Today, a large selection of insulation materials is presented on the construction market. Many manufacturers are constantly improving their technical indicators, which is associated with the tightening of customer requirements in matters of energy saving of buildings and structures. One of the best representatives of reflective thermal insulation is foil-clad penofol, which is characterized by universal properties.

Content [Hide]

- 1 What is the name of foil with insulation: acquaintance with penofol

- 2 The principle of operation of foil-clad insulation called "penofol"

- 3 Fields of application of foil-clad penofol

- 4 Foil penofol: what are its strengths and weaknesses

- 5 Differences between Penofol insulation and other heat insulators

- 6 Foil penofol: material specifications

- 7 Characteristics of regular and self-adhesive foam foam

- 8 How to properly lay foil insulation on the floor

What is the name of the foil with insulation: acquaintance with penofol

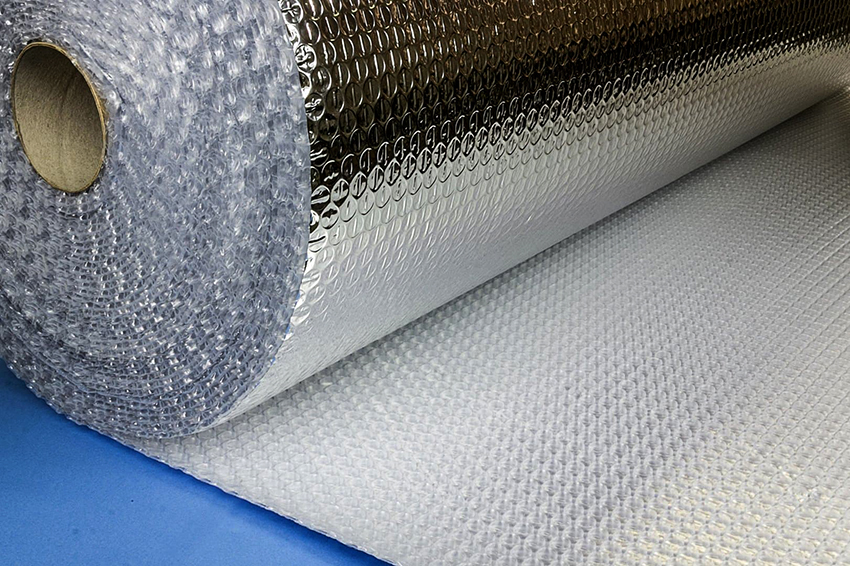

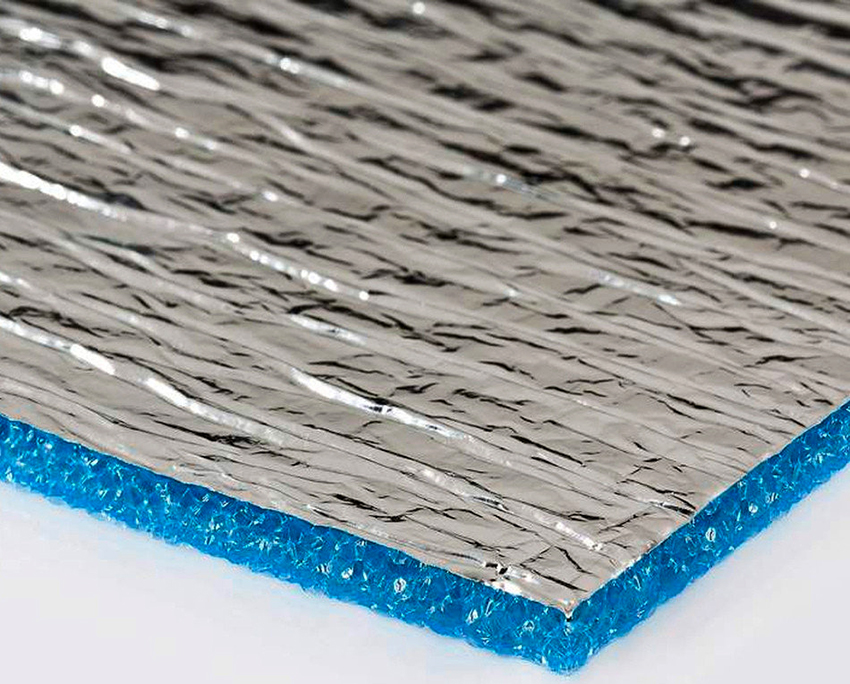

Foiled penofol is a registered brand. It is represented by a multi-layer material, which belongs to the class of reflective thermal insulation. The name of the insulation with foil is derived from two words: "foam" - from expanded polystyrene and "foul" - from foil.

Its main purpose is to protect building structures from wind loads, exposure to moisture, steam, condensate. Penofol is a versatile material that combines the qualities of heat, sound, steam and moisture insulation. The basis of such a heat insulator is polyethylene of the expanded type with closed pores, which are 95% filled with air, thereby excluding heat transfer. This polymer layer can be of different thickness, structure and density.

Polyethylene is coated on one or both sides with aluminum foil, which is pre-polished to achieve the maximum reflectance. The material is applied by means of heat welding, which ensures reliable adhesion of the foil to the polyethylene.

Important! As a result of the use of foil-clad penofol, it is possible to reduce the cost of heating the premises in the winter, and in the summer to slow down the heating of the house.

The principle of operation of foil-clad insulation called "penofol"

Having decided on the question of what the foam rubber with foil is called, it is necessary to understand the principle of action of foil-clad foam. It is based on the mechanism of functioning of a simple thermos.This development is associated with the name of the Scottish scientist in the field of chemistry and physics James Dewar, who at the beginning of the twentieth century conducted a series of experiments.

Scientists have found that any substance is capable of resisting heat transfer. It accumulates heat waves, while accumulating energy in itself. After a while, supersaturation is observed, leading to the fact that the material begins to give off heat.

Then the scientist identified a number of materials that can reflect thermal energy, and not accumulate it. Such substances include polished aluminum. When thermal waves reach the surface, they are reflected from it by 99%, which indicates excellent thermal conductivity. Such substances should be supplemented with other materials that function as "thermal barriers", which can be expanded polyethylene.

From the above, it becomes clear what penofol is and how it works. Due to the fact that the air cushion in the form of polyethylene foam is covered with a reflective element (foil), the material is able to retain the heat that it received from it for a long time. This is because polished aluminum does not store heat, but transfers it to another material that can store it. Due to its unique features, foamed penofol copes with this task in the best way.

Fields of application of foil-clad penofol

Penofol is available in rolls. Material thickness is 2-40 mm. At the same time, the same indicator of the foil varies within the range of 12-30 microns, due to which good heat-reflecting qualities of the material are provided. The thickness of the foil layer directly affects the price of penofol per m2. The thinner the insulation material, the lower its price. The most demanded is insulation 5 mm thick. The price of foil-clad penofol is 120 rubles / m².

This material is characterized by a wide range of applications. It is used for the purpose of thermal insulation of residential one- and multi-storey buildings, industrial and administrative buildings, saunas and baths, cold and heated hangars, warehouses, cold rooms, capital, stationary and mobile trading kiosks and shops, railway cars, refrigerators, vans, pipelines of various purpose, heating, air conditioning, ventilation and water supply systems, and is also designed for the technical insulation of equipment.

It can be safely used for waterproofing attics, basements, attics and basements. This is a reliable heat and sound protection of loggias and balconies. Penofol can be used to finish external and internal surfaces of walls, ceilings, floors, ceilings over cold basement rooms. With the help of the material, shielding of heating radiators, insulation and sealing of window and door systems is carried out.

Foiled penofol is in great demand among motorists. With the help of such material, you can perform high-quality noise and sound insulation of the body of a car and truck.

Foil penofol: what are its strengths and weaknesses

This type of reflective insulation has distinctive advantages, which are associated with the universal characteristics of foil-clad foam. Due to its small thickness, the material is able to provide reliable heat, sound, moisture and vapor insulation of the room. It is characterized by good strength, as a result of which it is resistant to deformation and mechanical damage.

Penofol is an environmentally friendly product that does not emit harmful substances into the atmosphere. It is odorless, free of dust particles and does not create them.It can even be used to store food. The material is able to protect the premises from beta rays, which is especially valuable in different enterprises or in hostile areas.

Foil-clad penofol can be used as insulation when performing repair work both outside the building and inside the building. Due to the low vapor permeability during its installation, it is possible not to equip an additional layer of vapor barrier. The material is characterized by a high degree of noise insulation, therefore it is used to protect workshops and residential buildings from acoustic and structural noise.

Due to the fact that penofol belongs to the class of fire-resistant materials, fire safety is provided when it is used. However, in the process of combustion, it causes high smoke content in the space.

Distinctive features of foil penofol

Penofol is easy to transport due to the fact that it is produced in rolls of small width. When installing this insulation, there is no need to use special tools. The material is fixed to the surface with an adhesive. The most effective result is achieved when using self-adhesive foil foamed foam.

Important! For the installation of foil-clad foam, you should not use nails or other fasteners, since such an installation will negatively affect the thermal insulation qualities of the material.

Penofol is characterized by a small thickness, but at the same time the proper level of thermal insulation is provided, which is achieved when using thicker heat insulators. This characteristic allows you to save internal space when laying foam foam in the room itself, which is especially valuable when it is in short supply. The thin structure of the material also excludes the likelihood of rodents arranging their holes inside the insulation.

Foil penofol 5 mm (and other thickness) is characterized by a long service life, which is at least 50 years. This material is also capable of providing protection against the harmful effects of electromagnetic radiation, reducing the level of its field by a factor of ten.

Despite the excellent advantages of this insulation option, it is characterized by a number of disadvantages. Penofol has a soft structure, for this reason it is not recommended to use it for insulating walls that will be plastered or covered with wallpaper. In addition, contact of the aluminum layer with paint or varnish often causes material damage. Even with the slightest mechanical stress, its integrity can be damaged.

Differences between Penofol insulation and other heat insulators

Heat transfer from one substance to another is carried out in three ways: by means of heated air, by means of radiation and due to the thermal conductivity of materials. Most thermal insulation products prevent one of the heat transport options. Foil-clad penofol is characterized by a complex effect, which is achieved due to the fact that polyethylene foam does not allow convection, and the thermal reflection index of aluminum foil reaches 97%.

According to its technical characteristics, penofol can be compared with such a heat insulator as izolon. The last option is sheet material, the thickness of which is 12-50 mm. However, the cost of such a heat insulator significantly exceeds the price of penofol. In addition, izolon is capable of accumulating heat, and penofol reflects it.

This insulation is also distinguished by its ease of installation (this especially applies to self-adhesive options). It does not need the construction of vertical posts, which are necessary when fixing mineral wool. The cost of penofol is the lowest in comparison with other options for heat insulators.

Foil penofol: material specifications

Foil penofol is able to withstand temperature fluctuations from -60 to 100 ° C, which expands the scope of its use. The thermal reflection of the material reaches 97%. The thermal conductivity coefficient is in the range of 0.037-0.052 W / m * C, which depends on the operating conditions.

This suggests that 1 cm of foam foam is able to provide the same thermal insulation as 4 cm of expanded polystyrene. The sound absorption level of the material is 32 dB, which creates a good sound insulation barrier. In addition, penofol can dampen vibrations, which is especially important when insulating metal surfaces.

Important! The heat transfer resistance index of ordinary or self-adhesive foil-clad foam is 10 mm higher than that of a brick wall with a thickness of 50 mm.

The specific gravity of the material is 44-50 kg / m³, which is much less than that of mineral wool. An important characteristic of penofol is a low level of moisture absorption. The water saturation threshold is 0.35-0.7%. The coefficient of elasticity varies in the range of 0.26-0.39 MPa. The vapor permeability of the material reaches 0.0001 mg / mhPa, making it a good barrier to evaporation. The specific thermal conductivity of foil-clad insulation is 1.95 J / kg * C.

Penofol is produced in the form of roll material, the length of which is 5, 10, 15, 30 and 50 m.The width of the product can be in the range of 0.6-1.2 m.The standard thickness is 2, 3, 4, 5, 8 and 10 mm. For some options, this figure is 40 mm.

Characteristics of regular and self-adhesive foam foam

Depending on the manufacturing technology of the heat insulator, there are three main types of penofol: A, B and C. The first group is represented by a polymer insulating material with one-sided foil. It can be 2 to 40 mm thick. The width of penofol is 40-120 cm. This type of insulation is often combined with other material options in the form of mineral wool or glass wool, it is often used for thermal insulation of floors.

Penofol type B has double-sided foil, due to which a higher insulation effect is achieved. The thickness of the material is 2-10 mm, the width is 58-200 cm. This version of the reflector is used for thermal insulation of supporting structures of walls, floors, waterproofing of the attic and basements.

Helpful advice! Laying insulation B under the roof will create an obstacle for hot air to enter the premises in hot summer.

Penofol type C is a self-adhesive version of insulation, which is covered with polished aluminum foil on one side, and on the back there is a moisture-resistant adhesive composition, covered with a protective film, which prevents adhesion. Such material can be used for thermal insulation of any surfaces, which makes it possible to significantly save time. Penofol C is especially preferable for finishing inconvenient parts of the structure. Before use, the material is cut into elements of a certain size.

Helpful advice! For ordinary insulation, the base is white, while for penofol 2000 type C, A or B it is blue, which indicates a cheap analogue of the standard material with lower characteristics.

Other types of polymer insulation with foil

There are other types of penofol that are in less demand. Type R material has a one-sided foil, on which a relief pattern is applied. This option can be used not only as a heater, but also as a decorative element to decorate the structure, which is shown in the photo of foam foam, which decorates the walls of the premises.

Related article:

LSU panels: a modern and multifunctional analogue of drywall

Description of material, advantages and features. Scope of application, prices and customer reviews. Painted magnesite slab.

Insulation brand M also has one-sided foil. The other side of the material has a relief surface. It is advisable to use penofol insulation of this type for finishing places where it is necessary to create an air layer, which is often required when arranging a loggia or balcony. In this case, the ribs on the surface should be located vertically, due to which a good level of ventilation of the structure will be achieved.

The highly specialized types of penofol include materials such as ALP and NET. The first option is coated with a polyethylene laminated film, which ensures high reflective performance of the material, increased corrosion resistance and good dielectric properties. This type of insulation is typical for finishing incubators, and is also ideal for the "warm floor" system.

Helpful advice! You can check the quality of the insulation by looking through it at a bright light, while all spots, stripes and irregularities of the material should be reflected.

Penofol type NET is similar to option B, but it is produced in narrow rolled strips, which makes it convenient to use as an insulator for pipelines, heating mains and air outlets.

Among the new products are perforated penofol. A distinctive feature of the material is its ability to “breathe”, which is achieved due to the presence of a large number of micro-holes. This option is most advisable to use for thermal insulation of wooden structures.

How to properly lay foil insulation on the floor

To lay foil-clad insulation on the floor, you must first prepare the base on which all irregularities, defects and cracks should be eliminated. Then the surface is treated with a soil solution.

Helpful advice! Many experts recommend laying 7-12 cm thick foam plastic under the foil insulation on the concrete floor to achieve the best thermal insulation properties.

When using a type A heat insulator, a thin uniform layer of foam foam glue is applied to the base. Particular attention is paid to the edges of the material, which must be carefully treated with an adhesive. Then you should wait 10-60 seconds. to dry the glue, which will contribute to its better adhesion. After that, the insulation is fixed with little effort, performing neat smoothing.

For indoor floor insulation, a more convenient option is penofol C 10 mm. To mount the material, it is enough to remove the protective plastic film from its inner surface. Insulation must be laid in such a way as to ensure 5 cm overlap on walls. Penofol strips should not overlap either. The protruding areas should be removed with a construction knife. The joints must be glued with insulating aluminum tape.

Important! When deciding on which side to put the heat insulator with foil, it should be remembered that the foil part of the insulation should face inside the room, while the opposite side is glued to the floor. In this case, reliable vapor and sound insulation is provided.

How to install insulation for the "warm floor" system and on the ceiling

For installation of the "warm floor" system, two methods of laying foam foam are used. The first provides for the installation of a log on a heater. It is advisable to use this option if a wooden floor is mounted on the heat-insulating material. The logs should be laid along such a base on top of the heating elements.

When arranging a warm floor under a tile, the base is covered with foil foam foam, which is fixed to the concrete surface with glue. Heating elements are mounted on it, which are covered with a reinforced mesh, followed by pouring a concrete mixture. For this option, it is recommended to use Leroy Merlin foil foil foam type ALP.

Laying of electric cables on foil foil foam is carried out in a protective corrugation. This also applies to radio cables and telephone lines. This safety measure is due to the fact that the foil is a good conductor.

Consider how the ceiling insulation is carried out using such a material. First of all, a self-adhesive foil 5 mm foam foam is fixed to the base surface. Wooden slats are screwed onto it to create a frame for type B insulation. It is attached to the bars using screws or a construction stapler. If it is necessary to install the third layer, the process is carried out in the same way.

How to insulate a wall from the inside in an apartment from the cold

Wall insulation is carried out using a type B heat insulator. For this, it is enough to use foil-clad penofol 5 mm. Installation of such material is difficult (in comparison with other insulation options). Installation involves adherence to the sequence of certain actions. First of all, wooden blocks 1-2 cm thick are attached to the concrete surface in a vertical position by means of dowels with a step equal to the width of the insulation. However, it should not be more than 1 m.

Penofol strips are fixed to the frame with staples or screws. The material is stacked close to each other. Overlapping installation of strips can lead to the formation of condensation, which will flow down the butt joints. Wooden slats are again installed on the insulation to create ventilation gaps. Sheets of drywall are attached to them, which are fixed with self-tapping screws to the slats.

Important! To avoid drafts, the connecting sections of foil-clad products should be covered with a damper tape.

When insulating the outer surface of the walls, penofol 10 mm is most often used, on top of which sheathing with corrugated board or plastic is made. In this case, work should be carried out in dry warm weather. For the installation of the insulation, special glue is used. For beginners, it is better to purchase a self-adhesive foil foam 10 mm, the price of which is much higher than the usual one.

As with the installation of insulation indoors, work begins with the construction of a frame from wooden slats. Next, penofol 10mm is fixed with glue. In this case, staples and nails should not be used, as this will contribute to the ingress of moisture on the rough wall. Butt joints must be covered with special aluminum tape.

Important! To achieve high thermal insulation properties, penofol is laid on the outer surface of the walls in 2-3 layers.

The construction market is replete with thermal insulation materials, which differ in technical qualities and prices. Foil penofol is one of the most reliable options, characterized by environmental safety and universal properties in terms of accumulation, preservation and transfer of heat, thanks to which it is able to give the room the long-awaited coziness and comfort.