The foundation is the most important element of any structure: from a light garden pavilion to a capital multi-storey country house. This is the beginning of construction and its foundation in the literal sense. The strength, durability and safety of the building depend on how correctly the foundation is chosen, calculated and executed. The question is what type of foundation to choose, arises at the stage of construction planning. Its optimal solution in many cases will be the decision to build a columnar foundation with your own hands: step-by-step instructions for performing work can give a complete picture of the principles of its design and the intricacies of the arrangement process.

Content [Hide]

Advantages and disadvantages of a columnar foundation

Self-calculated and self-equipped columnar foundations for frame houses and buildings without basements, which do not exert strong pressure on the ground, are simple to perform and relatively cheap.

Helpful advice! Column foundation is the optimal solution for lightweight buildings, the volumetric weight of which does not exceed 1000 kg / m3 (frame houses, baths, utility blocks, garden houses, terraces, awnings, garages, summer kitchens, gazebos, etc.).

According to reviews, support-column foundations have a rather impressive list of advantages:

- They can be designed, calculated and built independently, without the involvement of special equipment and specialists.

- They can be installed on almost any soil (excluding those where heaving processes are possible or there are high ground waters).

- They can be located in areas with noticeable differences in height (and even on hillsides).

- They do not require preparatory work to level the landscape.

- They can be erected in the shortest possible time (the maximum time for building a columnar foundation from scratch is 2 weeks).

- They do not need complex and expensive waterproofing.

- The strength and durability of the structure (a columnar foundation erected with careful observance of the technology of work can last more than half a century).

- Relatively low total cost.

At the same time, there are only two disadvantages of columnar foundations:

- Not suitable for heavy brick and multi-storey buildings.

- Eliminated the creation of basements.

Types of columnar foundation

Before proceeding with the detailed design and calculation of the columnar foundation, it is necessary to decide on which site, what type and by what technology the building will be erected on it. The choice of the material of the columnar foundations and the depth of their foundation depends on these factors.

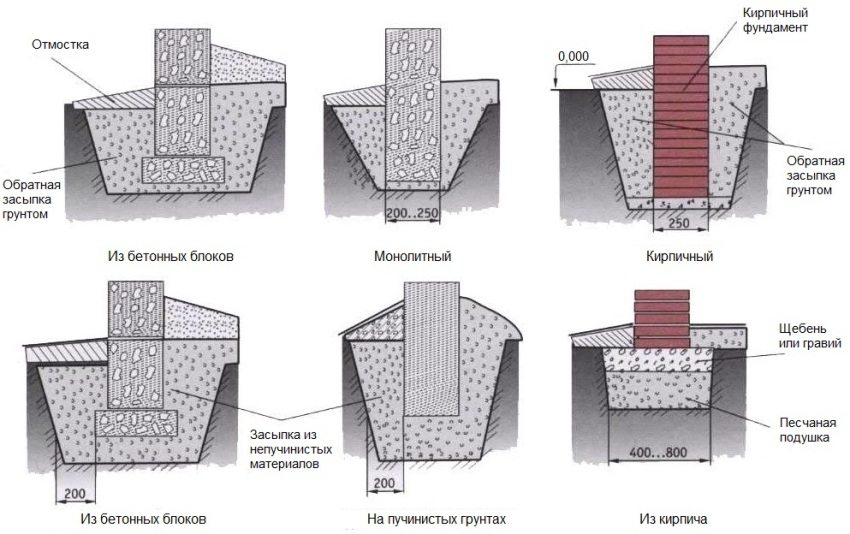

Materials for the construction of the foundation

The following materials can be used for foundations:

- reinforced concrete;

- rubble concrete;

- blocks;

- brick;

- a natural stone;

- tree;

- pipes: asbestos or plastic.

Foundation depth

The depth of the columnar foundation is determined by its structure, technological parameters of the structure and the geological characteristics of the soil in the building spot.

Helpful advice! On sandy soil, in which the groundwater is below 1 meter, a columnar foundation with a slab structure can withstand a brick cottage.

In terms of depth, columnar bases are divided into three main types:

- Buried - with a depth of laying below the level of soil freezing.

- Shallow - with a depth of 40-70 cm from ground level.

- Not buried - located on the surface of the earth in the complete absence of an underground part. At the same time, in the places where the posts are installed, the fertile layer is removed from the soil and the non-metallic material is added.

Do-it-yourself column foundation: step by step instructions

For the device of a columnar foundation with your own hands, step-by-step instructions are needed as the most detailed and visual aid.

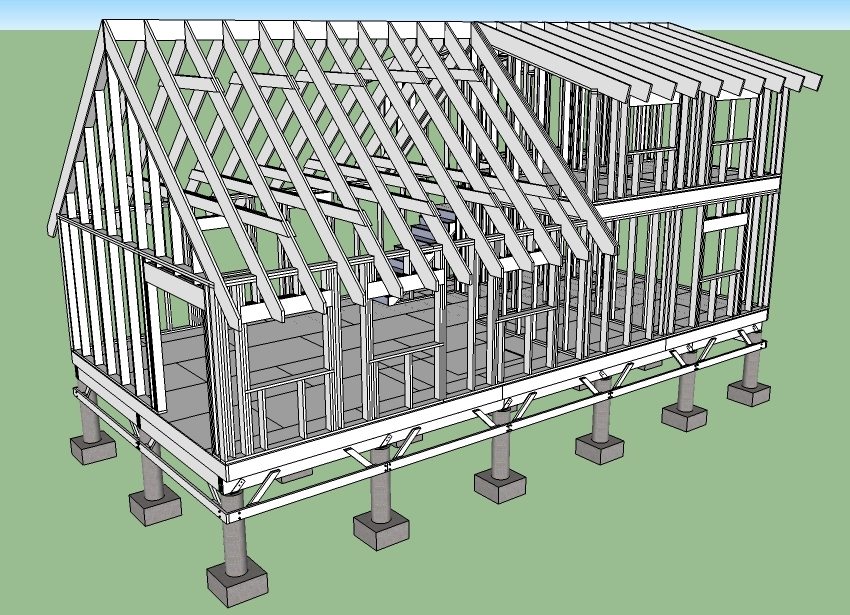

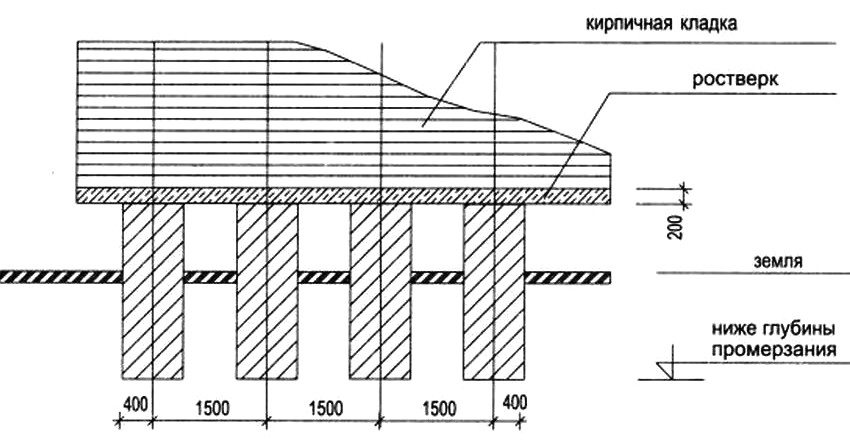

In the general case, the structure of a supporting-columnar foundation is a system of supports of the smallest possible cross-section, located at the points of concentration of the load: in the corners of the building, at the intersection of walls, under load-bearing beams, walls, under oven... To determine the number of free-standing posts, the distance between them is taken to be 1.5–2.5 m. To tie the foundation supports into a single structure, a grillage is made between them.

The height of the posts above the zero mark is individual and depends on the design features of the grillage.

Calculation of a columnar foundation

The construction of a columnar foundation begins with a calculation. Most likely, in order to independently perform calculations, you will need a program such as "Foundation" or some other that can be found on the Internet and downloaded for free. To work with such programs, you need the following parameters:

- The depth of the foundation and its reinforcement.

- Location of the future structure.

The technology of building a foundation with columnar supports also requires additional data:

- The approximate weight of the building, including the weight of its intended interior and furnishings.

- The total weight of the foundation itself.

- Seasonal load (wind and snow cover).

- Variety of soil and its properties.

- The level of soil freezing and the average temperature in the winter season.

- The level of occurrence of groundwater, taking into account its seasonal fluctuations.

As a result of the calculations made, the following values will be obtained, which are necessary for the arrangement of a columnar foundation:

- The minimum number of posts.

- The cross-sectional area of the pillars and their sizes.

- The value of the bearing capacity of the pillars.

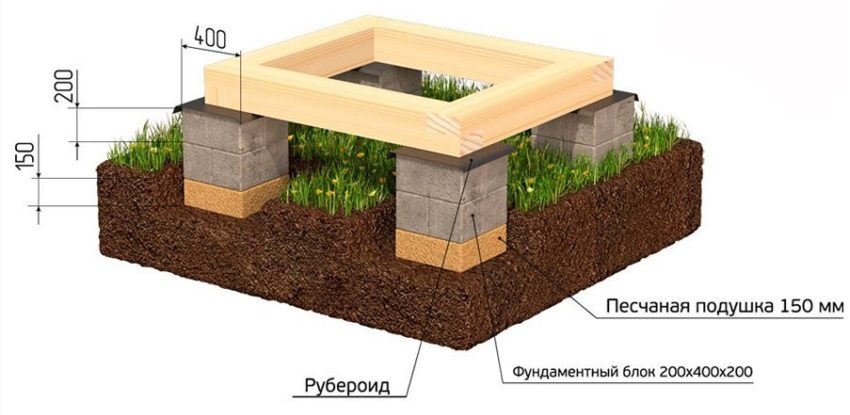

Columnar unburied foundation

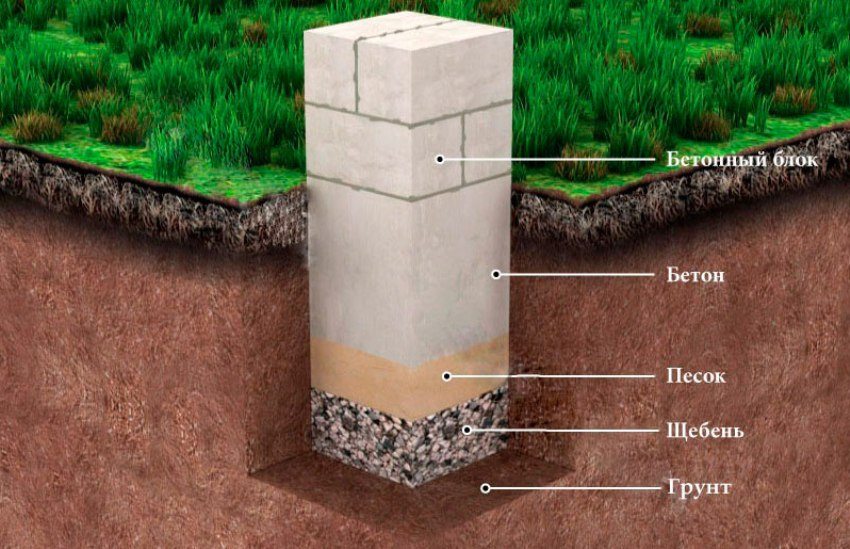

A columnar, unburied foundation on supports located with a pitch of 1.5-2.5 m is used quite often.Such foundations can be erected on non-porous and weakly porous soils, despite the fact that the building (a wooden or panel house, a bathhouse, a utility block, an extension or a summer kitchen) has a small area and, accordingly, a small weight. Moreover, if the construction is carried out on rocky, coarse-grained or not prone to movement soil, this type of foundation can also be arranged under a house made of a log or a bar that is large enough in area. It is also possible to erect a foundation on non-buried supports provided that the influence of heaving forces on the structure is reduced. For this, the soil under the supports is replaced with a sand cushion.

As a material for pillars, it is possible to use concrete, rubble concrete, sand concrete or concrete blocks for the foundation, the sizes and prices of which are very diverse. However, most often they take foundation blocks with dimensions of 20x20x40. The price of such a foundation, as well as the number of blocks required for its construction, can be calculated independently or with the help of a “foundation” online calculator. You can also make a brick columnar foundation with your own hands, but at the same time it is necessary to take into account that it is unacceptable to use silicate bricks or ceramic with low frost resistance.

Work on the construction of a non-buried columnar foundation from finished blocks can be divided into several main stages:

- Layout of the future construction site, soil cleaning, drainage layer arrangement and waterproofing works.

- Determination of the location of the supports for the foundation (concrete blocks 20x20x40). It is better to buy all the materials in advance.

- Preparation of places for supports. Installation of a sand cushion under each support.

- Installation of supports, each of which consists of at least 4 blocks for the foundation 200x200x400. Knowing this condition, the price of the entire foundation is calculated very easily. Supports (according to the instructions and photo) of a columnar foundation made of 20x20x40 blocks are laid out with their own hands in two rows with a staggered arrangement. A thick, undiluted cement mortar is used for the joints, the open part of the blocks should be finished with plaster.

- Mandatory waterproofing of foundation supports at the junction with the house with bituminous mastic, roofing felt, tar paper or glass insulating material.

Helpful advice! Sometimes (for example, in the case of a columnar foundation for a bath), the supports can also be wooden - from the butt parts of oak or pine with a diameter of 20-30 cm, impregnated with tar or waste oils. To increase the stability, the supports are immersed in a 10-15 cm layer of concrete mortar, poured into a previously opened hole.

When making a foundation of 20x20x40 blocks with your own hands, videos and step-by-step instructions will help you understand the technology of work, delve into the process and more accurately estimate financial costs.

Shallow columnar foundation

Shallow foundation is one of the most popular types of columnar foundation. The means and efforts required by its device are minimal, and the range of application for frame-type buildings is very wide.

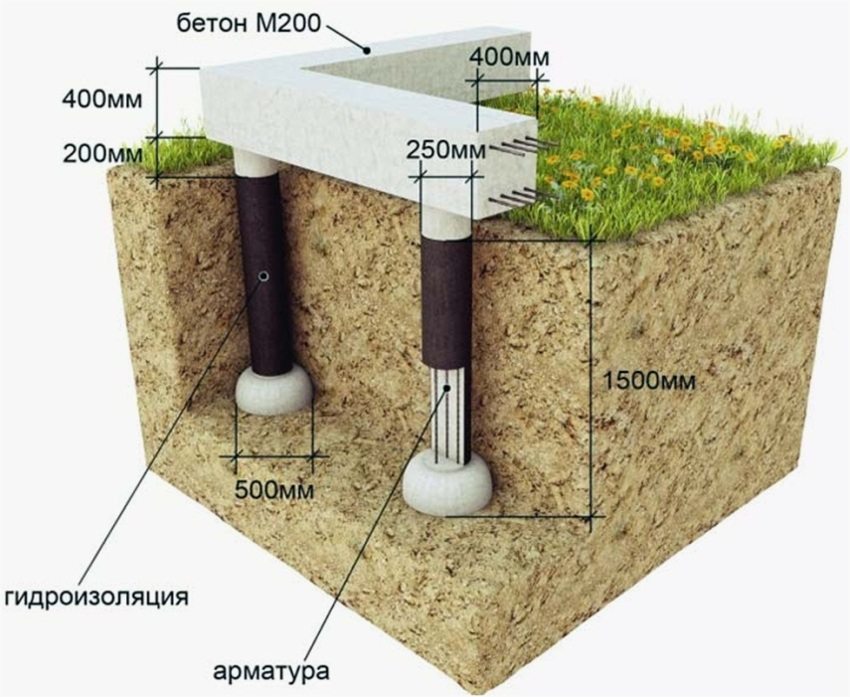

As a basis for frame house or a light bath, a columnar foundation is often made using pipes as formwork for the concrete mix. Since the reinforced concrete pillar will take all the load on itself, the material of the pipes does not really matter: both plastic and asbestos pipes, which are usually used for the construction of sewer networks, are suitable.

Related article:

Waterproofing the foundation with roll materials. Performing waterproofing work on the foundation with roll materials of various types: detailed instructions.

The diameter of the pipes depends on the load. For light structures such as gazebos or outbuildings, 10 cm is enough, for buildings made of logs, pipes of 25-30 cm are needed. The amount of concrete is ultimately determined by the diameter of the pipe. For 10 m of a pipe 10 cm in diameter, 0.1 m is needed3 concrete, a 20 cm pipe will require 0.5 cubic meters, 30 cm - 1 cubic meter. The calculation is made taking into account the concrete base pad.

Diagram of work on the construction of a columnar foundation made of asbestos pipes with your own hands (video of the process can be found on the Internet), in general terms, is as follows:

- site preparation - garbage collection, removal of foreign objects, sod removal and leveling. Marking the perimeter of the future building, corners, internal walls and their intersections. The installation sites of the foundation supports are marked with pegs;

- then with a hand drill for the posts, holes are made in the ground. The depth of the well should be 20 cm more than the calculated one: for the construction of a sand cushion;

- the device of a sand cushion with the obligatory compaction and spilling of sand with water. After the final absorption of water, pieces of roofing material should be laid on the bottom in order to prevent moisture from the concrete mixture from leaving the sand;

- installation of pipes in wells with a margin of at least 10 cm in height. Alignment of pipes in level and fixing them in wells using wooden blocks. With a close occurrence of groundwater, the pipes must be coated with bitumen mastic to the ground level for waterproofing;

- then the base of the pipe is poured 40-50 cm with a thoroughly mixed concrete-gravel mixture (1 part of cement and 2 parts of sand, diluted with water to the state of a batter, are combined with 2 parts of fine gravel). Immediately after pouring, the pipe is raised to a height of 15-20 cm and left in this position until the cement has completely solidified. This is necessary to create a foundation that resists pushing out when soil heaving;

- after the concrete has hardened, the pipe should be waterproofed from the outside with roofing material and the well should be filled with sand with a phased pouring and tamping;

Helpful advice! During work, you should periodically check the installation of pipes using a level.

- fittings are placed inside the pipes, after which the rest of the pipe is poured with concrete;

- after the final hardening of the concrete - after 2-3 weeks - continue construction work. It should be added that it would be useful to make the foundation waterproofing with polymer or bituminous solutions.

According to the same scheme, it is possible to do it yourself with a columnar foundation made of plastic pipes. Videos and photos will help you navigate the intricacies of the workflow, which is generally simple.

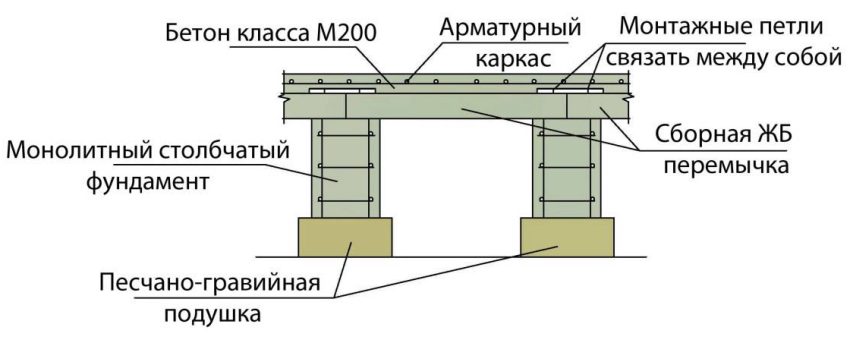

Column foundation with grillage

The grillage is a system of random beams and strapping beams. It rigidly fixes the foundation, excluding its displacement in the horizontal plane or overturning of the entire structure. In the presence of a grillage, the load from the structure is distributed evenly over all installed columnar supports, as a result of which stability and resistance to destruction increase.

To facilitate understanding of the process, the necessary work is outlined in stages.

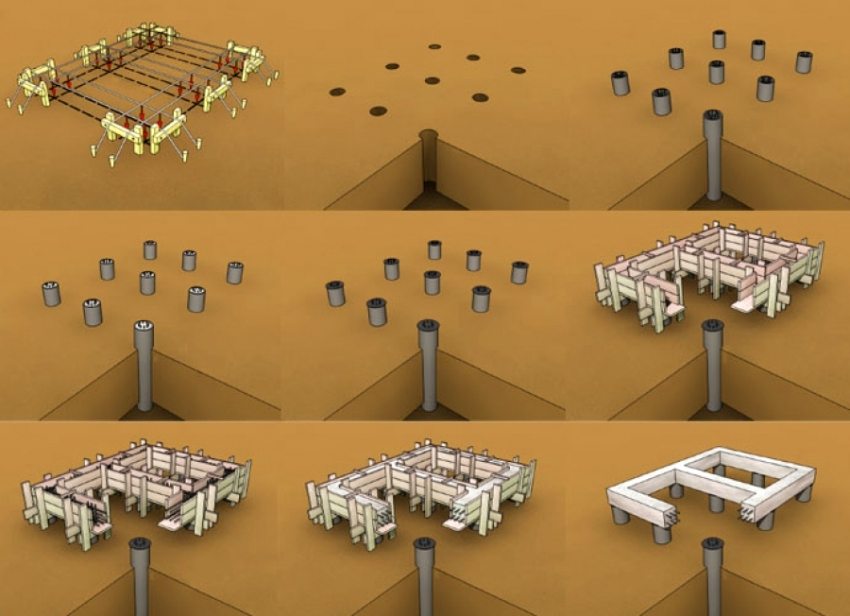

Preparation and installation of supports:

- in any case, the initial stage of preparation for the construction of the foundation is the arrangement of the construction site. After removing debris, etc. sod and topsoil are removed around the perimeter of the future foundation;

- for supports, it is necessary to dig holes 20 cm deep more than the level of soil freezing. The width of the pit should be 40 cm more than the width of the wall, since 20 cm is added on each side for formwork and spacers;

- at the bottom of each pit, they make a spilled and well-rammed pillow of sand and crushed stone mixture 20 cm high. The pillow is lined with roofing material or polyethylene so that moisture from the concrete poured into the pit does not go into the ground;

The reinforcement frame is placed in a dug hole, at the bottom of which there is a sand and gravel cushion

- formwork boxes are assembled from boards 20 mm thick;

Helpful advice! If the walls of the pits do not collapse and are dry, it is possible to simply cover them with polyethylene and do without formwork.

- it is recommended to thoroughly moisten the formwork installed in the pits to prevent moisture absorption from the cement mortar and facilitate removal;

- after installing the formwork, a reinforcement frame is placed in the pits. The frame is assembled separately from a rod 10-14 mm in diameter. The length of the rods is selected in such a way that the hardening of concrete, their ends sticking out above the ground level by 30-40 cm;

- the concrete mixture is poured continuously, in layers of 20-30 cm, leveling with a vibrator to avoid the formation of air bubbles;

- the formwork is removed after 3-4 days, the surface of the supports is treated with any suitable waterproofing mixture and the rest of the pit is covered with sand. Before backfilling, it is also possible insulation of the foundation extruded polystyrene foam.

After removing the formwork, the surface of the concrete support must be treated with a waterproofing compound

Grillage device:

There are two options for mounting the grillage: laying it on the ground or lifting it above its surface. The advantage of the second method is the elimination of the effect of heaving forces:

- Formwork installation. The formwork is installed solid around the entire perimeter of the foundation.

- Backfilling the bottom of the formwork with sand and lining it with polyethylene.

- Assembly and installation of a reinforcing cage from a rod with a diameter of 12-14 mm.

- One-step filling of the grillage with concrete with the removal of air from the solution with a vibrator.

- Removing the formwork after the concrete has set and removing the sand from the grillage.

The cost of work on the installation of a columnar foundation

The total cost of a columnar foundation is the sum of the cost of materials and the cost of the actual work. In most cases, it is much lower than the cost of other types of foundations, since almost all types of columnar foundations can be built with your own hands. Videos and photos, instructions and guides found on the Internet are also usually cheap or free.

The calculation of the cost of most types of columnar foundation can be done independently using special online calculators or programs. Many of them are quite easy to find on the Internet, are free and have an intuitive interface.