An effective way to insulate a house is to lay the foam under the floor screed. This material is ideal for such work, as it is strong and dense enough. Since the slabs of this modern insulation are perfectly flat, they can be used to produce screed, both in the classical way with the use of cement-sand mortar, and with the help of self-leveling self-leveling floors.

Content [Hide]

Laying foam under the floor screed in the classical way

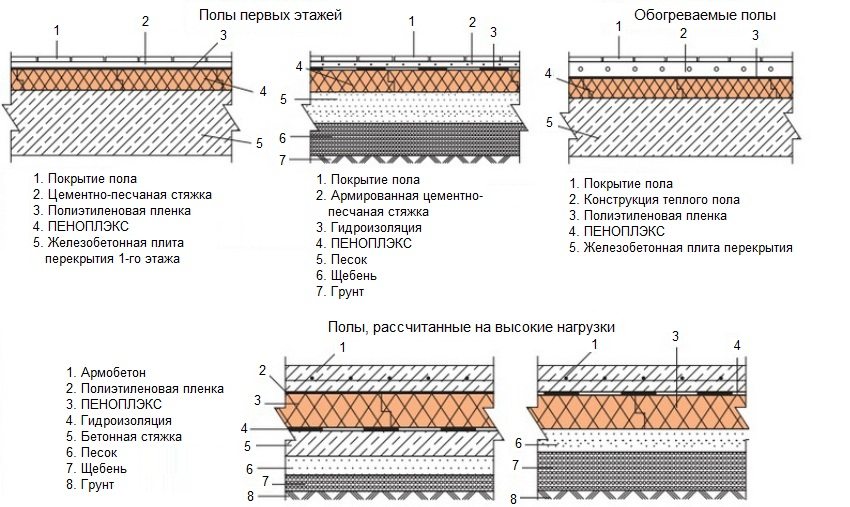

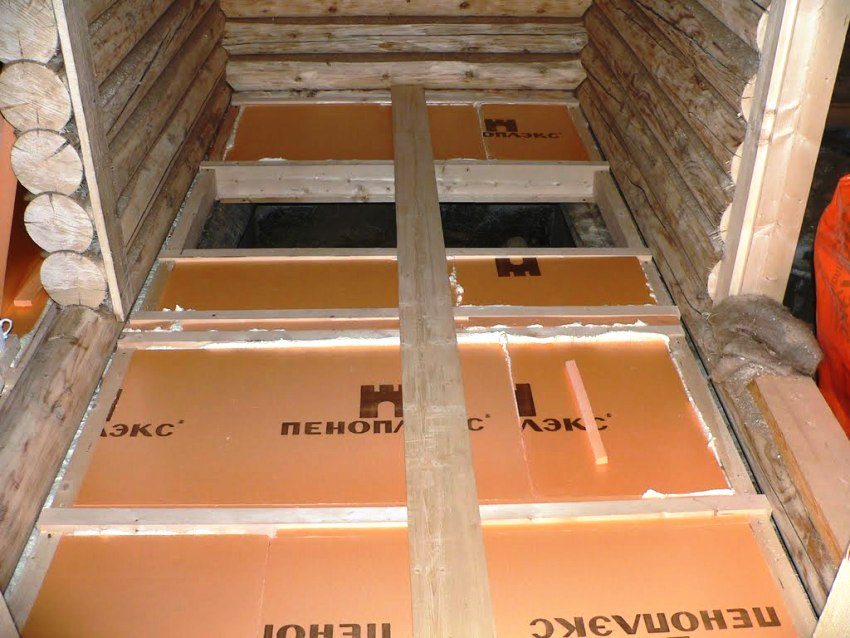

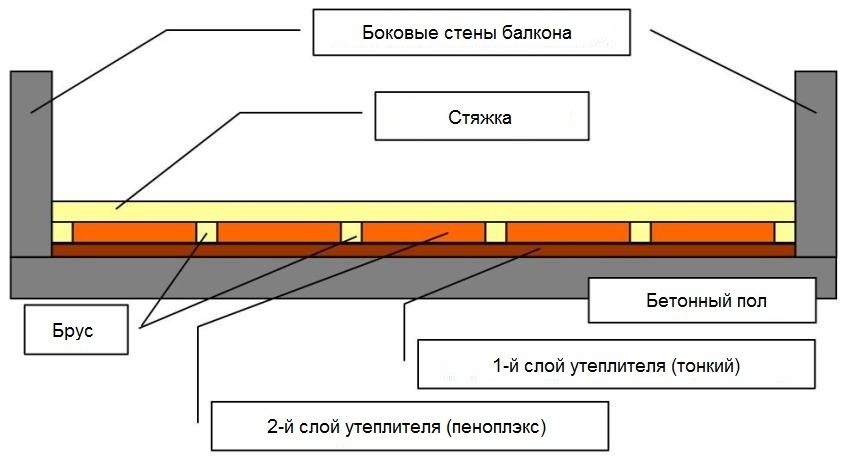

There are several floor bases that can be insulated with foam. There is no significant difference on what the slabs are laid on insulation... The main point here is the need for a waterproofing device for penoplex. This applies to any type of base. The slabs themselves can be laid without fixing or attached with glue or special self-tapping screws with plastic washers. The joints between the plates are glued, foamed polyurethane foam or insulate with tape.

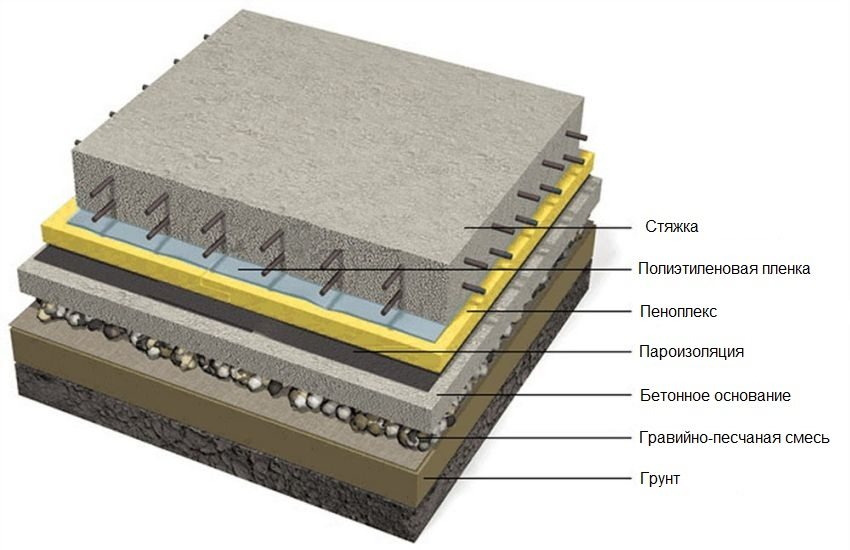

In any case, under the floor screed, the penoplex should be flat, dense and covered with a film vapor barrier... This rule applies to any method of creating an insulated floor. Classic concrete screed is a leveled and hardened mixture of cement, sand and plasticizers. The larger the cement grade, the stronger the screed will be. Most often, for these purposes, Portland cement of the M400 brand is used. In order to screed turned out smooth, you need to follow certain rules. It is best to do the work together. One person mixes the solution, and the second does the basic steps.

Then, when a vapor barrier membrane is laid on the foam plates, it is necessary to worry about the contact points between the concrete and the lower part of the walls along the entire perimeter of the room. They must be isolated. To do this, take a strip of foamed polyethylene and lay it along the walls with an overlap on them in the form of an angle. The polyethylene must be higher than the planned screed thickness. As a rule, they take 12 - 15 cm.

Helpful advice! To make the film better adhere to the walls, you can apply a primer to them. This will improve the adhesion between materials.

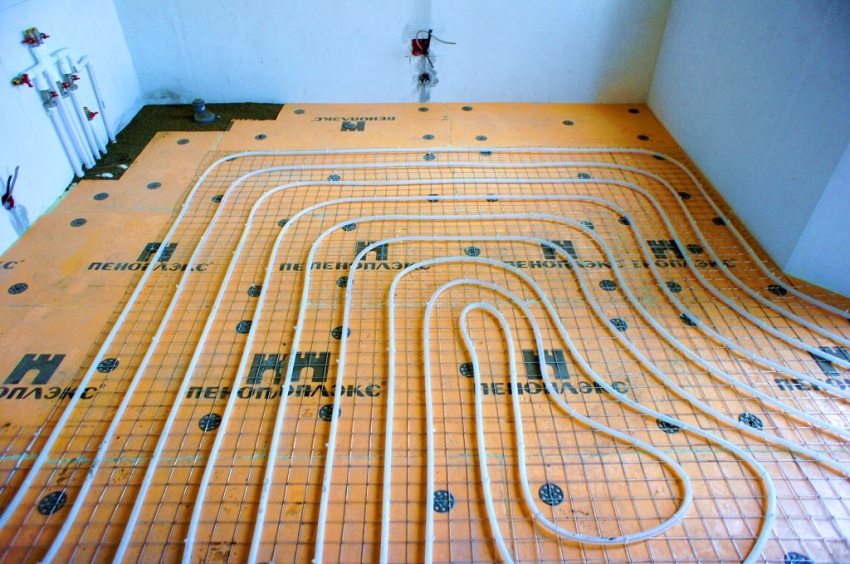

When the insulation vapor barrier and waterproofing of the bottom of the walls are completely ready, you can start the main work. The solution is kneaded in a bucket or other convenient container. It is convenient to do this with a drill with an attachment. If it is possible to install a small concrete mixer in the house, it will be even better. Pouring work begins after leveling beacons are installed on the floor. This is done using a simple or hydraulic level.Pour the solution from the farthest corner. When the first batch of mortar is poured onto the floor and leveled with a shovel, then a reinforcing mesh is placed on it. This will prevent the screed from cracking. Only then is the next layer poured.

Pouring is carried out between the guide beacons through one, so that using the rule it is convenient to level the solution along them. All operations are repeated until the entire room is completely covered with a solution. The thickness of the screed should be from 5 to 10 cm. It depends on what kind of load is supposed to be applied to the floor of this room in the future. Inside the screed, you can place structural elements of the "warm floor" system.

Helpful advice! When performing work on laying the foam under the floor screed and pouring the solution, you should wear soft shoes. This will prevent accidental damage to the material.

When all work is completed, it is necessary to periodically water the screed with water for 3 days. This will allow the cement to bond more strongly and achieve the best hardness without cracking. After that, it is recommended to wait a few more days for the cement to finally turn into solid concrete, which can only be broken with a perforator.

After the concrete has completely hardened, you can proceed with the installation of the final floor covering. It can be absolutely anything: parquet, laminate, linoleum or even an ultra-modern bulk 3D floor.

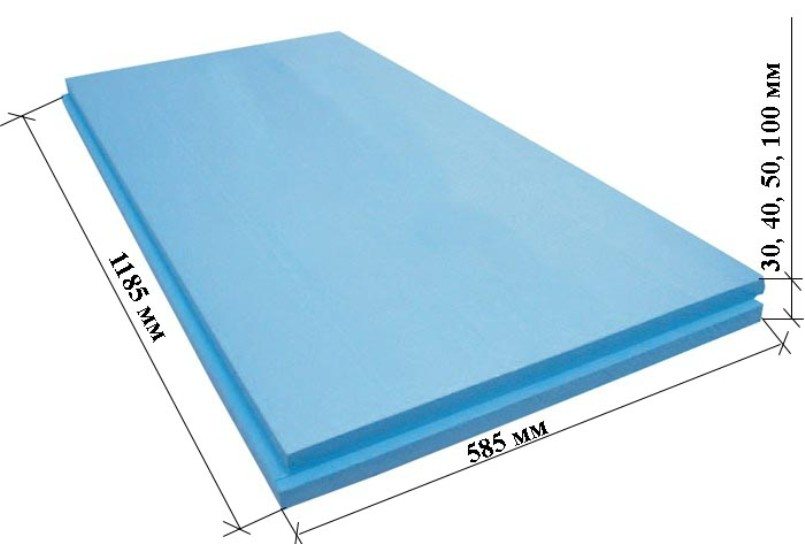

Thermal insulation of the floor with penoplex using self-leveling mixtures

To take a closer look at this case, let's take an example with a concrete base. If the apartment is not located on the first floor of the building, then the thickness of the insulation may be less than 5 cm. This is quite enough. Before starting the main work on laying the foam under the floor screed, a complete dismantling of the old coating... If there was a cement screed, then remove it with a perforator. Then floor slabs free from dirt and dust, close up all irregularities and foam holes from utilities.

When the base is prepared, then foam polyethylene plates are laid on it, which are best glued to the adhesive composition. The joints between the plates are also glued. Then put a vapor barrier film, along the perimeter at the abutments to the walls, lay a tape of foamed polyethylene and prepare a solution.

Self-leveling solutions do not require additional human actions to level them. You just need to gently distribute the mixture with a needle roller over the entire surface. It will spread itself under the action of gravity and fill the entire surface of the foam boards with a thin layer. Prepare the mixture according to the instructions. After pouring, you only need to wait a few hours for the solution to polymerize and harden to such an extent that you can lay the topcoat.

Helpful advice!If you plan to arrange a floor screed using self-leveling mixtures, then you need to know that the thickness of such a coating can be only 1 - 2 cm. Therefore, when creating the entire "pie" of the floor, you need to correctly calculate at what level the finish coating will be.

The use of foam under the floor screed solves two important tasks at once: leveling the surface and floor insulation... Both of them are being solved successfully. Particularly even coating is obtained using self-leveling floor... In addition, due to its small thickness, it also turns out to be light.