An external or internal staircase, as well as the porch of the house, are subjected to constant mechanical stress, temperature changes, and the influence of weather conditions. This adversely affects the condition of the facing material. Clinker tile for steps is the most suitable product that can withstand all of the above influences and last for many years. The article will consider the types, features, characteristics of clinker tiles, as well as tips for laying and the cost of the material.

Content [Hide]

Characteristics of outdoor clinker tiles

Today, the most popular finishing materials that can be used for facing the walls of a building, stairs, steps, platforms are porcelain stoneware and clinker tiles. However, the latter option is much cheaper, easier to install, and has a number of indisputable advantages, not inferior to natural material.

For the manufacture of clinker tiles, environmentally friendly materials are used, the main of which is considered to be refractory clay. Silicate materials, loamy nodules, and feldspars are used as additional additives.

A special technology for the manufacture of facing material, namely a single firing in ovens at temperatures above 1300 ° C, allows you to obtain a product with high operational and technical characteristics, which is ideal for finishing steps.

Clinker facing tiles are manufactured in two ways:

- the extruded method involves pressing the material, firing in ovens at high temperatures and drying the product;

- the semi-dry pressing method excludes the stage of product drying.

According to the first manufacturing method, the product is obtained resistant to mechanical stress and aggressive environment. Such tiles are intended for sidewalks, outdoor areas, stairs and paths on the street.

The material made by the second method will have a low thermal conductivity index... Such clinker tiles are suitable for cladding the facade of a building, since the abrasion resistance and mechanical stress for the walls are not as important as for the flooring of the porch and stairs.

Distinctive features of the product

Clinker tiles have characteristic features that make this product the first in the ranking of materials for outdoor cladding.

The main feature of clinker tiles for outdoor steps is their increased resistance to temperature extremes. This is especially important during the zero mark, when the liquid begins to move from one state of aggregation to another. The material is able to withstand about 300 such cycles without loss of strength. This is especially important for stairs. Here the joints between steps and risers are subject to great stress, and the slightest detachment can lead to the destruction of the entire structure.

Thanks to the extrusion method for the production of clinker tiles, it has a low water absorption rate. Its structure has capillary channels through which excess moisture is removed. Therefore, the occurrence of mechanical damage on the surface of the cladding is excluded.

Outdoor floor cladding material must have increased wear resistance. Since the clinker tiles for the steps have abrasion classes IV and V, this guarantees a long service life of the product. The material with the highest wear resistance is produced by German manufacturers.

The most durable coating is made by Stroeher. This tile can be scratched with effort, but not a single trace will remain on it. Spanish clinker is inferior to its German counterpart in this indicator, but its price is much lower. Polish companies very often issue ordinary ceramic tiles under the guise of clinker. Russian-made clinker stages combine high quality material and relatively low production cost.

Porch clinker tiles must have anti-slip properties to avoid injury. All ceramic products according to the European standard DIN 51130 are divided into five classes:

- clinker R9 is used for laying massive wide stairs that have several tiers;

- clinker tiles R10 are used for public premises, where it is possible to perform not only the facing of the stairs, but also all its elements;

- R11 tiles are used for finishing stairs in art studios, creative workshops, laboratories, in factories;

- R12 rating has outdoor porch clinker tiles. Due to its high indicators of wear resistance, strength and frost resistance, the material can be used for finishing freezers, cleaning systems, and fire stations.

An important indicator for ceramic products used for flooring is the material's resistance to flexural loads. The strength value of ceramic tiles is 20 MPa. Since the main load during operation of the ladder falls on the edge of the step, it is difficult to overestimate the strength properties of the clinker.

Due to the structural surface of the clinker, a better adhesion of the base with the adhesive is ensured, which affects the durability of the structure.

Varieties of clinker steps for the porch

Outdoor clinker tiles can be technical, waterproof and facing. The first option is used mainly for sidewalk paths, areas in front of the building, in rooms with high traffic of people, for example, underground passages, train stations.

Waterproof claddings are used in swimming pools, saunas, baths, showers and other rooms with high humidity. The cladding option is used for external finishing of the building facade, internal and external stairs.

Well-known manufacturers of clinker for stairs produce material in various formats:

- notched clinker steps;

- ordinary steps;

- slabs with a Florentine profile;

- corner clinker steps;

- corner plinth;

- right and left plinth;

- ordinary plinth;

- corner under the step;

- profiled steps with an angle;

- balcony facings.

All products are produced in various tonal and geometric variations, which allows facing even structurally complex stairs. The specific color of floor tiles is obtained as a result of the effect of high temperature on natural clay compounds, such as iron, magnesium, silicon, which change into other forms and color the product. Therefore, due to the different content of natural materials in the raw materials, the floor tiles have a rich range of colors at the end.

Clinker tiles for steps: product price

You can buy clinker tiles for steps starting from 150 rubles. per piece The price of a product depends on its thickness, variety, design and manufacturer. The simplest tile will cost 30-60 rubles. per piece More advanced models will cost 80-100 rubles. per piece

Corner tile modifications for street steps are very popular, the price of which is 300 rubles. per piece The average cost of clinker steps is 450-800 rubles. per piece

The price of clinker tiles for ordinary steps is 1500-2000 rubles. for 1 sq. m. While the Florentine profile will cost 3250-5600 rubles. for 1 sq. m.

The most popular facing materials are produced by the German company Stroeher. These are massive, monolithic, frost-resistant steps that will become the highlight of any interior. You can buy steps from clinker of the German brand starting from 1333 rubles. per piece

The Russian company "Ekoklinker" produces flooring, which is made by the extrusion method, which allows you to create products that have high compressive strength and bending, resistant to temperature changes and have an aesthetically pleasing appearance. The minimum price for Russian-made clinker tiles is 175 rubles. a piece.

The cost of domestically produced clinker tiles is much lower, and the quality is not inferior to foreign manufacturers

The Spanish manufacturer Exagres produces products at a more affordable price, which is 1,300 rubles. per sq. m., however, not of inferior quality. The Polish company Paradyz offers a wide variety of shades and colors of paving clinker tiles, which have high technical and operational characteristics, capable of withstanding significant loads without losing the strength of the structure and the original appearance of the product. The cost of a tile starts at 1100 rubles. per sq. m. The average price of Russian-made paving clinker tiles is 1300-1400 rubles. per sq. m.

Related article:

Facade clinker tiles: a versatile cladding material

The main advantages and disadvantages of the material. Selection rules and scope. Thermal panels and panels with clinker tiles without insulation.

If we talk about the cost of laying clinker tiles, the price of work will depend on its size. Facing the stairs with small products up to 60 cm will cost 700 rubles. for 1 running meter. Execution of work with larger tiles is estimated at 900 rubles. for 1 r.m.

Installation of clinker tiles

Cladding staircases is one of the most difficult jobs for a tiler, which undoubtedly affects the price. Laying clinker tiles on the steps is one of the most expensive services, along with other tiling work. Waterproofing must be done before laying the tiles.

Useful advice! Reinforced concrete is the best choice for the base of the stairs.

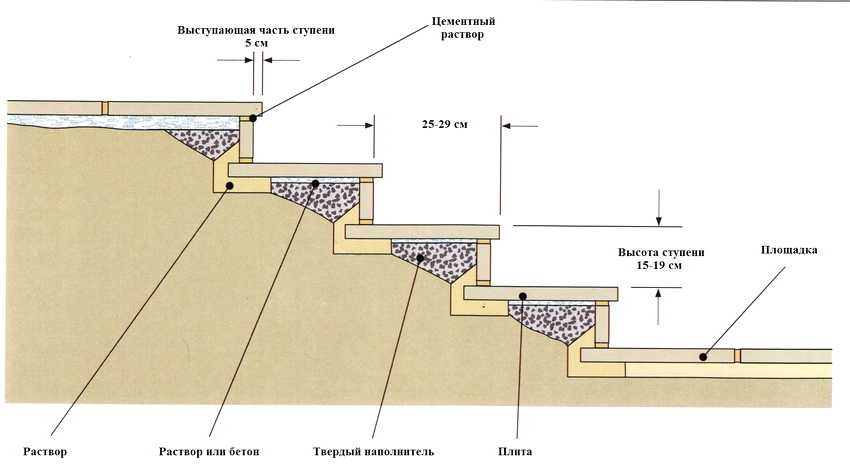

The first and most important step is the markup. It is necessary to take into account several parameters at the same time: flatness, evenness of the seams and the same height of all steps. The standard step height is 15 cm, width is 30 cm. The most popular size of clinker tiles for steps is 30x30 cm format and 15-30 mm thick. To calculate the number of steps, you need to divide the total length of the staircase by the height of one step.

When calculating the number of tiles, it is important to adhere to the integrity of the product. Each trim will degrade the appearance of the entire cladding. Also, when marking the stairs, it should be borne in mind that the porch has sidewalls, which consist of vertical cladding.

Next, you should place a horizontal lighthouse row. He will set flatness and seam. Now you can start laying the first row. The width of the joints between the tiles is 4-5 mm. When the laid tiles have set, the risers can be laid.

Important! The steps should be made with a slope of 1-1.5º to avoid stagnant water and the formation of puddles.

Since the back of the tile has a low porosity, it is necessary to glue both the base and the product itself. The thickness of the adhesive layer is approximately equal to the thickness of the tile. However, it is better to make the layer thinner than thicker. Be sure to level the surface so that there are no voids.

Due to the variety of form factors, steps and risers can be docked in different variations. To create a voluminous and effective laying of clinker tiles, an overlap is performed on the steps. With this method, a gap of about 2-3 mm is left between the spout of the figured step and the riser. The main advantage of this option is that it is not possible to achieve a perfectly even cut of the vertical slab. This method is used for laying clinker on wood or metal.

Butt-laying of steps is possible exclusively on a concrete base, since its coefficient of thermal expansion is similar to that of clinker.

Between the clinker steps, it is necessary to leave gaps of about 10-12 mm, which are rubbed with special semi-dry mixtures for wide joints.

Useful advice! Do not glue the protruding part of the step. This will preserve the integrity of the structure when the base is deformed.

Choosing an adhesive for clinker tiles

There is a wide range of adhesives for outdoor use on the construction market. Adhesives are classified into the following types:

- universal;

- reinforced;

- moisture resistant;

- white;

- heat resistant;

- mixture for non-standard surfaces;

- frost-resistant.

The universal adhesive is suitable for tiling the interior of a room with small and medium-sized tiles. This adhesive mixture is not suitable for outdoor use, since it does not have sufficient elasticity and frost resistance. It is not able to provide the strength of the connection, which can lead to the destruction of the clinker steps.

The reinforced type of glue is suitable for facing surfaces with large tiles with dimensions of more than 30x30 cm. It responds well to static and dynamic loads, but does not tolerate temperature fluctuations well. Therefore, this is not the best option for outdoor work.

Moisture resistant adhesive is used for objects that are exposed to constant or prolonged exposure to water. However, such glue is not suitable for outdoor use. The heat-resistant adhesive mixture is used for lining stoves, fireplaces and other objects with a high temperature. Adhesive for non-standard surfaces is used for laying tiles on metal or wood. White glue is used to cover transparent mosaic tiles.

For laying tiles outdoors, frost-resistant glue is intended. It guarantees the resistance of the cladding to temperature extremes. The composition is based on special additives that provide elasticity and good adhesion of the base to the clinker, and at the same time prevent the deformation of the adhesive.

Popular brands of glue

The most popular brands of frost-resistant glue are: Ceresit CM 17, Ceresit CM 117 and Eunice 2000.

The main advantages of the Ceresit CM 17 adhesive mixture are good adhesion and excellent elasticity. The glue is not afraid of moisture. The composition is able to withstand temperature drops in the range from -50º to 70ºC for 100 cycles. 30 minutes after application, the mixture is completely solidified.

Moisture-resistant and frost-resistant Ceresit CM 117 glue is suitable for various types of substrates: concrete, lime, cement. It can be used for indoor and outdoor use. The adhesive is ideal for cladding outdoor pools. It is able to withstand temperatures from -50º to 70ºC for more than 100 cycles. The time reserve for corrective work on laying tiles is 20 minutes.

The adhesive composition of Eunice 2000 has a wide range of applications. It can withstand temperature fluctuations from -50º to 50ºC for about 30-40 cycles. Completely hardens 10 minutes after application.

The steps made of clinker tiles not only protect the porch or staircase from destruction, but also create a monumental and graceful appearance of the entire structure. Despite the fact that this facing material is expensive, it has high technical and operational characteristics and can last for many years without losing its original appearance.