A significant part of the heat that is generated by heating devices is often wasted due to significant heat loss. This problem is especially common in older houses, where the thermal insulation layer was not provided during the construction phase, and the windows and doors are a source of cold. The ideal solution to this problem is PU foam insulation, the advantages, disadvantages and features of which will be discussed in this article.

Content [Hide]

- 1 Polyurethane foam insulation: production technology and material application

- 2 Varieties of polyurethane foam used for insulation

- 3 How much does polyurethane foam insulation cost, price per sq. m.

- 4 PU foam insulation: the pros and cons of using technology

- 5 What conditions are necessary for insulation with polyurethane foam: reviews and advice

- 6 How is the process of spraying polyurethane foam carried out

Polyurethane foam insulation: production technology and material application

A material such as polyurethane foam is obtained by mixing two components - a polyol and a diisocyanate. Despite the fact that both of these components are toxic and pose a threat to human health, as a result of their mixing, a completely safe polyurethane is obtained, which does not pose any danger and does not react when in contact with other substances. Moreover, the material obtained as a result of two toxic substances is often used even in the food industry.

The polyurethane production process is accompanied by active gas evolution, as a result of which a large amount of carbon dioxide is formed. Thus, it is inside a thin polyurethane shell, which provides a high rate of thermal insulation properties of the material.

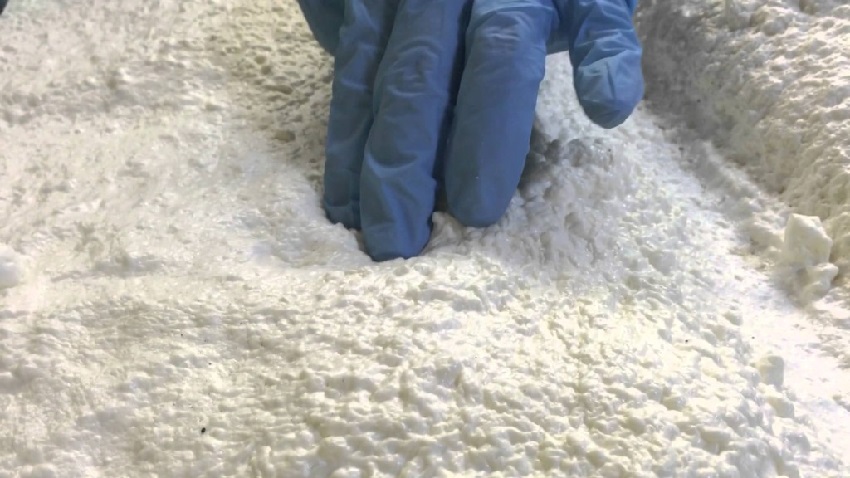

This whole procedure is carried out using a special pistol, inside of which there is a very high pressure, and the temperature that is maintained in it is 45 ° C. It is as a result of this effect that small particles, like dust, are mixed, after which they are sprayed onto the surface, allowing them to foam and harden.

In order for the resulting material to have all the necessary characteristics, its constituent components (polyol and diisocyanate) must be in equal proportions. If the amount of one of the components is greater, this will negatively affect the characteristics of the material. An excess of diisocyanate leads to the fact that the foam quickly "sits down" and collapses, not performing its main function - thermal insulation.

Polyurethane foam, in which there is more polyol, is characterized by high fragility, although it is capable of fully performing its functions. As you can see, the quality of insulation with this material directly depends on how well the initial components are prepared, as well as on the quality of the equipment used for this purpose.

The mixing of the components can be carried out qualitatively only if special high-pressure installations are available. Therefore, it is imperative to pay attention to what equipment the company of your choice uses. The production of polyurethane foam under conditions of insufficiently high pressure leads to a significant decrease in the thermal insulation properties of the material.

Varieties of polyurethane foam used for insulation

Despite the fact that there is one PU foam manufacturing technology, the final product has several varieties, differing from each other in properties and characteristics. Let's consider each of the options in more detail.

Lightweight open cell polyurethane foam... The thermal conductivity of this material is often compared with the characteristics inherent in mineral wool, while it has the same disadvantage - hygroscopicity. The cost of lightweight polyurethane foam is much higher, which makes its use not very justified.

If you want to use light open-cell polyurethane foam for insulation, you need to take care of the presence of layers of waterproofing and vapor barrier materials, as well as think over the facade ventilation system to remove excess moisture. But if we compare this option with the same mineral wool, then it is worth noting that the sound insulation performance in this case will be higher.

This material is rarely used as insulation for a roof or facade, since it does not do its job well, being susceptible to external factors. But if we are talking about the need to insulate internal ceilings or partitions, then its use is fully justified.

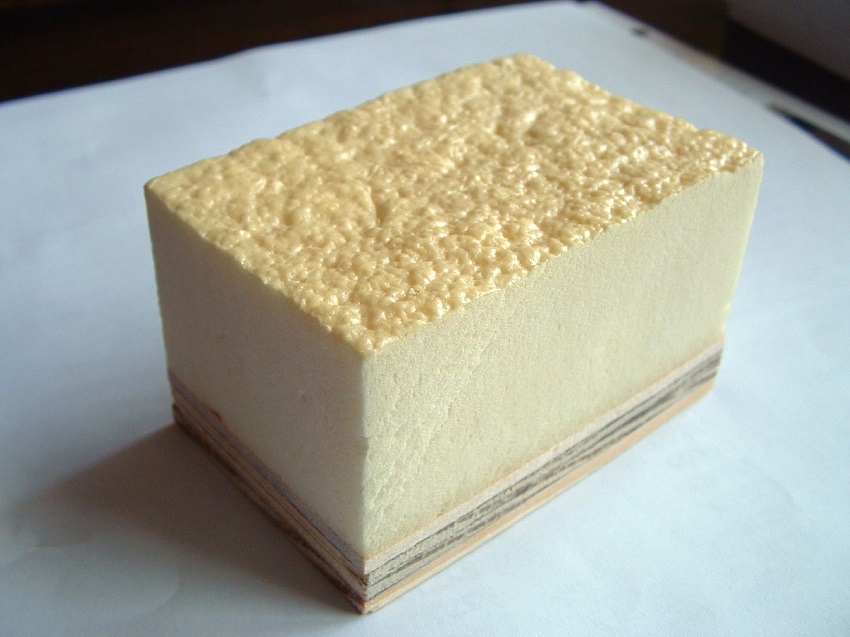

Closed cell polyurethane foam has much more acceptable characteristics: it adheres well to any surface (the only exception can be polyethylene) and is absolutely not hygroscopic. Depending on the density indicator, it is divided into three categories:

- low density (28-32 kg / m³). More often than other options, it is used for spraying on walls and ceilings in order to create an insulating layer. The thermal conductivity coefficient of this material is 0.02-0.028, which practically corresponds to that of air (0.022). As for vapor permeability, the indicator is as close as possible to wood - 0.05;

- medium density material for filling cavities. Its only difference from the previous material is a lower expansion rate, which makes it comfortable to use to fill the space of laminated walls, etc.;

- Polyurethane foam of increased density (40-80 kg / m³). Designed for thermal insulation of surfaces that are to be subjected to serious mechanical stress. At the same time, a higher density also provides a higher thermal conductivity.

How much does polyurethane foam insulation cost, price per sq. m.

Considering the issue of prices for PPU insulation of 1 sq. m., it is worth noting that the cost directly depends on what type of material was used. The cheapest is lightweight open-cell polyurethane foam. However, in order for the work to be carried out not in vain, you will also have to spend money on waterproofing and vapor barrier materials, which in total will lead to the same expenses as thermal insulation with medium density material.

The cost of work, provided that high-quality materials from popular manufacturers are used, starts from 400 rubles. for 1 sq.m. Of course, a lot depends on the thickness of the applied layer, because this is due to the consumption, but such subtleties are discussed individually immediately before starting work.

Useful advice! If you want to choose the most profitable material, you can simultaneously request from several companies a calculation of the cost of work, taking into account the required coverage area. This way you will receive information about all the current offers and will be able to give preference to the option that suits you more than others.

PU foam insulation: the pros and cons of using technology

PPU house insulation technology has a lot of various reviews, both positive and negative. Consider what is more, advantages or disadvantages, and whether it is worth giving preference to this type of insulation.

Positive characteristics of PU foam insulation: user reviews

The main advantage of this method to provide the building with high-quality thermal insulation is high efficiency. Due to its cellular structure, this material retains heat well. But there are other advantages that should not be overlooked:

- the absence of seams and joints eliminates the occurrence of such a phenomenon as "cold bridges", which has a positive effect on heat preservation;

- PPU can be sprayed on any surface, even a surface that is complex in design or texture;

- the low level of hygroscopicity of the material has a positive effect on the waterproofing qualities of the surface;

- PUF adheres to any surface except polyethylene. It is interesting that this is at first glance positive, the quality can also be attributed to disadvantages, since it is almost impossible to wash polyurethane foam, and there is no solvent for it. The only way to get rid of it is to peel it off by hand, and this almost always leads to significant damage to the surface on which it was applied;

- operating life of PPU with full preservation of all technical characteristics of the material - 25 years. After that, the thermal insulation continues to operate, although the thermal conductivity of the spraying increases;

- spraying is done quite quickly, so that all the necessary work will not take much time;

- the material self-extinguishes and does not support combustion even in the event of a fire;

- the vapor permeability coefficient is 0.05-0.06, which makes it possible to effectively remove excess moisture after the walls are insulated with polyurethane foam.

Useful advice! All flaws and shortcomings are identified during the first year of operation. If no shortcomings have been identified during this period, the next 25 years do not have to worry about it.

Disadvantages of polyurethane foam insulation: pluses and minuses

As you can see, the number of positive characteristics of this material is large, and we can say that all these positive aspects fully justify its use as a heater. However, PPU also has disadvantages, and it is better to know about them in advance:

- the cost of spraying polyurethane foam is about 1.5-2 times higher than if you use mineral wool as a heater;

- adherence to the spraying technology directly determines the period and quality of its service. Only with the availability of high-quality equipment and the appropriate experience of the pollen, it is possible to obtain the desired result;

- Do-it-yourself PU foam insulation is a very complex and often unjustified process. This is largely due to the high cost of the required equipment, as well as the lack of proper experience in this area;

- polyurethane foam does not burn, however, in the event of a fire, it emits a lot of dangerous corrosive smoke;

- as a result of exposure to ultraviolet rays, the foam deteriorates, losing its original appearance, changing color from white to dark brown.

Related article:

Wall insulation with foam: the technology of external and internal cladding

Wall cladding technology. Preparatory stage of work, adhesives, installation of plates on glue and nails, reinforcement of insulation.

Fortunately, most of the proposed drawbacks can be neutralized, for example, by inviting an experienced specialist to work with his equipment and providing the surface with a finish that will further protect the PU foam layer. But the main limiting factor for thermal insulation by spraying polyurethane foam is the price, which, nevertheless, is fully justified by the long service life of the coating.

What conditions are necessary for insulation with polyurethane foam: reviews and advice

In order for the costly PPU spraying procedure not to be in vain, it is necessary to carry out all the preparatory work with high quality and create the necessary conditions. This applies to both the insulation of walls in the apartment from the inside, and other works: insulation of the roof, facade, etc. with polyurethane foam.

This primarily concerns surface preparation. Even with good adhesion, it is imperative to remove anything that can peel off, such as old paint.

Useful advice! One of the worst enemies of PPU spraying is greasy stains. They must necessarily be neutralized and removed before starting work.

After that, you need to secure all surfaces that cannot be insulated. As already mentioned, the foam is almost impossible to wash off, so it is necessary to cover everything with plastic wrap, properly securing it with tape, leaving no gaps.

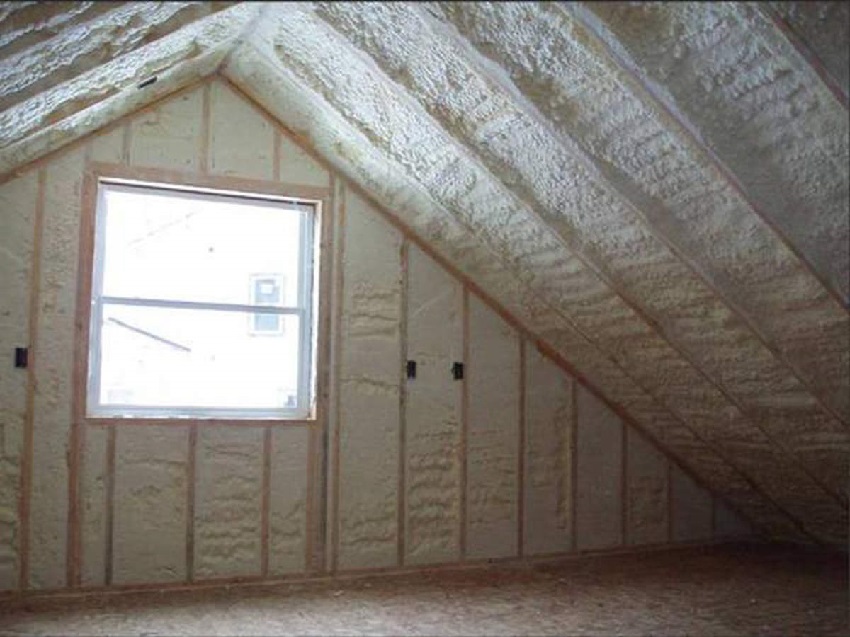

If we are talking about the insulation of polyurethane foam attic or roof, then there are two ways for this. In the first case, a permanent crate is prepared, on which foam is sprayed. Another option for insulating the roof with polyurethane foam is a temporary frame, which consists of two planes located in parallel.

If spraying is carried out on the outer walls of a building, whether it is insulation of PPU hangar or a house, the presence of finishing is considered mandatory. By the way, warming a hangar or warehouse with polyurethane foam is a very common phenomenon. It is only important to make sure that the covering can be fixed on the wall, since the foam will not allow this. For this, wooden or metal strips are pre-filled, which later serve as fasteners.

For example, if you decide to insulate your house with polyurethane foam for siding, the price of the work will be slightly higher, since it will include the installation of fasteners and all the necessary fasteners for further fixing the panels. Although we must admit that this is an aesthetic, and most importantly, an effective way.

How is the process of spraying polyurethane foam carried out

Having ordered in a company of the appropriate profile to carry out work on the insulation of the building with polyurethane foam, you negotiate a convenient time at which the minibus arrives with all the necessary equipment. In order to ensure the operation of the high-pressure apparatus, the voltage in the network must be 380 V, therefore, for its operation, the generator is usually started.

Useful advice! Please note that only low pressure devices, which provide a much lower quality of spraying, can operate from a 220 V network.

A hose is drawn to the surface on which the PPU will be sprayed through which the necessary components will be supplied to the gun. At the same time, all people who take part in work or are simply nearby must wear special protective suits and respirators.This is necessary to protect the respiratory tract from toxic fumes, as well as to avoid getting the PU foam on the skin.

Apply the foam little by little, moving from bottom to top in such a way as to avoid omissions. As the foam expands, it is necessary to monitor the thickness of the resulting layer as it is applied. Although it is worth noting that the excess can be removed by cutting off, while it will be impossible to eliminate the deficiency in the future. Based on technological data, the layer thickness should be 2-3 cm, however, they almost always do more - about 5 cm.

Having made a decision to insulate a warehouse, a house or any building with polyurethane foam, the most important thing is to find professional specialists who can provide you with really high-quality services. Only in this case your investments will not be in vain and will be able to justify themselves. Indeed, if all the technologies and recommendations for warming a house with polyurethane foam are observed, the price of the work will not be low, but it will last at least 25 years, and this is a considerable period during which you can live comfortably without worrying about anything.