occurs, accompanied by a gradual darkening of the composition.

When the surface is evenly dark, it is time to grout with the machine. The process is necessary for leveling the base and filling the industrial floor with topping. After the process of rubbing in the mixture, you should wait until the surface grabs. This will be evidenced by an imprint with a depth of 1 mm.

Further, the remaining mixture is evenly distributed over the surface. After 24-48 hours, the hardened base must be cleaned with blade knives. The process is carried out in 2-3 steps until a mirror surface is obtained.

Important! Average consumption of topping is 4.5-5 kg / m².

The finished base is covered with curing - a solution that forms a thin film that prevents moisture from evaporating from the concrete during the surface hydration. Curing can be applied by spray or roller. Finally, the expansion joints should be cut. They will prevent the concrete surface from cracking during the hardening and shrinkage of the base, which will be completely finished after 28 days. Seams must be filled with sealant.

When concrete floors are used as a finished coating, it is advisable to reinforce the base with impregnations or toppings. Such compositions increase the strength characteristics of the surface, providing impact resistance, wear resistance, resistance to stress, moisture and chemicals, and durability of the floor.