Steel corners are the most demanded rolled metal product. These products are regulated by state standards - GOST 8509-93 and 8510-86. The assortment of corners includes several varieties, each of which has its own characteristics and purpose. All the necessary geometric and physical parameters of the products are indicated in the regulatory documentation. This allows appropriate calculations during construction work.

In the regulatory documentation that regulates steel corners, you can find all the useful information about them.

Content [Hide]

- 1 Why do we need GOSTs of equal angles and other types of products

- 2 The main characteristics of the corners: GOSTs and the parameters specified in them

- 3 Varieties of steel corners: GOST 8509-93, 8510-93, 19771-93 and 19772-93

- 4 Corner accuracy index: GOST 8509-93, 8510-93 and others

- 5 Range of equal corners: types and characteristics

- 6 Sizes of metal corners: the most popular products

- 7 Metal corner 50x50: characteristics and operational scope

- 8 How to determine the weight of an equal angle corner

Why do we need GOSTs of equal angles and other types of products

Standardization rolled metal products allows you to control its quality and dimensional characteristics. GOST contributes to the determination of the required geometric indicators, which are a very important component of construction calculations. For example, the assortment of equal angles (GOST 8509-93) includes a complete list of dimensions and technical characteristics of these products. Let us dwell in more detail on the functions that GOSTs perform.

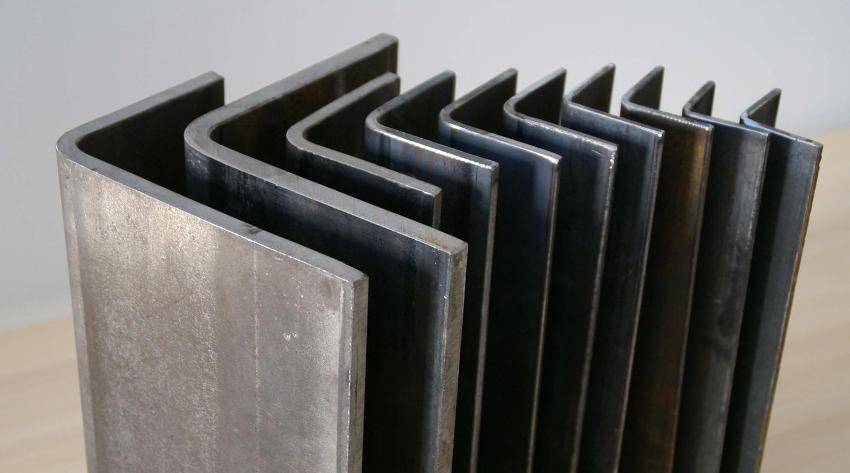

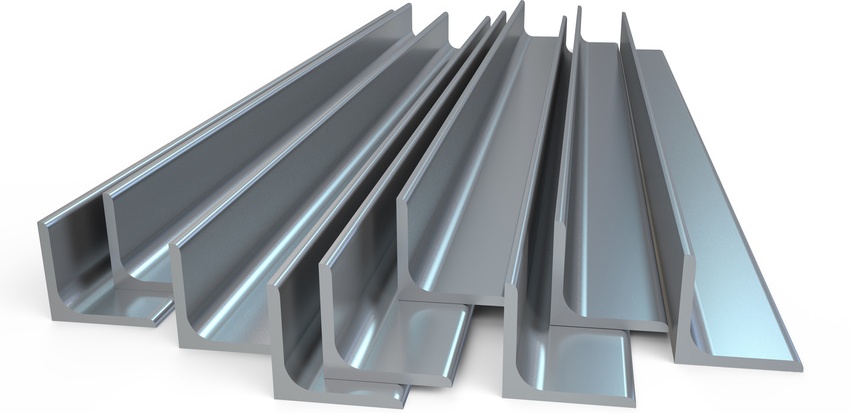

Metal corners available in a wide range of sizes

Quality control. Deviating from certain standards may result in performance issues. Therefore, the first and most important task of state standardization is quality control, which involves fixing the parameters of these parts.

Note! The entire range of metal corners is carried out taking into account GOSTs and the maximum permissible deviations prescribed in them.

Simplification of notation. Metal parts of this type are available in a wide range of sizes. Without regulatory documentation, all information on quality characteristics would have to be indicated in the product labeling.

Quick search for the desired part.Assortment tables for equal angles and other varieties of these products are indicated in GOSTs and allow you to quickly find the desired element. Classification according to the main parameters greatly simplifies the finding of corners, introduces them to their properties.

It should be noted that this documentation contains more than 10 different characteristics, organized in tables with corresponding designations. In turn, in order to find the applied marking, a special drawing is used. The cross-sectional diagram also makes it easy to find the properties you want.

The main characteristics of the corners: GOSTs and the parameters specified in them

In the normative documentation that regulates steel corners, you can find all the useful information about them. Using the appropriate GOST, it will not be difficult to calculate the material required for the construction of frame structures of varying degrees of complexity. Consider the main characteristics that can be found in regulatory documents or calculated using them.

To carry out construction calculations, you will need to calculate the mass of the corners. Calculation of the weight of one running meter allows you to determine the load factor acting on the structure. This indicator depends on the type of product and its dimensions. The size of the corners is an important parameter, since it determines the serviceability of these products. Length, width, as well as wall thickness - all these data are taken into account during construction. It is also necessary to take into account the shape of the products.

Another parameter worth paying attention to is the cross-sectional area. This indicator helps to determine the load factor. GOST for corners contains special tables that simplify the search for the necessary information.

Experts recommend paying attention to the radius of curvature of a metal product. Typically, this information is contained in the drawings. This value is not controlled, but it is necessary to calibrate parts.

All steel corners are divided according to the shape of the shelves into two types: equal and unequal. The tables that correspond to the standards contain information about the thickness of the corners. GOST 8509-93, the range of which regulates equal-shelf products, as well as document 8510-93 (contains information on unequal corners) can be easily found on the Internet.

It should be noted that a change in the thickness index affects the performance of parts. In this case, a certain pattern can be traced. The higher the thickness of the shelves, the stronger the corners themselves, and therefore the higher their resistance to stress.

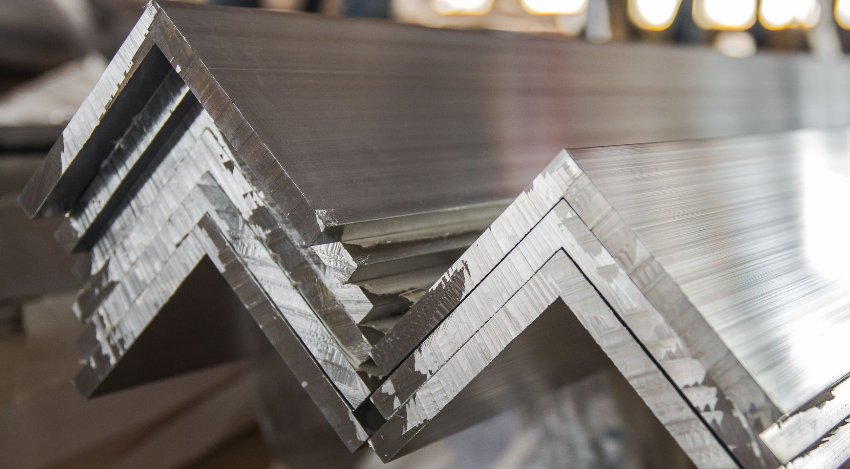

Using the appropriate GOST, it will not be difficult to calculate the material required for the construction of frame structures

Varieties of steel corners: GOST 8509-93, 8510-93, 19771-93 and 19772-93

The cross-sectional shape determines the type of steel rolled metal of this type. The corners can be hot rolled or bent (depending on the manufacturing method). According to the shape of the shelves, two types of products are distinguished: equal and unequal. The shelf is one side of the steel part. It can have different widths, which affects the strength and endurance of the part.

Helpful information! Equal-shelf products have two sides of the same length. Accordingly, the sides of unequal parts are characterized by different sizes. Such products have a limited assortment and are quite often made to order.

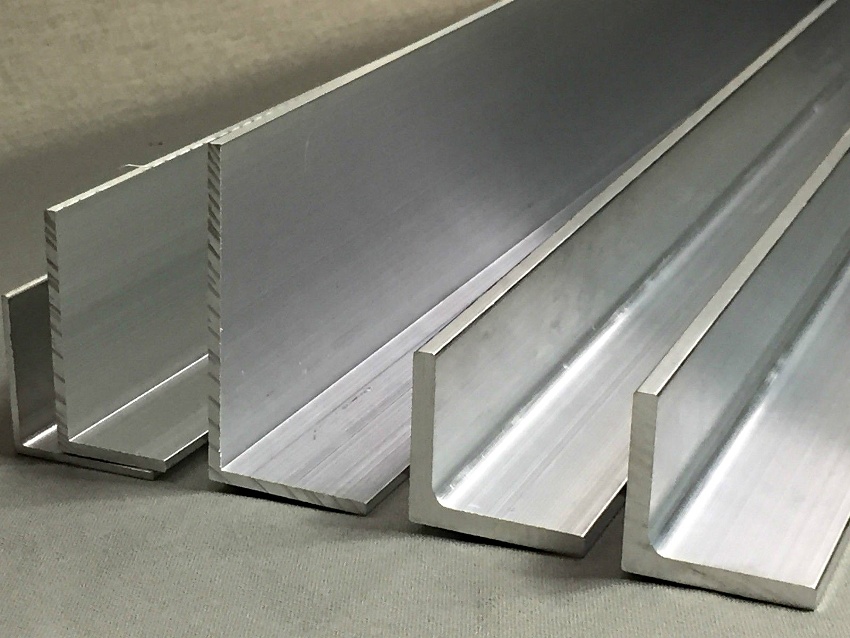

The width of the side of the steel angle can be different. This indicator ranges from 20 to 200 mm. In turn, the thickness does not exceed 16 mm.The mass of the product is calculated in kilograms per meter (kg / m). The length of such parts varies from 6 to 12 m (standard). The dimensions of the corners are needed to calculate the number of parts.

Another parameter by which these products are differentiated is the accuracy class. Depending on this criterion, two types of steel corners can be distinguished. Group A includes the parts that have the highest accuracy. Less accurate corners are classified as class B.

Regulatory documentation that regulates all types of steel corners can be easily found on the Internet. Various types of these products are regulated by GOSTs:

- 8509-93 - hot-rolled equal flange;

- 8510-93 - hot-rolled unequal;

- 19771-93 - bent equal legs;

- 19772-93 - bent unequal.

The above standards allow you to control all types of domestic steel profile corners. Using such documentation, you can easily determine the geometric and physical characteristics of standard metal products. The GOST also indicates permissible deviations from traditional figures.

In addition to differentiation by size, all steel corners are classified by purpose. The serviceability of these products may vary. Frame structures are formed from them, and they are also used in the automotive industry, furniture industry, etc. The composition of the steel angle differs depending on which alloy was used for its manufacture, which also determines the type of product.

Unequal corners are used for the manufacture and installation of building frames, strengthening of load-bearing structures, production of supports

Full range of corners: types by purpose and steel grade

Each type of corner has its own operational purpose. For any type of product, there is a separate GOST, which contains information about the production process, as well as the technical and physical characteristics of the product. The following information can also be found in regulatory documents:

- about steel grade;

- about the requirements for the product;

- about the scope.

Hot-rolled and bent steel corners, as mentioned above, can be equal-flange (GOST corner - 8509-93) and unequal (8510-93). Absolutely all products of this type, regulated by various GOSTs, are manufactured according to current standards and are subdivided into types according to their intended purpose. Consider what types of corners exist depending on the operational accessory.

Building corners. Products of this type are used in construction for the construction of various steel structures. They correspond to the peculiarities of installation, which is most often carried out using welding equipment. GOST steel construction angle - 27772-2015.

High strength corners. These products are manufactured using special technologies. In this case, low-alloy steel (or high-quality unalloyed steel) acts as a production material. The connection of individual parts is carried out using welding, rivets, and bolts. The regulatory document regulating these products has the following number –19281-2014.

Note! The corners, which have increased strength, are used for the installation of steel structures (most often load-bearing).

Standard (hot-rolled group) products. Carbon steel is used for their production. This material has standard specifications. GOST of metal corners for special purposes - 535-2005.

Shipbuilding products. Used in the construction of ship structures.The corners are made of steel alloys, which most often have excellent technical characteristics and, accordingly, higher quality. These products are regulated by the normative document GOST 5521-93.

Corners for bridges. They are used in the construction of transitional structures. For their production, it is customary to use low-alloy steel alloys. It should be noted that products of this type are highly resistant to adverse weather conditions. This allows them to be used in the construction of bridges in the northern regions. These elements are regulated by GOST 6713-91. They have special markings and designations. Bridge angles have a high strength factor.

Separately, it is worth mentioning products that are used in the most unfavorable weather conditions (for example, during the construction of structures in the Arctic). They are highly durable and can withstand high pressure. Another type of steel corners is alloyed. These details are used in the construction of pedestrian bridges. They stand up to extreme conditions well.

The list of steel grades used for the manufacture of angles does not end with alloys regulated by regulatory documents. Many manufacturers are engaged in the production of non-standard products, relying on individual orders from customers. Thus, the range of steel corners is incredibly wide.

Corner accuracy index: GOST 8509-93, 8510-93 and others

Another parameter by which steel corners are classified is accuracy. This is an indicator that determines the number of deviations from a fixed rate. Depending on this criterion, two main groups of steel products can be distinguished:

- normal precision (B);

Related article:

Channel: product dimensions or how to choose a suitable profile

The main characteristics and dimensions of the running grades - 10, 12, 14, 16 and 20. Formation of prices for products.

- high precision (A).

Note! When installing industrial-type structures, as a rule, corners are used, which belong to the first class. In turn, products ranked in group A are used in cases where it is necessary to ensure maximum reliability. This can be explained quite simply: they are distinguished by increased strength characteristics.

The dimensions of steel corners of class B may have deviations that are indicated in GOST. For this type of product, the following permissible differences exist:

- 1.5 mm with a side width of 90 mm;

- no more than 1 mm with a side width of 45 mm;

- no more than 3 mm for corners measuring 250 mm;

- 2 mm with a side width of 150 mm.

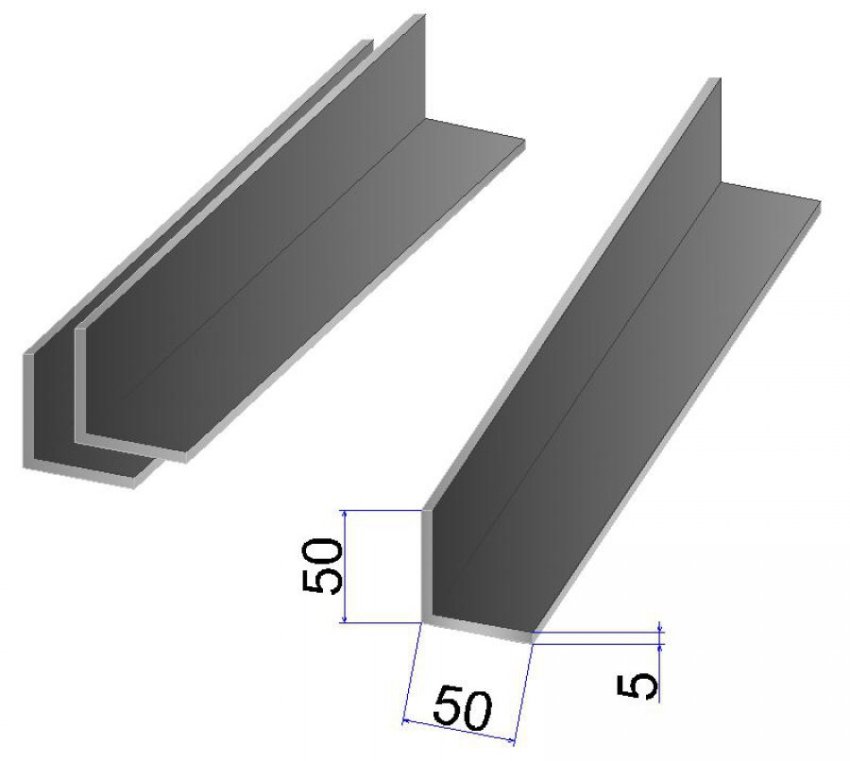

Separately, it must be said about the details, which have dimensions of 50x50x5. GOST of corners of this type takes into account their permissible errors in thickness in the range from 0.3 to 0.5 mm. Such products are popular and are used everywhere.

The curvature of the finished elements can also have an acceptable deviation, which is 0.45 mm (along the entire length). The discrepancies specified in the normative documentation must be unconditionally observed by the manufacturers of this type of rolled metal.

Range of equal angles: types and characteristics

Equal parts are subdivided into several types. This is due to the differences in the production process, and also takes into account what material was taken to make the corners. Equal shelf products are controlled by two main documents.The first of these is GOST 8509-93, which regulates parts made using hot rolling. The second document is GOST 19771-93, it contains all the necessary information about the corners obtained by the bending method.

As already mentioned above, equal-flange rolled metal products are called so because they have sides of equal size. Hot rolled products are very popular. The production process in this case is subdivided into several main stages. Before the advent of modern standardization, these products were regulated by GOST 8509-86.

First of all, the workpiece is heated. This is necessary in order to achieve the possibility of forming the product. Incandescent metal is more workable. At the next stage, the heated metal workpiece is passed through special shafts that exert the necessary pressure on it. The result is a corner with the required dimensions.

Thus, an equal angle part is formed. Steel for the production of such products can have a different composition. It depends on what characteristics the future product will have.

The production of bent angles from steel with equal sides has its own characteristics. To perform a similar type of rolled metal, you must first prepare a metal sheet of the appropriate thickness. Further, the sheets are processed on machines. Bending allows you to get fairly strong parts, however, in this indicator, they are still inferior to hot-rolled counterparts. Products obtained by bending have the following advantages:

- high accuracy;

- small mass;

- variety of sizes.

Helpful information! It is important to note that the range of these products includes parts made from heat-resistant, carbon, alloyed and high-alloy steel alloys. GOSTs of equal angular parts allow you to control their production and facilitate compliance with the necessary requirements, which are the key to safe construction.

Hot rolled steel equal angles: GOST 8509-93

These products are made by rolling. A distinctive feature of this process is that it runs continuously. This can significantly increase productivity. Rolling also has one significant drawback - the difficulty in reconfiguring equipment. Thus, in order to release a corner of a different type, it will take quite a long time. Such details are regulated by GOST 8509-93. In the USSR, they were controlled by another regulatory document - GOST 8509-72.

The features of the equipment used for hot rolling of steel make it possible to manufacture products that do not have length restrictions. In this case, the dimensions of the workshop in which the work is performed play an important role, since it depends on them how long the hot-rolled steel equal-flange corner can have. Certainly, certain standards are indicated in the regulatory documentation (from 6 to 12 m). However, upon receipt of an individual order, the manufacturer can make a product that will differ from traditional counterparts.

Before the start of forming, the rolled metal is heated to the required temperature. This makes it possible to manufacture products with thicker walls. Today you can find corners with a thickness exceeding 16 mm. They are highly durable and are used to assemble a wide variety of structures.

According to GOST, hot-rolled corners should not be crooked.The curvature index cannot exceed 0.4% of the entire length of an equilateral part. Otherwise, the product is considered a defect.

The peculiarity of the manufacture of steel products of this type is reflected in their appearance, which is not presentable. It is also worth noting that during hot rolling, changes occur in the steel structure itself, which makes it more durable, but at the same time it becomes prone to cracking. Based on the foregoing, these products are used in the construction of frame structures that serve as a support.

Bent equal angles: assortment, their characteristics

Regulatory documentation, which indicates the standards of this type of metal rolling, as well as the permissible deviations from them, can be easily found on the Internet. Equilateral products made by bending are regulated by GOST 19771-93.

Curved corners, due to their attractive appearance, are very popular when organizing cladding of load-bearing structures

Bending of steel blanks is carried out by applying high pressure, whereby forming on standard machines takes place. It is important to remember that this process takes place at normal temperature, that is, pre-heating of the part is excluded.

Regulatory documentation allows you to determine the standard dimensions of such products, as well as find out their physical characteristics, such as the weight of equal angles and the strength factor. As in the previous case, the type of production affects the technical and physical properties of products.

Note! The disadvantage of bending is its low productivity. In this case, the final length of rolled metal is lower (approximately 6 times).

In addition, bending makes it difficult to obtain metal corners with a large wall thickness. High pressure is applied to the steel during bending. As a result, steel stretching occurs at the bending point, which affects the strength characteristics of the product. The area corresponding to the bend is the weak point of the product.

The range of steel corners (GOST 8509-93) is more diverse, since these parts, unlike bent ones, do not have length restrictions. Despite all its shortcomings, these products are in demand. Bent equilateral parts are characterized by the following advantages:

- versatility;

- compactness of equipment for production;

- presentable appearance.

The operational scope of bent equilateral parts is quite extensive. Due to their attractive appearance, they are very popular when organizing the cladding of load-bearing structures. And they are also used in industrial enterprises that produce household appliances and lighting equipment. Such corners are indispensable when small lengths are needed.

Range of unequal corners (GOST 8510-93) hot rolled

The shape of these products resembles the letter "G". They represent a solid metal profile that is produced by rolling. For the manufacture of such products, two types of steel are used: low-alloy and carbon steel. In the first case, the products have increased strength, which is reflected in their operational purpose.

This type of rolled metal is used in the construction of frame structures that have a bend. An example is arched structures. The range of unequal angles manufactured by rolling has certain length restrictions. Standard lengths range from 4 to 12 m.

The deviation in length, according to GOST, should not be more than 30 mm if the length of the products is 4 m. With the length of the corners from 4 to 6 m - no more than 50 mm. If the length of the products exceeds 6 m, then the deviation is allowed no more than 60 mm.

These products differ from the angular equal-flange steel (GOST 8509-93) elements in their purpose. They are often used in the construction of arched structures and to strengthen walls.

Experts recommend taking into account the operating conditions when choosing these products. This is due to the fact that not all types of angled metal are suitable for use in harsh climates.

Helpful information! For the construction of frame structures in an aggressive environment, products equipped with a protective zinc layer (galvanized) are used. They are highly resistant to temperature fluctuations and are resistant to moisture.

Assortment of bent unequal angles (GOST 19772-93)

Curved unequal products also have their own characteristics, which are determined by the method of their production. For their manufacture, two types of steel are used. Both types of steel alloy are classified as carbonaceous (semi-calm and boiling). Another parameter by which these products are classified is profiling accuracy. In accordance with this indicator, products are:

- high-precision (A);

- increased accuracy (B);

- standard (B).

Before purchasing the required product, it is recommended to study the full range of unequal corners. GOST 8509-93, characterizing the hot-rolled equilateral variety of rolled metal products, emphasizes that the curvature of products should not exceed 0.4% of the entire length. In turn, parts made on bending equipment can have a deviation of up to 0.1%. This is very important as buyers often confuse the different types of steel corners.

Steel corners, for the production of which roll forming equipment is used, are used in the construction of various metal structures. Their advantages include versatility, light weight and a wide range of products.

Dimensions of metal corners: most popular products

These products can have different dimensions. Their operational belonging depends on this indicator. As mentioned above, a shorter type of rolled metal produced on bending equipment is used as frame elements for machine tools and furniture. The regulatory documentation contains tables that indicate all the necessary geometric characteristics of steel corners (including their length).

The assortment of equal and unequal steel corners includes many varieties. Some products are very popular with customers.

The most popular today are bent corners, which belong to class B. This is primarily due to their attractive cost, especially when compared with the price of parts included in group A. It should be noted that, despite their low cost, such the parts are quite durable. Therefore, they are often used when assembling various hull structures.

Among the many products of various sizes, the most used options can be distinguished. These include corners 30x30x3, 50x50x5 mm, as well as parts with dimensions 40x40, 70x70 and 100x100 mm. Metal products with a shelf width of 40 mm are popular, as they are used to install benches and outdoor tables.They can also be used in the construction of gazebos and canopies. Parts 50x50 mm are considered the most popular, since they are part of fences and other fences.

Corners 50x5 and 50x6 mm have sufficient strength, which allows them to be used when assembling frame structures. However, they are unable to withstand heavy loads and are therefore only recommended for lightweight structures.

Steel corners with a shelf width of 40 mm are the most popular, as they are used for the installation of benches and outdoor tables

Metal corner 50x50: characteristics and operational scope

Steel parts measuring 50x50 mm are the most popular type of corners. They belong to the group of equal products and are produced by rolling. The thickness of the shelves that are part of such rolled products can be different. It is this indicator that determines the serviceability of steel parts.

Note! The thicker the corner, the higher its cost. This is easy to explain, since this value determines the amount of raw materials used to manufacture a product.

Thickness also affects the mass of the part. For example, a product, this indicator of which is 4 mm, weighs 3.05 kg (1 running meter of a 50x50 part). The weight of 1 meter of a 5 mm wide corner will be 720 g more and is 3.77 kg. The length of the products belonging to the hot-rolled group reaches 12 m. If necessary, you can place an individual order by providing the executive organization with your own dimensions.

The maximum shelf thickness for these products is only 5 mm. Despite this fact, they have good density and high strength. The most common use of such corners is in the furniture industry. Due to the low weight of these products, you can design the frames of cabinets and other interior items. The use of corners is due to the fact that they contribute to obtaining the ideal corners, which are so necessary when assembling furniture.

Products with similar dimensions are regulated by the corresponding GOST. The assortment of equal angles allows you to select the necessary parts for different purposes. A corner with shelves of 50 mm is used in the construction of various fences in playgrounds.

How to determine the weight of an equal angle corner

Many people are interested in the question of how to determine the mass of equilateral and unequal corners. This parameter is necessary during the planning of the amount of material (before the start of construction), as well as other calculations are made using it. Knowing the weight of the rolled metal, it is possible to determine the load that will be exerted on the future structure. In any case, the weight of a running meter of a corner is a necessary characteristic.

Today there are several methods for calculating this parameter. The simplest of these is the tabular method. In the regulatory documentation that regulates equal and unequal products, you can easily find the desired table. It contains not only dimensional data, but also physical characteristics, which include the weight of 1 meter of the corner.

However, the tabular method has some disadvantages. It is not always possible to find the relevant documentation on the Internet. In addition, you need to be aware that some tables contain rounded values, the use of which will lead to an error.

Knowing the weight of the rolled metal, you can determine the load that will be exerted on the future structure

Note! Of course, when calculating the weight of one product or small batches of corners, such an error will not be fatal. If the number of products is large, then it is recommended to calculate their weight yourself.

To determine the weight of 1 meter of the corner, you can use the manual calculation method. This method involves finding the sectional area of the part. To determine this value, you need to measure the length of one side (shelf). After that, you need to multiply the length by the thickness of the shelf. Next, you need to measure the length of the second side and subtract the thickness from it. The resulting figure is multiplied by the thickness indicator. Both values (for 1 and 2 shelves) are added together to find the sectional area of the corner.

At the last stage, you will need to multiply the area indicator by the density and by 1 m. The density can be viewed in the table. Thus, as a result of a simple calculation, you can get the weight of 1 m of the part.

In addition, there are special online calculators that allow you to quickly and accurately calculate the weight of the product, as well as calculate other values. All that is needed for this is to enter the initial data in the corresponding columns. Such a program can be found on the Internet at specialized sites. After determining the weight of the corner meter, it becomes possible to carry out further calculations.

The range of steel corners is very wide. Today, there are several varieties of these products, each of which is actively used in construction and production. To determine the geometric and physical characteristics, there is a special regulatory documentation. GOSTs greatly simplify the selection and calculation of the number of steel corners.