Previously, the installation of an infrared floor was considered a luxury, however, today this method of heating rooms has gained wide popularity. Underfloor heating infrared film is a modern and practical option for organizing the main or additional heating in the room. In this article, we will look at the benefits of installing infrared film, its varieties and compatibility with floor coverings.

Thanks to infrared film heaters, an economical and efficient underfloor heating system can be built in a matter of hours

Content [Hide]

- 1 Infrared floor heating: pros and cons

- 2 Varieties of infrared films

- 3 Technical characteristics and operational scope of the film floor

- 4 Film warm floors Caleo

- 5 Infrared film floors from the Rexva brand

- 6 Features of IR films from Heat Plus

- 7 Warm floor infrared film Monocrystal

- 8 Infrared underfloor heating: consumer reviews

- 9 Drawing up a connection diagram for a film warm floor

- 10 Preparing the substrate for laying infrared film

- 11 Features of laying film warm floors under a laminate

- 12 Installation of infrared underfloor heating under tiles

- 13 Features of installing a film underfloor heating under linoleum

- 14 Infrared floor heating: prices

Infrared floor heating: pros and cons

Heating with IR foil has many advantages over other types of similar heating. Let's consider the main advantages of such a heating structure:

- such a system cannot fail at the same time, since it is connected in a parallel way;

- the ability to install on any type of surface - both horizontal and vertical, as well as on elements that are located at an angle;

The film does not contain components hazardous to human health, does not produce unpleasant odors and toxic fumes

- the design features of the IR floor allow you to achieve uniform heating of the room. This is especially important if laminate is used as a floor covering;

- another plus of such a system is ease of installation;

- the ability to disassemble if necessary;

- such a film is suitable for installation in rooms where the humidity level exceeds the permissible parameters;

- compatibility with different flooring options;

- installation of such a system is allowed not only in closed rooms, but also in open conditions (for example, on a veranda);

- high heat transfer coefficient, which reaches 97%;

- the efficiency of the infrared film floor is approximately 30% higher than that of other underfloor heating systems. The prices of film warm floors are fully consistent with their effectiveness.

Note! When choosing an IR film for organizing floor heating, one very important parameter must be taken into account - the height of the ceilings.The lower the ceiling height, the more efficient the heating of the room.

However, this design also has some disadvantages, among which they are especially distinguished:

- the need to comply with clear rules when connecting;

Unlike other heating systems, infrared floors act directly on the surfaces of heated objects and do not dry out the air in the room at all

- high inertness, due to which heating and cooling occur very quickly;

- weak resistance to mechanical stress in comparison with a tubular structure using water as a heat carrier.

The foil system is generally not suitable for installation as primary heating. It is recommended to use an infrared design for additional heating.

Varieties of infrared films

From a constructive point of view, all IR films are similar and have a common operating principle. However, for various types of premises and operating conditions, it is customary to use certain options for film warm floors. The differences between ICs are primarily due to the fact that different companies are engaged in their production.

Consider the types of IR films according to the maximum heating temperature and their compatibility with various floor coverings:

- high-temperature infrared warm floors for tiles. The maximum heating temperature of such systems reaches 50 ° C. They are incompatible with floor coverings that are more susceptible to heat (linoleum, laminate);

In terms of their structure and principle of operation, all infrared films are similar to each other, the main difference is the maximum heating temperature

- low-temperature infrared warm floors for linoleum and laminate. Such systems can heat up to 27 ° C;

- universal infrared systems that are compatible with all types of flooring.

The second parameter by which IR films are classified is the type of heating element. Today, there are two main types of IR floors, depending on the heating element:

- carbon;

- bimetallic.

The specific power of the infrared floor is the last indicator, which is very important when choosing a heating. Consider three main types of IR films, depending on this parameter:

- with low power (130–160 W / m²) - used in cases where it is necessary to organize heating of a room with a small area. Compatible with “light” floor coverings;

Infrared films from different manufacturers may differ in their appearance and technical parameters.

- with an average power (from 170 to 220 W / m²) - they are mounted in more spacious rooms. Perfect for the following flooring options: porcelain stoneware, tiles;

- with high power (above 220 W / m²) - installed in industrial buildings. They are also used for floor heating in saunas and various workshops.

If necessary, you can always contact the specialists who will help you choose the necessary system for a particular case. And it is also recommended to read the relevant reviews on the specialized forums before purchasing. Film warm floors are an innovative solution for any room that allows you to achieve maximum comfort.

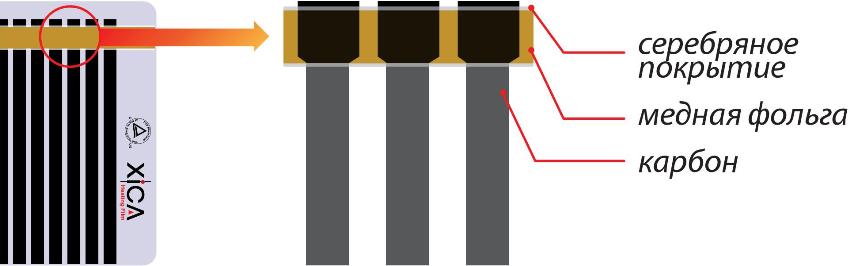

Features of carbon and bimetallic IR films

The carbon films used for underfloor heating are more expensive. Heating elements in such a system are made of a special carbon material that has a fibrous structure. In some cases, they are provided with a protective graphite layer. Spraying from this material helps to increase the strength characteristics of the system, and also affects the duration of its service life.

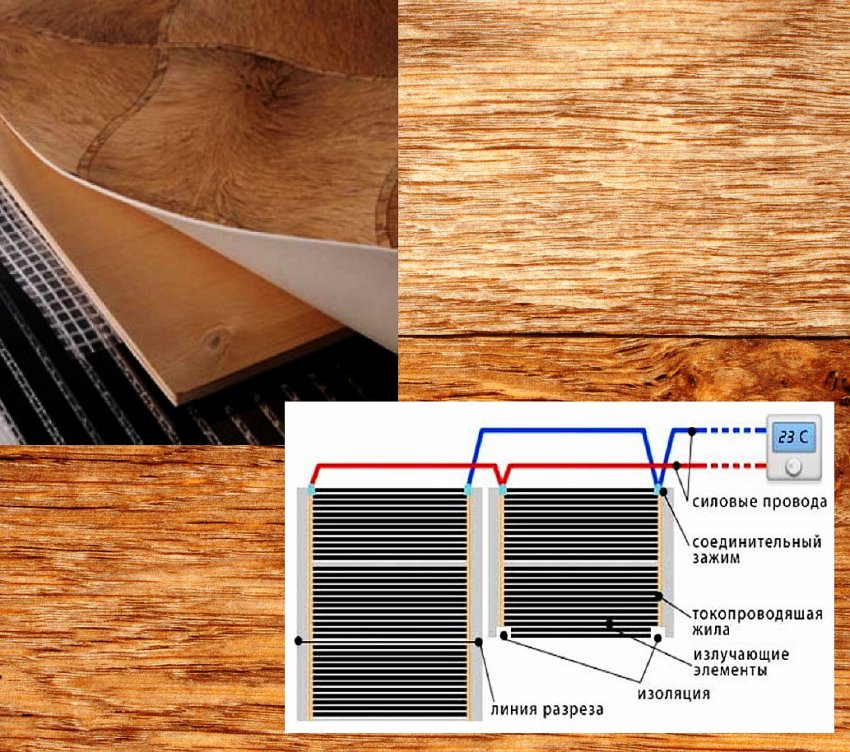

The basis of the material is represented by lavsan film.The carbon film infrared floor is installed on horizontal and vertical surfaces.

Helpful information! When installing a carbon film of a warm floor, the choice of a connection scheme is very important. In such a situation, experts recommend using a parallel connection option.

Bimetallic IR film differs from carbon film in that it has heating elements consisting of two metal layers (aluminum and copper). As a base for the material, a double polyurethane film is used, which has good elasticity.

The installation of a bimetallic system is complicated by the fact that an earthing switch cannot be connected to the system. Also, the bimetallic structure is incompatible with ceramic flooring. It is a low-temperature version, therefore its recommended heating level does not exceed 27 ° C.

Technical characteristics and operational scope of the film floor

Before buying an IR film, it is imperative to study all its main technical characteristics. This knowledge will help you select the required type of system and perform its calculation for a specific room. Consider the characteristics of such heating structures:

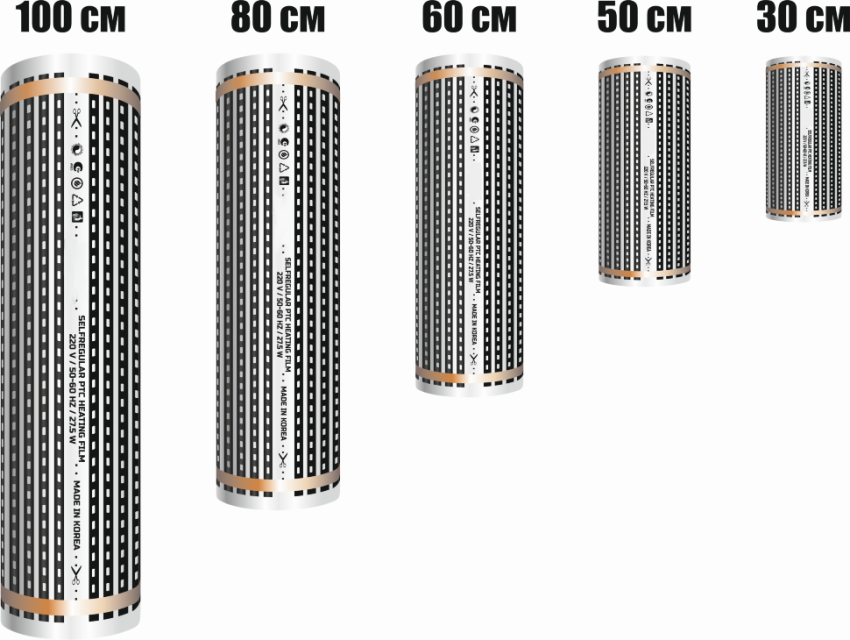

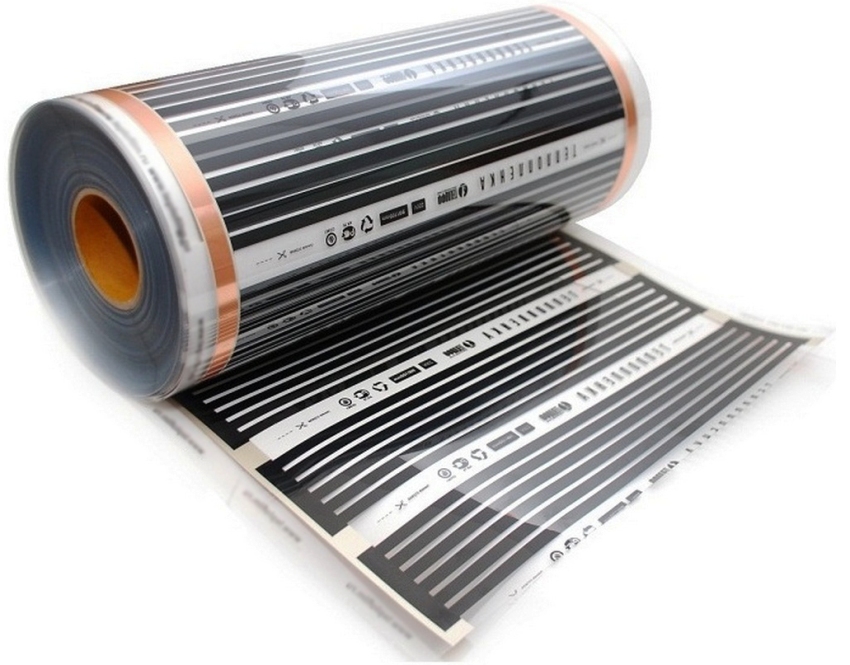

- IR film is produced and sold in rolls, the valley of which reaches 100 m. The roll width can be different (from 50 to 100 cm), and its weight is approximately 55 kg;

Rolls of IR film come in different widths - from 50 cm to 1 m, their thickness can be from a few microns to several millimeters

- the finished structure is powered from the mains, the voltage of which is the standard norm of 220V;

- per day the IR floor consumes approximately 20 to 70 W / m²;

- the speed of heating the film to the maximum temperature indicator is quite high (about 2 minutes);

- surface temperatures can reach 50 ° C.

If you decide to use such a film as the main heat source, then you need to remember that it must cover at least 70% of the floor area. In regions with cold climates, foil electric underfloor heating can only be used as additional heating.

Film warm floors Caleo

Caleo has a wide range of infrared underfloor heating films to help you choose the right system for your situation. The products of this brand are represented by both simple options and ultra-modern film coatings, the work of which is as automated as possible.

Today this company is engaged in the production of 4 major modifications of infrared film systems.

Caleo IR film is on sale complete with mounting kit: contacts and bitumen insulation, some also include connecting wires

LINE. An inexpensive system that is perfect for installation in a small room.

GRID. The product belongs to the middle price segment. A feature of the GRID infrared floor is the presence of an anti-spark grid, which is made of silver.

Note! Warm floors Caleo have their own characteristics. For example, their installation should be done only by the "dry" method. They are also not suitable for installation under ceramic floor coverings.

GOLD. As in the previous case, anti-spark grid technology is used here. And also such films can self-regulate, which allows to reduce energy consumption by up to 20%.

PLATINUM. The most expensive option for an IR floor. Differs in energy-saving qualities, which can reduce the consumption of electrical energy by 5-6 times. The PLATINUM IR floor can be installed under areas covered by furniture, without the danger of overheating.

All of the above models have a remote control function. Installation of underfloor heating Caleo is carried out without the necessary organization of the screed or special adhesive coating.

Caleo infrared film can be used as a primary and secondary heating system in almost all types of premises

Infrared film floors from the Rexva brand

Rexva IR films take the second position in the rating of warm floors. This company produces ultra-thin film communications that can be installed on various types of surfaces (vertical, horizontal and even on the ceiling). The Rexva underfloor heating range is represented not only by systems with a standard power range.

For heating residential and industrial premises, this company offers infrared films, the power of which reaches 400 W / m². As a rule, such models are used to organize heating in saunas. They are distinguished by a high rate of water resistance, since they have a special double-sided coating located on top of the main lamination.

Products from the Rexva brand are distinguished by their high strength and resistance to high pressure. Their operational scope is quite wide - from small rooms to sports halls. The price of the Rexva infrared floor is fully consistent with good quality and reliability.

New RexVa film floors with a self-regulating effect have appeared on the market, that is, when localized overheating, it changes its own heat transfer in this area

Features of IR films from Heat Plus

The Heat Plus brand is engaged in the production of warm floors (including infrared). Features of the models that are manufactured by this company are that they can have various forms of film, namely:

- striped;

- solid.

Related article:

Do-it-yourself water floor heating, video and description of the process

Description of the process of installing a water-heated floor. Its advantages and disadvantages in contrast to other types.

Features of the technology for the production of IR floors from this company allow you to avoid the presence of unheated zones. The production of such film systems includes the uniform application of carbon material on a polyester base, which allows achieving a high level of efficiency of heating communications.

Let's consider other advantages of Heat Plus IR floors:

- ease of installation;

- wear resistance;

Heat Plus infrared film consists of safe and environmentally friendly materials and is a coating with a thickness of 0.338-2 mm, consisting of 5-9 technological layers

- reliability.

The service life of similar products can be up to 15 years under normal use. If desired, the organization of such a system takes no more than one day, which is very convenient.

Note! The price of the Heat Plus IR floor is several times higher than the standard one. However, products from this brand pay off in the process of use in 1-2 years.

Warm floor infrared film Monocrystal

Monocrystal is located in Ukraine and is the only manufacturer of IR floors in the CIS. Thanks to South Korean technologies that are used in the production of IR films, products from this brand have taken a strong position in the construction market.

The main difference between the Monocrystal models is that there is no silver paste. To achieve the required electrical contact, products from the Ukrainian brand are equipped with a thicker layer of carbon paste. In this way, stabilization is achieved between the copper bar and the heating device.

Consider the main technical characteristics of Monocrystal IR floors:

- film width - from 30 to 60 cm;

- step - 20-25 cm;

- powered by an electrical network with a standard voltage (220V);

- maximum power indicator - up to 200 W / m²;

- the maximum heating temperature of the material reaches 50 ° C.

The service life of IR films from the Monocrystal manufacturer is 10 years. The lineup includes the following varieties: linear, perforated, solid. The perforations are arranged to be compatible with the tile flooring. Film warm floors for tiles are very popular with buyers.

Infrared underfloor heating: reviews consumers

Today, many home craftsmen refuse to install water heated floors and prefer infrared. This is primarily due to the fact that the water system requires a longer installation. And also its use is possible only after the screed has completely solidified. In many construction forums, consumers advise precisely infrared film warm floors. Reviews of these models are in most cases positive.

The infrared energy emitted by carbon elements is completely identical to that emanating from the sun, which is why it is so comfortable to be in a room with such heating.

Consumers also pay attention to the economy, which manifests itself in the process of using such heating systems. Studying various comments, you can see that many people point to the savings in energy consumption with a film warm floor. Reviews tell about the saving of electrical energy when using such systems up to 20%.

Helpful information! Some IR systems take no more than 3 hours to install and can be used immediately after installation.

Such heating communications are considered completely safe and maintainable. If individual segments of the IR system are damaged, it does not fail completely. In addition, they can be easily replaced and continue to operate the system, which is often indicated in reviews. Underfloor heating under the laminate is in great demand and usually costs the most.

Negative comments are much less common and usually indicate that when replacing the system, it becomes necessary to dismantle the flooring. Most often, infrared warm floors are installed under the laminate. In this case, negative reviews tell us that this flooring cools down very quickly and the heating system cannot be used as the main one.

Installation and connection of IR film heaters does not require special preparation and can be done with your own hands

Drafting wiring diagrams for film floor heating

In order to avoid installation errors and other surprises, experts advise, before installing the IR film, to choose a connection scheme and draw up a project plan. An elementary diagram will help not only to correctly calculate the amount of material, which is necessary in a particular case, but also to select the film necessary in terms of power.

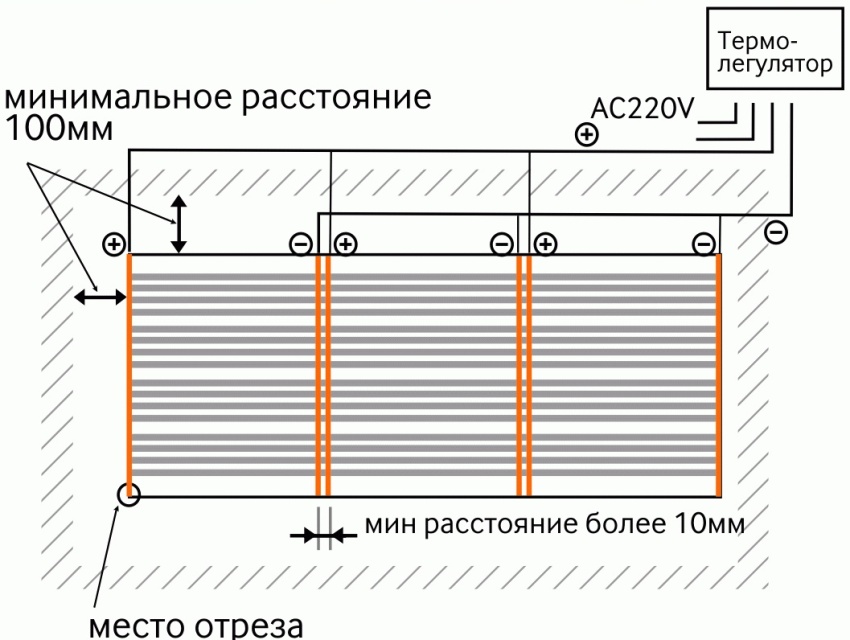

Consider the points that must be taken into account when drawing up a connection diagram:

- the cutting of the infrared cloth is carried out strictly in those places that were marked by the manufacturer;

- it is strictly forbidden to cut at any angles and try to form curly elements from the canvas;

- installation of the film is performed in parallel strips;

- stripes must be laid in such a way that they do not overlap each other;

- it is important to remember that the gap between the film sheet and the furniture should not be less than 3 cm. The same distance must be observed between the edge of the infrared sheet and the wall;

- the copper busbars of adjacent blades must not touch. The minimum distance between them is 1 cm;

- the number of connection points should be kept to a minimum;

- the best option for the location of the connection points is from the side of the wall on which the thermostat will be installed;

- the scheme must be drawn up in such a way that the main part of the wiring is hidden behind the baseboards;

- when using short film lengths (up to 100 cm), it is necessary to take care of additional insulation and purchase terminal clamps.

Helpful information! Docking of individual canvases to each other is done using adhesive tape.

The thermostat must be selected in advance, before starting the installation of an electric underfloor heating. Reviews of these devices can be easily studied on specialized forums on the Internet. If the area that needs to be heated is quite large, then you need to purchase additional temperature sensors.

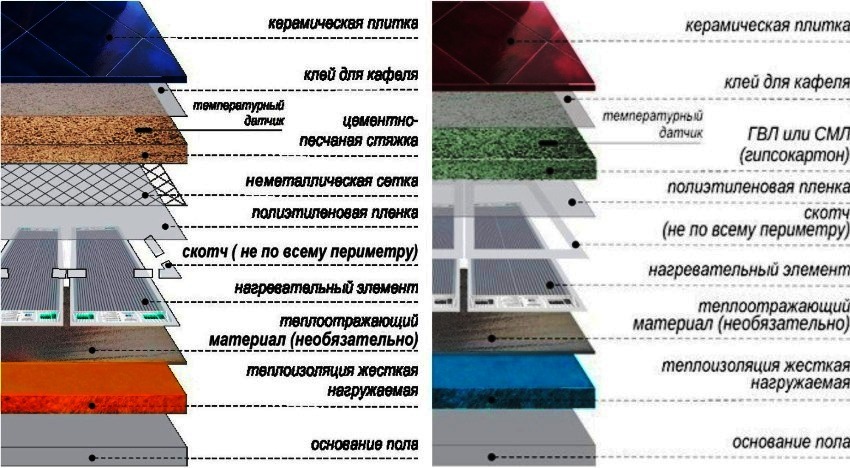

Preparing the substrate for laying infrared film

After choosing a laying scheme and purchasing material, you can start pre-installation preparatory work. A very important point is the preparation of the base for laying the IR floor. If the old concrete screed is not even, then it must be dismantled. However, if everything is in order with the screed, it is enough to simply clean it of debris and remove dust.

To prevent heating towards the neighbors living on the floor below, it is necessary to lay a heat-reflecting material for an infrared warm floor

In most cases, the base has many small cracks and chips before starting to lay the film. Experts advise to eliminate these defects using cement mortar, or any other suitable composition. In some situations, the owners find that the screed has begun to flake off from the subfloor. This situation requires the elimination of the old screed and the organization of a new one.

The joints that form from the connection of the walls to the floor must be carefully leveled and covered if they have cracks. If this is not done, then the film floor will lose heat through them.

After preparing the base, it is necessary to lay the heat-insulating material on the screed. As a rule, a polyethylene foam reflector is used for these purposes. The joints of the individual sheets of the insulator are glued with mounting tape and this is where the process of preparing for the installation of an infrared warm floor ends.

Features: laying film warm floors under the laminate

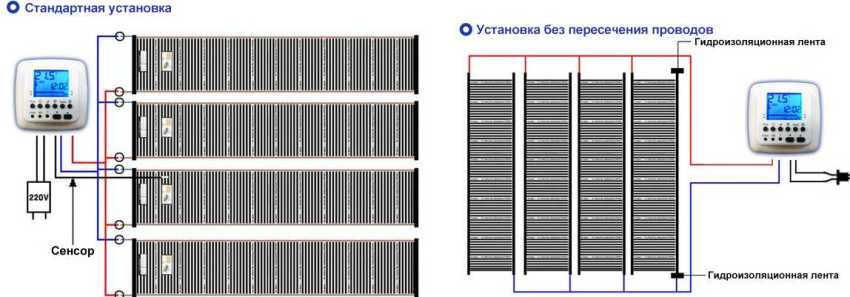

After completing the preparation process, you can proceed directly to the installation of the IR film. The algorithm for installing a film underfloor heating under a laminate is as follows:

- first of all, it is necessary to cut the material. The length of the strip should not be more than 8 m;

- at the second stage, the strips are laid. In order to reduce the number of joints, experts recommend laying sheets of infrared material along a long wall. The distance from the edge of the film to the wall should be at least 10 cm, and the distance between adjacent canvases should be at least 5 cm. Installation of a film heated floor is best done in a parallel method;

- then you need to do the docking of wires and insulation of unused contacts. The wires are connected by means of special clamps - terminals. And for insulation, a special bitumen tape is used, which has a high sealing coefficient;

- then the wires of the infrared floor are connected under the laminate. To do this, connect the wire to the terminal and insulate it;

- at this stage the temperature sensor (s) are mounted. Experts advise to start these elements under the second canvas (closer to the midpoint). The sensor is installed in the following way: it must be glued to the underside of the web on a black strip;

- then the infrared warm floors are connected to the thermostatic device. To do this, it is necessary to bring wires to it from the film and the temperature sensor. The connection itself is carried out through an RCD;

When carrying out work on the installation of IR films, only special types of laminate should be used, which are designed just for such systems

- then it is necessary to check how the installed communication functions. For this, a test run is made;

- The last step in the installation of an infrared floor takes into account the installation of a suitable floor covering over it, which in this case is a laminate.

Helpful information! The wire belonging to the sensor can be laid in a corrugated protection. This will simplify the repair procedure if necessary.

It is recommended to keep it in the room for 2-3 days before laying the laminate. This is necessary in order for it to acquire the appropriate temperature, which will further avoid its expansion. To get acquainted with the peculiarities of using IR films in this case, it is recommended to read reviews on profile sites. Film warm floors under the laminate are the most common today.

Installation of infrared warm floors under the tiles

Laying of the infrared floor under ceramic tiles can be done in two ways: "dry" and "wet". In the first case, the heating elements of the film do not come into contact with the cement screed. In turn, the "wet" method of installing the IR film is performed by pouring a cement mortar over the system.

Let's consider the algorithm of actions for the "dry" method:

- Installation of a film canvas, which is carried out according to the same rules as in the case of infrared heating under a laminate.

- Further, the installation of a protective layer, which is often used as a polyethylene film, is performed.

- At this stage, it is necessary to install the base under the screed over the film. For such purposes, plasterboard sheets (GKL) are excellent. When fixing the sheets, special care must be taken, as there is a risk of damage to the heating elements of the infrared floor.

- Then a thin layer of screed is poured over the substrate.

- The tiles are laid last. For this, standard tile adhesive is used.

In turn, the installation of infrared underfloor heating using the "wet" method is more profitable from a financial point of view. It includes the following steps:

- first of all, it is necessary to install the heating elements of the infrared floor;

Laying a film infrared cloth under a tile is carried out according to the same rules as under other coatings

- then a protective plastic film is laid. This stage is the most important in the entire procedure for the "wet" method of installing the IC. Experts recommend laying a protective plastic film in 2-3 layers;

- at the third stage, the reinforcement is installed. As a rule, a metal masonry mark is used for these purposes;

- then the screed is poured;

- at the end it is necessary to lay ceramic tiles.

Note! The thickness of the screed should not be more than 10 mm, otherwise the efficiency of such heating will significantly decrease.

Thus, the installation of film underfloor heating under the tiles can be done with your own hands. The only thing that is necessary for this is strict adherence to the sequence of work.

Features: installation of a film warm floor under linoleum

Installing an infrared floor under linoleum has its own characteristics. Let's consider this process step by step:

- At the beginning, the insulation material is laid.

- Next, you need to cut the IR fabric into pieces of the required length.

- At the third stage, the installation of film warm floors is performed. It is important to remember that they must be laid down with copper elements.

- Then, using pliers, the clamping terminals are mounted on the copper wire elements of the film.

- At this stage, the strips are fixed with double-sided tape. This is necessary in order to avoid their free movement.

- Next, you need to follow the procedure for connecting the film floor heating to the electrical network.

- After connecting the IR floor, you need to check its performance.

- Then a protective polyethylene film is laid on the heating elements, which is fixed with tape.

- The penultimate stage takes into account the installation of the base for linoleum. Fiberboard sheets can be used as a basis.

- At the last stage, linoleum is laid.

On the packaging with a roll of linoleum, there must be a pictogram indicating the possibility of using it in combination with a warm floor

Thus, the installation of a film warm floor under the linoleum is carried out. If you are not sure of your own skills, then it is recommended to contact the masters who will do all the work efficiently and in a matter of hours.

Infrared floor heating: prices

Today you can find various options for IR floors of carbon or bimetallic type. Their cost varies from 300 to 1700 rubles. per 1 m², depending on the manufacturer and specifications. Some carbon models can have a special protective graphite coating and cost up to 2,000 rubles.

The dependence of the price on the company that manufactures infrared floors can be traced to the naked eye. For example, the price of an infrared film underfloor heating Caleo can exceed 2,000 rubles. for 1 m², while Rexva sells some high-quality models for only 300-400 rubles. The price of a film underfloor heating under a laminate is the highest, which is due to high demand.

Note! If the cost of the IR is indicated immediately for a whole roll, then it is recommended to recalculate the cost of 1 m yourself. Some companies use this method to increase the price of products.

The price of a heat-reflecting base ranges from 80 to 200 rubles. The simplest model of a thermostat will cost about 1200 rubles, and more expensive devices equipped with touch programming, 2500 rubles. The cost of installation services is also different and can vary from 200 to 400 rubles. for 1 m².

Where can you buy film warm floors? These heating systems can be purchased at any specialized store or building hypermarket. You can also buy infrared film warm floors through the Internet. To do this, you need to go to the site that sells this product and place an order.