Linoleum gained popularity among other types of coverings several decades ago, when it was actively laid on the floors of Khrushchevs directly on concrete floors. During this time, manufacturers have been constantly working to improve the quality of the material, introduce new technologies and improve the design. It is laid on a different basis. This article will tell you how to properly arrange a floor under linoleum on a concrete floor.

Content [Hide]

- 1 Recommendations and steps for laying linoleum on a concrete floor

- 2 Preparing the floor for linoleum: leveling the base

- 3 Floor under linoleum on concrete floor: choice of material

- 4 How much does it cost to put 1 sq. m of linoleum: consumption and cost

- 5 How to lay linoleum on a concrete floor: work sequence

- 6 Laying linoleum on a concrete floor with your own hands: important nuances

- 7 Installation of underfloor heating under linoleum: instructions from A to Z

- 8 Water heat-insulated floor under linoleum: principle of operation

- 9 Electric underfloor heating under linoleum: types, disadvantages and advantages

Recommendations and steps for laying linoleum on a concrete floor

Owners of apartments, both in new buildings and in old buildings, during the renovation process usually ask a typical question: is it possible to lay linoleum on a concrete floor. And the most popular answer both on Internet forums and from experts: linoleum is the main flooring material in modern buildings.

In order for the linoleum coating of the concrete floor to be successful, it is necessary to adhere to all stages of installation

The process of laying linoleum includes several stages:

- selection of suitable material;

- preparation of the base and leveling the surface;

- surface waterproofing;

- calculation of the consumption of material for laying;

- marking and cutting of linoleum;

- fixing the floor covering with adhesives;

- fastening mechanically using skirting boards.

Each of the stages has its own sub-stages, features and importance. The guarantee of successful work lies both in the correct choice of linoleum, glue, and in the preparation of the base. The process becomes much more complicated if it also includes the installation of a warm floor under linoleum on a concrete floor.

Experts recommend not to neglect the stage of leveling the floor under linoleum before laying, since this is a guarantee not only of the beauty of the surface, but also of the duration of the coating. The smoother the base, the longer the linoleum lasts.

Preparing the floor for linoleum: leveling the base

Regardless of the type of linoleum, before installing it, you need to prepare the base. This is an important factor affecting the service life of the roll coating. It would seem that even minor cracks, depressions or protrusions can lead to rapid abrasion. linoleum in these problem areas. Therefore, the base should be as flat as possible and also be clean.

If you have a concrete floor, you need to take care of the sound and heat insulation of the surface. The base requires special preparation when laying a warm floor under linoleum. We will talk about this in a separate section.

Important! You should not use sheet materials to level the surface of an uneven concrete base, since sooner or later they will deform under the contours of the floor and subsequently modify the linoleum.

The usual preparation of a concrete base consists of the following steps:

- Dismantling the old coating. Before leveling the floor under linoleum, it is advisable to remove the old coating. In rare cases, you can leave the old linoleum. But the coating of linoleum tiles must be removed unambiguously, this also applies to old substrates, insulating layers. A bare concrete base should remain. The surface is thoroughly cleaned from dust and other contaminants.

- The assessment and diagnosis of a concrete base is determined by the totality of all flaws, including bulges, slopes, dents, drops. If they make up more than 20% of the total area of the room, then it is necessary to perform a concrete screed or fill the surface with a self-leveling mixture. Such measures will help to make the base as flat as possible.

- Elimination of minor flaws. If the screed is optional, then it is enough to spot minor damage. Particular attention should be paid to defects between concrete slabs. To do this, use a putty, epoxy resin or a solution of cement mixed with drying oil. The cleaned and flat surface is covered with a primer.

- Laying of layers of heat, noise and waterproofing. Before laying linoleum, you need to take care of thermal insulation, since concrete is cold in itself, and even a coating with a heat-insulating substrate will not save the situation. For thermal insulation, fiberboard or plywood can be laid on the floor under the linoleum.

It is recommended to use a polyethylene film not thinner than 200 microns as waterproofing. It is laid with an overlap of at least 20 cm and with an approach to the walls by 5-6 cm (the excess is removed after laying the linoleum). Masking tape works well for sound insulation.

Floor under linoleum on concrete floor: choice of material

A practical approach involves taking into account the structure and durability of linoleum.

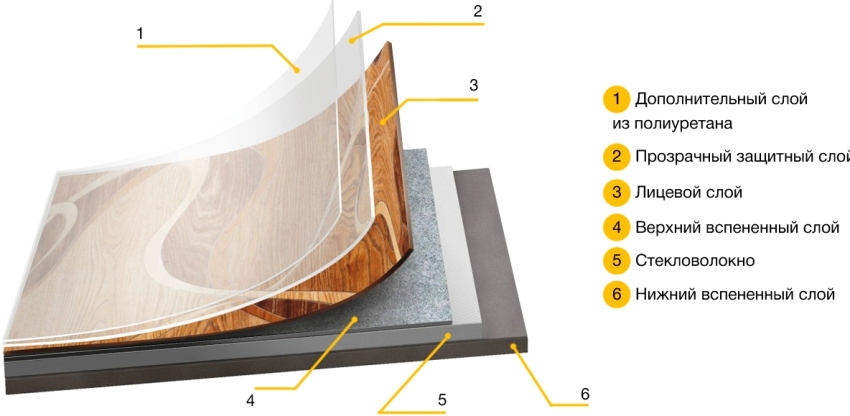

Depending on the structure, linoleum is divided into homogeneous (single-layer) and heterogeneous (multi-layer). The latter option is usually used in domestic conditions, since it already has the necessary basis, most often insulated or waterproofing.

There are two most common types of linoleum, which are used as a coating on concrete floors in apartments: polyvinyl chloride (PVC) coating and natural linoleum, which includes cork flour, wood resin, lime and linseed oil. Both of these species are harmless to health, resistant to bacteria and repelling fat.

Helpful advice! For the kitchen and hallway, where the permeability is the highest, it is better to take semi-commercial or even commercial class linoleum. In public buildings, the most popular option is commercial homogeneous linoleum.

Another classification depends on the degree of resistance of linoleum to stress. In this case, the roll decorative coating is divided into household, semi-commercial and commercial. Judging by the names, household coverage is intended for residential premises, but this is only at first glance. It is, of course, inexpensive, but has low wear resistance, that is, the price corresponds to the quality. All rooms in the house have different functionality, which should be taken into account when choosing a floor covering.

Household floor covering with a thickness of 1.5 mm is suitable for offices, living rooms and bedrooms. For the corridor, kitchen and children's room, it is better to take linoleum with a thickness of at least 3 mm, which is easier to protect from mechanical damage.

Aesthetic characteristics of linoleum of different collections

First of all, it should be noted that the color of the flooring should correspond to the overall design of the room. The choice of quality material also depends on the manufacturer. Tarkett has been considered the most popular campaign on the flooring market for many years. Commercial, semi-commercial and household linoleum can be found in different series of this supplier.

Linoleum manufacturers took into account taste preferences in different versions. For example, the Tarkett Linoleum Discovery series maximally conveys all the beauty and charm of natural materials, allows them to be brought closer to natural ones without harming nature. The Tarkett Grand linoleum collection is a variety of decor and fancy patterns. It includes both whimsical lines and the maximum imitation of natural parquet.

In turn, Tarkett Idyll linoleum differs not so much in aesthetics as in practicality and increased strength. It can withstand the stress of pins and sharp legs of mobile furniture. The material has good heat and sound insulation. This series includes various models, including those designed for rooms with high traffic. An example is Tarkett Atlant 1 linoleum from the Idylle Nova collection. The durability of this coating allows it to be used in offices with an average intensity of work and childcare.

Calculation of the size of linoleum: width standards, consideration of features

When calculating the size of the canvas, you need to take material with a margin - several centimeters more than the area of the room. This is quite easy to do in standard square and rectangular rooms. It is enough to measure the dimensions of the room and add 10 cm on each side.

Helpful advice! An online calculator will help you accurately calculate the required amount of material. The length and width of the floor are entered into the windows (for example, the width of linoleum is 2 m). How many meters of linoleum is required from such a roll will be indicated in a special window.

If there is a pattern on the linoleum, then you need to take into account the allowances for joining

In rooms with complex outlines, you need to approach the cutting process more carefully and make more stock. When buying linoleum with a pattern, you should also take into account the allowances for joining the pattern. It is equally important, when purchasing a coating, to check that the batch number indicated on the labels of linoleum rolls matches.

To avoid seams on the floor, the width of the roll should be equal to the length of one of the walls of the room. The standard width of linoleum is 2 m - 5 m in half a meter increments. Various coating sizes allow you to calculate the most economical option and avoid joints.

A simple secret to avoiding seams is to size the roll according to the length of one side of the room. For example, in a narrow hallway of 1.8x6 meters, linoleum 2 meters wide is suitable. How many meters of linoleum is required in total depends on the length of the hallway. In this case, it is 6 meters.

When deciding where to buy linoleum, you can resort to the classic options and visit a hardware store. Today's consumers are increasingly using the Internet to order goods, this service - online shopping and delivery - extends to flooring.

In order not to be mistaken with the size of linoleum, it is necessary to measure the room and add 10 cm to each side

How much does it cost to put 1 sq. m of linoleum: consumption and cost

It is logical that linoleum is the most important component in the installation process, it is on it that the main costs fall. In addition, you must consider the financial resources required to purchase other materials. For example, installation of linoleum is impossible without a backing and glue.

In order to calculate how much it costs to lay linoleum per square meter, as well as the total cost of laying the coating on a concrete floor, it is necessary to add up the cost of such materials:

- linoleum;

- cement, putty or self-leveling mixture for the base;

- insulating boards, films and elements for their fixation;

- glue or mounting tape for fixing linoleum;

- skirting boards and materials for their fastening.

To calculate the price of laying 1 sq. m of linoleum, you need to add up the cost of all the materials necessary for work

Now it's not a problem to buy cheap linoleum. Where to buy high-quality is a more difficult task, and in this matter it is better to trust prestigious stores and professionals.

The price of linoleum per square meter depends on the above qualities of the coating: material, wear resistance, decorative features. The class and series of coverage have a pricing value. The price per m² of commercial linoleum, as a rule, does not always exceed the price of semi-commercial. Sometimes a household covering from an elite series from a brand manufacturer is more expensive.

Related article:

Linoleum: photos of coatings in various rooms and tips for choosing a material

Advantages, disadvantages, characteristics and properties of various classes and types. Recommendations for the choice of material.

The total cost of materials for leveling the floor depends on its condition. The calculation of the consumption for the cement screed and primer is made based on the area of the room. The thickness of the leveling layer must be at least 3 cm.

Helpful advice! The mortar for pouring a concrete base must be made quite thick. It is leveled with a special spatula. To orient the level, special marks are made on the walls and slats are installed.

For a primer, one top coat is sufficient. The need for insulating materials is also calculated based on the quadrature of the room. They should be installed with a minimum number of joints.

Adhesive for linoleum on a concrete floor: types of fixers and price calculation

When calculating the amount of fixer for linoleum coating, the length of the joints and the total perimeter of the room for gluing the coating under the walls are taken into account. The price of the material depends on its type. For example, the cost of mounting or masking tape is cheaper and more economical compared to glue, in addition, it is easy to dismantle it if necessary. At the same time, the fixation with its help will be less strong and reliable.

Linoleum glue or mastic is applied to the entire floor area, which is then covered with linoleum. Therefore, the consumption and price of glue for linoleum is calculated based on the total quadrature. Working with such clamps requires special care and step-by-step steps with careful leveling of the surface to avoid wrinkling.

Before you buy glue for linoleum, you need to decide on one of its types:

- polyurethane;

- one- or two-component;

- water-dispersive;

- adhesive with solvent.

For different types of linoleum, special adhesive bases are selected so as not to spoil the substrate and the coating itself.For example, glue for commercial linoleum is characterized by increased adhesive power. It is better to take Tarkett linoleum glue from this manufacturer, since it is intended for a certain series of coating. Manufacturers, as a rule, indicate the average consumption of glue for linoleum per 1 m² on the packaging.

Joint materials: cold welding linoleum adhesive

In spacious rooms or in rooms with a complex layout, when laying linoleum, you often cannot do without material joints. To connect the seams of linoleum, different materials are used: slats, strips, construction tape. The most popular and reliable in this regard is the modern method - cold welding. To do this, use a special adhesive that forms a colorless seam. Finding the place of bonding after the procedure is visually difficult, it can only be determined by touch.

With linoleum adhesive, cold welding will make the seams solid, secure and neat, while hot welding will make the seams rough and change the natural color of the coating. The method does not require special skills and efforts. Also, no special tools and equipment are required.

The correct calculation of materials will help to maximize the rational distribution of the costs of laying the floor and plan a budget. Having bought everything you need, you don't have to throw away the surplus or additionally run around the shops to buy additional materials. All costs are based on floor space calculations and material manufacturers instructions.

Helpful advice! It is necessary to approach the process of calculating linoleum with special care, when laying it, it is supposed to combine patterns at the joints. In this case, the section of the covering should be approximately 1.5 m longer than the area of the intended installation. It is also important to consider that linoleum with an ornament should be laid in the longitudinal direction.

An example of calculating the amount of required materials

Below are approximate calculations of the consumption of materials for a room with an area of 4x5 m, taking into account the fact that the concrete floor requires leveling.

- Calculation of screed materials. Taking into account the area of the room in 20 m², multiplied by the height of the cement screed in 0.03 m, we get 0.6 m³, which in terms of liters is equal to the value 600 (4 * 5 * 0.03 = 0.6 m³ = 600 l) ... If a self-leveling mixture is used, then its consumption will be slightly less due to the pouring height of 0.02 m. In general, 0.4 m³ or 400 liters will be needed (4 * 5 * 0.04 = 0.4 m³ = 400 liters).

- Consumption of insulating materials.Sheet will need approximately 22 m², where 20 m² is the area of the room + 10% of the stock. The same consumption and roll materials. The waterproofing film will need a little more, taking into account the allowances for overlapping on the sides of 20 cm, that is, approximately 28 m².

- The required amount of linoleum.If the coating does not need to fit the pattern, then, taking into account the 10 cm gap around the perimeter, approximately 21 m² (5.1 * 4.1 = 20.91 m²) will be needed. If it is necessary to match the patterns, you need to throw about another 5m2. As a result, 26 m² is required.

- Retainers.Glue or a mastic-like base will need approximately 12-15 kg (more accurate calculations can be made based on the characteristics indicated on the package). In the case of using a mounting tape, it will need 25-30 m.

- Expendable materials.Their number mainly depends on the condition of the base, so we give an average amount. The consumption of the putty will be 400-500 g, epoxy resin or cement mortar - up to 1.5 liters. Also, do not forget about rags and necessary tools.

How to lay linoleum on a concrete floor: work sequence

If a concrete floor not perfect, it is recommended to align it first

After the surface of the base is completely dry after leveling, a roll is unrolled on it and the material is allowed to "lie down" in the room where it is supposed to be laid. Ideally, it will take a couple of days. This is necessary in order for the canvas to reach the same humidity and temperature indicators that the room itself corresponds to.

On an ideal concrete base, linoleum is laid, skipping the leveling stage. The temperature in the room during installation should be at least + 15 ° С, the humidity should not exceed 68%. The canvas is carefully leveled on the surface.

Cutting is carried out along the contours of the room using a sharp construction or clerical knife. It is advisable to pre-cut with a margin of 3-5 cm on all sides, and remove the excess after gluing or cover it with baseboards.

If the styling assumes the presence of intersecting stripes, then they need to overlap, and then cut off the excess using a ruler and a sharp knife. If there are protrusions on the walls, then there is no need to rush to cut. It is better to measure everything carefully and apply preliminary markings on the canvas.

Important! In a spacious room, where laying linoleum is impossible without seams, the strips must be positioned longitudinally so that joints do not form across the aisles. Thus, the seams will be less susceptible to mechanical stress, and the likelihood of their divergence will be lower.

The next step is to fix the coating. There are several types of it:

- using bituminous mastic;

- using adhesives;

- using mounting tape;

- glueless (or mechanical) method.

Fixing linoleum with mastic: advantages and technology

The choice of a suitable method of fastening a roll covering depends on the type of room, its area, the type of linoleum, the presence of seams and the preferences of the owners.

One of the most popular and practical options is the use of bituminous mastic. It is a good waterproofing material with a pasty consistency that fills in irregularities and microcracks that remain after leveling. There are different compositions of mastics. The most common option for gluing to a concrete floor is dispersive, which is suitable for linoleum with a fabric or heat-insulating base. If the coating does not have a base, then it is glued with a rubber-based mastic.

The technology for gluing linoleum using mastic includes the following stages:

- base primer;

- spreading the floor covering, holding for a day;

- applying mastic with a notched trowel to the floor on one side of the material, for this part of the blade

- raise;

- the cover is carefully lowered to the floor and carefully straightened to remove air.

Similarly, the other side of the linoleum sheet is glued. If you need to fix different types of material, then apply a layer of mastic of a certain thickness.

Mastics come in different compositions; for gluing linoleum to a concrete floor, dispersion is most suitable

In a spacious room, the following trick will help to evenly glue the linoleum to the concrete floor. It is necessary to fold the canvas in half with its face inward, then glue or mastic should be applied first to one side of the cut and glue it to the base, then the same operation must be carried out with the other side. Use a roller to remove wrinkles on the surface.

Linoleum adhesive and mounting tape: rules of use

A similar (as when using mastic) method of fixing linoleum is the use of special adhesives. Linoleum glue has one drawback - it does not have insulating and leveling characteristics.

When applying the fixing material to the floor, special attention should be paid to the entrance area and joints.For more reliable adhesion at the seams, you need to bend the edges of the canvases and grease the places of contact with the floor with glue well.

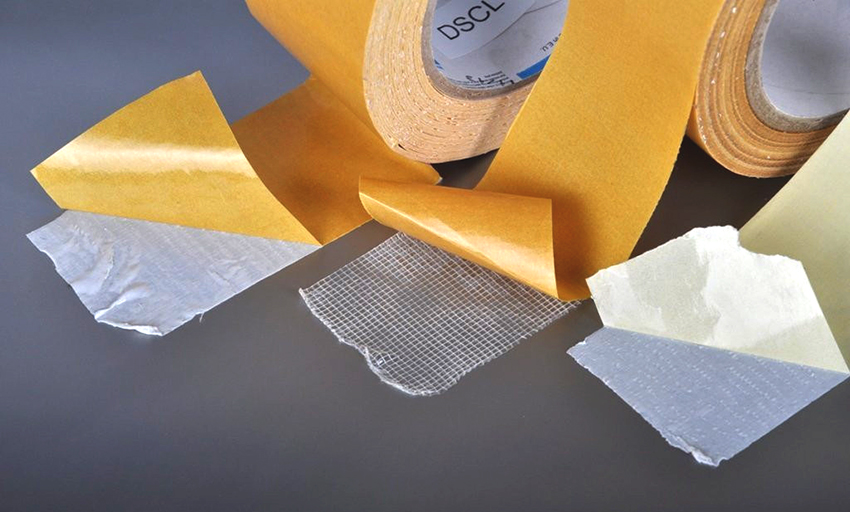

The use of mounting tape is the easiest way of fixing, but the material itself is short-lived, especially at the seams. Therefore, it is advisable to use it in rooms with an area of no more than 20 m², with low traffic, implying linoleum flooring in one piece.

In the process of gluing the coating to the tape, it is first laid around the entire perimeter and in doorways. If the installation involves several strips of linoleum, then the tape is also glued at the seams. To avoid swelling of the web, place several strips of adhesive tape in the center of the area.

Helpful advice! In a small room or room with low traffic, you can use linoleum flooring without the use of bonding material. The technology is very simple: the material is laid with allowances, without cutting it. After the canvas settles, the excess is cut off, and the plinth is attached around the perimeter of the room. The disadvantage of this method is that the coating can wrinkle under the influence of stress.

The advantage of the mounting tape is easy dismantling of the coating and the preservation of its integrity. If glue or mastic was used in the installation, then removing the linoleum is a more complicated process, and the integrity of the canvas is violated.

Laying on double-sided tape is quite simple. The room is divided by eye into several squares and tape is attached to the floor, on which the canvas is carefully laid.

Laying linoleum on a concrete floor with your own hands: important nuances

Installation of linoleum can be done on your own, but first you need to take into account several important points, on which the final quality result directly depends.

In particular, there are two installation technologies: trimming (up to 10 cm of material is left along the perimeter of the room); without a bend (cut immediately clearly along the contours of the room). When making a choice, it must be borne in mind that walls can have curvature, therefore it is more advisable to cut the material directly on site. The second option is suitable for rooms with perfectly flat walls.

Therefore, when preparing the base of the floor, you need to take care of leveling the walls. If a overhaul was not planned, then you need to adjust the walls at least at a height of 7-10 cm from the floor so that the linoleum and baseboard lay flat. When choosing linoleum with an ornament, you need to take canvases from the same batch, otherwise there may be differences in color.

If the walls of the room are not perfectly flat, then it is recommended to lay linoleum using trimming technology

When installing linoleum on a concrete floor, you should not neglect the substrate. Sheets and polyurethane foam cover are fixed, like linoleum, with mastic or glue. In this case, it is better not to use scotch tape. To lay the coating directly on concrete, you need to take multilayer insulated linoleum, which has an additional felt or foam backing.

It is advisable to treat the seams and joints during the laying of the floor covering with a special compound. To do this, you can use mounting tape, glue or mastic. The most reliable option is a combined one: for fixing, both mounting tape and adhesive material are used, with which the edges of the canvases are carefully processed.

Helpful advice! In the question of cutting linoleum, the proverb is relevant: "Measure seven times - cut one!" Therefore, you should not rush to cut off large pieces of the coating, since it will be almost impossible to correct the error.

Installation of underfloor heating under linoleum: instructions from A to Z

Installation of linoleum on a heated concrete floor is a more laborious process, since it also directly includes the stage of installing a warm surface. There are several ways to heat floors. The most popular ones are:

- warm water floor using the circulation of the coolant in a closed loop;

- electric underfloor heating, where heating is carried out using an electric cable, heating mats or infrared film.

Which floor heating for linoleum is preferable to choose, the owners themselves decide. In a private house, all types of installation of a warm floor are allowed, in a high-rise apartment the possibilities are limited. The option of a water-heated floor is excluded here.

It should also be noted that not every coating is suitable for underfloor heating. Linoleum must be selected with a special marking on the packaging indicating that the material is designed for high temperatures - up to 28 ° C. In addition, it is necessary to provide for the installation of sensors and thermostats.

For a warm floor, it is better to choose durable linoleum, but not very thick. Household thin linoleum should not be used for this purpose. The optimum coating thickness should be 2-3 mm.

Plays a special role linoleum underlay... It is advisable not to use it for covering on a warm floor. For the purpose of better thermal conductivity, it is recommended to take homogeneous linoleum. Rolls of different sizes can be used. The work of the warm floor does not depend on this. Therefore, for a narrow corridor, a roll with a width of linoleum 2 m or even 1.5 m is suitable.

As for the wear resistance class of linoleum, it should be as high as possible. At the same time, the most durable class 44 coating should not be taken for residential premises, as this requires extra costs. The best option for a warm floor is class 34 linoleum.

The choice of floor heating depends not only on the preferences of the owners, but also on the type of housing

Water heat-insulated floor under linoleum: principle of operation

Water floor heating began to be used as an additional source of heat to the centralized system. Now it acts as an independent heat supplier. But its installation is quite complicated and is permissible only in private houses; specialists should be engaged in the installation.

The advantage of hot water underfloor heating is that it can operate on almost any energy source: gas, electricity, liquid and solid fuels. It should be noted that the coolant does not need to be heated to a high temperature: at the outlet it should be 30-40 ° C.

Another plus of hot water heating is energy savings due to the low pressure in the system. At the same time, the elements of the device work in a sparing mode in comparison with other alternative types of heating. This significantly extends the service life of the system to an average of 50 years or more.

In addition, the operation of hot water heating does not generate electromagnetic radiation harmful to human health. Qualified, professional installation of underfloor heating excludes the presence of detachable connections, which reduces the likelihood of system leakage to almost zero.

Helpful advice! Having opted for water heating, one should take into account the relative high cost of such a warm floor under the linoleum. The price of the system itself, equipment and materials is much higher than other types of heating You should also take into account the considerable costs of installation work.

Electric underfloor heating under linoleum: types, disadvantages and advantages

When deciding which to buy a warm floor for linoleum, most prefer electric types. Their main advantage is ease of installation and operation. In addition, they can be installed in high-rise apartments.

The species difference of electric underfloor heating depends on the type of heating elements.They are divided into cable, matte and film. Cable underfloor heating has the form of a heating cable that is laid in the floor screed or placed in the form of heating mats covered with a heat-resistant film with a cable in the middle.

For heating, a single-core and two-core cable is used. Laying a single-core cable involves returning the second end to the same point where the first is. A two-wire cable does not require this. In addition, it is more environmentally friendly: radiation from it is 5 times less.

There are self-regulating cables that protect the floor from overheating, but they cost several times more than simple ones. The price of cable underfloor heating is also influenced by the specific power factor per 1 m² of the room.

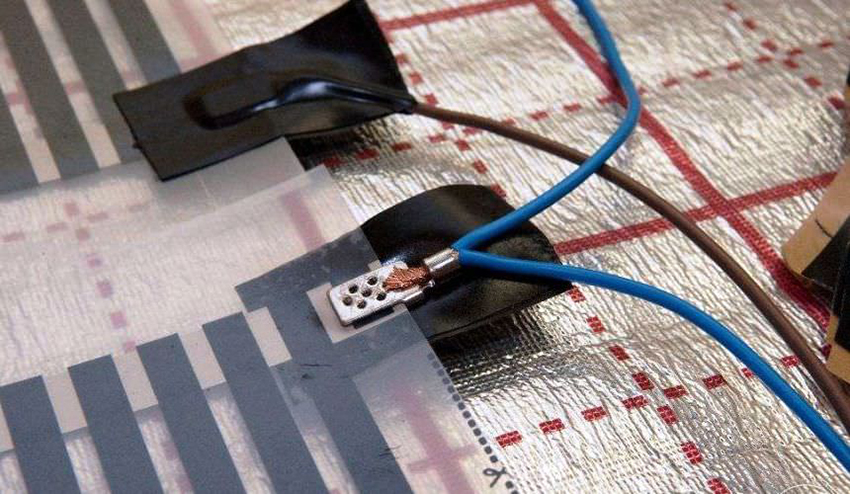

The basis of heating in film warm floors under linoleum serves as a thin film equipped with soldered graphite plates and copper conductors that transmit current. The advantage of this system is ease of installation. It can be installed under laminate, linoleum and walls.

An infrared floor for linoleum is the most economical; no screeds are required under it. With a guaranteed service life of 15 years, it can work even 50. In addition, film floors are cheaper than cable ones. Thus, this type of floor is the most profitable for DIY installation.

DIY installation of a film warm floor under linoleum

Film heat-insulated floors are produced in special packages that contain a roll of thermal film, wiring, bitumen insulation and terminals. The number of packages required for purchase depends on the square of the room. In addition, for the installation of the floor, you will need thermostats, heat reflectors, a protective film made of polyethylene, double-sided tape, tools.

Preparatory work for the installation of a warm floor under linoleum, as in the case of simple web laying, includes leveling and cleaning of the backing, as well as marking and cutting of the film. On a flat base floor, determine the locations of the film layout, measure the length of the canvases. The place of installation of the thermostat is determined in advance. Next, the thermal film is cut in special places marked with a dotted line.

Important! During the marking, the manufacturer's requirement should be taken into account, which prohibits the installation of thermal film under heavy furniture and objects.

For the purpose of thermal insulation, an Izolon heat reflector is placed on the concrete floor. The canvases are attached to the base with tape. In the same way, parts of the heat-reflecting material are glued together, ensuring their reliable fixation. It is important to cover the entire floor with a heat reflector to prevent heat leakage. Next, pre-cut pieces of thermal film are laid, while the copper strip must be located at the bottom.

The sections of the copper bus are covered with bitumen insulation in such a way as to reliably close all the silver contacts that are responsible for connecting the copper bus to the carbon strips. Then, at the place where the electric wire is connected to the copper bus, the contact clamps are mounted so that one end enters the middle of the thermal film, and the other remains outside. The terminal clamp is tightly fastened. The strips of the film are fixed with tape on the heat reflector, as well as between themselves.

Insulation and connection of infrared warm floor under linoleum

The points of connection of electric wires to the thermal film are carefully fixed and insulated from above and below. Pieces of insulation are connected to each other. All silver contacts at the edges of the film must be covered with bitumen insulation. She also fixes the floor temperature sensor to the black graphite strip of the heating element.

Sensors and wires are hidden in special cutouts on the heat reflector, so that as a result, a uniform surface is obtained for the finishing floor covering. The panel with the thermostat is mounted on the wall.

For the purpose of additional protection, we cover the film warm floor with plastic wrap, and install a protective material on it. The best option for these purposes is sheet plywood. The sheets are carefully screwed to the main floor so as not to snag the thermal film.

Linoleum is easily laid on the protective layer. The installation process is the same as in the case of glueless laying on a flat base of a concrete floor. The cover is fixed with plastic skirting boards. It is because of the possibility of easy dismantling, for safety reasons, linoleum is laid on the infrared floor. Warm floors, provided that they are installed correctly, ultimately create additional coziness and comfort, and the coating is a beautiful addition to the overall decor.

Thus, linoleum is ideal as a concrete floor covering. It is an economical, environmentally friendly and easy-to-install material. Knowing what linoleum is, having mastered the rules for laying it, you can independently arrange the flooring. In addition, it is linoleum that is most suitable for installing a warm floor on a concrete floor.