Foam blocks are a relatively new material that, thanks to their properties and technical characteristics, has taken a strong place in modern construction. Blocks are produced from cement mortar, water, sand and a special foaming agent. The use of foam concrete blocks allows for high heat and sound insulation of the building, and the various sizes and prices of foam blocks make it one of the most convenient and affordable building materials.

Foam blocks have gained great popularity due to their unique technical characteristics, availability and high environmental friendliness

Content [Hide]

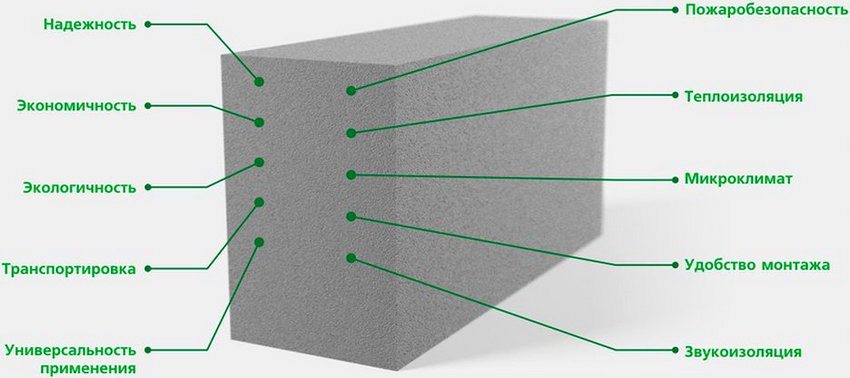

Advantages of foam concrete blocks

Despite the fact that there are also disadvantages, the advantages of foam concrete blocks have made this material very popular. Let's take a closer look at the positive characteristics of foam blocks:

- high strength of the material - foam blocks can be used without problems for the construction of buildings up to 9 m high. Their compressive strength can range from 3.5 MPa to 5 MPa, depending on the manufacturer's brand and technical purpose;

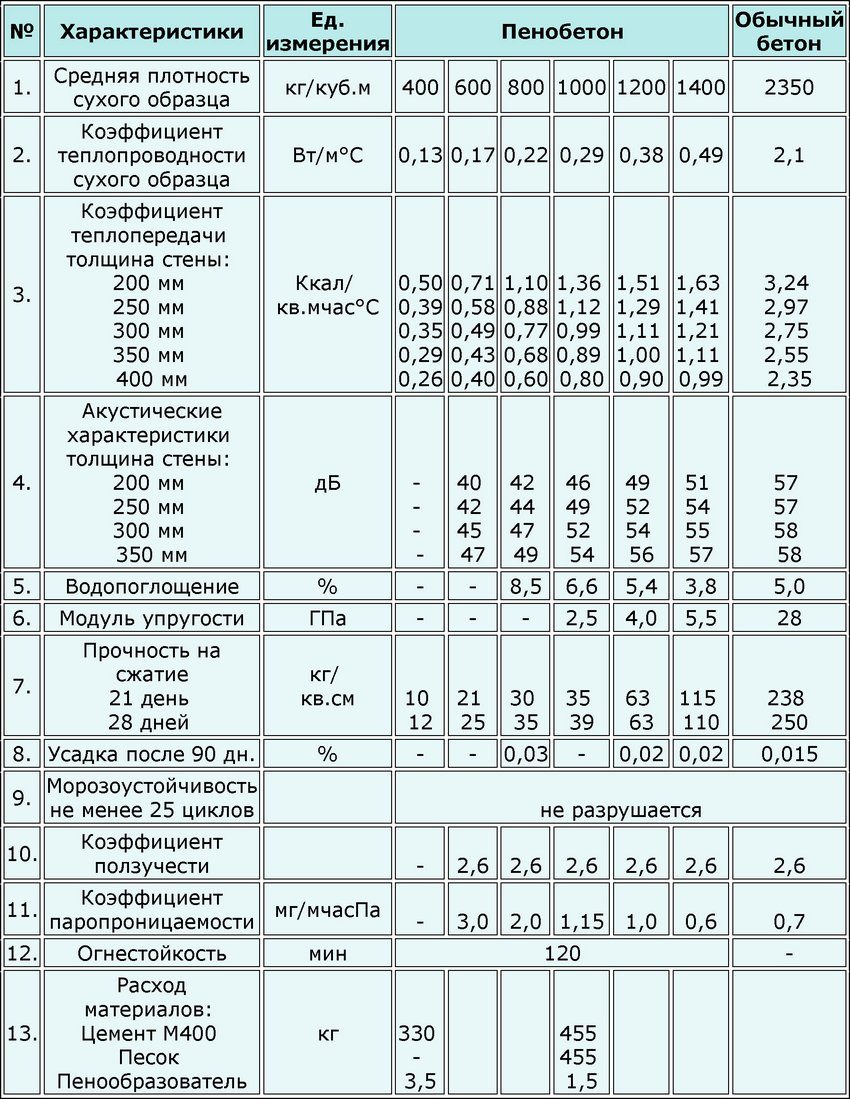

- low density - foam blocks are 2-4 times less dense than, for example, expanded clay concrete. This greatly facilitates their transportation, storage, and the process of working with them. Technical indicators for this material range from 400kg / m to 1600kg / m, which practically corresponds to the density of solid wood;

- low thermal conductivity is one of the main advantages of this building material. With their thermal insulation properties, foam blocks are several times superior to clay bricks. A standard wall, lined with one row of foam blocks, with a thickness of 60 cm to 80 cm, retains heat as well as a brick one;

- high sound insulation of the material - foam blocks have a porous structure, due to which they perfectly absorb sound. In big cities, where noise is a constant annoying factor, this is a big advantage over other building materials;

- high moisture resistance of the material - according to established standards, foam blocks are manufactured so that they do not have open pores. Thanks to this, they are able to stay in water for more than 7 days without damage;

- high frost resistance - the same porous structure ensures the material's resistance to very low temperatures. Inside micropores, water can freeze or migrate without damaging the foam block;

- high fire resistance of the material - foam blocks do not burn, do not support the combustion process. Moreover, blocks resist fire and are able to contain it for up to 8 hours. But even if such a block is heated to a very high temperature, the released substances will not be toxic and will not harm the environment;

- homogeneous structure of the material - due to their fine-pored structure throughout the entire thickness of the material, such blocks can be subjected to any mechanical treatment, for example, drilling, gouging and even sawing.

3D project houses made of foam concrete blocks

Currently, this building material is widely used for:

- Erection of structures of any complexity, as well as load-bearing walls. For this, materials with the highest density are used.

- Construction of structural and thermal insulation products and structures that do not bear the load. In this case, the required density ranges from 600-1100 kg / m³.

- Creation of heat-insulating products and floor insulation. For this, the density indicators of the material should be minimal, since it is in this case that the thermal insulation properties are highest.

Foam blocks or gas blocks. What's better?

How to understand which is better for construction: a foam block or a gas block? Both are made of aerated concrete - a porous material. But they have a number of distinctive characteristics. You can understand which option to give preference by considering and evaluating the differences between them.

Visually distinguish gas block from the foam block is very simple:

- The foam block has a smooth, even surface of light color.

- The gas block has a raised, rough white surface.

To begin with, let's figure out what components are included in the composition of gas blocks and foam blocks. And what determines the differences in their characteristics.

The composition of foam blocks includes: water, cement, lime, industrial waste, for example, blast furnace slag, and, of course, a component that forms foam. Most often it is sulphide lye.

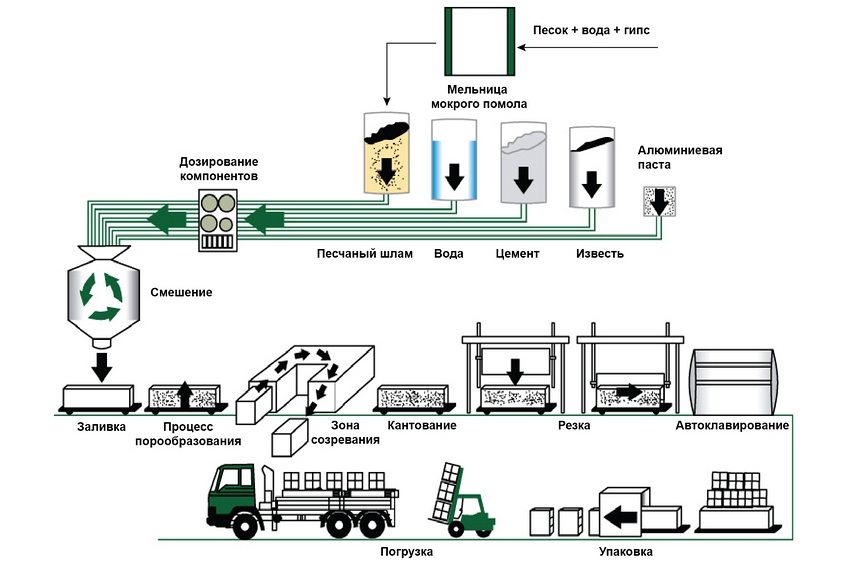

For the manufacture of gas blocks, you need: water, quartz sand, cement, lime, aluminum paste. Many are skeptical about the use of the latter component in the production process, as this element is hazardous to health. But it is important to know that in the process of processing its particles dissolve, so the finished blocks do not pose any threat.

The production of these materials also has a number of significant differences, which are responsible for the different technical characteristics.

Features of the production of foam blocks:

- All components are mixed with the addition of a special filler to form a foam.Mixing of concrete and foam is done mechanically.

- The hardening of the finished composition occurs in natural conditions.

The production of foam blocks is an inexpensive process. That is why it is often taken up by middle-level entrepreneurs who want to build their own business, but are not very well versed in the requirements for building materials. As a result, finished products often have significant dimensional deviations and an uneven surface. This negatively affects the quality of the masonry.

Features of the production of gas blocks:

- The porous structure is the result of a chemical reaction between the main components.

- Autoclaving gives the finished product extra strength.

The manufacture of aerated concrete is an expensive process that requires a large amount of equipment, therefore, such blocks are produced only at specialized plants. All products are almost perfect, which greatly facilitates and speeds up further construction.

Benefits of foam concrete:

- has closed pores and absorbs less moisture;

- lower material cost.

The advantages of aerated concrete:

- more durable;

- the best thermal insulation;

- higher quality of manufactured products.

So, if you are ready to spend considerable money in order to build a durable house, aerated concrete is what you need. Expensive? Yes. Qualitatively? Yes, too. But do not forget that, having paid due attention to the choice of blocks from foam concrete, as well as leveling out minor errors with the help of cement mortar, you can get almost the same quality material as aerated concrete, but you will save a lot.

It is very easy to make sure of this - it is enough to study the offered sizes and prices of foam blocks per piece in the global network. It is difficult to say unequivocally which is better - foam concrete or aerated concrete - but in any case, both materials are excellent options for construction.

The choice of material. Sizes and prices of foam blocks

When choosing foam concrete blocks, sizes and prices are the first things that are usually paid attention to. How to navigate them and choose quality material?

Depending on the area of application, the blocks can be divided into two broad groups - for the construction of walls and for the creation of internal partitions. In the first case, it is recommended to use 20x30x60 foam blocks. The unit price will depend on the strength and thermal insulation values indicated on the package. The cost of one cubic meter of such blocks is from 2650 rubles.

For the construction of internal partitions, blocks of 10x30x60 cm are traditionally used. Their price is slightly lower - from 1800 rubles / m³.

Having decided on the manufacturer, sizes and prices of foam blocks, you can make an order. But how do you know how much material you need? In this case, the quantity is measured in cubes.

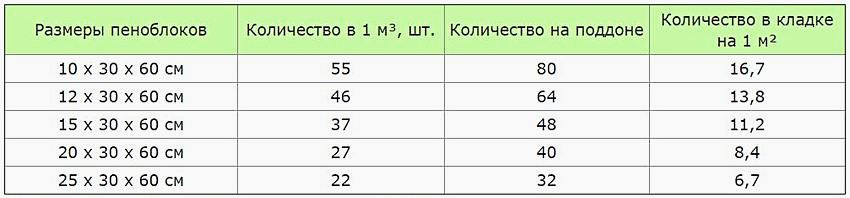

Table of sizes and consumption of foam blocks. The number of blocks in the masonry per 1 m2 provided that the horizontal support area of the blocks is 30 cm in width (wall thickness) and 60 cm in length

As an example, let's count how many pieces of foam blocks 200x300x600 in a cube. Obviously, the dimensions are indicated in millimeters, but since we are talking about cubic meters, then the measurements of the block must be converted into meters - 0.2 mx 0.3 mx 0.6 m. So, it turns out that one block contains 0.036 m³. Simple calculations show that in one cubic meter there are 27.78 pieces.

House of foam blocks: pros and cons

Having started building a house, the first question arises: what material to choose for this. Should you choose foam blocks if you want to build a full-fledged residential building? Having considered all the advantages and disadvantages of this building material, having studied the photos and projects of houses from foam blocks, widely presented on the Internet, you can make the right choice.

The advantages of using foam blocks in construction:

- foam concrete is an opportunity to save money on construction. In addition to the low price of the material itself, such a house does not require the construction of a powerful foundation: the blocks are very light, and the weight of the structure will be much less than, for example, a brick building;

- you can build a house from foam blocks very quickly and on your own. The speed of erection of walls from this material is much higher than from the same red brick, and does not require special skills;

- foam blocks are environmentally friendly material. The main components for its manufacture are water, sand and cement. Of course, special admixtures are also used, but their percentage is so small that it will not affect your health in any way;

- ease of handling. The use of foam blocks for building a house makes it easy to adjust the material to create complex structures. It will not be difficult to install electrical wiring and even water pipes into such a wall;

- excellent ventilation - due to the high environmental friendliness and the porous structure of the material, the walls of the foam block will breathe;

- resistance to temperature changes. Living in a strip with a changeable climate, in the process of choosing a building material, one has to take into account its ability to withstand the effects of external factors. Foam concrete equally well tolerates the effects of strong winds, frosts and high heat, while maintaining the optimum temperature inside the room;

- foam blocks provide excellent sound insulation, which is important if you are building a house in the city.

Helpful advice! After the construction is completed, for wall decoration you can use not only the usual plaster or decorative compositions for facade decoration. Special tiles, natural or artificial stone look great.

Disadvantages of using foam blocks in construction:

- fragility and fragility. Of course, you should not expect that a foam block house will last 200 years. Over time, after shrinkage, cracks may appear in the walls;

- fragility - this drawback is noticeable even before the start of construction. The blocks can be easily damaged during transportation;

- poorly made foam blocks can be saturated with water like a sponge;

- there is a possibility that the material will change its structure over time. Exposure to carbon dioxide on cement can lead to chalk formation. As a result, shrinkage occurs within the block itself, and the structure becomes more fragile.

How to avoid possible difficulties and unpleasant consequences of building a house from foam concrete?

In order for the built house to serve you as long as possible, it is important to know several rules for choosing and working with this material even before starting its construction. Given these tips, you can make the most of the positive qualities of the foam block and minimize the disadvantages of its use.

Related article:

Features of projects of baths from foam blocks, photo and technology. Project options. How to build a sauna from foam blocks. Advantages and disadvantages of foam block baths. Photo of foam block baths.

There are a lot of foam concrete manufacturers today, but, unfortunately, the goal of most of them is easy money. This inevitably leads to the production of huge amounts of substandard material. Therefore, before purchasing foam blocks for construction, read the available information about the manufacturer.

Helpful advice! When choosing a foam block, be sure to thoroughly inspect it for cracks or oily stains. These are signs of poor quality material. After breaking one block, make sure that its structure is uniform.

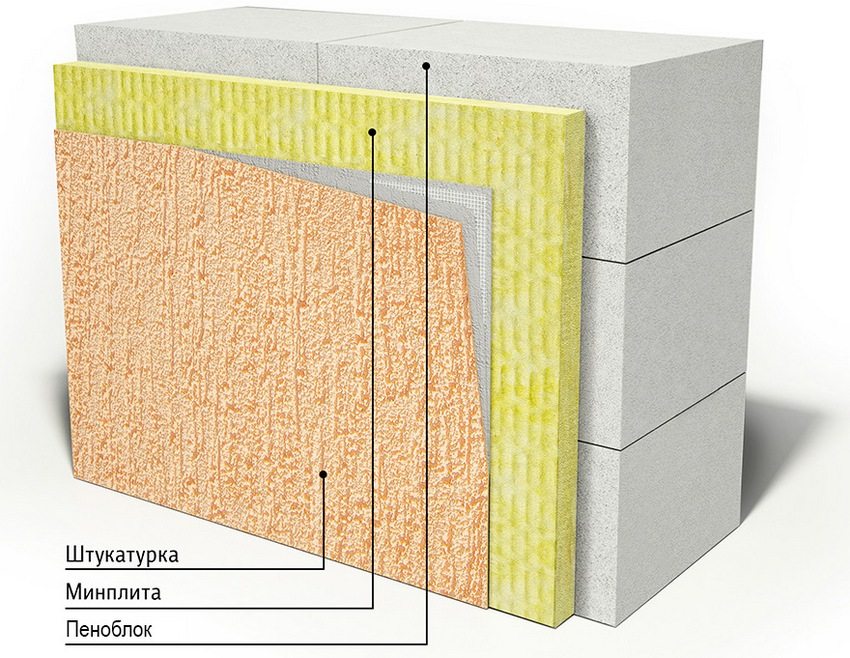

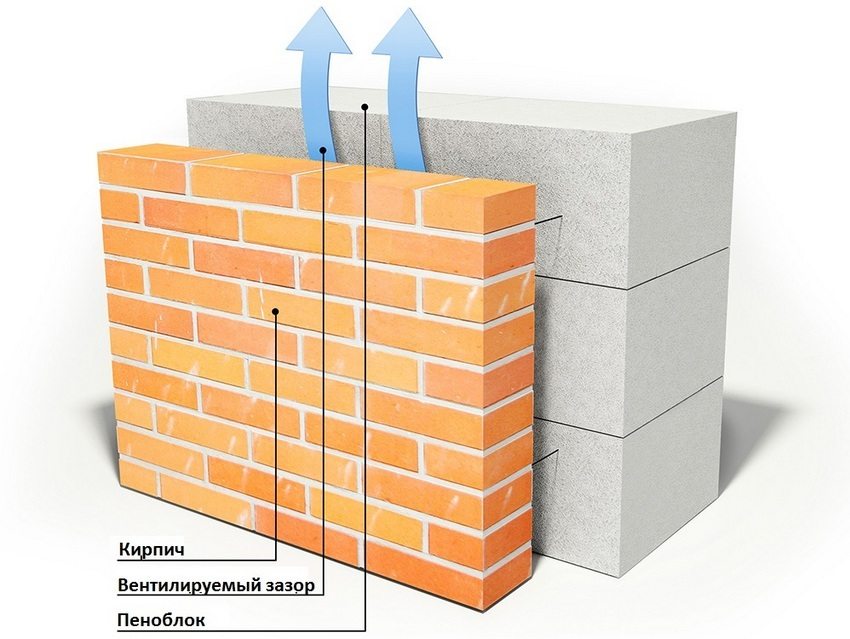

As for the construction process, here the existing disadvantages can be neutralized by combining materials. Brick is great for this. Load-bearing walls can be laid out of it, which will evenly distribute the load. In this case, you can use both ordinary and decorative bricks. So, the structure will turn out to be more durable, and at the same time retain all the advantages of foam concrete. Also, extensions from foam blocks to wooden houses are often made.

In order to further avoid the appearance of cracks in the walls, special attention should be paid to the foundation. It is better to lay it out of a monolithic slab using a special monolithic tape with a small depression. Additional reinforcement will also have a positive effect on the quality of the building.

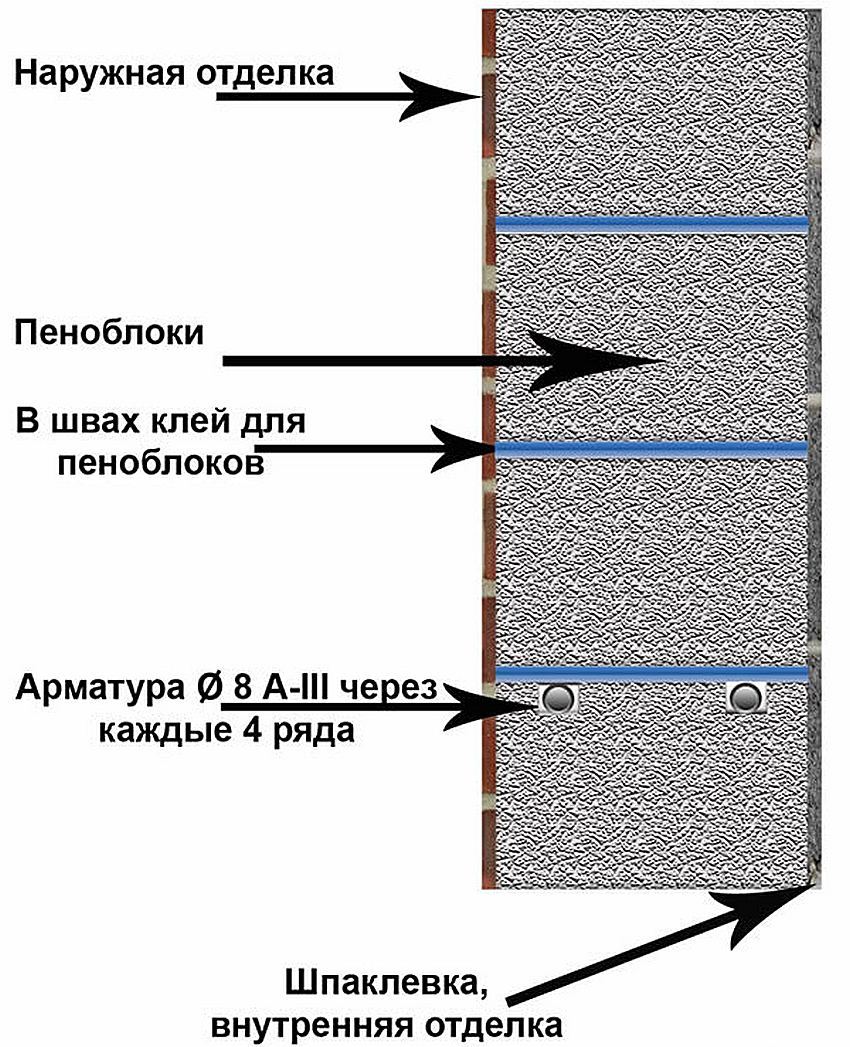

To increase the strength of the walls of the future home, use a special glue, a layer of which is applied between the blocks for better bonding.At the same time, it is not recommended to use a mixture of sand and cement instead of glue, since the thickness of the seam should not exceed 3 mm, otherwise the sound and heat insulation properties of the material will significantly decrease.

Helpful advice! During installation, make sure that no voids remain between the blocks. Fill all vertical and horizontal joints thoroughly with glue. This will help avoid additional heat loss.

Construction tips, as well as projects of one-story houses from foam blocks are presented on specialized sites. There you can also find recommendations for choosing building materials, sizes of foam blocks and creating a foundation.

It is important to understand that building a house begins at the stage of choosing and buying building materials, so it is better to approach this process with all responsibility. Then, taking into account all the pros and cons of foam blocks, strengthening the foundation, and also using additional materials in your work, you can not fear for the quality of the house built. Foam blocks will give your home warmth, provide you with comfort and coziness for many years to come.

Construction of baths from foam concrete blocks

Foam blocks are a versatile material suitable for the construction of not only residential buildings. The video of the step-by-step construction of a foam block bath with your own hands perfectly demonstrates this. But the use of this building material for the construction of highly specialized buildings has its own characteristics and is widely discussed on the forums.

According to reviews, a foam block bath requires additional hydro and thermal insulation. Otherwise, due to high humidity, there is a high risk of cracks in the walls. After reading the reviews of the owners of foam block baths, you can get a complete picture of the advantages and disadvantages of such a choice.