Today, for the installation of utilities, plastic and metal-plastic pipes are most often used, which displace metal products. This is due to the reliability, durability and easier laying of elements. To connect individual products, fittings for plastic pipes are used. They not only contribute to the sealing of joints, but also make it possible to create systems of any complexity and configuration.

Content [Hide]

What are fittings: characteristics of connecting elements

Fittings - what are they? These are the structural elements of the pipeline system, which are used for the installation of highways, arrangement of different turns, branches, transitions between different types and diameters of pipes. Thanks to such fittings, the assembly process of the system is quick, while a reliable and tight connection of its component components is created.

Fittings must provide a high degree of strength of the connection, do not impede the free passage of liquid, do not lose their original properties when the pressure in the system and the temperature of the transported medium change, be easy to install, have wide distribution and an acceptable cost.

Plastic pipes and fittings for water supply, sewerage and heating systems are made of polyethylene, polyvinyl chloride, polypropylene and metallized plastic. Products are characterized by low weight, ductility, corrosion resistance, dielectric properties that increase the safety of use of the material, low thermal conductivity, chemical inertness and ease of installation. For PVC fittings, there are certain restrictions on the temperature and chemical composition of the liquid that is transported.

Important! When installing the system, pipes and fittings must be made of the same material, which will ensure the reliability and durability of its operation.

Plastic pipe fittings are widely used for laying plumbing, sewerage and gas systems.When installing networks of plastic elements, you can do without welding, which greatly facilitates the installation process, making it possible to carry out it in difficult, inaccessible places.

Fittings: these are mandatory elements of systems for various purposes

In order to understand in more detail the question of what pipe fittings are, it is necessary to consider the types of products. The fittings are characterized on the basis of configuration, purpose, design features and installation method.

Depending on the installation option, plastic pipe connections are compression, cast and electrowelded. The first type of fitting consists of a body, an O-ring and clamping ring, a nut and a sleeve. The principle of operation of the part is as follows. The O-ring is held in place by a sleeve. To prevent unwinding of the device, its depressurization during vibrations and water hammer, a clamping ring is used. Thanks to the push-off fittings for sewer pipes and water supply, a high level of tightness of the system is provided, which does not decrease even if the pipeline is kinked.

This type of shaped elements is presented in a wide variety of species, which makes it possible to select a part that is suitable in terms of diameter and purpose. Installation is quick and easy. Compression fittings can be reused.

Cast fittings are monolithic elements made of dense material, which contributes to the strength and reliability of products. Their installation is a guarantee that there are no leaks in the system. Installation is carried out by means of shaped welding.

Important! Cast fittings are used when laying a system from PE100 pipes.

The electrowelded type of connecting elements is made of polyethylene and is distinguished by the presence of terminals inside the products, which serve to connect the welding machine. Under the action of the equipment, the terminals are heated, while the fitting is melted, which is firmly connected to the pipe during reflow. This type of shaped elements is widely used not only in domestic mains, but also in industrial pipelines.

Important! For plastic pipes, fittings for metal-plastic products can be used, which is not allowed in the reverse order.

Design of pipe fittings

Depending on the structure, plastic pipe connectors are straight flanged, made in the form of a tee or a branch. Products can have a thread, with which they are installed, or be without it. Shaped elements can be divided into collapsible and non-collapsible. When using threaded fittings, a special tape or flax is used to seal the connection, which is screwed onto the thread.

The design features of fittings directly affect their purpose. Depending on this, fittings are distinguished in the form of adapters, couplings, bends, crosses, tees, corners, compensators, American women, control valves, plugs with plugs. Each type of plastic element has different sizes, which allows you to select parts for engineering communications of a certain diameter.

The simplest shaped element designed to connect two parts of a pipe is a coupling, which is represented by a cylindrical segment. It can be used for soldering (it must be made of the same material as the pipes) or used to transition from a smooth pipe section to a corrugation.

There are several types of couplings. Connecting plastic fittings are used when brazing a pipeline of the same material.Another type of shaped element can be designed to connect two sections, one of which is joined by soldering, and the other by means of a nut. The third type of couplings is represented by fittings for plastic sewer pipes, used to switch from a rigid section of a pipeline to a corrugated one. The fourth type includes adapter couplings, the so-called American.

An American woman is often used to connect a plastic pipe to a metal one or to connect plumbing elements to a water supply system. This fitting is a one-piece non-separable structure. The American woman is able to ensure reliable sealing of the connection thanks to a special cone with a rubber or silicone O-ring. This type of fitting can be straight or angled, with an external or internal thread.

Adapters for PVC and PE pipes are similar in appearance to couplings. They serve to connect two sections of pipes of different diameters, which is achieved due to the fact that the elements have unequal end sections. On adapters for sewer pipes of different diameters, there can be an internal or external thread.

Fittings for plastic pipes of various designs

Angles are used in the system to turn the flow movement. Pipes are connected using an element at a certain angle. They are also often used to connect plumbing equipment. Products are produced with an angle from 45 to 90 °, have an external or internal thread. There are combined elements that allow you to combine parts of the line of different cross-sections. Plastic pipe corners not only serve to rotate the system, but also protect it from stress and excessive tension.

Important! Elbow fitting eliminates the need for additional adapters.

For joining several lines, crosses and tees for plastic pipes are intended. Such shaped elements are presented in a wide variety of species. Their ends can have a different cross section and type of thread for connecting pipes made of heterogeneous materials. Depending on this, a distinction is made between bushing and equal bore options. To bypass all sorts of obstacles in the trunk system, contours are used.

Taps and valves are used as shut-off and control valves for a structure made of plastic pipes. Products are produced in the form of manual and thermostatic elements. Fittings can be classified according to their tightness level and application. The valves are characterized by a high degree of tightness. The most convenient type of shut-off and control valves is the American crane, which can be mounted or dismantled without disassembling the system.

Important! When choosing shut-off and control valves, the manufacturer's instructions on the scope of use of the device should be strictly observed, since a cold water tap cannot be installed on a hot water supply pipeline.

Plugs are dead-end elements that are connected to the pipeline by means of threads or soldering. They reliably protect the system from the penetration of dirt and foreign objects. Caps can be used in tandem not only with pipelines, but also with other options for fittings for plastic pipes. In addition, such elements in the future allow for the modernization of the system with the addition of new sections.

Features of fittings for connecting metal-plastic pipes

Reinforced-plastic pipes and fittings are widely used for the installation of hot water and heating systems.This distribution is caused by the fact that the MP pipeline is made of heat-resistant cross-linked polyethylene, in the inner cavity of which there is an aluminum sheath, due to which the material is able to withstand the temperature of the pumped liquid up to 95 ° and the pressure up to 15.2 bar. Reinforced-plastic pipes and fittings for them are characterized by durability: their service life is at least 50 years.

No welding is used to connect metal-plastic pipes. Docking of individual elements of the system is carried out using compression, push fittings and press fittings for metal-plastic pipes.

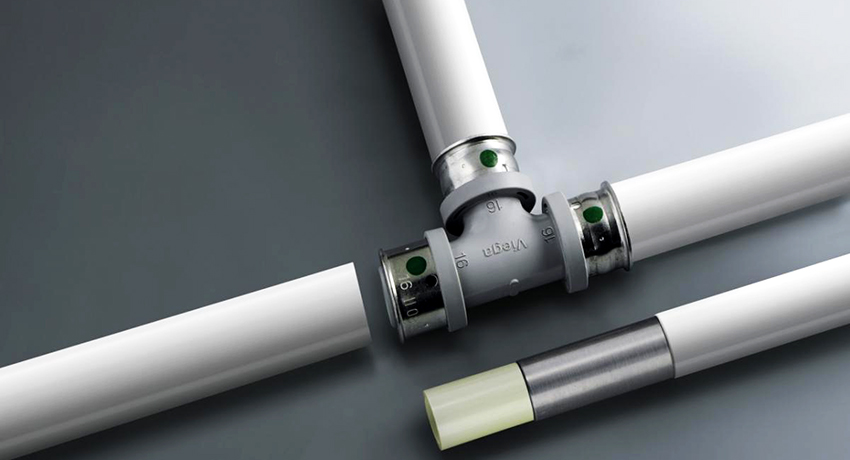

The last two options are new engineering developments. The connection of system elements by means of push fittings is carried out in a matter of seconds. This type of reinforced plastic fitting consists of a body, retaining shoe and ring. The first element is made of polyphenylsulfone or non-ferrous metal. The product has the shape of a corner, a cross, a tee, and is also used as a coupling.

The retaining block is made from the same material as the body. It is fixed on its slip ring, which makes it possible to obtain a non-separable connection. There are disc and spacer rings between the body and the block, which ensure reliable fastening.

Features of push-fitting for metal-plastic pipes

The push-fitting inlet is inserted into the pipe, which is accompanied by a characteristic click. This indicates the reliability of fastening the reinforcement. Its feature is the ability to rotate 360 ° around its axis.

This type of connection for plastic pipes with an aluminum sheath can be used for the installation of heating networks, pipelines for cold and hot water supply, and floor heating systems, providing high reliability, tightness of connections and durability of the structure. The use of such fittings contributes to the quick installation of the system, since the fixing of the elements is carried out without the use of a special tool, which even a novice master can do. Work can be performed in restricted access conditions.

Push fittings can withstand temperature fluctuations and high temperatures, up to 90 ° C. Such connections are able to withstand many freeze / thaw cycles of the system without loss of tightness. These elements are recyclable.

The disadvantages of such fittings for plastic water supply pipes with an aluminum sheath include their high cost. O-rings are able to take the required position, ensuring the reliability and tightness of the connection, after three hours.

Features of compression fittings for connecting pipes

If the question arises of how to connect two plastic pipes of the same diameter, it is worth considering a compression fitting, which consists of a union, a ring, a union nut and a gasket. The first element is inserted into the internal cavity of the pipeline. It is predominantly made of galvanized brass. Grooves are made on the surface of the product, where inclined ribs and sealing rings are inserted, which prevent the connection from opening.

The forcing ring is equipped with a diagonal slot and a ribbed inner surface, which improves the contact between the fitting and the pipe. The element is made of non-ferrous metal. The union nut is made of galvanized steel. It presses the forcing ring against the fitting through the pipe sheath.For the reliability of the connection, a fluoroplastic or Teflon gasket is used, which is put on the fitting, contributing to high-quality insulation.

Related article:

Fittings for polypropylene pipes and other types of polymer products

Varieties of fittings according to configuration, scope of use and installation method. Leading manufacturers of fittings.

When installing compression fittings for plastic water supply pipes, no special tools are required. The process is done manually. Since this type of fittings is a dismountable joint, it can be used repeatedly. The service life of such a system is about 10 years. It needs constant monitoring of the state of the connections.

As a result of pressure drop and temperature fluctuations in the structure, self-loosening of the union nut can occur, which will cause a leak. Therefore, this type of fitting for a metal-plastic pipe is recommended for outdoor installation of the system.

Special features of crimp press fittings for multilayer pipes

Compression press fittings are represented by elements that consist of a body, a sleeve and a ring. The body is made of bronze or brass, often has a galvanized coating. Depending on the purpose, the element can differ in different designs and be presented in the form of a corner, plumbing adapter, tee, cross or water socket.

A sleeve is used to fix the body in the pipe cavity. The element is made of stainless steel AISI 304. It is usually inserted into the body of the fitting. However, there are options for which the sleeve is separately. Before fixing, it is inserted into the grooves of the main element. To control the depth of immersion of the pipe in the fitting, some models are equipped with inspection windows, which are located on its body.

The ring serves to securely connect the sleeve and the body, acting as a gasket. The part prevents the occurrence of low voltage currents.

Important! With the help of press fittings, they create a reliable and tight connection of system elements, therefore they are recommended for use when laying water and heating mains in the walls of a building.

Before connecting plastic pipes using press fittings, it is necessary to prepare a special tool in the form of press tongs, which even a master with little experience can handle. At the same time, work takes a minimum of time. As a result of the use of such products, high strength and tightness of the connection of individual elements of the system is ensured, capable of withstanding a pressure of more than 10 atm. The service life of press fittings reaches 50 years.

Such a structure does not require constant maintenance and control, therefore it can be implemented for laying communications in a hidden method in concrete screeds. Press fittings are resistant to linear expansion of metal-plastic pipelines, which can occur during temperature fluctuations of the transported medium and pressure changes. These fittings reduce the installation costs of the system, which is explained by the reduction in pipe consumption and a decrease in the number of fittings used.

The main disadvantage of press fittings is their unsuitability for reuse, since these elements can only be dismantled together with a part of the pipe.

Connection of plastic pipes of large diameter and small section

The connection of plastic pipes can be detachable, where it is assumed the use of special fittings and heating sleeves, as well as one-piece, which is carried out by welding.The second option is used mainly for large diameter pipelines. This requires a special installation. The ends of the pipes are inserted into it, which are heated and joined together, forming a reliable and sealed seam. For pipes with a small cross-section (up to 110 mm), various fittings are used, photos and information about which were given above.

Heating sleeves are used when carrying out repair work on large-diameter pipelines. A heater is built into the product. When an electric current is applied to it, the plastic heats up and fusion.

The choice of the connection method is also determined by the material for the manufacture of plastic pipes, which can be made of polyvinyl chloride, polypropylene, polyethylene and metal-plastic. Before connecting PVC pipes, a special adhesive should be prepared, which is applied to the edges of the products. After that, their adhesion occurs with a rotation of 25 ° in different directions relative to each other. Compression, press and push fittings are used to connect metal-plastic pipes.

Polypropylene products are joined by welding or using solder plastic pipe fittings. Polyethylene elements are connected using compression fittings. In addition, the creation of a system of plastic pipes with push-in fittings is widespread.

Installation of a structure made of plastic pipes through fittings is carried out in the following sequence. The ends of the pipes are cut at an angle of 90 ° relative to the axis with further cleaning of the surface from dirt and burrs. The pipe ends are chamfered, which eliminates the risk of material scuffing when installing the fitting. A mark is applied to the surface of the pipe, beyond which the end of the fitting should not go. The plastic pipe is inserted into the shaped element up to the stop, followed by fixation with a nut.

Helpful advice! The end of the pipes can be treated with liquid soap, making it easier to fit into the fitting.

Plastic fittings for PVC, PE and MP pipes are presented in a wide variety. They are used to connect sections of the system, make various branches, turns, transitions between network elements of different diameters and materials. Installation of parts is quick and easy, while creating reliable and tight seams.