Many are familiar with the problem of insufficient heat and sound insulation of metal-plastic window structures. Most often it occurs due to wear of the cushioning material. The seal for plastic windows can be made of different materials and have a different look, but in any case, it must be changed regularly. Only in this way will your windows maintain their high performance for a long time.

Content [Hide]

- 1 Why do we need window seals

- 2 When you need to replace the seal in a plastic window

- 3 Types of window seals: silicone, rubber, rubber and thermoplastic

- 4 Seal options by mounting type

- 5 Marking of polymer, rubber and silicone seals for plastic windows

- 6 Replacing a seal in a plastic window with your own hands

- 7 Installation and replacement of the seal in wooden windows

- 8 Prices of seals for plastic windows from popular manufacturers

- 9 Seal for plastic windows: care of the gasket

Why do we need window seals

Window gaskets are made of rubber, rubber and other materials and perform the following functions:

- protection from external noise - buying window seals for plastic windows is especially recommended for those who live in a noisy area. If the windows of your house overlook a busy highway, a kindergarten yard or other places, the noise from which bothers you, then installing rubber, silicone or rubber seals will easily solve this problem;

- dust protection - most of the particles enter the house from the street through the cracks in the windows. Installing gaskets will significantly increase the level of cleanliness in your home and eliminate the need for frequent cleaning of window sills and space near the window;

- maintaining the temperature in the house - with poor thermal insulation of the windows, heat leaves the house very quickly, and in summer even an air conditioner does not save from the heat. This leads to high energy costs. Sealing gaskets in the windows will make living in the house much more comfortable, will allow you to keep warm in winter and cool in summer, and will also help save on utilities;

- protection against moisture - often moisture from rain or snow seeps into the house through the windows. Even minor crevices can ultimately lead to constant high humidity.Rubber, rubber or silicone does not allow water to pass through, so your home will always be dry and comfortable;

- more comfortable operation of double-glazed windows - sashes with gaskets made of elastic materials open and close better, do not pop or creak;

- extending the service life of windows - no matter what kind of windows are installed in your house, wooden or plastic, the use of gaskets will allow them to last much longer, protect them from the harmful effects of moisture, temperature changes and mechanical deformation. Thus, by installing a gasket, you ensure your windows a long life.

Helpful advice! Even if you purchased a window with already built-in rubber gaskets in the profile, they still need to be replaced some time after the start of operation. With high quality windows, it is carried out approximately once every 5 years.

When you need to replace the seal in a plastic window

There may be several signs that the window needs replacement of the seal. Among them are the following:

- clear signs of depressurization - constant drafts have appeared, heat does not linger in the room for a long time;

- the formation of condensation - the appearance of water drops on glass and in the corners of glass units;

The seal must be replaced if it starts to crack

- ice appears on the windowsill and on the window itself, which has a very negative effect on the indoor climate;

- windows cease to protect against noise - all sounds from the street are heard, with the wind a characteristic hum also appears;

- fungus and mold appear on the windows - this indicates a violation of the tightness of the glass unit, the accumulation of moisture on it;

- the installed seal begins to crack - this means that it has already far exceeded its service life.

If you notice any of the above signs, then it means that you should buy a seal for plastic window to replace the failed one, and install it. Otherwise, the windows will no longer perform their protective functions.

It is also worth understanding that several separate factors affect the tightness of the window:

- the quality of the seal. It all depends on the material from which it is made. High-quality cushioning material must withstand repeated compression and stretching during the opening and closing of the window, withstand regular temperature changes and other negative factors;

- type of connection of the seal with the window. The performance of the latter depends on how the sealing material is attached. This can be gluing, soldering and other options;

- replacement quality. Even the best quality wood and plastic window seals lose most of their properties if installed incorrectly. It is relatively easy to do the installation yourself, but if you absolutely lack the necessary skills and tools for this, then it would be better to seek help from experienced specialists.

Helpful advice! If you decide to change the sealing gasket on the window on your own, then you should first familiarize yourself with the numerous instructions and training videos on the Internet.

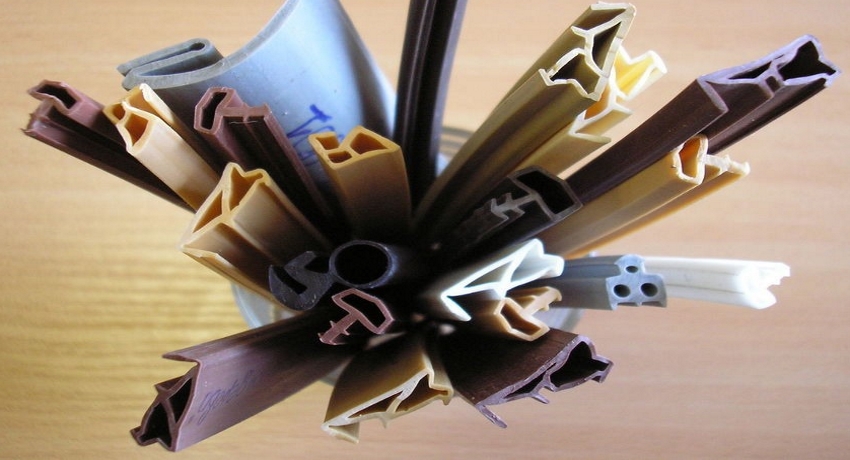

Types of window seals: silicone, rubber, rubber and thermoplastic

As already mentioned, the material from which it is made is of great importance when choosing a seal for a window. There are several options, each of which has its own operating characteristics, advantages and disadvantages.

Synthetic rubber based on ethylene with propylene

EPDM is an ethylene propylene or synthetic rubber.This material is characterized by high quality, reliability, durability and, in turn, comes in various types. EPDM types are distinguished by what chemical processes occur during its vulcanization. If sulfur acts as a vulcanizing agent, then such a rubber is called sulphurous. This type is not recommended for use in combination with white PVC windows, as sulfur can react chemically with the window profile, leaving yellow traces on it.

The second option is pyroxide EPDM, in which organic peroxides act as a vulcanizing agent. It is more expensive than the previous type, but it boasts higher levels of durability and reliability. Both types of EPDM gaskets have the following advantages:

- large temperature range of use - from -60 to 120 degrees Celsius;

- high resistance to temperature changes;

- practically insensitive to direct sunlight and ultraviolet radiation;

- are distinguished by a high level of strength to mechanical deformation;

- long service life - 10-20 years, subject to regular maintenance.

The disadvantages of this type of window seal, which can be bought at any specialty store, are also available:

- it can be fixed exclusively with glue, it cannot be welded;

- if you need colored seals for plastic windows, the price of 1 meter will be higher than for the same material, but black;

- if you chose a sulphurous based gasket, it may have an unpleasant odor.

EPDM gasket is a good option due to its high resistance to all kinds of adverse influences.

Features of thermoplastic seals

TPE or thermoplastic elastomer is most often found in finished insulating glass units. It is a modified PVC and has a high spring rate. TPE is intended for use in mild climates, as it responds rather poorly to low temperatures. This gasket property is corrected in a new type of thermoplastic elastomers - TPE blended. They differ in that they contain rubber and polyethylene, therefore they can boast of greater resistance to negative temperatures and, in general, higher operational characteristics.

The advantages of PVC window seals, which can be bought as easily as EPDM, are as follows:

- absolutely safe for human health, as it is made from environmentally friendly materials;

- can be welded, not glued;

- non-flammable, that is, it can be installed in rooms with an increased risk of fire;

- is much cheaper than EPDM;

- differs in high rates of springiness;

- there are many color options.

This type also has disadvantages:

- loses its properties at too high or too low temperatures, in the first case it softens, in the second it completely loses its elasticity;

- quickly breaks down with regular mechanical stress, is easily deformed;

- does not have a high level of elasticity.

Related article:

Adjusting plastic windows yourself: video tutorials

Winter-summer mode. Adjusting the pressure mechanism. Buttonhole adjustment. Repair of plastic windows.

It is recommended to install a TPE seal if you live in a warm climate and do not use windows too actively. Otherwise, it will quickly fail and you will have to change the gasket on the windows again.

Helpful advice! If you nevertheless decide to give preference to a TPE seal, then choose modern options made on the basis of polymer blends, since they have higher performance characteristics.

Silicone seals for plastic windows: advantages and disadvantages

Silicone seals are not very popular due to their high cost. The performance characteristics of this option are high, and it is based on silicone rubber, which contains methyl. The main advantage of this type is a high level of resistance to high and low temperatures. In addition, the following advantages are distinguished:

- very soft material that does not lose its properties in the temperature range from -60 to 100 degrees Celsius;

- perfectly tolerates not only temperature changes, but also other negative factors, for example, constant exposure to moisture;

- resistant to aggressive chemical environments;

- not afraid of ozone radiation;

- is distinguished by its durability.

The disadvantages of a silicone seal are as follows:

- susceptible to mechanical stress, tears and deforms quickly enough;

- high price.

The last point is the most significant disadvantage of the silicone-based gasket, therefore it is not popular with buyers.

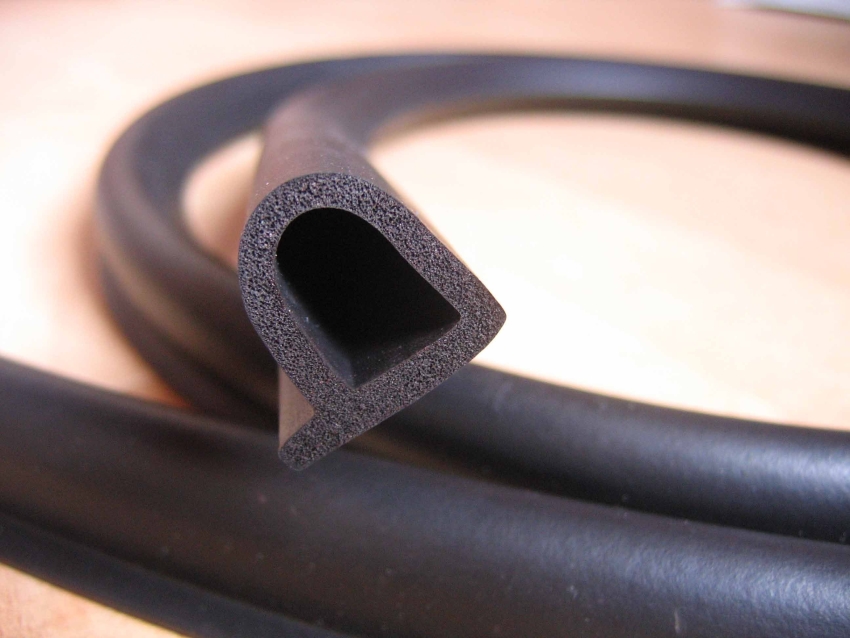

Features of rubber seal for windows

A rubber gasket made from conventional vulcanized rubber is a good alternative to the materials described above. It has the same advantages and disadvantages as any other rubber product. The material provides a high level of tightness of the window and is relatively inexpensive, but it can lose its performance during temperature changes, crack or dry out, and also suffer from strong mechanical stress.

The quality of a rubber seal largely depends on its manufacturer. In the composition of this type, various fillers can be used that increase or, conversely, reduce the properties of the material.

There is no unequivocal answer to the question of which sealant for a plastic window is better. Silicone is very popular, due to its resistance to negative natural factors, but EPDM is cheaper, while also boasting high performance characteristics. TPE is well suited for use in mild climates, and natural rubber will save you money. For example, a silicone gasket costs about 55 rubles per running meter, you can buy EPDM window seals for 30 rubles, and TPE for 35 rubles.

Helpful advice! When choosing a gasket, pay attention to the country of the manufacturer. As a rule, gaskets made in Finland and Turkey are of high quality.

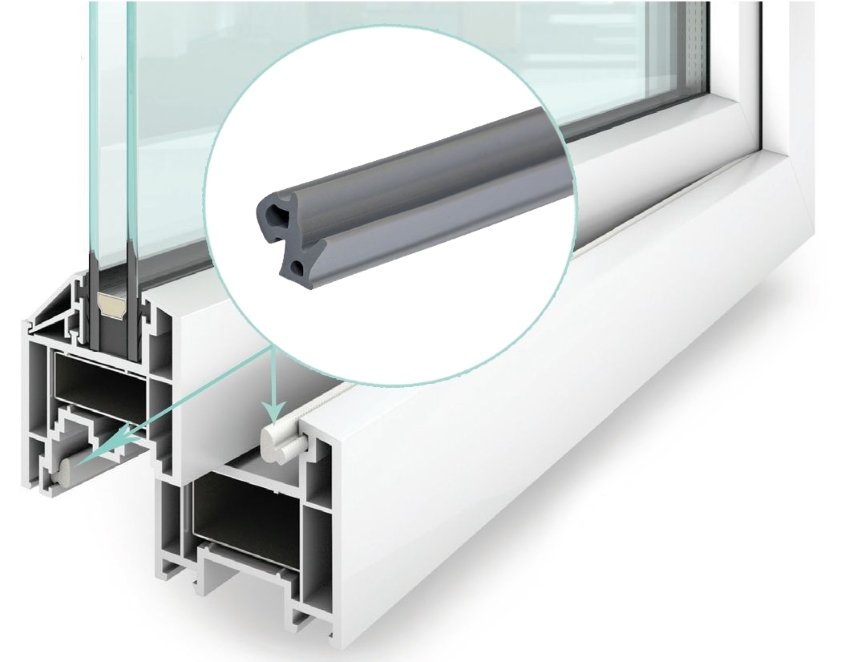

Seal options by mounting type

Apart from the material from which they are made, window seals differ in how they are installed. There are such types here:

- Self-adhesive window seals - equipped with a special adhesive layer and are best suited for self-installation.

- The gaskets that are mounted on glue differ from the previous ones in that they do not have a ready-made glue layer.

- Slotted - used mainly to improve the performance of wooden windows.

When choosing self-adhesive gaskets, great attention should be paid to their shelf life. An expired seal can come off very quickly or not stick at all.In addition, it must be soft enough to adhere evenly even on a not very flat surface, which can be relevant in the case of wooden windows. Roto seals for wooden windows are very popular.

If you install a self-adhesive seal, then the surface of the window must first be thoroughly cleaned of dirt and dust, degreased with acetone, and you need to glue it at a positive temperature, but not higher than 40 degrees Celsius.

When installing the groove seal, the window sashes must be removed from the hinges, and the groove in them is made using a cutter.

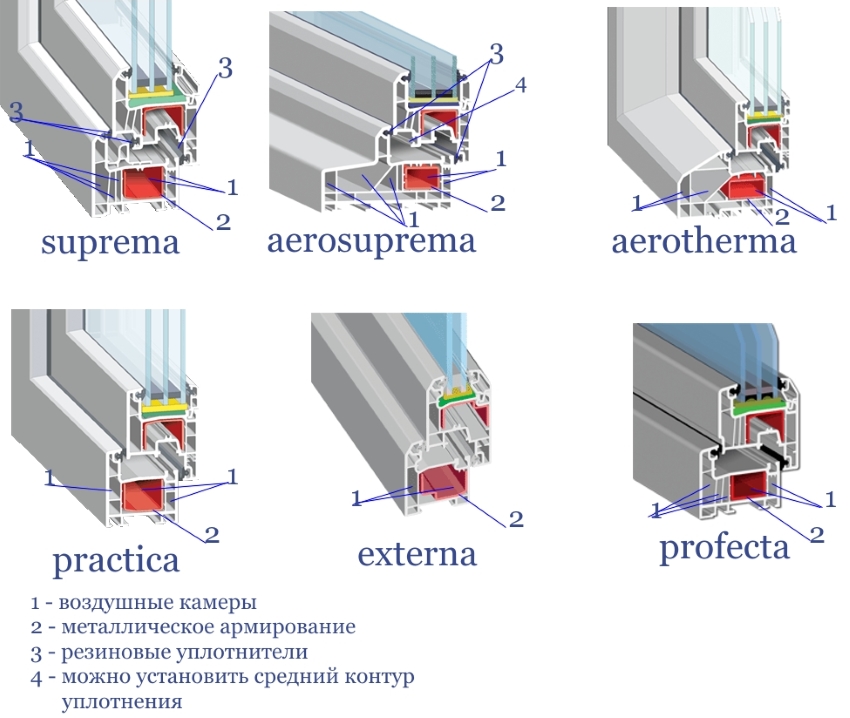

Marking of polymer, rubber and silicone seals for plastic windows

Despite the fact that in specialized stores you can find a huge number of varieties of gaskets for windows, in fact, there are only three main types, and they are marked with the following designations:

- KBE;

- Rehau;

- Veka.

All other types are varieties created on the basis of the above, and differ from them in minor modifications and features.

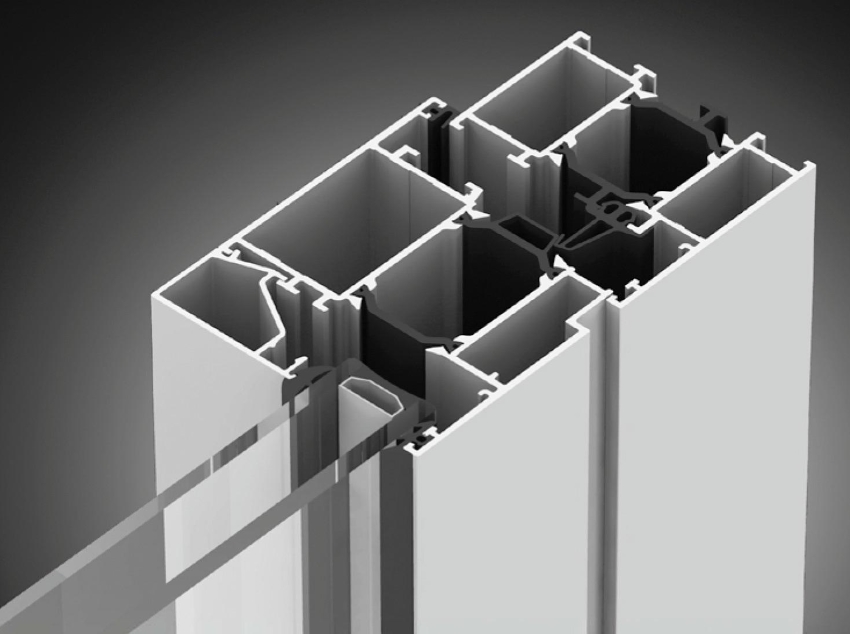

Rehau type seals can be recognized by their two characteristic, slightly curved single teeth. The barb that is closer to the middle of the spacer is slightly longer than the other. The KBE has this exact tooth in the unmodified version, and the modified one is characterized by the presence of a stiffener that extends from the opposite edge. Veka pads differ from the previous ones in that the prong is at right angles to the base, while in previous models it clearly bends.

Helpful advice! When choosing the marking you need, it is best to pay attention to which gasket is already used in your glass unit, or which one the manufacturer recommends to use.

Replacing a seal in a plastic window with your own hands

First of all, you need to decide on which part of the window you need to replace the seal. Most often, the sealing gasket becomes unusable on the frame, which can be easily seen in the warm season - on windowsill dust constantly settles. In winter, leaky seals can be traced by regular drafts.

Before changing the gasket, it is necessary to adjust the window hardware. This is done as follows:

- Take a specialized head turning wrench and a marker, mark the starting position of each head so that if you twist it incorrectly, you can return it to its original position.

- Using a wrench, screwdriver or pliers, rotate the head in the desired direction. Due to the large number of such heads on the frame (6 or more), it is possible to eliminate drafts even without replacing the seal in plastic windows. The cost of such a procedure will also be much lower.

It is possible to remove microcracks in the seal of the plastic window using silicone grease. This will protect the product from premature drying, protect it from frost and moisture, and, in general, significantly extend its service life. It is necessary to apply lubricant with a regular cloth or rags, and this must be done at a positive temperature.

If, however, you cannot do without changing the gaskets, then before starting this process, it is recommended to take a picture of the frame. This is done so that you can refer to the photograph when putting on a new seal.

To remove the seal from the frame, it is necessary to remove the window sashes. To do this, simply pull off the decorative caps that cover the hinges, and then knock them out with a chisel and hammer. Remember that the sashes are removed from the hinges in the closed position, and also that the sash itself has a lot of weight.

After that, the seal is removed from the frame, and the recess in which it was is wiped with a dry cloth. It is better to cut a new segment of the seal several centimeters longer than the old one, since the rubber shrinks during installation and operation. If you need more reliable heat and sound insulation, then the ends of the gasket are glued together with a sealant.

The next step is to replace the rubber seal for plastic windows in the area of the hinges, this is why the sashes were removed. Here you also need to take a slightly larger piece of material than the connector for it. After replacement, you can reinstall the sash. To do this, it rises a few centimeters above the windowsill and is put on the lower loop. The pivot of the upper hinge is carefully driven in with a hammer.

Remember that in most modern glass units, the gasket is installed along the outer and inner contours. In some models, there is also a third circuit, which serves to protect against condensation, as well as for better insulation from noise. If you have a window with three sealing profiles installed, then you need to change them all at the same time.

Checking the reliability of the installed seal

Immediately after you have installed a new gasket, you need to check if everything has been done correctly. To do this, you need to check the following points:

- whether the sash closes and opens easily;

- whether the drafts have disappeared;

- whether the seal remains in the grooves when opening and closing the window.

If the answer to all these questions is yes, then immediately apply silicone grease to the gasket on the fabric. It extends the life of the product and enhances its performance.

Helpful advice! It is not recommended to use a lubricant to treat the seal during the cold season. It is best to do this twice a year - in the fall and spring.

If you do not have the time, effort, skills, tools or a banal desire to install the gasket on your own, then this can be done using the services of experienced specialists who will replace the seal on the plastic window. The price of this work is not high - about 1000 rubles, it depends on the type and size of the window, the complexity of the work and a number of other factors.

Installation and replacement of the seal in wooden windows

Improving the performance of windows made of wood is somewhat more difficult than plastic ones. Especially many problems arise when it comes to insulating old wooden windows, however, this problem can be solved. First, you need to determine for what reason a wooden window loses its performance:

- The frame and sashes are made of raw, untreated wood, which deforms very quickly, which, in turn, compromises the tightness of the window.

- The window is made of solid wood blocks. In this case, the weakest point of the structure will be high humidity, which inevitably deforms the frame.

- The window is insulated only with glazing beads, without the use of modern rubber seals.

The correct wooden glass unit must be made of glued wood, which has been specially dried and vacuum impregnated. Such a tree can withstand changes in temperature and humidity, and a window made from it can last 40-60 years.

Wooden windows are insulated in the same way as plastic ones - with the help of modern sealing materials. For wood, it is better to choose options made of rubber or PVC, the latter do an excellent job with cold weather, and the former are more profitable to use if you live in a warm climate.Sealing gaskets are fastened using silicone sealant; it is better not to use self-adhesive options for wooden frames, as they can come off in the cold season.

The best option for insulating a window frame is a tubular profile. Despite the fact that it is intended for plastic windows, it is possible to buy a sealing rubber of this type for wooden ones, and its performance characteristics are distinguished by high wear resistance and durability. The service life of a tubular profile, subject to proper care, is 5-6 years, while it looks aesthetically pleasing and is easy to install.

Also, the following materials can be used to insulate a wooden window:

- PVC coated felt tape, which is mounted on the lower part of the window sash and provides reliable protection against drafts.

- A sponge pad that fits in the same way as the previous version and also effectively copes with heat loss.

- Ordinary foam is good because it has a fairly low cost, but quickly breaks down.

- Foam seal with special coating. Insulates windows better than polystyrene, but cannot boast of a long service life.

- Metal gaskets are stainless steel or bronze strips that are used to close the gaps between the window frame and the frame. For effective use of such strips, it is necessary that the inner surface of the box is absolutely flat.

- Construction tape is the simplest and cheapest, but also the most inconvenient option. The scotch tape can come off the cold air flow, and it will be simply impossible to open the window sashes with such insulation.

Helpful advice! If possible, use tubular silicone or rubber gaskets to insulate wooden windows. They will cost more than scotch tape or styrofoam, but they will last much longer and provide reliable protection from the cold and noise from the street.

The procedure for installing a seal in wooden windows

If you need high-quality insulation and sound insulation of a wooden glass unit, then the work must be carried out in the following order:

- The future gasket installation sites are thoroughly cleaned of paint, dust and dirt. It is highly recommended to degrease the surface before proceeding with the installation of the seal. This can be done with alcohol or solvent.

- The gap between the sashes and the frame is studied and measured. This is done in order to determine the thickness of the seal, which will not interfere with the closing of the window.

- If the thickness of the gap is not enough, then the groove for the seal is done by hand. If the required distance between the flaps is present, then you can proceed with the installation of the gasket.

- The edges of the gasket can be secured with small nails for better sealing performance.

The result of these works will be windows that will protect your home from the penetration of noise, dust and cold air. The main thing is to remember that if your wooden window has served for more than a dozen years, then it may be easier and cheaper to buy a new one instead, and not engage in attempts to restore the old one.

Prices of seals for plastic windows from popular manufacturers

In the modern building materials market, there are several popular companies specializing in the manufacture of window seals.

Seals Rehau

The first well-known manufacturer of gaskets is the German company Rehau. Its products are made from ethylene propylene rubber (EPDM) or thermoplastic elastomer (TPE). Rehau products have the following advantages:

- ensures high quality of sealing of the seal along the entire perimeter of the glass unit, regardless of the configuration and size of the window;

- boasts a wide range of temperatures at which it can be operated - from -55 to 60 degrees Celsius;

- has high performance characteristics - resistance to mechanical stress, temperature extremes, ultraviolet radiation and high humidity;

- the service life of the products is several decades.

It is possible to buy seals for plastic windows from the Rehau company at retail at a price of 15 rubles per running meter. The cost of the product depends on the material from which it is made and the configuration features. At the same time, color options can cost more than black ones.

Window seals Veka

Another popular manufacturer of window gaskets is Veka, which is also from Germany. Veka seals have been on the market for more than four decades, which indicates their high quality and demand among customers.

The company manufactures rubber seals for both the window sash and glass, and among the advantages of the company's products are the following:

- high durability and resistance to deformation;

- well withstand temperature changes, humidity, frost and other adverse influences;

- provide a high level of heat and noise insulation.

Helpful advice! If you have double-glazed windows installed in your house from the company Veka, then to increase their performance, it is recommended to use seals from the same company, since the configuration of the windows is very poorly suited for insulation using alternative options.

A meter of a seal from the Veka company costs about 20-25 rubles. The cost depends on the product model and its purpose. For example, a glass spacer is slightly more expensive than a porch spacer.

KBE products

KBE is a company for the production of insulating glass units and accessories, founded in Germany in 1980. The company's products in many countries are considered the standard of quality in the field of translucent structures and have been popular among customers for over 30 years. A feature of KBE window seals is that they roll tightly into the window groove, so if you are wondering how to replace the seal on a plastic window from KBE, then you will need a knife or scissors for this. And it is recommended to roll in a new gasket using a specialized tool.

KBE gasket options are made from high quality rubber and are excellent for enhancing the performance of all window materials. The service life of the product is up to 10 years, and the cost of a running meter of a sealant is from 15 rubles.

Domestic analogues

If you do not want to spend money on expensive European products, you can use cheaper Russian-made seals. Companies such as "Obninskgazpolimer" or "Standard Prof" offer their products at an affordable price, and their quality is not much inferior to foreign counterparts. However, it should be borne in mind that the shape of PVC window seals for some domestic samples may not be suitable for foreign double-glazed windows.

Helpful advice! If your house has branded plastic double-glazed windows from a well-known manufacturer, then it is better not to save money, but to install seals from the same company as the window.

Seal for plastic windows: care of the gasket

Regardless of which gasket material or manufacturer you are using, special care is required to prolong its life. This includes the following items:

- Rinsing - the product must be regularly wiped with a damp cloth or a sponge dipped in a specialized LOC solution. The frequency of flushing depends on the material from which the seal is made. For example, for a product made of silicone, this is required much less often than for gaskets made of other materials - about once a season. Another option for washing window seals is with a special Edelweiss set, which includes all the necessary tools and means.

- Lubrication - for this it is best to use solutions based on silicone. You use glycerin-based formulations at your own peril and risk, as some models may react poorly to it. It is strongly not recommended to use petroleum jelly as a lubricant, as well as butter, vegetable or machine oil, as they can significantly reduce the service life of the product.

- Removing dirt and dust from under the gasket tabs - this must be done with a soft object, since when using a knife or screwdriver there is a high risk of damage to the material, which will lead to a decrease in its performance and a significant decrease in its service life.

Do not clean your gaskets too often. The optimal frequency is once every 1 to 2 years unless you live in a heavily polluted area. And if you are afraid to damage the seal as a result of careless cleaning, then at your service there are a large number of companies that can do it for a relatively low fee.

There are several answers to the question of where to buy seals for plastic windows. This can be done in the construction market, in a specialized store, or ordered via the Internet. In any case, before buying, you need to decide on the type and configuration of the product, as well as the material from which it is made. Also, great attention should be paid to the manufacturer, and if you have modern double-glazed windows from a well-known brand installed, then it is recommended to use gaskets from the same company to increase their performance.

As for the gasket design, it all depends on the color of the windows, as well as your imagination. Usually, the shade of the product is matched to the color of the glass unit, however, you can be original, install a color model and thus create an original design. It should be remembered that colored models of seals are usually worse at restoring their shape after deformation than their black counterparts.

Helpful advice! When choosing a seal for plastic and wooden windows, buy a product with a margin of length, since errors are inevitable during the installation process, in which the length of the gasket will constantly be cut.

Seals made of modern materials for your windows are reliable protection against cold, heat, dust and noise. You can easily buy them in a store, on the market or via the Internet, and self-installation will not take much time if you have minimal skills in this area.