During the construction of a house, you should consider such a facade, thanks to which the microclimate in the house will be improved, and the supporting box will be well protected from external forces. If the building is built of materials that freeze through easily, then insulating the facade of the house from the outside is a mandatory task that reduces heating costs, especially in winter. In summer, a properly selected insulation will prevent strong heating of the air inside the house.

Insulation of the facade of the building from the outside contributes to the normalization of the microclimate inside the house

Content [Hide]

- 1 Why is it recommended to insulate the house outside

- 2 How to properly insulate the facade of a house

- 3 The better to insulate a house, how to choose the right material

- 4 Materials for insulating the facade of the house from the outside: penoplex, foam

- 5 Features of facade insulation with mineral wool

- 6 How are foam blocks and heat-insulating panels used for insulation

- 7 Basic technologies for insulating facades of private houses

Why is it recommended to insulate the house outside

According to the sanitary norms and rules of SP 23-101-2004, the walls should be insulated from the outer part of the building, although there is no specific prohibition on internal work. Moreover, in some cases it is impossible to carry out facade work. For example, if a building is on the list of architecture houses and the bureau responsible for it does not give permission to work, if the facade is a complex decorated structure.

Helpful information! If it was decided to insulate the facade of the building, a continuous vapor-permeable layer should be created in the room. Otherwise, when warm air gets on the insulation, and then on the cold wall, condensation will form, which causes mold and the rapid growth of fungus.

If possible, most owners prefer to insulate the walls from the outside. Firstly, useful living space is not taken away, and secondly, the building frame is reliably protected from negative atmospheric influences. Other functions that are performed by the insulation of facades from the outside include:

- Attractive appearance of the building, even if after the construction of the box it did not have a very aesthetic appearance.

- Creation of a special microclimate inside the house due to the fact that correctly performed insulation will play the role of a thermos, when the cold does not penetrate inside in winter, and heat in summer.

- Extending the service life of the carrier box.A frame that is not constantly wet / dry will last much longer.

- Elimination of the so-called cold bridges, which inevitably arise when the rules for the construction of walls are violated or when the building material is chosen incorrectly.

- Providing reliable sound insulation. An additional layer on the façade prevents excess noise from entering the premises.

- Prevention of condensation in the thermal insulation layer.

- A simple solution to the problem of sealing joints in a situation where the house is made of panels.

Before insulating the facade of a house, you need to know about the shortcomings of external insulation. The main disadvantage can be considered the cost not only for the purchase of material, but also for ordering high-rise works, if we are talking about a multi-storey building. In a private house, for proper installation, you will have to acquire a good "goat", a stepladder, or scaffolding if the building has more than one floor.

How to properly insulate the facade of a house

If the facade of the house is not insulated, the building will be constantly exposed to temperature changes, which will not have a positive effect on its frame. The presence of facade insulation also prevents other problems, such as:

- destruction of interpanel joints;

- cracks in the main building material caused by frost / heating, especially if the frame is made of foam blocks;

- changes in the bearing properties of walls due to wear.

In addition, by insulating the house from the outside, it will be possible to improve its thermal insulation properties, which will help reduce heating costs and increase the comfort of life for home owners. Before insulating the facade of the house, it is necessary to choose the right heat insulator, the use of which will be economically and practically justified.

Based on the normative documents, according to which the insulation of the facades of private houses is carried out, two- and three-layer thermal insulation structures are distinguished. At the same time, the top layer of plaster is often not considered an independent unit, although it still differs in some thermal insulation qualities. If we talk about three-layer walls, then here the structural material acts as the third layer.

Helpful information! In addition to dividing by the number of layers, facade insulation is also classified depending on the ventilated and non-ventilated layer.

According to the regulatory documents indicating how to insulate the house from the outside, it is recommended to use the following types of materials, depending on the type of box:

According to regulatory documents, the insulation of house facades is divided into two- and three-layer thermal insulation structures

- Houses made of brick or reinforced concrete with flexible connections, as well as buildings made of expanded clay, can be clad with any type of insulation.

- Buildings made of wood are protected by an enclosing structure with two- and three-layer walls, separated by a ventilated air gap.

- Thin sheet framed walls require three-layer walls with a layer of thermal insulation in the middle, which is surrounded by a ventilated or non-ventilated interlayer.

- Aerated concrete load-bearing walls also require ventilated and non-ventilated interlayers. The top is decorated with brick cladding.

When is it better to insulate the facade of the house outside

Before insulating a house, you need to know that you can start any facade work only after the rest of the construction and repair work has been completed, these include:

- roof installation;

- external waterproofing of the foundation;

- installation of window and door openings;

- fixing the ventilation system and other utilities.

It is possible to start insulating the facade of the building only after the rest of the construction and repair work has been fully completed

Many experts argue that it is necessary to carry out insulation of building facades only after the house has undergone complete shrinkage and completely dries out after construction. Otherwise, there is a high probability that the finished facade will be covered with cracks and lose its neat appearance.

Before insulating the house, you should make sure that no intense heat or frost is expected. It is best to wait until there is a constant positive temperature during the day. The optimal time is considered to be the end of spring or the beginning of autumn, when the temperature ranges from +5 to +25 degrees. Many people recommend to finish all internal work, which is accompanied by the release of condensate, such as the organization of the screed and pouring the floor, before starting the facade insulation.

Starting from the outside, the insulation of the facade of a wooden house or building from any other material should be after a careful examination of the entire surface. If there is no experience in carrying out construction work, it is better to entrust this task to a specialist who will perform the mandatory tests and check the surfaces of the external walls for adhesion of the adhesive used for the installation of insulation. As a result of the work carried out, the bearing capacity of the walls will become clear, and the maximum load that will arise as a result of the fasteners will be calculated.

Useful advice! In addition to the fact that it is important to choose the right material for fastening to the walls, it is also necessary to withstand the technology of facade insulation in order to prevent the appearance of so-called cold bridges, as a result of which the insulation can collapse or delaminate.

The optimal time of the year for starting work on the insulation of the facade is considered the end of spring or the beginning of autumn.

It is important not only to carry out insulation, but also to choose a modern and high-quality insulation that is most suitable for a particular building. The insulation must be not only vapor and water permeable, but also heat-resistant to avoid accidental ignition and rapid combustion. It is best if the material is environmentally friendly, and the load-bearing walls are protected from the penetration of fungi and other microorganisms that can destroy the frame, especially if it is made of natural building materials.

The better to insulate a house, how to choose the right material

When buying insulation for the facade, you need to ensure that they are components of the same system. Sometimes, when buying, you will need the help of a professional, because the materials are not always sold in a single set, but must match each other in such characteristics as:

- vapor permeability;

- frost resistance;

- thermal expansion.

And also when choosing, one should take into account the chemical processes that will occur in a single system. Materials for insulation should be selected not only taking into account the type of frame. In this case, you need to make allowances for the climatic features of the region, architectural characteristics and technical purpose of the building.

When insulating the facade of a house from the outside with foam or other material, the continuity of the contour should be observed. There should not be any gaps, gaps or gaps on the facade, through which moisture or frost will get on the frame. It is also important to observe the vapor permeability of the system. Here, the main rule is that each next layer from inside to outside should have a higher degree of vapor permeability. This is done so that the walls can "breathe" and condensation does not form on the surface.

The cost of facade insulation will depend on the material chosen for this. The most common are:

- Mineral wool (mineral wool). Refers to the group of fibrous insulation. It is most often made from fiberglass or basalt fiber.

- Ecowool. Modern insulation material based on cellulose.

- A group of polymer insulators. Polyurethane foam, polyurethane, expanded polystyrene.

- Loose radiators - expanded clay, vermiculite.

- Natural traditional materials - dry leaves, reeds, straw, sawdust, pine needles, which can be used together with clay.

When insulating the facade of a house from the outside with foam plastic, the continuity of the contour must be observed, there should be no cracks, gaps or breaks

How to determine the thickness of the material for external wall insulation

Another key issue is to determine the coefficient of heat transfer through the walls, which depends on the choice of a particular thermal insulation material. In theory, the thicker the insulation material, the lower the ratio and therefore the more beneficial. In this case, it should be emphasized that the degree of insulation of mineral wool or polystyrene depends not only on their thickness (although this, of course, is of great importance), but also on the thermal conductivity coefficient. The indicator is also more favorable if its value is lower.

Insulation boards with a lower coefficient can be thinner while maintaining a good thermal conductivity. This is important because the thinner the insulation, the smaller the recess will be for window and door openings.

Useful advice! Studies show that after exceeding a certain thickness of insulation, there is a minimal improvement in the thermal insulation properties of the wall, which is completely disproportionate to the cost of each subsequent centimeter of insulation. The thinnest insulation will be made of expensive but ideally insulating PIR polyurethane, offered in the form of panels. Therefore, “thicker” does not always mean “better”.

Studies have proven that exceeding a certain thickness of insulation does not lead to a significant improvement in the thermal insulation properties of the wall.

Each house is individual, therefore, when choosing the thickness of the insulation, not only climatic features are taken into account, but also the heat capacity of the floor covering, the specificity of the roof and basement insulation, as well as the glazing area of the house.

Related article:

Insulation of a wooden house outside: the choice of material and technology

What materials are used for this purpose. Do I need to insulate the foundation. The best modern technologies for insulating wooden houses.

Today, when choosing an insulation material, you have to choose between three thickness standards (in centimeters):

- 50;

- 100;

- 150.

It is not difficult to calculate the layer thickness. To do this, you need to calculate the initial wall thickness and estimate how much is missing to the norm, and then calculate how thick the facing layer should be. In addition to the thickness of the insulation, other criteria must be taken into account:

- plaster layer;

- exterior decoration;

- air gap.

Materials for insulating the facade of the house from the outside: penoplex, foam

Insulation of the facade with expanded polystyrene is considered effective due to the closed cellular structure of the material. 98% of the heat insulator is air or inert gases, which fill the tightly closed cells, which provides the sheets with a low weight. Polyfoam is not susceptible to moisture absorption, which means that it can be effectively used both for the facade and for warming the foundation, basement and constantly damp basement. The material is optimal for insulating the facade of the house from the outside under plaster. Advantages of using expanded polystyrene:

The disadvantage of foam is its low vapor permeability and susceptibility to destruction when exposed to direct sunlight

- Due to its low weight, the insulation material will not exert much stress. This means that it can be used when renovating the facade of an old house without performing any work to strengthen the foundation.

- The sheets are easy to install, which allows you to insulate the facade of the house outside with expanded polystyrene with your own hands, even for a beginner in the construction business.When working with the material, it is not required to use personal protective equipment - gloves and a respirator, because the process is not accompanied by the release of toxic substances or small particles.

- The synthetic components that make up the sheets of insulation are not susceptible to the reproduction of microorganisms, so the material is not afraid of either fungus or mold.

- The shelf life of the material reaches 50 years, especially if you follow the installation technique. Insulation shows good resistance compared to salt and chloride solutions, and also does not change its structure under the influence of alkali.

The disadvantages of insulating the facade of a house with foam are considered to be low vapor permeability of sheets and susceptibility to destruction when exposed to direct sunlight. In addition, it is worth noting the low sound insulation performance, as well as the fact that when heated over 30 degrees, the material begins to release formaldehyde, styrene and other toxic substances, the amount of which increases during combustion.

Styrofoam does not absorb moisture, so it can be used both for insulating the facade and for the foundation or basement

Important! It is not recommended to insulate the facade of a wooden house with foam plastic, because upon contact with drying oil or varnish, the structure of the sheets begins to collapse. It should be noted that polystyrene (penoplex), like wood, is a combustible material, so you should not combine them on the same facade.

The main advantages of using penoplex

Extruded polystyrene foam, or penoplex, is produced in a similar way. In contrast to foam, a lower gas content is observed here, as a result of which the sheets are thinner, denser, slightly heavier, but at the same time more durable. Before insulating the facade with penoplex, you need to distinguish between its varieties:

- Plates marked with 31 are used for facade insulation and roof insulation.

- Penoplex-35 is most often used in construction. In addition to the facade, it is laid as a layer of insulation under the floor covering.

- Sheets 45 are suitable for insulating the roof, even if it is under load. Due to their high cost, they are rarely used in construction.

Unlike foam, penoplex has a lower gas content, so sheets of this material are thinner, denser and stronger.

When insulating the facade of a house outside with penoplex with your own hands, the following types of material are used:

- "Foundation". Great for those parts of the house that are underground - a basement or basement.

- "Roof". High density allows using the material for insulation of any roofs.

- "Wall". The material is specially designed for external structures and is weather-resistant.

- "Comfort". Suitable for use in all conditions, even with high humidity.

It is important to pay attention to the fact that both Styrofoam and Styrofoam are susceptible to rodents who like to gnaw the pellets. Therefore, pest control should be carried out regularly.

Polystyrene foam, like foam, is susceptible to rodents, therefore it is necessary to regularly carry out pest control

Features of facade insulation with mineral wool

The popularity of polystyrene is due to its low purchase price, easy workability and the possibility of very fast gluing. However, the insulation of the facade of the house from the outside with mineral wool under the plaster comes to the fore. The material is used for finishing not only commercial, but also high-rise and public buildings. According to the updated standard, cotton wool is obligatory for use in the construction of structures over 20 meters high.

In addition, insulation of the facade outside the house with mineral wool provides excellent sound insulation. Therefore, the material can be used to insulate houses on busy streets.In combination with special gypsum plasterboards, mineral wool sheets can be used in the construction of partitions when good acoustics are required.

Advantages of thermal insulation of the facade of an apartment building outside with mineral wool:

- The material, due to its low resistance to diffusion, has excellent vapor permeability and prevents the formation of mold.

- When used correctly, mineral wool has a virtually unlimited life, making it an excellent choice for insulating buildings.

- High fire resistance. If it is a high-rise building, insulation with cotton wool must be used starting from the seventh floor. On the lower floors, strips of mineral wool are inserted next to the windows, as well as under the roof, in order to prevent the spread of fire in the event of a fire.

Insulation of the facade of the house from the outside with mineral wool provides excellent sound insulation

The material is impregnated with chemistry, therefore it does not absorb moisture, as a result of which it is not afraid of corrosion or decay. And also, thanks to its simple shape and flexibility, even the smallest gaps and bends can be filled with cotton wool. Disadvantages of facade insulation with cotton wool:

- heavy weight, causing difficulties in installation;

- the price of insulation will be about a third higher than when using polystyrene, the cost of wall insulation from the outside for 1 sq. m starts from 1900 rubles.

Helpful advice! If the cotton wool gets wet before installation, you need to give it time to dry. If the sheets are very wet, it is better not to use them, because they will not provide the proper characteristics after installation.

Varieties of material used for wall insulation

There are two main types of materials used in the production of cotton wool - glass and mineral. Glass wool is made by cooking cellulose with the addition of other ingredients. Mineral wool is obtained by melting rocks, it is also called stone or basalt. Glass wool is non-flammable, vapor permeable and flexible, suitable for all unloaded and non-slip structures such as sloped walls, various cavities and gaps, even ceilings.

It is slightly more difficult to use stone wool for facade insulation due to the fact that it is heavier than glass wool and less elastic, but the material provides ideal thermal insulation for the outer cladding of the building. Any façade wool should always be glued to a dry and solid base.

When insulating the facade with mineral wool, the following types of material are used:

- Transverse fiber orientation. Suitable for facade systems for which heavier tiles will be used. The material has high tensile strength.

- Longitudinal orientation of fibers. Designed for application to external walls and thermal insulation contact systems.

Due to its good characteristics and low flammability, cotton wool can be used in conjunction with any materials. It is popular to insulate the facade of a house outside with mineral wool for siding, in this case it will be possible to get both a heat-efficient and a beautiful house.

How are foam blocks and heat-insulating panels used for insulation

The foam block is produced in the form of facing slabs, which are laid according to the brickwork principle in order to exclude the appearance of cold bridges. The foam block is glued directly to the bearing wall, and the adhesive mixture acts as an additional waterproofing layer.

For better adhesion, umbrella dowels are additionally used. Foam and gas blocks are characterized by low weight, which facilitates their installation. Due to the fact that the concrete mixture foams during manufacture, the material is capable of freezing and losing strength. Therefore, it is best used with a moisture-proof finish. It is not recommended to insulate the facade with a foam block under plaster.

Decorative panels are a set consisting of insulation and a decorative layer. The basis of the panels is made of polystyrene (penoplex), and plaster or brickwork acts as a decorative layer. It is mounted using a special adhesive solution. The main advantage is the speed and ease of installation.

In this case, it is not necessary to additionally insulate the facade with plaster, because the decorative layer is applied in advance at the factory. The panels look attractive and retain heat well. The only drawback is the peeling of the sheets from the surface, especially if you use the wrong glue. If you use dowel umbrellas for better adhesion, the appearance of the facade will deteriorate. The cost of the panels is about 3000 rubles / m², excluding installation.

Basic technologies for insulating facades of private houses

In general, there are two ways to carry out the insulation of external walls:

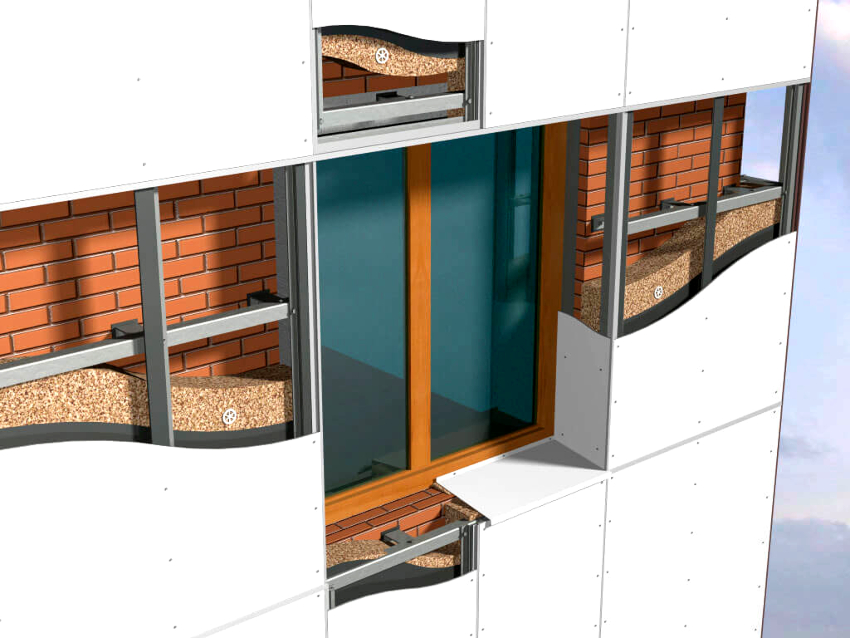

- Dry. This includes options such as prefabricated and curtain walls. The technology involves the use of a prefabricated structure, which is made from ready-made elements, connected together by a dry method.

- Wet. This installation technology includes the use of water-soluble building materials, which include glue, plaster and other solutions.

There are also several systems of facade insulation:

- Ventilated. In this case, it is additionally required to make an interlayer, placing it between the external facing material and the insulation layer. For this, a metal or wooden crate is mounted. Insulation of the facade with siding is carried out only after the installation of the battens.

- Unventilated. Here the insulating layer is represented by an integral system, in which the presence of an air gap is not provided.

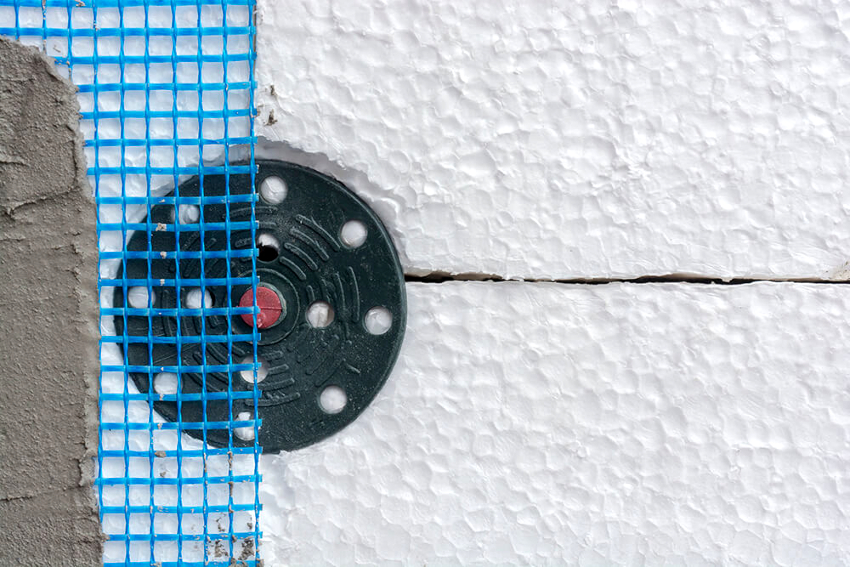

When creating a wet facade, heat-insulating, adhesive, protective and decorative layers are successively applied, which form a wall array of a single thickness. Key recommendations:

The creation of a wet facade includes the application of thermal insulation, adhesive, protective and decorative layers

- You should choose the right materials in terms of density: for mineral wool - 150-180 kg / m², for foam - 35. The moisture absorption coefficient should not exceed 1.5%.

- An adhesive mixture is used, intended only for outdoor work, in addition, the sheets are attached with umbrella dowels.

- The presence of a reinforcing layer is mandatory, for which a fiberglass mesh treated with an anti-alkaline solution is used, laid with overlapping sheets.

- With a large facade area, for every 24 squares, consider the presence of an expansion joint.

Facing the facade with the wet method using foam plates will cost 1000 rubles per square.

The most popular facade insulation system is a hinged ventilation facade, the essence of which is the presence of a through air gap between the facade and the insulation. The ventilated interlayer prevents moisture penetration, and the air currents in the hinged frame cool the wall well in the hot season, even in direct sunlight.

For a curtain facade, it is permissible to use the same types of insulation as when performing a wet facade, but you can purchase less durable materials. This is due to the fact that in this case they will not be affected by the heavy cladding layer, because it is mounted on a frame installed on the main part of the outer wall.

Helpful advice! If blown insulation such as rock wool is used, it should be covered with a diffusion membrane that protects the insulation from wind and moisture, but allows water vapor to pass through.

Thermal insulation of the facade for siding by the dry method is considered one of the popular options.The frame for cladding can be made of metal or wooden lathing. If wood is used for this, it should be pre-treated with anti-mite and fire-fighting mixtures. The step of the lathing should be chosen 2-3 cm less than the width of the insulation sheet itself. The size of the air gap between the facing material and the insulation should vary from 60 to 150 mm.

The prices for the implementation of the ventilation facade will depend mainly on the type of frame for cladding. If a metal prefabricated structure is used, the cost will be about 2,000 rubles per sq. m, in the case of using a wooden crate - 1000 rubles.

Insulating the facade of a house from the outside is a profitable investment that will help not only significantly reduce heating costs in the cold season, but also save on air conditioning during the hot season. Correctly performed insulation will create an ideal microclimate in the house and provide reliable protection for the supporting structure. The main thing is to choose the right material and adhere to the laying technology.