What warm floors are better for tiles: reviews of various options can help you make the right choice. The main criterion in this case should be the ability of the structure to meet the technical requirements that most users impose on it: heat transfer per 1 m2, ease of installation, cost, resource consumption.

Content [Hide]

What warm floors are better for tiles: reviews of electric and water options

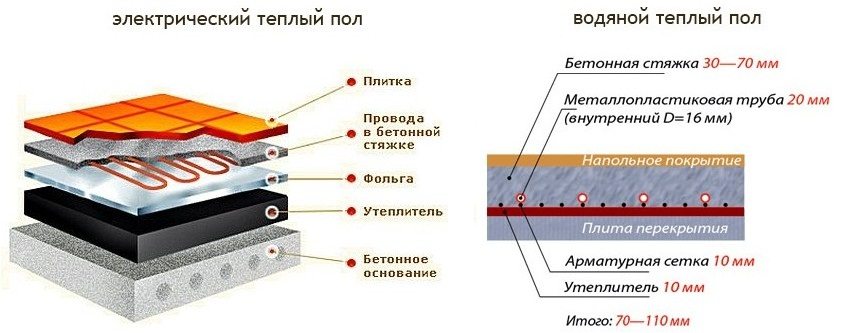

There are currently two types of systems warm floor: electric and water. They have the same tasks - to heat the floor surface from the inside, creating a comfortable environment in the room. As the name suggests, these two systems differ in their heat source. In the first case, thermal energy is generated when the work is performed by an electric current in the process of passing it along conductors with electrical resistance. An option is also considered as a subspecies of the electric floor infrared systems... In them, the electric current causes vibrations leading to the emission of infrared waves, which, in turn, are capable of heating all the objects around them, including the floor surface.

In the second case, the effect of heat transfer from heated water or other liquid heat carrier, which circulates through pipes located in zigzags under the floor surface, is used. This system, most often, has a common circuit with heating a house or apartment.

What warm floors are better for tiles? Reviews on this account are very contradictory. It all depends on consumer preferences and many different circumstances. If, in general, we compare the electric and water options, then you need to do this according to certain criteria. In terms of heat transfer: it all depends on the power of the device. It can be in the range of 110 - 160 KW2 electric underfloor heating. The more power the system has, the more power it consumes.

However, water heated floorhaving a similar heat transfer does not create any additional costs. This statement is true when using central heating. If the house is heated from an autonomous source, then an additional circuit in the heating system increases energy consumption in proportion to its area.

What warm floors are better for tiles in terms of ease of installation? The answer is obvious. An electric floor is much more convenient to install.It is enough to spread it on the floor and interconnect the components of the system, and then plug it into the network. The contour of the water floor must not only be laid correctly, but it is also necessary to carry out a tie-in with the heating system.

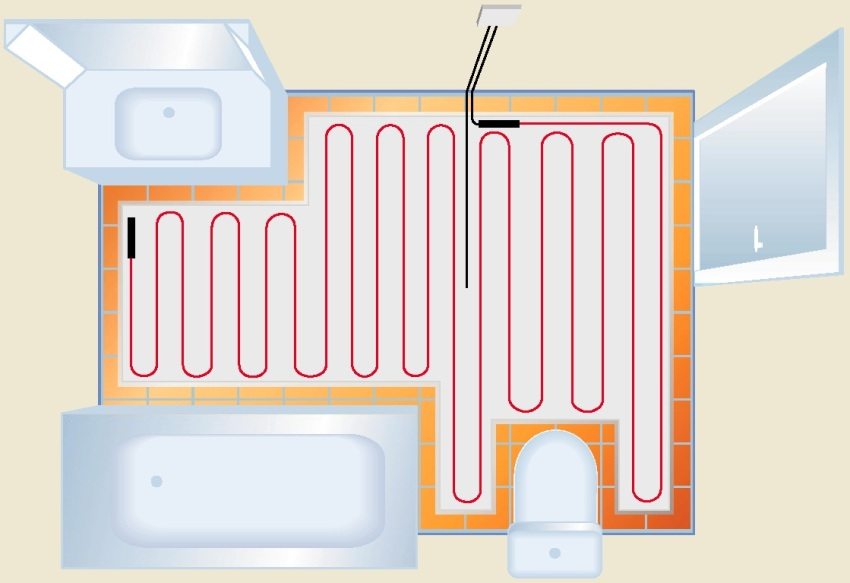

An example of laying a heating cable under bathroom tiles

The cost of electric underfloor heating ranges from 15 to 150 USD. per m2... The cost of installing a warm floor with a water circuit depends on many factors and can range from $ 30 to $ 200. per m2... The fact that the coolant in it very quickly gives off heat and cools down does not add to the popularity of the water floor. This leads to the fact that the radiators located after it do not work at full capacity. Such a system also consumes more water, reducing pressure. In addition, during freezing, water cannot be drained from the circuit, which in an emergency situation leads to the destruction of the entire floor.

Therefore, the answer to the question of which warm floors are better for tiles, everyone should find for themselves, depending on their priorities. If the main thing is the low cost of operation and the absence of electromagnetic radiation, then the water floor should be chosen. If the convenience of installation, the ability to adjust heating, a relatively low cost and no inconvenience for neighbors, then an electric underfloor heating will be the best option. Its infrared subspecies is characterized by low power consumption.

Installation of various types of underfloor heating under tiles

As mentioned above, the installation of an electric and water floor has significant differences in technology. In order to get additional arguments when answering the question of which warm floors are better for tiles, consider the features of both types of devices.

Installation of a water heated floor under the tiles

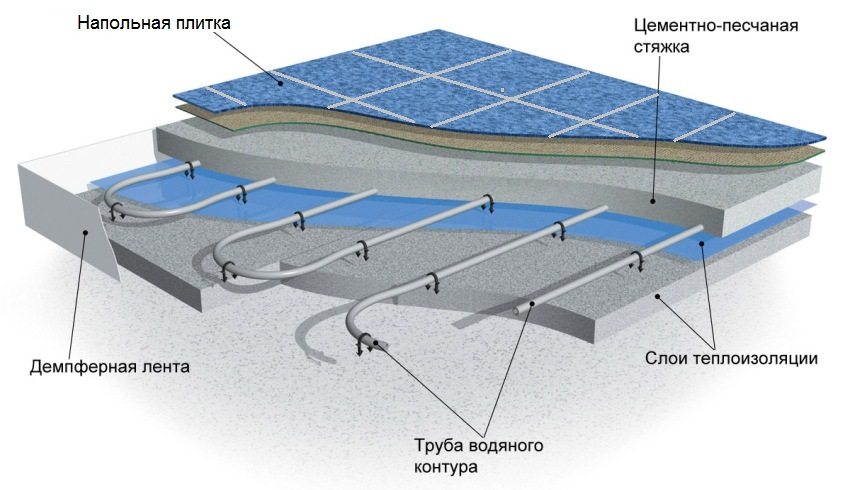

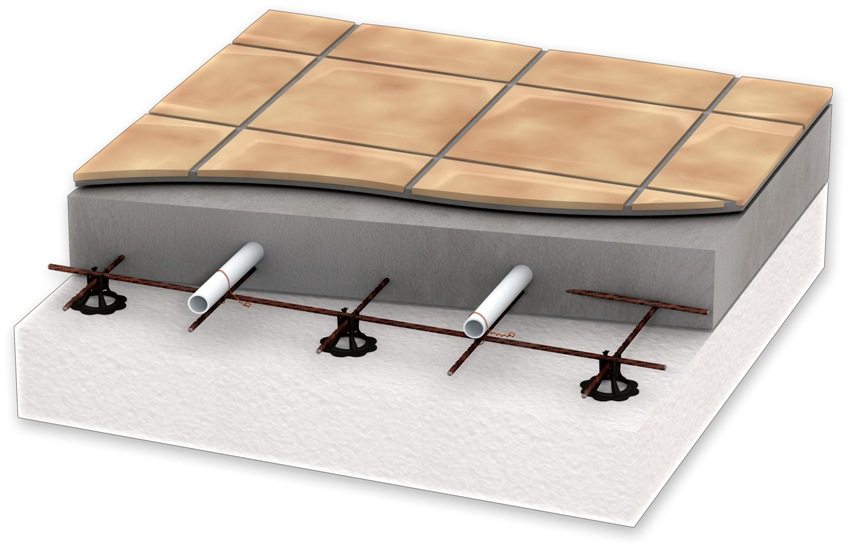

There are two ways to build a water heated floor: screed and flooring. The first method is the most common. It involves pouring a concrete screed over the pipes of the circuit. This method provides good heating of all layers of the floor. The second method is less laborious, since the pipes are placed on a screed or slabs, after which they are covered from above with a rough and clean floor. This method reduces the efficiency of heat consumption.

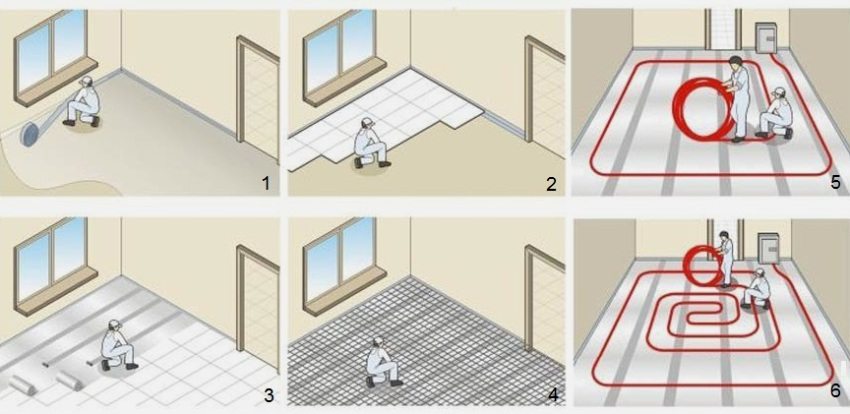

To lay the water floor under the screed, you must:

- It is very good to clean the base of the floor from various dirt and level it. Sometimes it is desirable to make a preliminary concrete screed up to 2 cm.

- Provide thermal protection for the subfloor. To do this, make a layer of foam, foam or polystyrene. Its thickness should be 3 cm. This is necessary so that the heat rises into the room, and does not descend to the neighbors. The damper tape is laid around the perimeter of the room and on the boundaries of solid sections.

- Reinforce the entire floor area using a mesh with a 5 mm rod and 15x15 cm cells. In this case, the reinforcement should lie on the damper tape between the sections.

- Lay the pipes on the fittings and secure them with plastic clamps. On top of this structure, you need to put an additional layer of reinforcement.

- Pressurize the circuit with compressed air. If a leak is found, the tightness must be restored. Then it is necessary to make a tie-in of the circuit into the heating system and start the water, raising the pressure to the working one. The system should be in this state for 3 days.

- If a breakthrough has not occurred, then you can make a screed. For this, concrete M300 is used. The thickness of the screed over the pipes must be more than 3 cm.

- After the screed has completely dried (2 - 3 weeks), tiles are glued on top of it.

Helpful advice! It is important to know not only which warm floors are better for tiles, but also for a warm floor itself should be chosen taking into account its physical characteristics. Ceramic tiles with the highest thermal conductivity are best suited for this purpose. It will warm up very well and give off heat to the surrounding space of the room.

It is much easier to make a water heat-insulated floor in a flat way. For this, there are polystyrene sheets, in which the grooves for pipe laying are already made. These sheets are fastened together with grooves. They themselves are thermal insulation, so there is no need to do it additionally.

Pipes are laid in grooves and covered with foamed polyethylene, pre-pressing. Then plywood is laid as a sub-floor. Obviously, this method is not quite suitable for laying tiles as a topcoat. In this case, you still need to make a screed for better adhesion of the tile adhesive.

Fixing the water heating pipe inside screeds

Do-it-yourself warm water floor (video)

Installation of electric underfloor heating under tiles

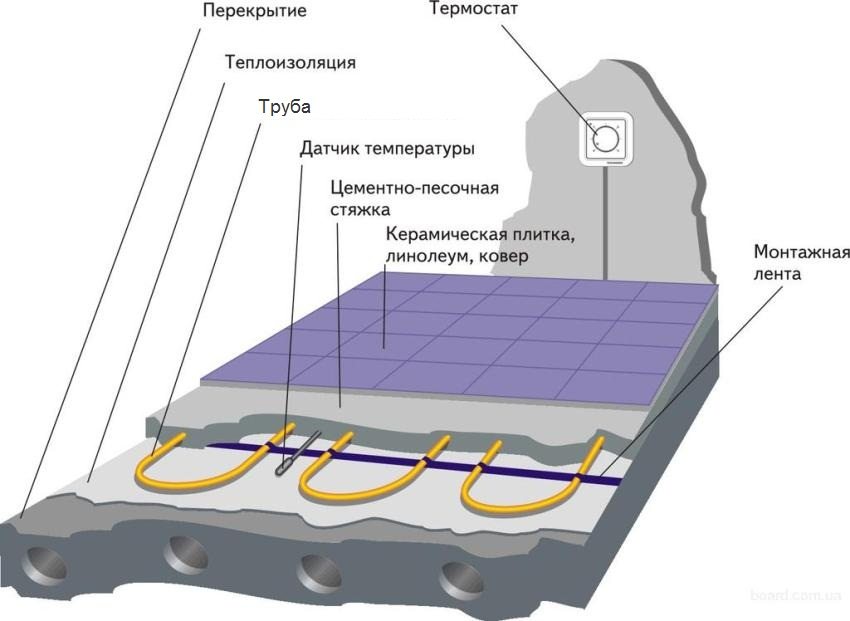

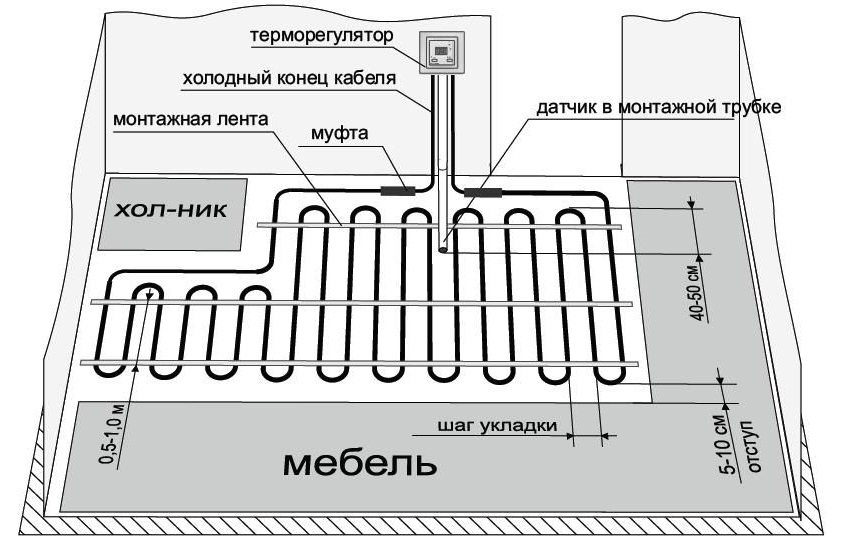

If the question is which warm floors are better for tiles, If you answered - electric, then you need to choose from two options: an electric heating cable or films with infrared elements. Installation of an infrared floor is easier, since the sheets of film are simply connected to each other through electrodes. There is no need to calculate the spacing between elements as the sheets are ready to use. The cable is laid in different ways: spiral, snake, zigzag.

Helpful advice! When choosing an electric floor heating, it is better to stay on ready-made kits. The kit contains all the necessary components that are compatible with each other in all respects.

The procedure for installing an electric underfloor heating is as follows:

- Substrate preparation, including cleaning and leveling.

- Waterproofing with roll materials.

- Warming with polystyrene or expanded polystyrene plates.

- Laying the underfloor heating system and interconnecting all components of the electrical circuit.

- Connecting the thermostat and plugging in.

- System health check.

- Reinforcement if necessary. Some designs of underfloor heating systems are manufactured directly with reinforcing components.

- Filling the screed 3 cm above the entire structure.

- Drying of the screed (2 - 3 weeks).

- Gluing tiles.

Helpful advice! Always place foil-coated polystyrene sheets under the foam. It reflects warmth into the room. The foil should be on top.

To understand which warm floors are better for tiles, user reviews will help first of all.