Polypropylene pipes are used to create reliable and durable water supply and heating systems. They are distinguished by their strength, resistance to high temperatures, high pressure, mechanical stress. When installing the line, to connect its individual elements, make branches, transitions and turns, it is necessary to use a variety of fittings for polypropylene pipes.

Fitting provide reliable and durable pipe connections

Content [Hide]

- 1 Features of polypropylene pipes and fittings for them

- 2 Types of material for making polypropylene fittings

- 3 Varieties and diameters of polypropylene pipes

- 4 Fittings for polypropylene pipes: an overview of fittings

- 5 Types of fittings for polypropylene pipes with the name

- 6 Fittings for reinforced polypropylene pipes

- 7 Leading manufacturers of polypropylene pipe fittings

- 8 Special features of fittings for HDPE pipes

- 9 Features of using fittings for PVC pipes

Features of polypropylene pipes and fittings for them

Polypropylene pipes are very popular for the installation of hot and cold water supply systems, radiator and floor heating systems. This is due to the fact that the products are characterized by strength, corrosion resistance, durability, resistance to high temperatures, the ability to withstand freezing and thawing without changing the structure. Due to the presence of a smooth inner surface, the system does not clog up, deposits do not accumulate in it, which is important for gravity sewer networks.

Products made of polypropylene (the photo clearly shows this) can be solid and reinforced. The first type is suitable for organizing a cold water supply line, and the second is more preferable for installing a hot water supply system and a heating network. This is due to the fact that solid pipes under the influence of high temperatures are able to deform in length, which is deprived of reinforced products due to the presence of a frame made of fiberglass or aluminum foil. This contributes to a low coefficient of thermal expansion.

For joining pipes of the same or different diameters, for the formation of branches, corners and bypasses, special elements are used, called fittings for polypropylene. Thanks to such fittings, it is possible to block the system, if necessary, to dismantle it. With the help of these connecting elements, a backbone network of any configuration and complexity is created.

The connection of polypropylene pipes and fittings is carried out by soldering the components of the system. As a result, it is possible to obtain reliable and sealed connections, which is a guarantee of uninterrupted and durable network operation. The process is quick and easy due to the fact that polypropylene products are chemically neutral.

Types of material for making polypropylene fittings

PP pipes and fittings can be made using polypropylene of different composition, which affects the thermal stability of the product. Depending on this, there are three modifications of the starting material: homopolymer, random copolymer and block copolymer.

The first type of products is marked with PPH or PP-1. The elements are made of polypropylene with the addition of modifying additives in the form of fire retardants, nucleators and antiseptics, due to which the final product has certain properties. Such pipes and fittings are used exclusively for the installation of the cold water supply network.

The second type of polypropylene pipes and fittings is marked with PPCR, PPR, PP-3. The material has a crystalline structure, which allows products to withstand a large temperature range (from -170 to +1300 ° C) without violating the integrity of the structure. This type of PPR pipes and fittings belongs to the universal class and can be used for the installation of any engineering communications.

Products made of block copolymer are designated RRB, RR-2, RR-C. For their manufacture, a polymer is used, consisting of homopolymer micromolecules, which are arranged in a certain order. These products are characterized by increased impact strength, the ability to withstand high temperatures without violating the integrity of the material, good resistance to bending and abrasion, low vapor and gas permeability, excellent dielectric qualities. This type of pipes and fittings is ideal for organizing a hot water mains network.

In the characteristics of polypropylene, there is such a parameter as MRS, which indicates the lowest durability. This indicator determines the maximum allowable pressure in the system, at which pipes and fittings can last about 50 years when transporting water with a temperature of 20 ° C. This characteristic depends on the wall thickness of the products.

The maximum allowable pressure can be found by the numerical value added to the abbreviation PN. The larger this indicator, the higher the pressure the pipe and fitting can withstand.

Varieties and diameters of polypropylene pipes

Polypropylene pipes and fittings can be classified according to the nominal fluid pressure in the system. There are four groups of fittings: PN10, PN16, PN20 and PN25. The first class includes products with a small wall thickness. They are able to withstand pressure up to 1 MPa and temperature of the transported liquid up to 45 ° C. Products are produced with a diameter of 20-110 mm, have a wall thickness of 1.9-11 mm. Such elements are ideal for the installation of a low-temperature heating system such as "warm floor".

The marking of polypropylene pipes PN16 indicates that the products are designed for a coolant temperature up to 60 ° C and a working pressure in the system up to 1.6 MPa. You can use such PP pipes and fittings for high pressure water supply. Products are produced with a diameter of 20-110 mm, wall thickness - 1.9-11 mm.

The third type of elements is designed for operating pressure in the system up to 2 MPa. The temperature of the pumped liquid can reach 80 ° C. The pipes are produced with a diameter of 10-73 mm and a wall thickness of 1.6-11 mm. These products can be safely used to equip water supply and heating systems.

The last type of pipes, marked PN25, defines elements that are able to withstand pressure up to 2.5 MPa and a coolant temperature up to 95 ° C, which is carried out due to the reinforcement of elements with aluminum foil. The dimensions of the polypropylene fittings and the dimensions of the pipes are in the range of 21.5-78 mm (diameter), the wall thickness is 2.7-16.4 mm. Such products can be used for the installation of a heating system and a hot water supply line.

The pipe diameter is selected based on the throughput and temperature resistance of the pumped medium. Depending on this, products with a diameter of up to 25 mm should be selected for the internal wiring of the cold and hot water supply system. For an external network, elements with a size of 40-100 mm are suitable. At the same time, for cold water supply, a section of 20-40 mm and a wall thickness of 1.9-11 mm are sufficient, and for hot water it is worth purchasing products with a diameter of 20-100 with a wall size of 2.8-15 mm.

Helpful advice! To create a reliable and durable system, you should choose pipes and fittings with higher performance than those stated.

For internal sewage, products with a diameter of 32, 40, 65, 63 and 75 mm are used, and for an external one - at least 100 mm. The heating system is laid using elements with a cross-section of 16-75 mm with a wall thickness of 3.4-10.5 mm, which is determined by the dimensions of the room and the type of boiler.

Fittings for polypropylene pipes: an overview of fittings

For the installation of water supply, sewerage and heating systems, it is necessary to purchase different types of fittings for polypropylene pipes, due to which the connection of network sections, branches, transitions, contours, connection to plumbing fixtures is carried out. Fittings are represented by bell-shaped elements, as a result of which they are put on the end of the pipes, which are preheated with a welding iron. The sizes of fittings in mm for polypropylene pipes are selected, according to the dimensions of the products.

Important! PP pipes and fittings for them must be made of the same material, designed for the same pressure and temperature of the transported liquid.

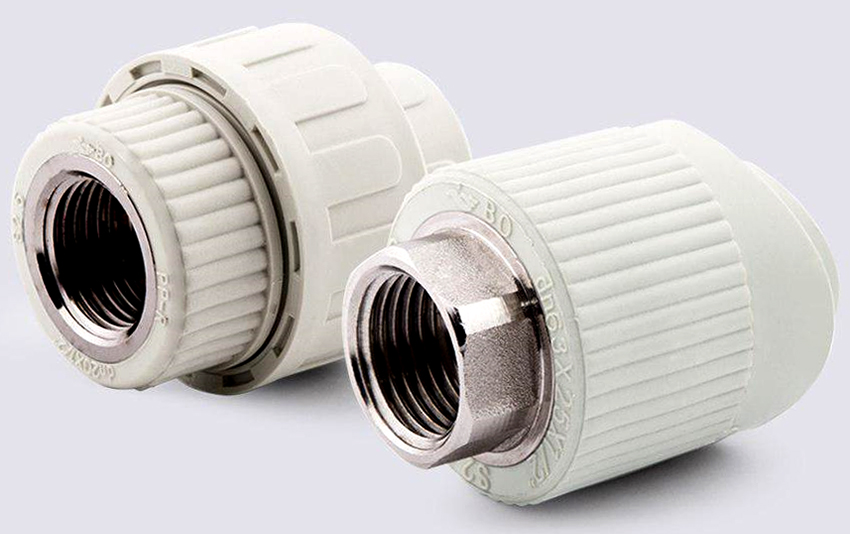

Polypropylene fittings can be completely made of plastic or combined, in this case metal inserts with an external or internal thread are pressed in. The first type of products is used for any method of laying the line, including hidden. Such fittings are characterized by increased strength, while having a higher cost. The elements of the system are connected by soldering, which ensures reliable and tight seams.

Combined products combine metal with polypropylene. Fittings of this type are used exclusively for open installation or with a combined method of installation, involving the partial installation of false panels, covering with tiles, decorative grilles or drywall, which is necessary to monitor the condition of the joints.

It is also important to know what kind of fittings for polypropylene pipes are according to the principle of execution. Shaped elements are divided into cast and segmented. The first option is represented by a one-piece product, which is characterized by maximum strength and reliability. Segment fittings are made up of individual polypropylene elements that are soldered together. Such products have a large number of seams, which reduces their reliability, durability and cost.

Types of fittings for polypropylene pipes with the name

To connect two pipe sections of the same diameter, special couplings for polypropylene pipes are used, which have thickened walls.Products are produced with a section of 20-160 mm. The coupling should be inserted into the pipe with some effort. In this case, it is necessary that the pipe sections are absolutely smooth. Before installation, the product is tried on, which fixes the pipe until it stops. It is subsequently heated with a low-temperature soldering iron and sealed to the fitting.

Helpful advice! Before installing a system of polymer elements, you should study the information on how to use an iron for polypropylene pipes.

If it is necessary to do the joining of two elements having different sections or made of different materials, transition couplings with an external or internal thread are used for the latter option. Products have different diameters - in the range of 20-75 mm, which can be learned in more detail from special tables of sizes of fittings for polypropylene pipes, which are easy to find on the Internet.

To connect a polypropylene pipe to a flexible hose, fittings with a union nut are used. To change the direction of the pipe, elbows and corners are used that provide a 45 or 90 ° rotation. They can be straight (for connecting elements of the same section) or transitional with an internal or external thread, with or without a union nut. The sizes of fittings for polypropylene pipes are in the range of 20-160 mm.

To connect faucets, water sockets are often used, which are additionally equipped with special hinges designed to be fixed to the wall. If pipelines cross each other or to overcome other obstacles, bypasses are used, which can be short, medium and long. Such products will allow you to change the direction of the line smoothly - with a more round bend.

Important! With the help of contours, you can turn the line by 120 °.

Other types of fittings for polypropylene pipes

To execute branches in one direction, polypropylene tees are used, which are produced in the form of straight, transitional, one- and two-plane, collector products. The latter option is more convenient due to the detachable connection.

For branching the main pipe in two directions, polypropylene crosses are used, which can be one-, two-plane and coplanar. The latter type of products allows you to dock polypropylene pipes located in the same plane, without the use of bypasses and bends. This solution contributes to the preservation of free space and gives the structure a more aesthetic appearance.

Polypropylene filters are often installed to protect the pipeline from dirt, rust and mechanical impurities. In order to prevent the reverse flow of fluid in the system during a water hammer or stopping the operation of plumbing equipment, check valves with a threaded plug are mounted on the line, which makes it possible to clean the mechanism. They are installed in front of water meters, boilers and water heaters.

To protect the pipeline from deformation changes in the event of a pressure or temperature drop, it is advisable to install expansion joints for polypropylene pipes. They are represented by bent pipe sections in the form of a loop. Compensators for polypropylene pipes are mandatory when arranging a heating and hot water supply system. To cover dead-end sections of the network, plugs, caps and plugs with and without thread are used.

Helpful advice! Plugs can be used when testing the system at any stage of its installation.

The fluid flow is regulated by means of valves.The plaster version of the product is used for hidden installation of the system. The radiator valve is used to connect the line to the radiator, thus eliminating the need to operate the combined coupling.

It is possible to completely close or open the section of the pipe using a ball valve, which has two positions. Such a device is more durable, but if it malfunctions, the product will have to be changed completely.

Related article:

PVC pipes for water supply: features of application and installation

Sizes of plastic pipes for water supply and their correct connection. Creation of a summer water supply system at a summer cottage from plastic pipes.

Characteristic features of American women for polypropylene pipes

Another name for a fitting for polypropylene pipes, made in the form of a split coupling, is American. Such elements are additionally equipped with union nuts. American women are used in systems that need periodic removal of elements to clean them. These fittings are often installed in front of the meters.

The installation of the American is easy and quick, which is carried out by tightening the nut. This not only facilitates installation, but also makes it possible to instantly shut off the pipeline in the event of leaks. This type of fitting is convenient to use when replacing a network section or inserting new entries. In this case, the pipes are not destroyed due to their rotation, since they remain immovable.

Fittings-American for polypropylene pipes are convenient to use for joining system elements in hard-to-reach places. Such fittings are equipped with their own seal, which eliminates the need for additional gaskets, and the tightness of the connection is quite high.

Important! American is considered a universal type of fitting and can be used as a coupling, adapter, plug and shut-off element.

Polypropylene American women, depending on the design, come with an internal or external thread, with a union nut and a soldering end, as well as combined. The thread can be tapered and cylindrical. The first option provides a high tightness of the connection without the use of additional gaskets, it resists the effects of aggressive media and temperature changes. American women with cylindrical threads need to use seals. Such assemblies require periodic inspection with the possible replacement of a worn out gasket.

Fittings for reinforced polypropylene pipes

To connect reinforced polypropylene pipes, extruded and compression fittings are used, which are made in a brass body.

You can solve the question of how to make a detachable connection of polypropylene pipes using a compression fitting. The product consists of a body, a union, a compression nut and O-rings. The connection between the pipe and the shaped element is ensured by squeezing the sealing material while pressing the pipe. For this, an adjustable or open-end wrench is used, with the help of which the nut is tightened. The connection is characterized by reliability and durability. It can withstand pressures up to 35 bar. The period of operation is about 30 years.

Important! It is advisable to use compression fittings with an open installation of the system, where it is possible to observe the connection and periodically tighten the nuts if necessary.

The connection of polypropylene pipes without soldering is performed using press fittings. Such fittings are represented by a body and a union with a crimp sleeve. To make a hermetic connection, you will need a special tool in the form of pliers.A system with such fittings is able to withstand high pressures up to 75 bar, having a service life of about 50 years. It can be laid both open and closed inside monolithic structures.

Leading manufacturers of polypropylene pipe fittings

For the reliability and durability of the system, it is advisable to purchase PP pipes and fittings from one manufacturer. The following companies have proven themselves well in the industry.

One of the best manufacturers is the German company Banninger Kunststoff-Produkte, which manufactures fittings from high-quality plastic, due to which the products are characterized by increased strength, chemical inertness, and the ability to easily endure freezing. Fittings of this company are used for the installation of water supply and heating systems, and have a high price in comparison with analogues.

The Russian-Italian manufacturer Valtec produces polypropylene fittings with a tapered socket, which greatly simplifies the installation process. The company offers a wide range of products that are soldered or threaded. The maximum size of a polypropylene fitting is 50 mm.

The Czech company Wavin Ecoplastic produces various connecting elements made of neutral propylene. Pipes and fittings from this manufacturer are ideal for arranging a drinking water pipe. The Turkish company Tebo specializes in the manufacture of fittings with a diameter of 20-160 mm, which are able to withstand pressure in the system up to 25 bar. The products of another Turkish company, Kalde, are characterized by high quality performance of straight and transitional products of different cross-sections, which can be used for the installation of water supply and heating systems.

Special features of fittings for HDPE pipes

Low pressure polyethylene is a type of polymer that is environmentally friendly, resistant to chemicals, able to withstand temperatures up to 80 ° C, abrasion resistance, high density, dielectric properties, good elasticity, which reduces the likelihood of damage due to water hammer. It is advisable to use this universal type of products for arranging cold water supply systems, sewerage systems, transporting gaseous and liquid substances, as well as combustible gases.

Helpful advice! There is a special type of polymer, the so-called cross-linked polyethylene, which is characterized by increased thermal stability, due to which it can be used for the installation of heating systems.

HDPE pipes and fittings are able to withstand pressure in the range of 6-16 atm. Products are distinguished by a long service life, ease of installation and affordable cost.

Fittings for polyethylene pipes are produced in several types. To connect the parts of the system, equal-bore, compensating elements can be used, providing a transition from a larger diameter of products to a smaller one, and flange couplings (from a smaller section to a larger one).

Varieties of fittings for low pressure polyethylene pipes

Adapters are used to attach the valves to the system. This type of fitting is used when connecting pipes made of different materials. To change the direction of the line, bends with an angle of 45, 60 and 95 ° are installed. Tees and crosses are intended for branching.

To create a secondary branch on the main line, saddles in the form of a clamp, crimp-type elements and linings are required, which are attached to the pipe by means of electrodiffusion welding.Such products are used for tapping new parts into the existing manifold and are often represented by fittings for 32 and 40 mm HDPE pipes.

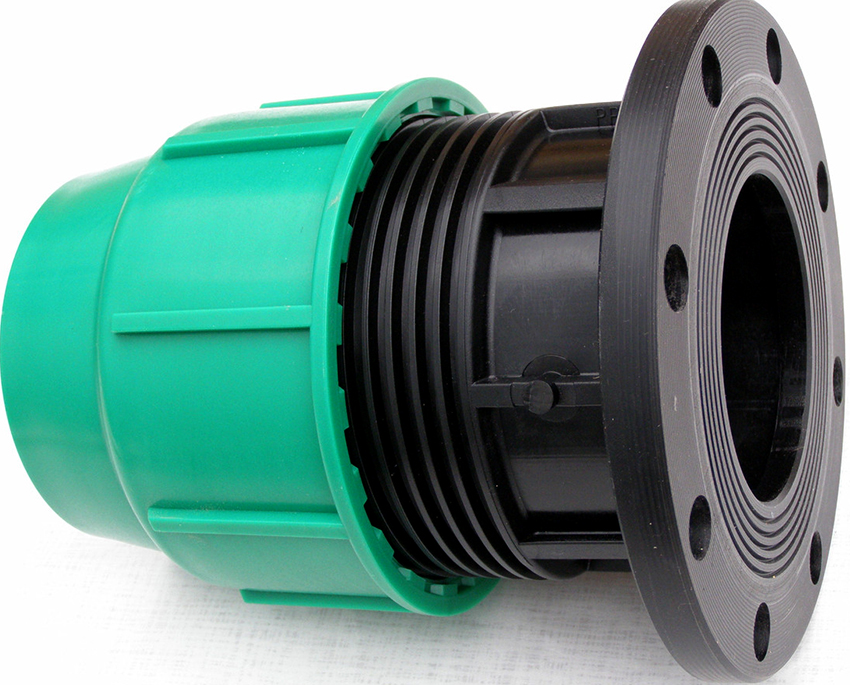

Depending on the connection technology of the system elements, fittings for HDPE pipes can be one-piece, fixed with a welding machine, and detachable, which are mounted using plumbing keys. The second type of products is represented by compression, crimp, threaded, flange and press fittings.

One-piece products are intended for the arrangement of an external water supply system. Installation of compression fittings for HDPE pipes is carried out by means of a union nut, and the reliability and tightness of the connection is ensured by an O-ring. Threaded fittings are purchased for non-pressure systems and for joining cable channels.

Flange elements are used when connecting a plastic pipeline with a metal one. These products consist of a steel flange and a sleeve. The first part is fixed with studs or bolts to the counter flange, which is welded to the metal pipe, and the second is joined to the plastic section of the line.

Features of using fittings for PVC pipes

Another type of polymer products are polyvinyl chloride pipes. They have found their application in the installation of cold water supply and sewerage systems. The material is characterized by strength, non-combustibility, good dielectric properties, high density, and an increased level of rigidity. PVC pipes withstand the temperature of the transported liquid up to 65 ° C. A strong impulse effect on the pipeline may damage it.

Fittings for PVC pipes have the same qualities as the material itself. Polyvinyl chloride elements can be used to create both indoor and outdoor water supply and drainage systems.

For the organization of the latter, products are used made of plastic of a special modification - unplasticized polyvinyl chloride (PVCVC), the material has a high level of mechanical strength. A system that includes such elements is capable of withstanding high pressure, which is especially important for external pressure water supply and sewerage networks.

Important! For the installation of external systems, only cast fittings are used, and for the internal network, segment variants of fittings can be used.

Varieties of polyvinyl chloride fittings

Depending on the method of connecting PVC pipes and fittings, fittings can be adhesive, threaded, detachable, designed for soldering and combined. The first type of fittings is fixed to the pipe using cold welding. PVC elements have sockets, into which the ends of the pipes enter with a minimum gap, which are processed with special glue.

Threaded fittings are attached using a tube equipped with an external thread and a nut. Elements are made of a harder polymer, which is characterized by a lower coefficient of elasticity. This technical solution provides a high density of the threaded connection.

Detachable fittings are mounted using elastic rubber couplings. Such products are not able to withstand high pressure. It is advisable to use them for the installation of a gravity drainage system. Solder fittings provide a reliable and tight connection by using a low temperature apparatus.

In combined versions, on one side of the product, a branch pipe is glued, and on the other side of it, a threaded connection is applied using a union nut.This option is used in places with increased requirements for tightness and mechanical strength of fasteners.

Depending on the performance characteristics, fittings for PVC pipes are pressure-free (for water supply systems), non-pressure (for sewers and storm drains) and used for discharged media. According to their purpose, PVC fittings are divided into connecting, branching and regulating.

Polypropylene is considered a versatile polymer. With the help of products made of polypropylene pipes with your own hands using fittings, you can equip various engineering communications. Elements made of HDPE and PVC have some limitations in the field of application, which is related to the technical characteristics of the material. To create a reliable and durable system, it is necessary to purchase fittings and pipes from the same material, and also an important criterion is the correct choice of the method of installing network elements.