Brick is one of the most popular types of building materials that is actively used all over the world. It is reliable, durable, easy to manufacture and install, and is relatively inexpensive. There are many varieties of bricks, but it is the silicate brick that has been the most popular in recent years. The size of silicate brick and its other characteristics are of great importance, therefore, we will consider them in detail below.

Content [Hide]

What is the silicate brick used for, the size of the silicate brick

Any brick is 90% quartz sand, and the rest is lime and various additives. All this is pressed by the dry method, fired, as a result, briquettes of the correct geometric shape are obtained. The dimensions of a silicate block, like any other, are universal and are 250 × 120 × 65 mm. There is also a so-called one-and-a-half brick, which is 88 mm thick.

Silicate brick differs from other types in that it is manufactured using a special technology, which involves autoclaving with hot steam under high pressure. The steam temperature can be up to 200 degrees, and the pressure - 12 atmospheres. As a result of this treatment, the lime and sand molecules firmly adhere to each other, which is why the silicate brick is characterized by increased strength characteristics.

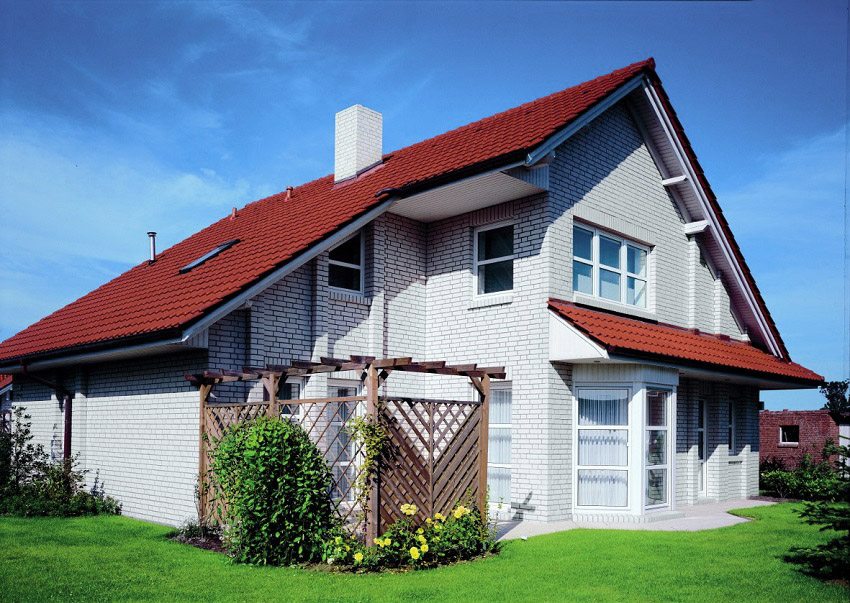

The dimensions of one-and-a-half silicate brick, like ordinary ones, allow it to be used for a wide range of tasks. So, it is used in the construction of low-rise buildings, facade decoration, erection of interior partitions. But for the construction of high-rise buildings, silicate brick is not suitable.

Helpful advice! HIt is not worth using sand-lime brick for the construction of structures that are planned to be exposed to high temperatures, for example, fireplaces and stoves. Under the influence of temperatures above 200 degrees, a brick can burst or explode.

The performance characteristics of silicate brick make it an excellent material for facade cladding. It can be white or painted in almost any color, which opens up a wide scope for design imagination.

Advantages and disadvantages of sand-lime brick

Each brand of silicate brick differs from another in strength. But, besides this, any brick has the following advantages:

- ease of installation - it is as easy to lay a wall or other structure made of this material as with any other type of brick, for this you do not need to have specialized engineering skills or tools. The only difference is the greater weight of sand-lime bricks 250 × 120 × 88 compared to other one-and-a-half bricks;

- increased material strength - in comparison with ceramic, the strength characteristics of silicate bricks are one and a half times higher. This has a positive effect on the quality and reliability of the structure being built;

- high performance of sound insulation - silicate brick is an excellent soundproofing material and will reliably protect the room from external noise. This makes it a good choice for building partition walls in apartment buildings;

- democratic price - if you ask the question of how much silicate bricks cost, then the answer will delight even the most skeptical buyer. The price is usually 20-30% lower than that of ceramic. This is due to the fact that it takes much less time and energy to make it;

- presentable appearance - colored silicate bricks are perfect for external finishing works. In addition, they boast a smooth surface and an even shape, so the facade made of silicate bricks does not need additional processing, for example, plastering;

- environmental safety - according to GOST, silicate brick is made from environmentally friendly materials, and mold or mildew does not form on its surface.

Thus, it can be seen that sand-lime brick is a very good choice for your construction. Photos of silicate bricks demonstrate its presentable appearance, and expert reviews confirm excellent performance characteristics. This material has been used at construction sites all over the world for several years, and its popularity is constantly growing, which indicates its high quality and reliability.

Helpful advice! The answer to the question, how many silicate bricks in 1 m² depends on whether they are one-and-a-half or ordinary blocks. Therefore, asking such a question to the seller, be sure to specify the dimensions of the product.

Silicate brick is a building material that is not without its drawbacks. It also has a number of weaknesses that are important to be aware of:

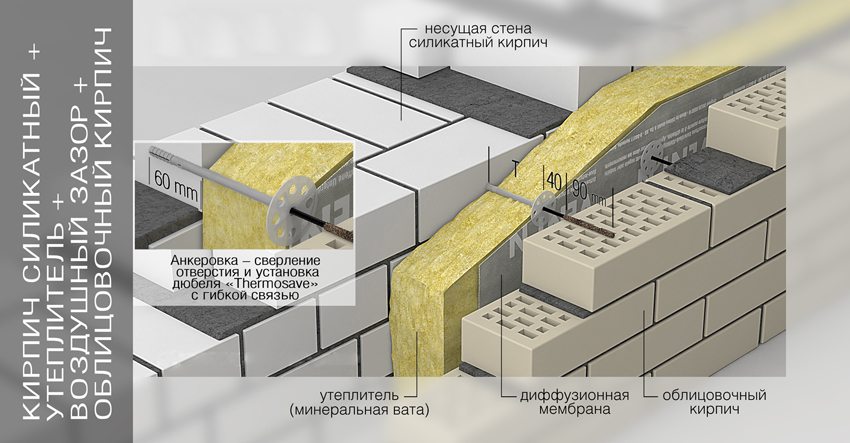

- low indicators of frost resistance - if you are building a house from silicate bricks, then keep in mind that it will have to be additionally insulated. Whichever size of sand-lime brick you choose, its structure is very susceptible to low temperatures, and can also suffer in the cold season due to moisture absorption;

- relatively low thermal insulation - silicate brick copes well with sound insulation, but it does not hold heat very well. Therefore, regardless of how many silicate bricks are in 1 m³ of masonry, you still have to additionally insulate the walls of the house from this material;

- large weight is both a plus and a minus of the material at the same time. The weight of one-and-a-half silicate bricks, like ordinary bricks, has a positive effect on the strength characteristics of the structure, but creates a number of inconveniences when transporting and laying the material;

- unsuitability for the construction of certain types of structures - it is not recommended to build multi-storey buildings from silicate bricks, as well as stoves, fireplaces and chimneys, that is, structures that may be exposed to high temperatures.

The controversial point is the moisture absorption of the material. According to GOST, moisture absorption is allowed up to 6%. At the same time, the rate of moisture absorption in a silicate product is lower than that of a ceramic one. Therefore, no matter how many silicate bricks are in 1 m³ of masonry, it will resist moisture better than the same masonry made of ceramic bricks.

With all these disadvantages, the positive aspects, for example, the prices per piece of sand-lime bricks, outweigh them. That is why this material is so popular in many countries around the world.

Types and weights of silicate bricks

Before erecting a structure from a material, it is worth deciding on its type. It has already been said that sand-lime brick can be standard or one-and-a-half. Its weight, respectively, will be lower or higher. In addition, there are the following types:

- porous brick;

- brick with a chipped texture;

- structural brick - subject to obligatory facing;

- slag and ash;

- colored brick;

- facing brick - combines the properties of structural and facing.

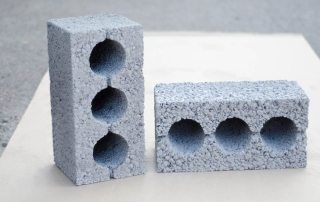

In addition, a distinction is made between hollow and solid bricks. Blocks of the first type, as the name implies, have voids. This reduces the weight of the unit and affects such parameters as thermal conductivity and sound insulation. Solid brick weighs more, but also boasts greater strength.

Each of these types of material is designed for specific construction work. Regardless of how many bricks are in a pack of sand-lime bricks, each type has its own characteristics, so you should choose based on the specifics of your construction. The size of the silicate brick is also of great importance.

For example, if you are building a low-rise building, then it is better to use a one-and-a-half or even double block for this purpose. This will reduce the financial costs of the material, while improving the appearance of the object. It is logical that it is better to cover facades with smooth and colored bricks. The latter is also well suited for building exterior walls.

Related article:

The size of the white sand-lime brick, characteristics and features of laying. Types of bricks, performance characteristics. Finishing nuances. Advantages and disadvantages of the material.

The external cladding of the building with smooth silicate bricks of various types is good because you will not need additional finishing. This will help save not only construction time, but your finances.

The nuances of laying sand-lime bricks

As already mentioned, you do not need any special construction skills or specialized tools to lay bricks. All you need is an ordinary building level, a tape measure, a trowel, a plumb line, a spatula for supplying mortar, a hammer for cutting and leveling blocks, as well as a container for cement mortar.

Helpful advice! Before laying silicate bricks, it is advisable to soak it in water so that later it does not absorb moisture from the solution.

First, it is worth deciding how many silicate bricks are in the pallet. Then you need to start styling. This is best done from the corners of the building, between which you need to pull the cord. It is under this cord that the entire brick row will subsequently fit, so this point should be given special attention. Longitudinal, transverse and vertical seams must be tied with steel wire every 2-3 rows.

There are two main methods for laying sand-lime bricks. The first is "press-on", that is, using a hard solution and filling all the seams with it completely. This method takes more time, but guarantees a high strength and reliability of the building. The main thing here is not to forget about the seams.

The end-to-end method involves partial filling of joints using a plastic mortar. This method is faster, but of lower quality, so it is recommended to additionally strengthen the resulting structure with plaster. The seams must be processed so that cracks do not form.

Laying sand-lime bricks is done quite quickly if you already have certain skills in this matter. Numerous videos and photo instructions on the Internet will help you get the knowledge you need in an easy and accessible way. There you can also find out how much silicate bricks of one type or another weigh, which one is better to use for specific work, which mortar composition is better suited for laying and other important information.

General tips for working with sand-lime bricks

There are a number of general points that you need to know for the effective use of a building material such as sand-lime brick:

- there can be no question of using material for the construction of the foundation and the basement of the building. The main obstacle to this is increased moisture absorption;

- walls made of material, regardless of the size of standard or one-and-a-half silicate bricks, will have to be additionally insulated. An alternative option is to make thicker walls, but insulation is easier and more economical;

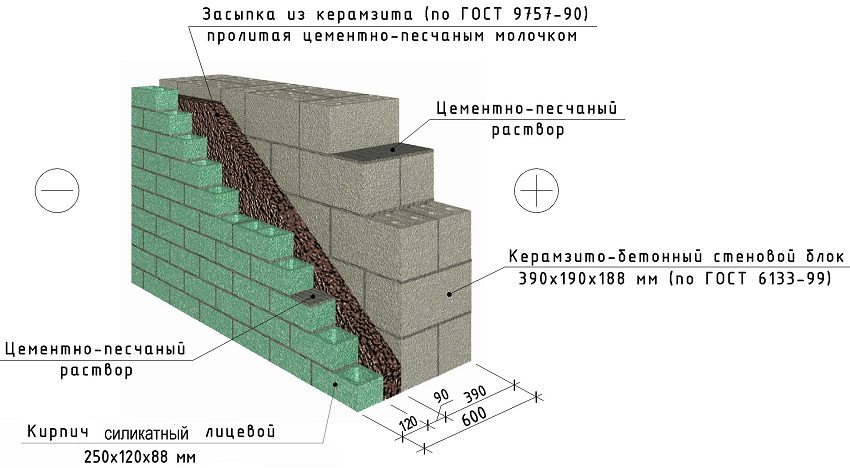

- the best construction option is a combination of ordinary and silicate bricks. In some moments, it is quite possible to get by with cheaper types of building materials;

- sand-lime brick is best suited for the construction of internal partitions and walls. The dimensions of one-and-a-half silicate bricks are also well suited for external facing of facades;

- you need to choose the color, size and type of sand-lime brick only after you have decided where exactly the material will be used. If you are not well versed in the matter, then it is better to seek help from an experienced specialist.

Helpful advice! Silicate brick differs little from ordinary brick when it comes to laying it. Therefore, you can safely use the same tools and technologies, taking into account the above features of the material.

As a result, we can say that a silicate brick house is a very profitable and reasonable solution. However, you should not thoughtlessly use the material for the construction of absolutely all elements and structures, you should carefully weigh the pros and forgiving, learn the recommendations for choosing, working and laying. With a competent approach to construction, a silicate brick house will stand for many years, and its repair and reconstruction will not be needed very soon.