All defects tend to increase exponentially - this is an axiom. Without any qualifications, it applies to concrete floors. Regardless of the grooves that have appeared on the surface of the linoleum, or the serious creak of the laminate, the situation can be brought to the need for a complete replacement of the filler base. It is much easier to make timely repairs to the concrete floor. This will greatly save money and physical strength.

In order not to bring the situation to the point of the need to completely replace the filling base, it is necessary to timely repair the concrete floor

Content [Hide]

- 1 The main types of damage and repair methods for floor screed

- 2 Purpose and classification of repair mixes for concrete

- 3 Repair of epoxy floors related to concrete base problems

- 4 Do-it-yourself floor repair in an apartment: some tips

- 5 Specificity of bathroom floor repair

- 6 Basic rules for performing high-quality repairs to a concrete floor in a garage

- 7 Repair of concrete floors: prices for various types of work

- 8 Concrete floor repair: recommended formulations

The main types of damage and repair methods for floor screed

Concrete is a strong and durable coating. But over time, various defects may appear on it, requiring floor repair: cracks, chips, potholes, irregularities. Most often they are the result of a violation of the pouring technology. There are several main reasons:

- Lack of shrinkage joints, poor-quality base reinforcement. As a result, chips and cracks appear in the concrete screed.

- Presence of air that tends to form small holes on the surface of the pour. The defect appears due to poor-quality processing of concrete with a needle roller.

- Pouring onto an uncleaned area or lack of a waterproofing layer. These violations contribute to the flaking of the top coat.

- Use of low grade cement, mortar of wrong consistency. Such violations cause the appearance of a large amount of dust on its surface during the operation of the floor.

Cracks and chips are visible defects, voids and delamination should be attributed to latent defects. The latter may not be detected for some time, their presence is determined by tapping with a hammer - in places of voids and detachments, the sound will be dull.

Depending on the degree of damage, the method of repairing the floors in the house is chosen: fragmentary, major, or complete replacement of the screed. The technology for performing work will also vary, it will require the use of certain tools and mixtures.If there is no knowledge about pouring a concrete floor, then it is better to entrust the determination of the type of repair and its implementation to specialists.

Purpose and classification of repair mixes for concrete

Concrete floor repairs are performed using special mixes. The use of a standard cement mortar will not give the desired results, that is, it will not provide the necessary adhesion, plasticity, heat resistance, etc.

As a rule, mixtures for repairing a concrete floor have a dry composition (less often - pasty), into which water and, possibly, other components are added before use to enhance certain properties of the material.

Formulations are classified by scope:

- mixtures for the repair of concrete structures under heavy load: floor slabs, beams, etc .;

- to eliminate defects in the concrete floor;

- preventing corrosion of reinforced concrete.

Repair mixtures are also divided into the following types:

- thixotropic (do not spread, used for vertical embeddings);

- injection molding (eliminate defects in horizontal position).

To carry out repair work on the concrete floor, casting compounds are used.

The market offers a huge number of mixes for the repair of concrete floors. In order not to purchase the material in excess (it is not stored for a long time in the open state), it is necessary to correctly assess the degree of damage and calculate the amount of the mixture. Consumption in grams per 1 m² always indicated on the packaging.

Important! To repair a concrete floor, it is necessary to purchase only non-shrinking compounds.

Repair of floors in a private house, apartment: repairing small cracks

The operation of the concrete floor in private houses and apartments can be considered moderate, that is, the screed is not exposed to heavy mechanical stress associated with the installation of equipment and the constant movement of a large number of people. Therefore, the most common type of defects in living quarters is cracks. This problem is especially typical for Khrushchev apartments, in which floor repair is necessary due to the prescription of the filling.

Before you understand the technology of carrying out work to eliminate cracking, it is worth voicing the consequences in the absence of response to the defects that have appeared:

- concrete in the edge of the cracks will crumble;

- the gap will expand and lengthen;

- liquid will seep through it, moisture will penetrate;

- creases and holes may appear on the floor covering that is laid on top of the concrete fill.

The process of liquidating small (up to 2-4 mm) and large (up to 50 mm) cracks has its own differences. Small cracks, which are more typical for residential premises, are repaired as follows:

- The crack is enlarged to a depth of 8-10 mm.

- With the help of a construction vacuum cleaner, the formed crumbs and dust are removed.

- The formed cavity is poured with a primer (polyurethane or epoxy), previously diluted with solvent R-648 in a ratio of 1:10.

- Then the prepared crack is filled with a repair mortar, sifted quartz sand is used as a filler.

- After complete solidification, the area is polished.

Such a floor repair in an apartment has a moderate price - 350-450 rubles per m² (excluding the cost of consumables). Therefore, in the absence of opportunities or skills, it is quite possible to use the services of specialists.

Helpful advice! Before carrying out repair work, the concrete floor in residential premises should be dried for several days to remove any remaining moisture.

Large-scale renovation of industrial floors: large cracks, correction of expansion joints

As mentioned above, the technology for sealing large cracks is somewhat different. It is performed in several stages:

- Regardless of the depth, using a grinder, the crack is increased by another 10-15 mm.

- Then, in the longitudinal direction, using the cutting method, two grooves are made that allow you to extract the damaged concrete.

- The resulting cavity is dedusted, treated with a previously diluted primer, and then filled with a repair mixture. The filling process is done in several stages: a new amount of repair solution is applied to the frozen first portion.

- After hardening of all layers, grinding is performed.

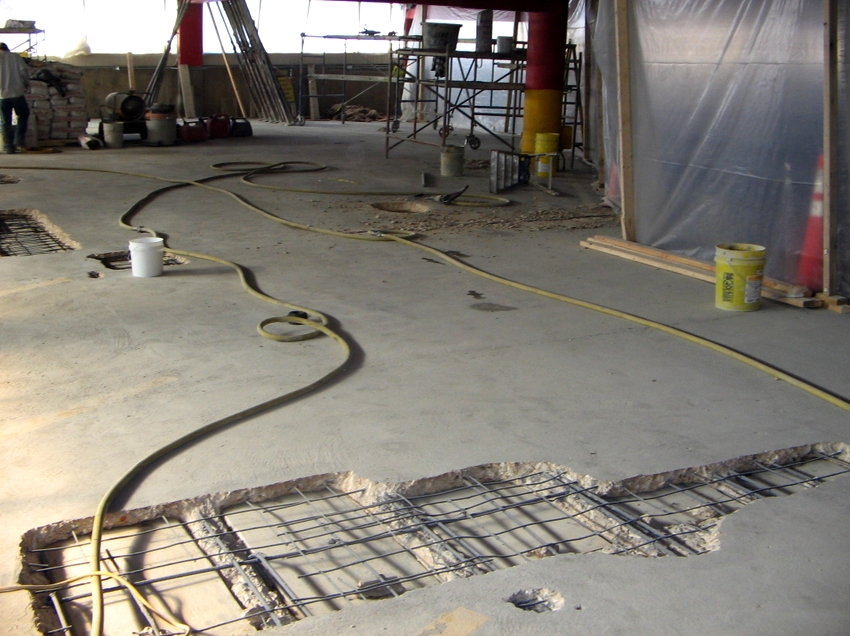

If in the course of work it was necessary to remove a significant amount of damaged screed, metal staples are used to ensure a good quality repair of industrial concrete floors. This is done as follows:

- in the gap prepared for applying the primer, transverse grooves with a depth of 25-30 mm and a width of 100-150 mm are made;

- the cut surface is dust-free, a small amount of the repair mixture is placed on the bottom, into which metal staples are laid;

- further work is carried out in the same sequence as when filling deep cracks without staples.

The use of staples provides additional reinforcement of the concrete screed, which significantly extends its service life.

Amendment of expansion joints should also be referred to serious repair work. Elimination of this defect is performed in the following sequence:

- The damaged seam is enlarged, the damaged concrete is removed, the preparation is carried out as when sealing the seams (dust is removed, primed), the repair mixture is poured by inserting beacons along the entire length of the seam.

- After solidification, the surface is sanded flush with the floor, the beacons are removed and a new seam is cut in their place.

- Then, with the help of a vacuum cleaner, the dust is removed, a Vilaterm cord is inserted, the crack is closed with silicone sealant.

The functional state of the expansion joints will ensure the integrity of the concrete screed even with significant differences in the level of the base on which the concrete is laid.

Repair of concrete floors in industrial premises

The specificity of the operation of a concrete floor in industrial premises contributes to the need for frequent repair of the screed. The main reason is the constant significant mechanical impact: the installation and operation of heavy equipment, the movement of goods, the movement of workers. Naturally, there is a repair of cracks in the concrete floors of such premises, it is carried out in accordance with the technologies described above.

Usually, floor defects appear in the form of potholes. The formation of dust on the casting surface is also an urgent problem. In residential premises, other materials are most often laid on the concrete floor, while in production the pouring remains open.

Regardless of the depth of the crack, with the help of a grinder, it is increased by another 10-15 mm

The pothole patching technology generally repeats the crack elimination method. Using an angle grinder, damaged concrete is cut to a depth of at least 20 mm and eliminated using a perforator.

Important! All loose parts of the filling must be removed, otherwise the repair will be ineffective.

Then the cavity is dedusted, primed, filled with a repair mixture, polished. If the depression is more than 50 mm, the filling should be done in two stages.

Cement dust on the floor is a violation of labor protection laws. Such a defect must be corrected immediately. It is necessary to grind the screed, carefully remove the dust and apply the compound. For light loads on the floor, a coating thickness of 150 microns is sufficient (Elakor-PU, Neomer-LP, Ashford-formula are recommended).

But for workshops with heavy equipment, such protection is ineffective. The coating should be at least 250-300 microns.

Related article:

Leveling the floor with a self-leveling mixture: process technology, types of mixtures

Types and properties of mixtures. Self-leveling floor technology. List of tools. Features of leveling wooden floors.

More often in production premises, not fragmentary, but overhaul of the floor is carried out. What process can be considered capital? It is quite simple to determine: if 30% (or more) of the concrete screed is damaged, major repairs are required. It involves the removal of large areas with the obligatory renewal of defective seams.

Repair of epoxy floors related to concrete base problems

Epoxy flooring is very popular today. It is not only a durable coating, but also allows for decorative design that contributes to the creation of a unique interior. The repair of self-leveling floors is significantly different from the elimination of defects in the concrete screed, for the very reason that other problems arise: the epoxy floor can become cloudy, exfoliate, sagging and bumps appear on it, the surface becomes sticky.

All of the above disadvantages are the result of the use of low-quality materials or a violation of the pouring technology. This article will highlight the problem of the appearance of defects in an epoxy floor associated with a poor-quality substrate - a concrete base.

In case of problems with the concrete underlay of an epoxy floor, the cost of repairing it will be quite high.

- Blistering and flaking may appear on epoxy. If the polymer layer comes off along with the primer, then the concrete base was poorly sanded and dust-free. Detachment from the primer is a consequence of the ingress of dirt or moisture before pouring the epoxy.

- Poor quality concrete substrates can result in cracking of the epoxy layer without loss of adhesion to the substrate.

- The appearance of through pores is observed when no primer is applied to the concrete screed.

The cost of repairing an epoxy floor in cases of concrete backing problems will be quite high. The fact is that you cannot do with cosmetics. It is necessary to remove the polymer layer completely or even with part of the concrete screed. Sometimes a complete dismantling of the floor and base is required.

Do-it-yourself floor repair in an apartment: some tips

It is quite affordable to repair the concrete floor yourself. It is necessary to start by determining the nature of the defects. If they are local, financial and physical costs will be minimal. If the damage is widespread, most likely, you will have to do a partial or complete dismantling of the screed.

The fewer defects in the concrete floor in the apartment, the less financial and physical costs will be

How to close up cracks, potholes, remove dust has already been discussed above. In this section, attention will be most of all paid to the independent production of mixtures and the process of leveling, grinding the concrete pavement.

To understand how to level a concrete floor, it is enough to read the instructions on the purchased mixture and consistently follow the recommended steps:

- thoroughly clean the floor surface, rinse with water several times with the addition of soda ash;

- moisten the screed with a spray bottle;

- prepare the mixture and pour it onto the floor, distributing it using the reiki rule.

Important! The leveling compound sets very quickly. In the absence of experience, it is worth cooking it in small portions.

To repair the floor in a wooden house or apartment, you can make the composition yourself.To do this, you should purchase a busylate or PVA glue, dilute with water in a ratio of 1: 3; using the resulting suspension, knead the cement-sand mortar also in a ratio of 1: 3. This composition is suitable for sealing small cracks. For more significant damage it is worth buying a factory mix.

How to grind a concrete floor at home? Professional machines are very effective, but they have a high price, and it is impractical to purchase them for repairing a small area. The Bulgarian will help out. Of course, you will have to make a lot of effort, but you can get a good result.

For grinding with a grinder, two attachments are suitable: an abrasive disc and a diamond bowl. This method of concrete floor processing even has advantages: the disc can penetrate into places inaccessible to a professional device. When using a grinder for grinding, be sure to protect yourself in case of a disc crumbling.

Specificity of bathroom floor repair

Despite the smaller bathroom area compared to living rooms, floor renovation is more difficult here. And the reason for this is the presence of a layer of tiles. Dismantling the old coating requires the use of a hammer drill, after which irregularities remain on the concrete surface. Repairs to floor tiles cannot be done without bringing the concrete base into proper condition. This must be done as follows:

If, after removing the old tile, there are many defects in the concrete base, it is better to abandon the repair and make a new screed

- Remove the remnants of tiles, remove irregularities from the surface of the screed.

- Fill cracks, chips, potholes using appropriate technologies. Particular attention should be paid to the joints between the walls and the floor - this will provide high-quality waterproofing.

- Impregnate the concrete screed with a waterproofing compound that will resist the accumulation of moisture and the development of fungi.

If, after removing the old tile, there are a lot of defects in the concrete screed, it makes sense to replace the fill completely, since the special environment of the room requires the ideal state of the base.

If the bathroom requires repair of an electric floor heating, laid in a screed, then the problem of its restoration becomes even more difficult: it is almost impossible to remove the electrical elements without serious damage to the concrete. And here we should talk about the overhaul of the filling.

Basic rules for performing high-quality repairs to a concrete floor in a garage

The concrete floor in the garage collapses much faster than in other, even industrial, premises. And it's not just about the increased load created by the car. Most of all, this is due to the influence of temperature. In cold winter time, the floor freezes, moisture contributes to the expansion and, consequently, destruction of the screed.

To prevent the coating in the garage from freezing, it is necessary to lay insulation sheets before pouring concrete

Minor damages in the garage concrete base are repaired using the methods listed above. But the overhaul of the screed has its own characteristics. The price of a floor renovation, involving the complete dismantling of the old base, will be high.

First, removing the old coating is a laborious process. Secondly, in order to reliably repair the floor, it is necessary to create a solid foundation - a bed of sand (100 mm) and crushed stone (200-300 mm), and then lay a reinforcing mesh and perform waterproofing. Thirdly, so that the concrete coating does not freeze, it is worth making insulation: before pouring concrete, lay sheets of polystyrene or polystyrene foam.

Important! Insulation boards must be laid in a seamless way - by gluing with a mixture that is resistant to temperature changes.

In order for the screed to remain intact monolithic structure for a long time, it is necessary to add granite chips to the concrete

Returning to the question of the strength of the base, it is worth noting that many are interested in how to cover the concrete floor on the street so that it does not crumble. That is, what composition should be used so that the screed remains intact for a long time in a monolithic structure under conditions of exposure to moisture and temperatures. The most reliable way is to add granite chips to the concrete. The coating will be quite expensive, but the long service life will justify the investment.

Repair of concrete floors: prices for various types of work

For many, material costs are an important factor in determining the scope of repair work. Naturally, in each case they are different. After reviewing the content of the price lists for a certain type of work, you can get a rough idea of the cost of repairing floors in an apartment or house. Prices are not the same for different regions, but if you try to display the average, they will be as follows:

- installation of reinforcing mesh for concrete, 1 m² - 150 rubles;

- lighthouse floor screed (50 mm), 1 m² - 300 rubles;

- insulation under the screed in 2 layers, 1 m² - 200 rubles;

- rough screed (50 mm), 1 m² - 500 rubles;

- screed dismantling, 1 m² - 450 rubles;

- dismantling of ceramic tiles, 1 m² - 400 rubles.

A professional invited from an officially operating company will definitely make an estimate for the repair of concrete floors. Unfortunately, the more common option is to use the services of a private specialist. However, even in this case, you should receive a receipt from him, which clearly indicates what exactly he will perform and what value it will have, up to accounting for payment for the purchase of materials. This will eliminate the possible occurrence of misunderstandings and give a clear understanding of the cost of repair work.

Concrete floor repair: recommended formulations

There are many photos of floor repair posted on the Internet, which give an idea not only of the result, but also of the process of implementation, even of the materials used. It should be noted that repair mixtures of domestic production are quite often used. The leading position among them is occupied by the dry compositions "Emako", manufactured by the "Basf" company.

"Emaco" N 5100 is used to eliminate minor defects: shallow cracks and cavities. Composition N 900, N 5200 is recommended for sealing delamination and significantly chipped surfaces. For cracks, the depth of which is more than 100 mm, mixes "Emaco" T1100 TIX, S 466, S560FR are suitable. Bare reinforcement and chips with a depth of more than 20 mm are restored with Emaco A 640 and anti-corrosion Emaco Nanocrete AP. The latter mixtures are also suitable for the restoration of a concrete base when repairing a warm floor.

The leading position among the repair mixtures of domestic production is occupied by dry compositions "Emako"

Dry compositions of domestic production "Birss" have also proven themselves quite well:

- "Birss" 28, 29, 30, 30H - for small cracks and chips;

- "Birss" 30 С1,58 С1, 58 С2 - restore more significant damage;

- Birss RSM - for the most difficult concrete demolitions.

The Russian composition "Osnovit Selform T-112" is also an excellent repair mixture. It has a high level of adhesion and is water-repellent.

Helpful advice! When choosing a mixture for repairing a concrete floor, you must pay attention to its protective functions. This is especially true when using the floor in difficult temperature conditions.

Repair work to eliminate defects in a concrete floor often not only improves its performance, but also significantly extends its service life. Restoration actions must be carried out on time and in compliance with appropriate technologies. Only then will the concrete fill become a comfortable and reliable basis (in the literal sense of the word) of the living space.