On trading floors, there is a large selection of window sills, for example, made of wood or natural stone, but such structures are quite expensive. Plastic products, firstly, have a lower cost, and secondly, thanks to modern technologies, plastic is not inferior to natural materials in quality and appearance. If you choose the right size for the plastic window sills, the products will decorate the window and make the repair complete.

Content [Hide]

- 1 The main dimensions of PVC window sills: what role do they play

- 2 The main advantages and disadvantages of plastic window sills

- 3 Sizes of plastic window sills: why some people prefer wide products

- 4 The main types of window sills for plastic windows

- 5 What accessories are needed to install a window with a window sill

- 6 How to choose a PVC window sill: prices for various options

The main dimensions of PVC window sills: what role do they play

When choosing a window sill, you should not save money, because often the need to replace a window sill can entail a cosmetic repair of the slopes, which will also require certain costs, especially since the price of a plastic window sill allows you to choose the most high-quality and durable option.

Checked! If you buy a higher quality window sill, the price of which will be 400-500 rubles more expensive than the cost of the bulk of the goods, most likely you will not have to repair the window in the near future. And any, even the most minimal, repairs will cost at least 1500-2500 rubles.

In any case, it should be borne in mind that even the most expensive plastic window sill is not designed for heavy weight. For this reason, you should not plan to install a heavy aquarium, coffee machine or other large items here. The main purpose of window sills is not so much practicality as an aesthetic function. It is thanks to the windowsill that the window will look more attractive, and the room will look organic and complete.

As far as the window standard is concerned, the dimensions mainly vary depending on the type and functional significance of the building. There are both products of traditional dimensions, which are often found in residential apartments, and windows of various shapes, which require modeling of the window sill in accordance with certain requirements.

Among the advantages of PVC material, it is worth highlighting the ability to choose almost any color scheme, and many manufacturers also offer options that imitate wood, marble, granite, labradorite and other stones. Often the imitation looks so natural that you can only distinguish it from the original by touch.

To choose the correct size and thickness of the plastic window sill, you need to take into account the indentations left over from the previous product after replacing it. Often, new window sills are 0.5-1.5 cm longer than old ones, the width can increase by 0.3-0.4 cm, because metal-plastic windows, in comparison with old wooden frames, are 4-5 cm thinner.

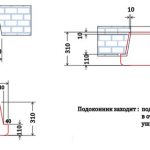

The size of the plastic PVC window sill should be 5-10 cm larger than the width of the niche in order to beautifully close the joints. At the same time, it is important to remember that the structure should not overlap the heating devices, because this will violate the microclimate in the room. The maximum distance from the wall that the window sill can protrude above the battery is 10 cm.

First of all, the size of the window sill is selected taking into account the parameters of the window

What are the sizes of plastic window sills

As in the case of purchasing metal-plastic windows, it is better to place an order for the individual production of a window sill (after removing and rechecking the necessary measurements). The size and price of a plastic window sill can differ even in the conditions of one multi-storey building, because the dimensions of the window opening, depending on the floor and location of the apartment, may differ by 7-10 centimeters or even more. In addition, the depth of the window opening can also change, which will also affect the change in parameters.

Helpful advice! When buying, you should not be guided by the size of the window indicated in the passport for the product, it is better to re-do all the measurements or invite a specialist for this from the company where you plan to order the product.

As for the standard parameters, you can focus on the following numbers:

- Length - 405-600 cm. In most cases, products with a length of 6 m are delivered to retail outlets, already on the spot the finished product is cut to the desired size.

- Width - 10-100 cm. The step of changing the width is 5 cm. This allows you to select the desired size depending on the parameters of the window and the thickness of the wall partition.

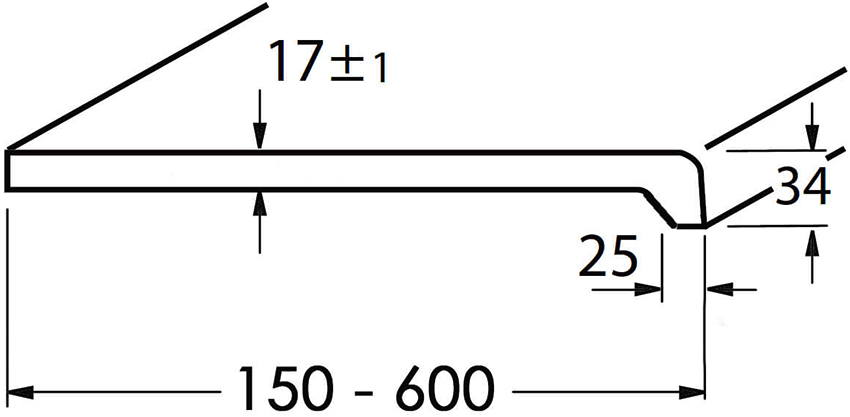

- Thickness - 1.8-2.2 cm. It is the thickness of the window sill that largely affects the strength of the product and the period of operation.

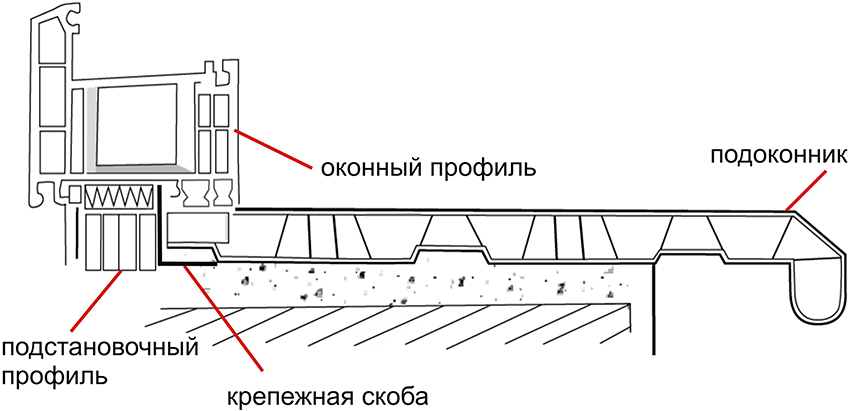

A window sill is mounted, regardless of size, using a support profile, which has a rectangular cross-section. Most often, you can see that the installation takes place at an angle of 90º relative to the plane of the window, although sometimes the installation is performed at a slope. In this case, you need to maintain the correct proportions - 3 cm of slope for every 30 cm of the width of the product.

It should be borne in mind that depending on the size of the plastic window sill, the price will change: the larger it is, the more it will cost. You should be aware that there is a certain template for calculating the cost. For example, if we consider that the average price of a product 10 cm wide is 200-250 rubles, then for every 10 cm the price will increase by the same amount. Thus, a material 30 cm wide will cost approximately 750 rubles. When installing, you need to take into account that, most likely, you will need to additionally purchase a plug for a PVC window sill, the cost of which is 30-40 rubles.

To roughly calculate the price, you need to take the window width as a basis (for example, 39 cm), 5 cm will need to be added to the installation - in total, 44 cm is obtained.The most suitable standard width is 45 cm, respectively, this indicator must be adhered to when determining the cost of the finished product ...

An important feature of a plastic product is its versatility, which allows installation in residential and work premises, including hotels, restaurants and medical facilities. Even at some industrial facilities, it is permissible to use PVC window sills.

The main advantages and disadvantages of plastic window sills

The high demand for the material is determined not only by the low cost, but also by a large number of other advantages:

- Moisture resistance. For these reasons, the products are not subject to decay or corrosion processes, even if they are used in rooms with high humidity.

- Stability. Due to its composition, plastic is chemically resistant to hydrogen peroxide and acetone.

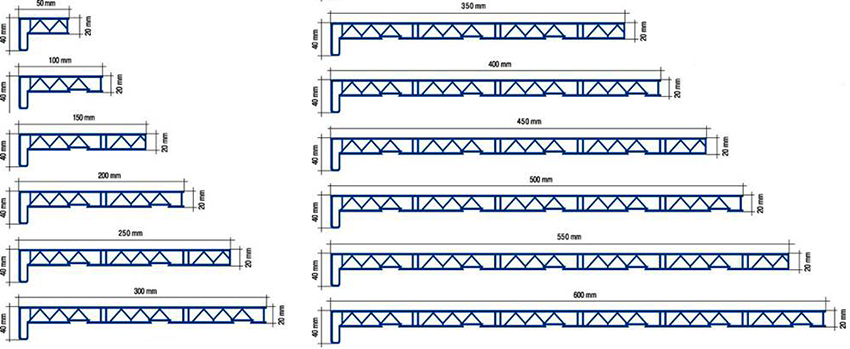

- Strength. The space inside the profile is divided into several chambers, resembling honeycomb in appearance. Inside, there are also diagonal and vertical stiffeners, which allow even a long product not to bend or break.

- Simple installation. Even a person who has no experience in construction work can cope with the installation of a plastic window sill.

- Additional insulation of the space. The presence of internal chambers gives the product heat-saving properties.

- No shrinkage. Unlike natural wood, which can deform depending on changes in humidity or temperature parameters, plastic can withstand such changes.

- Big choice. Due to the fact that the plastic window sill can be presented in any color, the window is given an interesting and individual design. You can also choose options for a stone or wood.

- Heat resistance. Most manufacturers use the application of additional compounds to the surface, which significantly improves and improves the consumer qualities of products.

It is important to understand that plastic, like any building material, also has its drawbacks:

- Relatively short term of use. In most cases, especially if the window sill is under constant exposure to the sun, it can fade.

- Failure to withstand high temperatures. If you place an object that is too hot on a surface, it will most likely leave either a stain or a deformed area.

- Exposure to mechanical stress. If a heavy object falls on the material, there is a high probability of a crack or chip, as a result of which a complete replacement of the window sill will be required, because local repairs cannot be performed.

Some people believe that there is no need to purchase and install a window sill, but most experts will not agree with this opinion, because the product performs many useful functions:

- It plays the role of a barrier that does not let cold air into the room and does not let out warm air.

- Forms a microclimate in the room. Thanks to the installed window sill, the movement of heat flows is regulated, because warm air is repelled from the surface and falls directly on the glass, which prevents the appearance of condensation on the windows.

Interesting information! Basically, a window sill on a balcony or in a room acts as a thermal air cushion that insulates cold or hot glass and the atmosphere in the room. Without a window sill, the likelihood of high humidity around the window increases many times over, which will affect the entire microclimate in the room.

Sizes of plastic window sills: why some people prefer wide products

Some people think that window sills are practically invisible in a room, but most designers strongly disagree with this statement, because even the most unfortunate interior can be refreshed with a window sill. Moreover, considering that modern products are much more interesting and functional than outdated options.

If the thickness of PVC window sills affects their strength, then the width determines the functional purpose. For example, in a narrow space, a maximum of several pots of flowers, vases or some other accessories can fit, but the wide version already significantly expands the possibilities and allows you to experiment. The large width of the plastic window sill helps to take a fresh look at the arrangement of the room, especially if the structure is located quite close to the surface of the floor covering.

Unusual ideas for playing with a product that has a large width:

- Sleeping place under the window. It is the window sill-bed that is considered the most functional and practical solution. It is especially important to organize this option in the case when there are high and voluminous windows in the housing.

- Desktop. It is not necessary that it was just a desk; in the conditions of a studio apartment, it is very important to make the window sill a functional part of the kitchen space.

- Storage space for books. The mini-library can be supplemented with a side-by-side table and lighting fixture.

Related article:

Artificial stone window sills: an exquisite and stylish addition to the window

Advantages and disadvantages of designs. The choice of material for manufacturing. Installation and replacement of the product. Features of price formation.

If the idea of organizing a plastic window sill with a large width has appeared, the dimensions must be selected correctly, especially the thickness. A large product will not only be subjected to pressure itself, but will also affect the entire window opening. In this case, preference should be given to the maximum thickness.

When choosing a wide option, you need to take into account some negative points:

- Obstruction of natural air currents. A wide PVC window sill interferes with the heat supply from the battery, which causes fogging of the windows and the appearance of condensation, especially in the lower part of the glass unit.

- The need for additional ventilation. In order not to impede normal air circulation, it is recommended to install ventilation grilles for the free rise of warm air.

- Carrying out measures to increase the strength characteristics. If the space under the window will be used for sitting or as a berth, you need to purchase a thickened version of the product, which will cost more than standard counterparts.

The main types of window sills for plastic windows

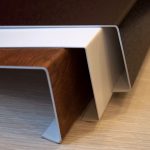

A large selection of plastic products has ensured a wide distribution of the material in the building goods market. Manufacturers specializing in the production of window sill blocks offer customers a wide range of products. Particularly popular are window sills imitating natural materials, allowing you to save money on purchase, while ensuring good quality and attractive appearance of products.

Such window sills are sometimes better than their natural counterparts. For example, plastic, unlike real wood, does not require constant treatments from pests and fungi. The material does not decay, and it is much easier to care for it.

There are also double-sided window units, which are less common on sale, but nevertheless are sometimes used in multi-functional interiors. The main difference between the product is the presence of two edges.This option, if necessary, can be easily transformed into a regular window sill.

If the surface is planned to be used as a bed, it is recommended to purchase options for increased strength, for example, with the addition of wood filler. Due to the fact that the product has a greater thickness and an increased number of stiffeners, it is able to withstand loads of up to 100 kg and more.

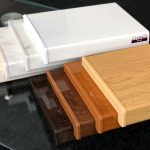

In addition to the size, PVC window sills for windows also differ in appearance. The following options stand out:

- matte;

- glossy;

- laminated.

Important! Most designers focus on the fact that matte and glossy window sills can fit into any interior, because they can be given any color that perfectly complements the surrounding design.

Matte window sills have been used for a very long time, but glossy ones began to gain popularity relatively recently. Of course, a matte window sill looks traditional and does not attract too much attention, but a glossy one looks more catchy and unusual. Among the advantages of the glossy option, one can single out the fact that the window sill is less susceptible to absorbing dust and dirt, but it will be impossible to restore the surface in case of mechanical damage. For a matte window sill, there is a special composition to update the appearance of the surface.

For those who want to save money, there are special laminated overlays for PVC window sills on sale, which add texture to the material, increase the period of operation and strength. In this case, the surface is laminated using a colorless thermoplastic polymer, which is a laminated film. When it comes to a white window sill, only one layer of film is used. If you need to add colors for interior decoration, several layers with the addition of dye are applied.

Other types of window sills: the feasibility of using colored products

A separate group can be divided into subwindow blocks, which are made using a special technology - by mixing PVC solution and wood flour. Thanks to this unusual combination of components, this type of plastic window sills has acquired a significant number of advantages:

- increased resistance to mechanical damage;

- insensitivity to direct sunlight;

- long service life without deformations, color changes and other possible troubles.

As for the choice of color, first of all you need to know that white is not the only option in which products are made. The market of modern building materials is constantly replenished with new products and interesting products, which make each interior unusual and unique.

New technologies have made it possible to produce plastic window sills in any shade. Also available for purchase are plastic marbled window sills with a matte and glossy surface. Among the most popular shades, it is worth highlighting brown and its variations, as well as gray products.

It is interesting!To obtain a brown sill, white plastic and acrylic dye are mixed. To achieve an attractive appearance, the finished product undergoes a lamination process.

A large number of brown materials are available in retail outlets - from light cream to rich coffee. Brown window sills will complement the interior of a wooden house, and in other cases they will look respectable and expensive. Due to the high popularity of modern styles such as minimalism, hi-tech and loft, gray products are also at the peak of popularity.In addition to the fact that gray window sills emphasize the unusualness of the interior, they, unlike the white version, are less susceptible to pollution.

What accessories will be needed to install a window with a window sill

Installation of window sills does not require any skills or special knowledge. Any owner will be able to handle the installation on their own and without using any complicated tools. However, in order for the installation to go smoothly, you will need to take care of all the necessary related items in advance, which do not always come with a complete set when selling a window sill.

First of all, for installation, you will need a connector and a double-sided end plate for the windowsill. The main task of the plug is decorative, because the end part that has been cut will not have an attractive look and will require a frame. The part has 2 spouts, and before installation it will need to be divided into 2 parts: one is inserted on the left side, the second on the right.

You will also need a PVC window sill connector, which is used to join the product at an angle and join along its entire length. In addition, you must additionally purchase:

- brackets;

- coasters;

- slopes.

After dismantling the old window sill, the slopes are often severely damaged, which will require at least a small repair. The slope itself is the perimeter of the window, located from the frame to the edges of the wall surface. Brackets come in handy during installation, because they are able to prevent surface deformation after installation. As you know, the window is considered a favorite place for planting flowers in pots, because here the plants receive the greatest amount of sunlight necessary for their normal growth. But still, if the flowers are heavy and voluminous, it is recommended to use special stands for this purpose.

What are decorative overlays for a window sill

Plastic is not considered a particularly durable material and, under any influence, it can lose its appearance, while not just cracking, but also changing color or scratching. It is for such situations that the repair linings on the windowsill were invented, allowing you to give the damaged product an attractive appearance.

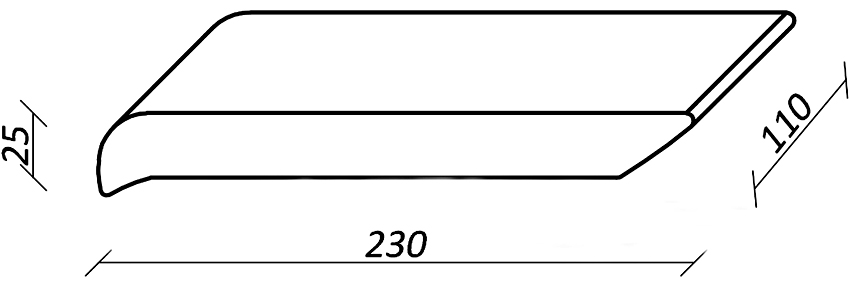

The size is selected based on the parameters of the already installed window sill. Here, the main material is also PVC, which gives the parts the necessary strength and rigidity, which is required to protect the surface. In some cases, the overlays are equipped with a profiled edge and plugs that help to hide not only flaws, but also irregularities in the main window sill. The main thing is to choose the correct size, for which you should carefully measure the already installed option and add 2 cm to the obtained value, because the overlay should be slightly larger than the window sill.

Important information! The plastic overlay on the window sill should be larger than the main surface, since the position will have to be adjusted during installation. In this regard, there must be a certain margin, otherwise the product will not look aesthetically pleasing.

The rules for determining the size of the overlay on the windowsill:

- the length of the material must fully match the length of the window sill;

- the width is recommended to be measured from the frame to the edge of the slab.

A large number of options are available for the color design of the linings, including those imitating natural materials. But the most common are white shades. In this case, the end must be closed, because otherwise the window, window sill and even the room as a whole will look unfinished.

How to choose a PVC window sill: prices for various options

The quality of the product is considered a criterion that determines not only durability, but also cost.Despite the fact that outwardly plastic window sills on the balcony and in the room look almost the same, nevertheless, various technologies and production methods are used in their manufacture. Window sills made of plastic, taking into account their quality and cost, can be divided into 3 classes:

- economy;

- middle;

- luxury.

Basically budget models are produced in Russia, China and post-Soviet countries. Here, the main characteristics can be considered:

- small selection;

- a light weight;

- short warranty period;

- low cost.

Economy products are characterized by thin stiffening ribs; they must not be subjected to heavy loads. Many users in the reviews mention that thin window sills, even after a short time after the start of operation, change color and become covered with spots that cannot be removed in simple ways.

In the variants of the middle price segment, the stiffeners are already denser and larger, which contributes to a significant increase in strength properties. The material has a protective polymer layer. A wide variety of colors and shades can be found on trading floors. Some domestic manufacturers are engaged in the production of similar products, but Belgium is the leader.

The cost of luxury PVC window sills is the highest. It produces such goods and exports to other countries, mainly Germany. The main difference between the German window sill is its heavy weight, which is due to the fact that the entire block is covered with a layer of acrylic. It is this additional application that makes the product resistant to both mechanical and thermal influences.

Regardless of which price category the material is selected from, the following points should be considered:

- the window sill must match the size of the window opening;

- the product must be accompanied by a certificate confirming the quality.

Checked! Materials with an additional acrylic coating will last the longest.

Among the most popular manufacturers are the following:

- Moeller. A German company that produces products that are 30% wood flour, the remaining 70% is PVC. Window sills belong to the class of hardly flammable, do not fade in the sun and do not get scratched. Designed for installation in rooms with high humidity, so it is permissible to use them for saunas and baths. The maximum surface load is 428 kg.

- Elex. Domestic firm. The product has an attractive appearance. Made from ecological materials. Has high wear resistance and unpretentious cleaning. The cost starts from 60 rubles. per running meter.

- Masterplast. Also a domestic manufacturer that produces models exclusively for marble. The cost of window sills starts from 150 rubles.

The window sill is considered one of the important elements that decorate the window opening. By installing the element, it will be possible not only to decorate the window, but also to close the sloppy assembly joints. It is the windowsill that plays an important role in protecting the room from the penetration of cold and outflow of warm air. It is important not only to choose the right size, design and color, but also to take the installation seriously, because the service life of the product will depend on this.