Polymer board is a very stable and durable building material. At the initial stage of its production, wood is mixed with a special type of plastic. After the future polymer decking board passes the polymerization stage, the material is endowed with improved properties and attractive external characteristics.

Content [Hide]

Decking decking board: varieties and application features

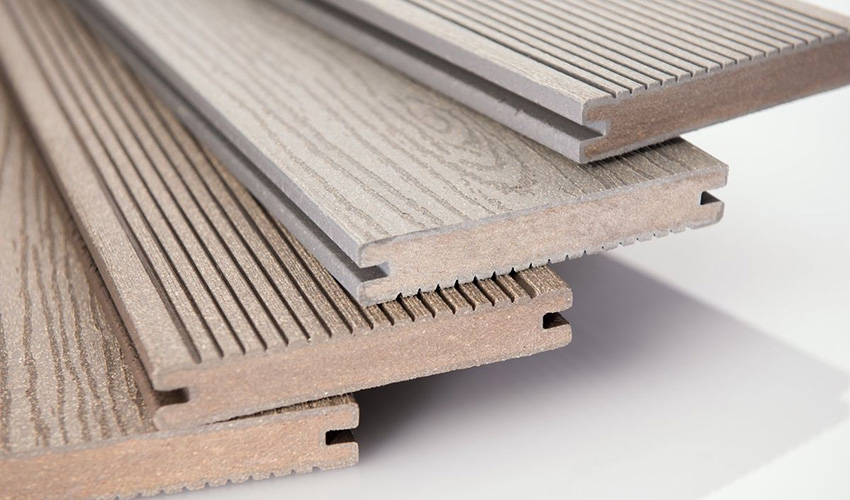

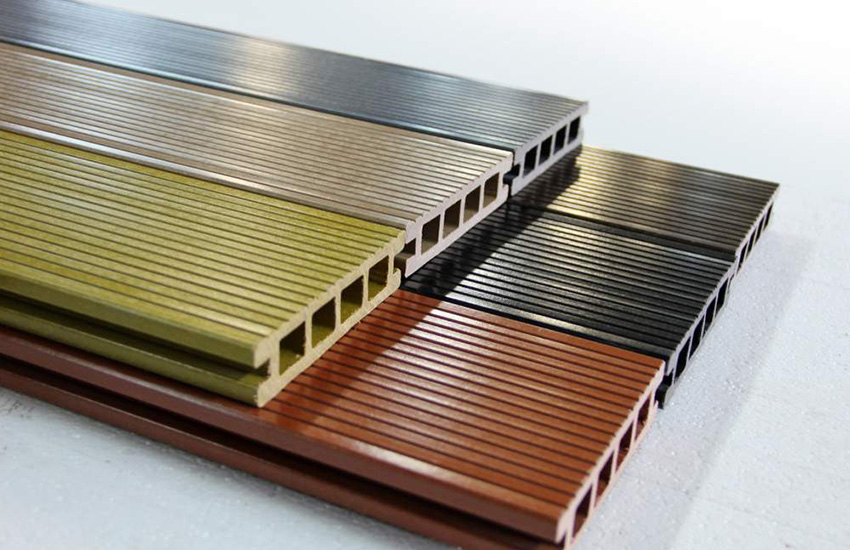

Experts distinguish three main groups of decking. The main difference between them lies in the material of manufacture. Although consumers should focus on the installation method, surface texture and other equally important characteristics.

A fairly popular plastic decking board is called a wood-polymer composite (WPC). To produce the appropriate material, the polymer materials are mixed with wood flour. Such a flooring is resistant to moisture, does not rot, and also tolerates significant mechanical loads without problems.

Among the negative points, one can single out not the most attractive appearance of such products. It is logical that plastic decking is inferior in this regard to analogs made from natural wood. In addition, plastic may deform somewhat over time.

WPC boards are divided into sanded and unpolished. In terms of external parameters, they practically do not differ in anything. Experts say that the surface of the sanded version is absolutely non-slippery. Although in practice, after a month, this difference will be leveled. In terms of sliding, polished and unpolished boards will become almost identical against the background of external factors.

Useful advice! It is not always necessary to blindly give preference to sanded plastic boards. It is possible that as a result of this action, unscrupulous manufacturers deliberately try to hide the shortcomings of their own products. Defects in the board may result from the use of substandard raw materials.

Before buying a WPC decking, you should make sure that the top layer of polymeric materials is not damaged as a result of sanding. If this happens, then the product will be destroyed in the shortest possible time.This will happen due to the continuous contact of wood particles with environmental factors.

As for the price of WPC decking, it largely depends on the authority and recognition of the manufacturer. On average, this parameter varies from 1,000 to 1,500 rubles. per sq. m. Larch is notable for its low cost; the price of decking from this species will be much lower.

Treated wood board

So that natural wood does not lose its natural characteristics rather quickly, the two most common methods of processing it are used. The first of these is impregnation. We are talking about vacuum impregnation of wood using special chemicals.

To achieve a positive result in this case, a special technology was invented. After the completion of processing, the resistance of the material to the growth of fungus and other harmful microorganisms, as well as to decay, increases significantly. As a result board will definitely serve its owners for about 15-20 years.

Before you buy a decking made of treated wood, you need to make sure of the positive effect of impregnation. To do this, experts recommend that you carefully scrape off the top layer, which just encountered the vacuum impregnation procedure earlier. All wood layers must have an identical shade. Such a product can be safely purchased. If it was found that the layers are characterized by different colors, then it can be assumed that only the surface of the board collided with the application of a special protective coating.An alternative method of producing a decking board involves its heat treatment.

The wood is heated at a temperature of 200 degrees. Then the workpiece becomes denser and lighter. The process of repelling water in this case occurs without the additional use of aids. It is very important to know that any wood that is exposed to heat treatment will not rot in the future.

On the other hand, when laying decking after heat treatment, it is necessary to take into account the fact that it becomes more fragile. Chips, cracks and dents on the surface may well appear after impacts or falling of sufficiently heavy objects.

To buy a decking board, the price of which ranges from 700-1700 rubles, you need to know exactly how it will be processed. To do this, it is quite possible to use the above tips.

Seamless solid wood decking

Various types of wood can be used to make the corresponding boards. The most common ones are:

- oak;

- Pine;

- cedar, etc.

It is no problem to buy decking made of larch or rare woods, which are specially imported from Asia, Africa and South America.

Helpful advice! Consumers can choose products from the most durable varieties of trees. In this case, the boards can serve for about 80 years.

Among the durable species, the well-known Masaranduba mahogany can be distinguished as an example. You need to know that the price of polymer decking made of this raw material will be quite high. The corresponding mahogany is characterized by a high content of rubber resins. This leads to increased wear resistance of products. Even molds cannot infect this type of wood.

The effective resistance to sea water is characteristic of the Australian walnut board. It is no coincidence that this decking from the manufacturer is actively used in the field of shipbuilding.This type of wood will not lose its positive qualities even if it is constantly under the open sky.

Most of all, solid wood products are suitable for consumers who prefer natural materials. True, they need to carefully look after such a board. Only in this case it will last a very long time. To date, you can buy a decking board (decking) made of very rare wood species for at least 5000 rubles. The most expensive models have a price of 13 thousand rubles. per sq. m.

More affordable is the price of decking decking made of larch, cedar or oak. It is in the range of 500-1000 p. per sq. m. These products can already afford the average consumer.

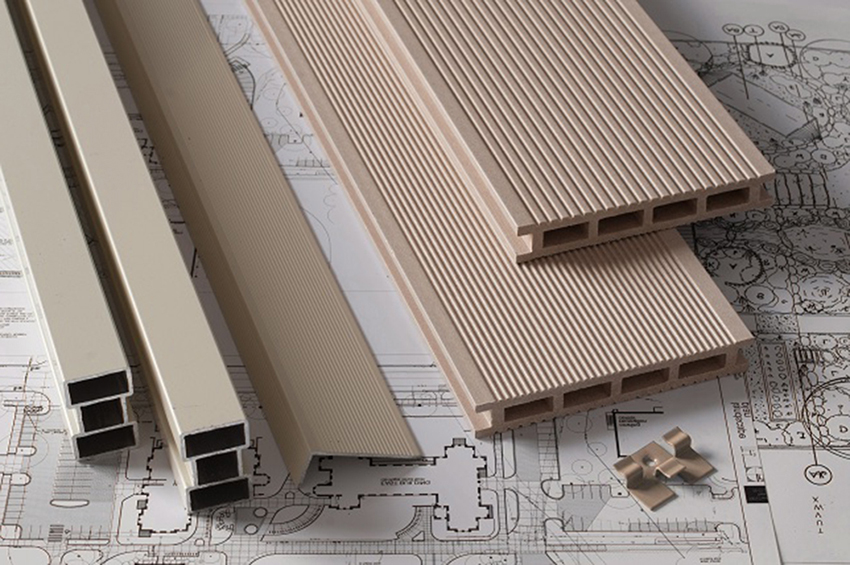

Polymer decking: dimensions

The width of these products can vary considerably. This important parameter can vary from 90 to 250 mm. There are standard sizes of decking, which should be guided by when choosing. The length of the product can be 3-6 m. Due to such a variety, boards can be selected even for specific operating conditions.

You must be very careful when choosing the thickness of the products. For the thickest boards, this parameter is usually 42-48 mm. The average dimensions of the decking in terms of thickness are 25-30 mm. The thinnest products are also in demand. Their thickness is in the range of 18-22 mm.

Special attention should be paid to the tiled decking, which is made of WPC. It is best used to cover a small area of the area. The installation of a WPC decking board can become in demand if there is no opportunity to use other types of products on a specific site.

Helpful advice! Due to the fact that the size of the decking can be very diverse, when choosing it is necessary to build on your own needs, as well as on future operating conditions. You can give preference to small options with dimensions of 25x25 cm.Larger options have parameters of 50x50 cm.

Major manufacturers of decking

If we talk about companies engaged in the production of decking from the most valuable and rare species of wood, then the leader of the corresponding market segment is definitely the large corporation JUNGLWOOD. The enterprises of this company are located today in Indonesia and Portugal. The use of only the most advanced technologies allows finished products to preserve the unique characteristics of rare types of wood.

The Italian company Ital Parchetti is also a fairly recognizable manufacturer. This company uses only the highest quality raw materials for the manufacture of products, which are brought from Africa and South America. Future deck planks for a deck are delivered in the form of logs that collide with primary processing at the point of production.

Without exception, all stages of production are under strict control. More extensive is the production of composite deck boards, which are also in high demand. In this case, you can safely give preference to the well-known American brand TREX. In this case, the product quality guarantee is 25 years. The famous Korean company WOOZEN provides a 10-year guarantee for its own products. Many other companies guarantee the preservation of the original quality of their products for 7 years after release.

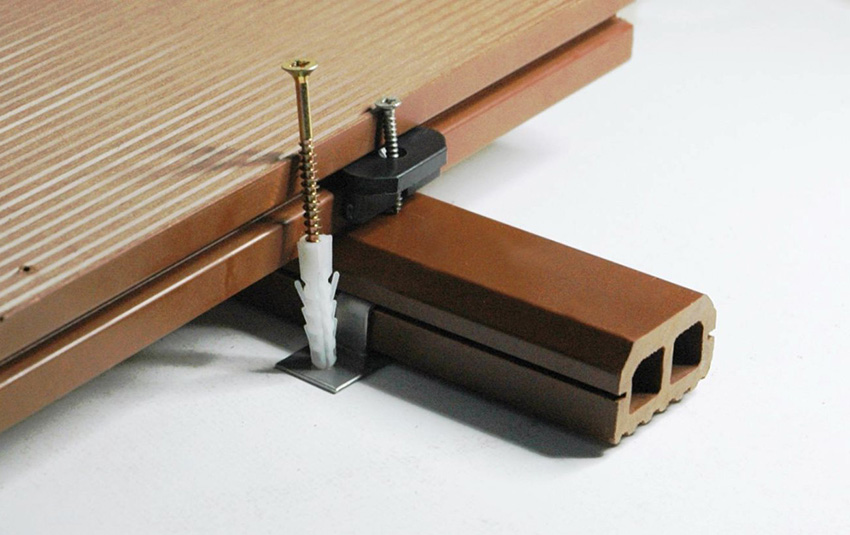

Decking board fixing and additional materials

Regardless of the option chosen for the board, before installing it, it is imperative to install reliable bearing supports. It is especially important to use supports when installing a composite decking board that needs additional fastening. Lags can be:

- wooden;

- aluminum;

- composite.

The installation of wood supports under the velveteen and other types of decking is carried out at a distance of about 60-100 cm from each other. This parameter directly depends on the section of the selected timber. Logs are made only from dry wood species. Their humidity indicators should not exceed 25%. Before starting installation, they are necessarily treated with highly effective protective equipment.

The popular decking made of wood-polymer composite, which is supposed to be used in difficult climatic conditions, needs composite supports.

Helpful advice! Composite logs are best purchased for use in a private house. These supports are not able to withstand too severe mechanical stress. Before the main stage of installation, a dense layer of rubber must be placed between the concrete base and the ground. The width of the step when mounting data lag is on average 30-40 cm.

The most expensive option is definitely aluminum logs, characterized by an increased level of strength. For this reason, these supports are best purchased for areas that face maximum loads. With the appropriate supports, the optimal pitch is 100 cm.

Before starting the installation, it is very important to understand the features of the WPC, what it is and how to use its strengths. This type of boards needs additional framing with the help of end elements. Special abutment strips should be installed between the deck and the wall of the structure. There are also various profiles and an edging strip.

The purpose of the edging is to provide protection for the exposed cuts of the product. Thanks to its use, materials will be protected from the negative effects of environmental factors, and will also retain their attractive appearance for a longer period of time.

Related article:

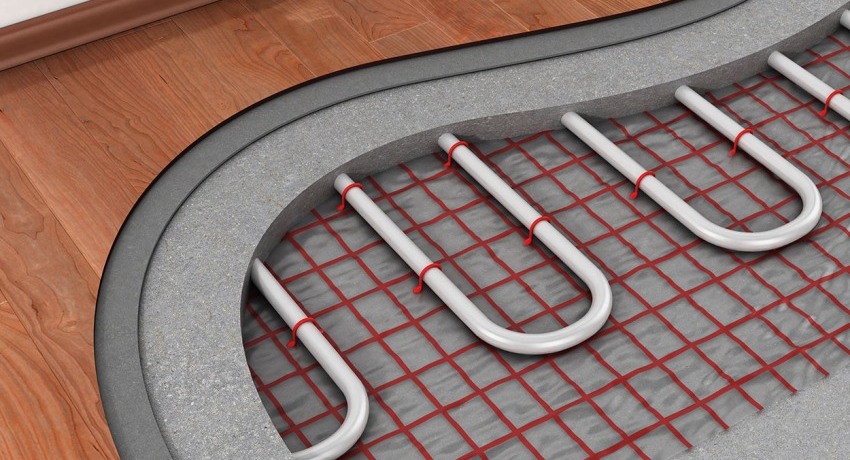

Warm floor on the balcony and loggia: an overview of heating systems

Characteristic features, positive qualities. Repair methods and advice from experienced builders.

When installing these products, be sure to use strong screws. They are just the only auxiliary elements. As for the boards made of solid timber, their correct operation involves the use of various means of protection. They are necessary for the impregnation of wood.

It should be noted that due to periodic processing, the cost of decking can increase significantly. The first time this procedure is carried out before installation. It is very important to handle the board from both sides. The re-finished coating needs an appropriate procedure after 2 years. Protection of the surface from decay and negative effects of direct sunlight is ensured by the use of glaze oil. On quays and near swimming pools, special oils are required to reduce slip.

The cost of all the drugs presented above is quite high. To cover approximately 40 sq. m. cover, you need a full can of oil. Its cost is within 500 rubles. Given that the cost of decking itself is high, the overall cost will be tangible for any consumer. On the other hand, without additional protection, these coatings will not be able to last the period guaranteed by the manufacturers.

DIY board installation

After evaluating the photo of the decking in the exterior, many consumers will be interested in this type of flooring for the house and the adjacent area.Despite the apparent complexity of the installation process, this task can be done on your own. It is only important to heed the advice of experienced specialists.

Installation of WPC siding and other types of coverage can only be carried out on a flat surface. This can be a wooden structure, a concrete screed, or various types of supports. Installation on gravel or sand bed is not recommended.

Helpful advice! The space between the deck on supports and the ground can be waterproofed, as well as provide good ventilation. The gaps formed as a result of the appropriate actions can be used to conduct a variety of communications.

When self-installation, it is recommended to stop the choice on non-adjustable supports. Thanks to their use, even a decking made of a wood-polymer composite will not face problems due to the slope and height of the relief. Propylene supports will eliminate these problems. They can easily withstand temperature extremes, high humidity and significant loads.

Even on difficult terrain, you can equip outdoor terraces and areas. True, for this it is necessary to use screw piles. This type of foundation will be characterized by increased strength, as well as better bearing capacity. Previously, it is recommended to study in detail the video of the installation of decking and screw-type piles performed by professionals.

Nuances and installation rules

During installation, you can safely listen to the advice of manufacturers who know the technical features of their own products better than others. There are two main ways to install larch corduroy decking and other coverings. You can leave a gap of 4-6 mm between the boards or make the installation seamless. In addition, linear expansion is also taken into account. This figure is 4-5 mm per running meter. It is prohibited to place boards close to a fence or wall. The minimum distance from the corresponding surfaces should be 1.5-2 cm.

Installation of the flooring should be carried out at a slope of 2-2.5%. This is done in order to effectively drain rainwater. Often the terrace is adjacent to the building. In this case, the pendant should be directed away from the walls. There are logs under the flooring, and it is better to leave the gaps between them without filling. This solution will ensure high-quality ventilation of the structure.

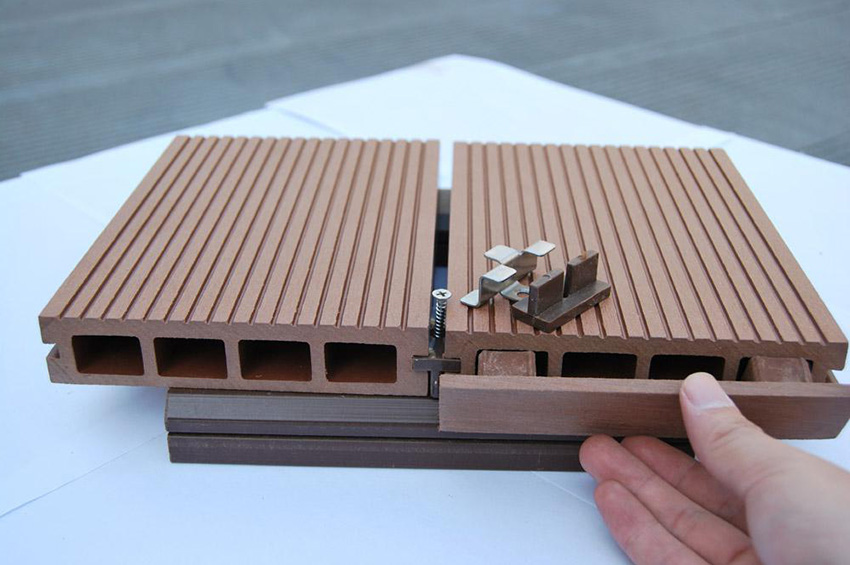

In addition to the price of composite decking, even the most minimal installation rules should be taken into account. The step between the lags should be 40-45. Although these are average figures. Usually reputable manufacturers provide more accurate recommendations for the installation of their products. If an open type of fastening was chosen, then all the elements should be visible. In fairness, it should be noted that this option will reduce the attractiveness of the design, because the fastening elements will be visible above the surface.

With a hidden type of installation, preference is given to secret fastening elements. Usually manufacturers provide them to customers along with the boards. This means that the price of a plastic decking board will not increase because of this.

Helpful advice! All joints and ends during installation must be on the joists. At the very beginning of the installation, you must fix the starting profile. Before finishing work, it is necessary to close the ends with the help of a finishing strip.

Beginners should understand that at all, without exception, the intersection of the lag with the boards, connecting clips, screws and other types of fasteners must be installed. Certain types of supports have structures with special grooves for rubber terminals.They are used when installing structures in those places that are characterized by significant temperature differences.

It is very important for beginners to study in detail the instructions for the relevant materials. Each manufacturer applies it to their own products. It is very convenient if the instructions are accompanied by illustrations, as well as a step-by-step description of each procedure.

After installation, polymer flooring is not particularly demanding in terms of maintenance. Every season it is necessary to carry out preventive actions. They must be directed against fungus and a variety of parasites. Proper care involves wet cleaning. Surface cleaning is easiest and most effective at high pressure.

There are no significant restrictions, let alone bans on the use of certain floor cleaning products. Considerable effort needs to be made to get rid of more serious contaminants. These are coffee or wine stains that are very difficult to remove. In this case, even the use of rather hard metal brushes is allowed. Additionally, you can use a fine type of sandpaper.

Summing up, it is necessary to focus on the variety of decking. Different materials are used to produce the respective flooring. Even composite models are in high demand. In general, it is a safe, modern and reliable flooring, and this floor also has an attractive appearance that does not change for the worse over time. A decking floor can easily fit into any room interior. The same applies to landscape design, because such boards are quite often used today in open space when arranging private houses or summer cottages.