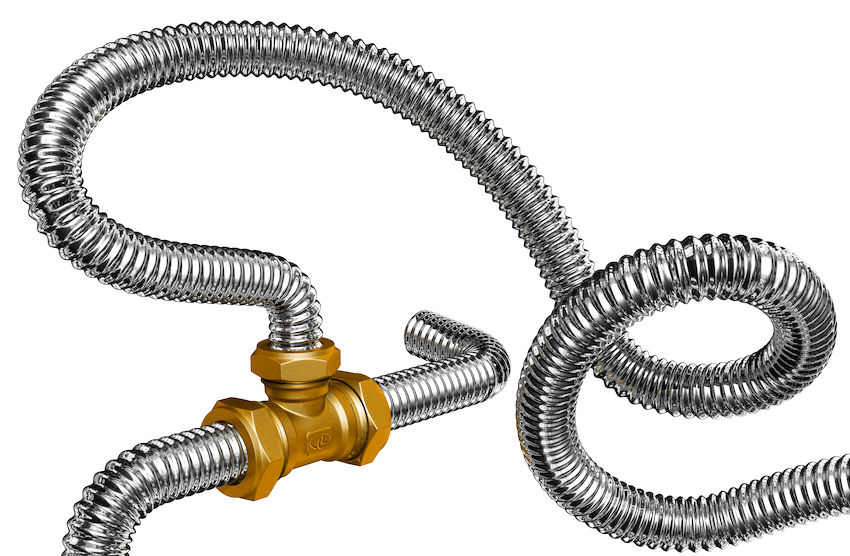

Corrugated stainless steel pipe has become a real breakthrough in plumbing engineering. Thanks to a number of advantages and a wide range of applications, this innovation has rapidly gained popularity in construction. It is used to lay a variety of communications. Practicality and flexibility allow the use of corrugation in a variety of, even the most difficult conditions. More details about this type of product can be found in this article.

Content [Hide]

- 1 Corrugated stainless pipe: the history of invention

- 2 The main advantages of flexible stainless steel pipes

- 3 Corrugated stainless steel pipe: product classification

- 4 Corrugated Stainless Steel Pipe Fittings

- 5 Corrugated stainless steel pipe installation technology

- 6 Popular manufacturers and price of stainless steel pipes

- 7 Tips for the selection and installation of a corrugated stainless steel pipe

Corrugated stainless pipe: the history of invention

An invention such as a stainless steel corrugated pipe appeared at the end of the twentieth century. Its authors are Japanese scientists who were looking for the best option for laying communications in conditions of increased seismic activity on the islands. This is how a versatile product appeared that combines the flexible qualities of rubber and the strength of steel. It took world experts quite a bit of time to come to the general conclusion that flexible metal pipes have a number of advantages over their counterparts made from cold-rolled sheet steel, as well as over polypropylene and metal-plastic pipes.

In this regard, almost immediately after the invention of corrugated pipes, their serial production began in Germany, and then in South Korea, which is currently the leader in the production of flexible stainless steel pipes. The Korean company "Kofulso" belongs to the well-known companies engaged in their manufacture. Due to the popularity of the brand, the metal corrugation is also referred to as the cofulso pipe. Gradually, enterprises in different countries began to specialize in the production of corrugated products, and their use became ubiquitous in the installation of engineering networks and other communications.

Features of Corrugated Stainless Steel Pipe

Thus, flexible stainless pipes gradually replaced steel and polypropylene structures, as well as metal-plastic communications used in the creation of plumbing, heating, ventilation and even gas systems. The strength of the material is ensured by the fact that only high quality stainless steel with impurities of nickel, chromium and carbon is used in the production process.

Interesting to know! The concentration of additional elements such as nickel, chromium and carbon in the alloy is calculated with extreme precision. This guarantees the strength, durability of the corrugated pipe and its corrosion resistance.

The manufactured material must comply with a certain list of characteristics that guarantee certain product quality standards, in particular:

The strength of the material is ensured by the fact that only high quality stainless steel is used in the production process

- Normal working pressure is 10 atmospheres with a permissible maximum load of 60 atmospheres.

- During operation, the corrugated stainless steel pipe withstands the temperature of the passing substance from 0 ° C to 100 ° C. In this case, the maximum limit can reach 150 ° C and higher.

- Pipelines for the organization of construction work and individual repairs, depending on the scope, are produced with a diameter of 15, 20, 25, and 32 mm.

Stages of production of corrugated stainless steel pipe

The versatility and high quality indicators of stainless steel corrugations are due to strict adherence to the technology of its manufacture, which, surprisingly, is quite simple. The production process itself includes the following stages:

- The pipe is formed using a special steel tape.

- Workpieces are cooked using tungsten electrodes. At this stage of production, special automatic TIG equipment is used. The process takes place at high temperatures, which can reach 1150 ° C.

- The reliability of the seams is checked on a special laser installation.

- Corrugation is formed using special shafts of various diameters.

- Heat treatment of parts is performed. Different types of pipes lend themselves to a certain degree of temperature exposure, since the annealed pipe has a higher degree of flexibility.

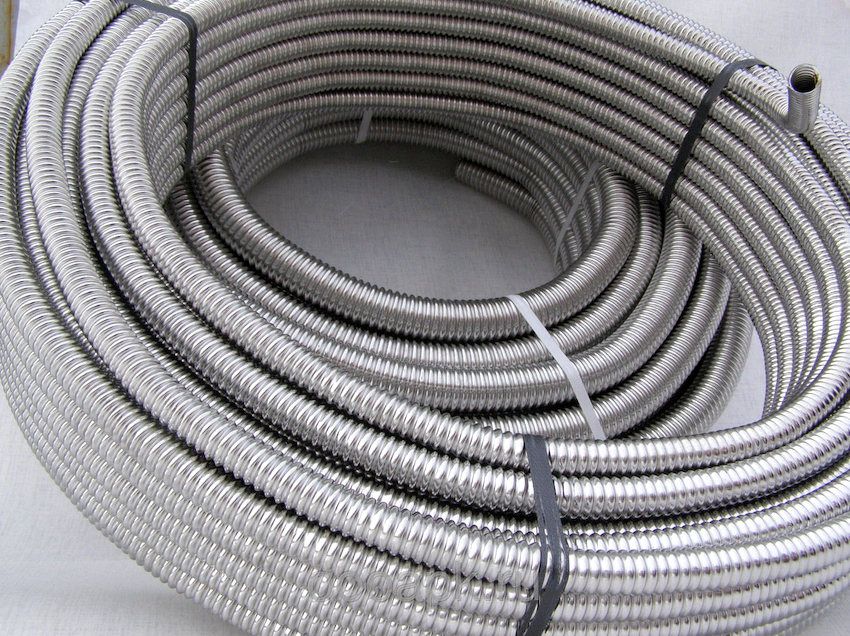

- Products are packaged. The pipes are divided into sections of a certain length. Products with a small diameter are rolled into coils, and thick parts are packed in groups.

- They check the quality and filter out defects in the form of products with microcracks. For this purpose, a metal corrugated pipe is placed in a liquid under high pressure. At the same time, a special device is attached to each bay and the pressure is gradually increased to 10 atmospheres, then it is gradually reduced.

The main advantages of flexible stainless steel pipes

The special design in the form of a corrugation provides this type of pipes with a high degree of flexibility at different bending radii, which does not entail a narrowing of the flow and does not lead to deformation of the product. Moreover, after unbending, the pipe does not bend, but takes on its original flat appearance. Installation of a corrugated stainless steel pipe does not require special efforts and the organization of additional manipulations using bending equipment. In the process of work, you only need fittings to connect parts and special fasteners.

In addition, the stainless steel pipe provides a high degree of wear resistance. Products can be operated over a wide temperature range. In this case, the minimum indicator is -50 ° C, which allows substances with a low temperature, for example, liquid nitrogen, to be passed through them.The upper temperature mark can reach 150 ° C.

Important! The boundary temperature indicator is not dictated by the pipe itself, but by the plastic parts of the fittings, which cannot withstand higher temperatures. The pipes themselves remain intact at a load of 800 ° C.

Corrugated steel pipes are also valued for their ability to withstand large pressure drops. On average, the product limit reaches 50 atmospheres, and special stainless steel tubes are able to withstand a load of 210 atmospheres.

Thus, corrugated pipes have the following advantages:

- strength and durability;

- flexibility;

- resistance to pressure and temperature changes;

- stainless steel pipe prevents corrosion if exposure to aggressive substances is avoided;

- do not require special maintenance, so they can be mounted inside walls and floors;

- do not need cleaning, as no deposits form inside.

List of disadvantages of corrugated flexible pipe

In addition to the listed technical characteristics, it is worth mentioning the convenience of transportation, storage, installation of structures, as well as the advantages of the pipe during operation, which consists in environmental safety, resistance to the effects of rodents, the appearance of fungus and mold. At the same time, do not forget about the weak points that this versatile and practical product has, the main ones are as follows:

- Due to the small thickness of the pipe walls, there is a risk of damage in places where strong impacts are likely. Therefore, as a precaution, sometimes a protective cover should be installed.

- The high degree of heat transfer, characteristic of a corrugated stainless pipe, will be a plus for heating, but in places of heat supply, installation of thermal insulation will be required in order to save thermal energy.

- A corrugated surface is difficult to clean, so a simple sponge or cloth will not work here - you need to do this with a special brush.

- Corrugated stainless steel, despite all its anti-corrosion properties, can still be unstable to the effects of a number of substances, as well as subject to electrochemical corrosion, therefore, during its installation in such places, it is necessary to use neutralizing screens. In order to protect against stray current, it is worthwhile to provide grounding and install dielectric gaskets.

- The appearance of corrugated pipes is not very attractive, and therefore it is advisable to hide them behind the decoration on the walls, and the radiators should be covered with decorative panels.

Due to the small thickness of the pipe walls, there is a risk of damage in places where strong impacts are likely

Corrugated stainless steel pipe: product classification

Corrugated stainless steel pipes have their own classification. Pipes are divided into types depending on the diameter, scope and degree of flexibility of the corrugation. In the installation of domestic communications and for industrial needs, as mentioned earlier, pipes with a diameter of 15, 20, 25 and 32 mm are mainly used. These are the most popular models, but they are no exception.

Products of various diameters are produced, including pipes with a meter section. Such products are used to transport various liquids in production. Models of other sizes can also be made to order, but the price of corrugated stainless steel pipe made in this way will be much higher.

Helpful advice! Due to their special flexibility, corrugated pipes can be used to create systems and communications of various levels of complexity.

Depending on the purpose of the pipe, its properties are determined, products are classified into the following types:

Depending on the purpose, corrugated pipes in household construction are used for the installation of heating, water and gas supply

- corrugated annealed stainless steel pipe - characterized by increased flexibility, to achieve this effect during production it is subjected to a special heat treatment;

- unannealed pipe - does not lend itself to heat treatment, therefore it has less elasticity and weighs a little more;

- stainless corrugated pipe with a protective polyethylene coating - designed for gas supply, for systems that are subject to concreting, and it is also used for laying communications underground.

Depending on the purpose, corrugated pipes in household construction are used for the installation of heating, water and gas supply. We will talk in more detail about the scope of application of corrugated pipes below.

Scope of application of corrugated stainless steel pipe

Corrugated pipes are distinguished by their versatility, therefore they are widely used in the installation of both centralized and autonomous water supply and heating. This is possible due to the properties of stainless steel to withstand high pressure, although the walls have a maximum thickness of 0.3 mm.

Due to their special flexibility, corrugated pipes can be used to create systems and communications of various levels of complexity

Corrugation perfectly tolerates high temperatures, under the influence of which it does not deform. In this regard, corrugated pipes outperform analogues made of polypropylene and metal-plastic. Therefore, a corrugated pipe for heating and hot water supply is perfect. In frosty conditions, such a stainless steel product does not suffer from contraction and expansion of the material, therefore freezing and thawing does not affect its flexibility. The flexibility of the material is so high that the hoses, depending on the diameter, can bend with a radius of up to 30 mm.

Thanks to these unique advantages, stainless steel pipelines are used in a wide variety of applications. They are used by builders, repair workers, electricians and utility mechanics as:

- flexible pipes for heating;

- wall and floor insulation systems;

- corrugated pipes for plumbing and hot water supply;

- pipes for piping boilers;

- channels for connecting meters;

- heat exchangers;

- gas distribution pipes;

- corrugated pipes for ventilation, chimney and air conditioning.

These are the most common applications for corrugated pipelines, but in modern construction they have also begun to be actively used to create metal hoses in electrical wiring and as elements in a solar collector system.

Corrugated stainless steel pipe for heating

A corrugated stainless steel pipe for heating began to be used relatively recently, but it has already managed to prove itself excellently in this area. Due to the fact that the product has the property of adapting to temperature and pressure changes, it is installed both at the heat supply inputs and directly in heating systems.

Helpful advice! Due to flexibility, excellent thermal conductivity and increased strength, corrugated stainless steel pipes are most often used in the "warm floors" system. The price of such products is slightly higher, since they have a special coating that allows you to freely pour the floors.

A special advantage of corrugated pipes for heating is that the installation is carried out without the presence of special equipment and tools. In this case, the products are bent at different angles without narrowing the ducts.

Related article:

Exhaust corrugation: ease of installation and ease of use

Materials of manufacture and classification, advice on selection. Features and installation procedure. Care recommendations.

When purchasing a corrugated pipe for heating, you should heed some expert advice, in particular, it is recommended to study the markings on the coil label and indicate the scope of application, since it is impossible to apply it to the pipes themselves. If the integrity of the packaging is broken, you must beware of substitution. The real price of a fake corrugated pipe can be an order of magnitude less than the cost of the original.

When purchasing a corrugated pipe for heating, it is recommended to study the markings on the coil label and indicate the scope of application

Thus, high-quality corrugated products are distinguished by the following properties:

- the price of heating pipes is slightly higher than the cost of water pipes and is an order of magnitude higher than the price of products for chimneys;

- pipes have a very high degree of flexibility;

- the seams must be even, without visible violations;

- it is difficult to detect defects by visual inspection.

Gas Corrugated Stainless Steel Pipe

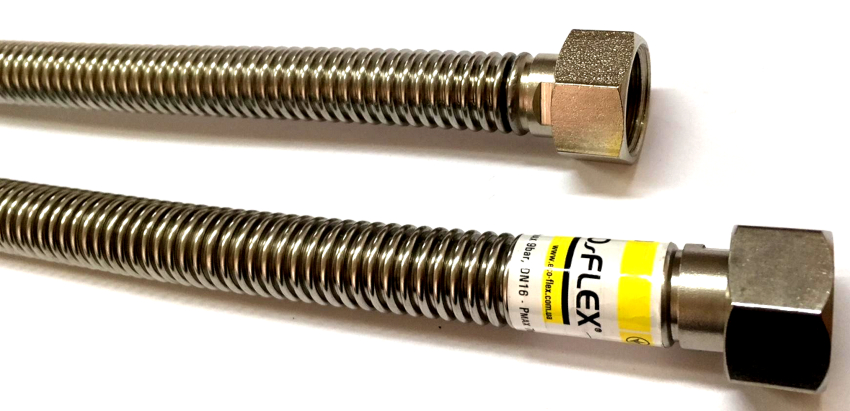

To connect heating boilers, gas stoves, gas-type water heaters to the gas supply system, flexible connections are most often used recently. There are several types of products that differ in size, material and price of corrugated stainless steel pipe. Flexible gas connectors can be made:

- made of elastic material and braided with stainless steel;

- made of stainless steel, and have the form of a bellows.

Experts advise to use a flexible hose of minimum length to connect gas appliances, which guarantees reliability and safety. It is better to move the slab as close as possible to the pipe than to use a long corrugation.

The braid of the corrugated stainless steel gas pipe is marked with a yellow stripe. This is done due to the fact that externally flexible hoses for water and gas are very similar to each other, therefore, water pipes are marked in red and blue, and gas - in yellow. The inch stainless steel liner is usually equipped with special fittings, which are fixed with nuts at the joints, and copper or aluminum washers are used for additional tightness.

The price of a stainless steel pipe for gas is slightly lower than the cost of rubber-fabric analogs, but at the same time it is no less reliable. This feature has influenced the increase in demand for corrugated steel products.

The price of a bellows-type stainless steel pipe for water is higher than the cost of products for gas equipment, which is justified by their reliability. The bellows itself is in the form of a corrugated pipe with fastening nipples at the ends. Connect the bellows line using washers and nuts. The connection can withstand a pressure of 6 atm.

Metal corrugation for ventilation and chimneys

Stainless steel pipes are used as connectors between hoods and ventilation ducts, as well as chimneys. At the same time, the steel product largely outperforms aluminum pipes, although the price of stainless steel and aluminum is practically the same.

Stainless steel pipes are used as connectors between hoods and ventilation ducts, as well as chimneys

Helpful advice! It is steel corrugation that is best used for chimneys, since the material is durable and anti-corrosion, which ensures safety and a long service life.

A conventional corrugated stainless steel chimney pipe in diameter ranges from 10 to 15 cm with a compressed length of 60-70 cm. Inside, it is reinforced with thicker steel wire, which gives it the desired configuration. When expanded, the pipe can reach three meters. In this case, you can select the required chimney length.

Corrugated stainless steel pipes can withstand temperatures up to 900 ° C, so they can be used in heating systems with different fuels, including coal and wood. It is quite easy to remove combustion products from such pipes. In addition, the harmful condensate containing sulfuric acid that forms inside the chimney does not have a destructive effect on steel, as it is resistant to chemicals.

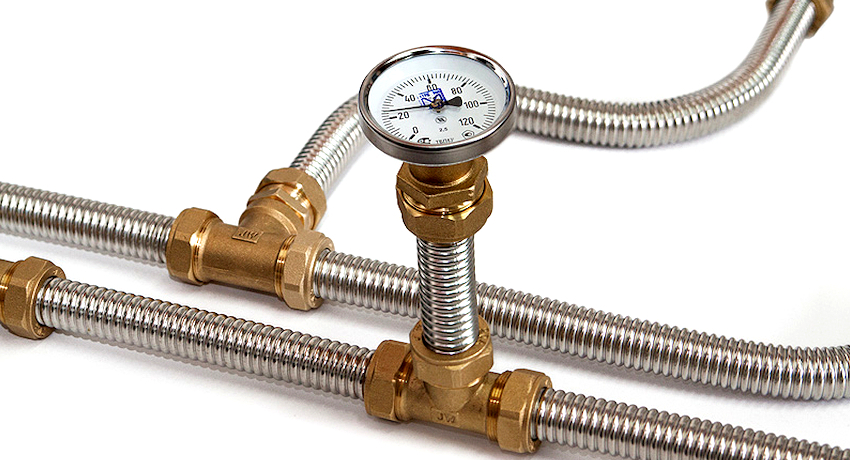

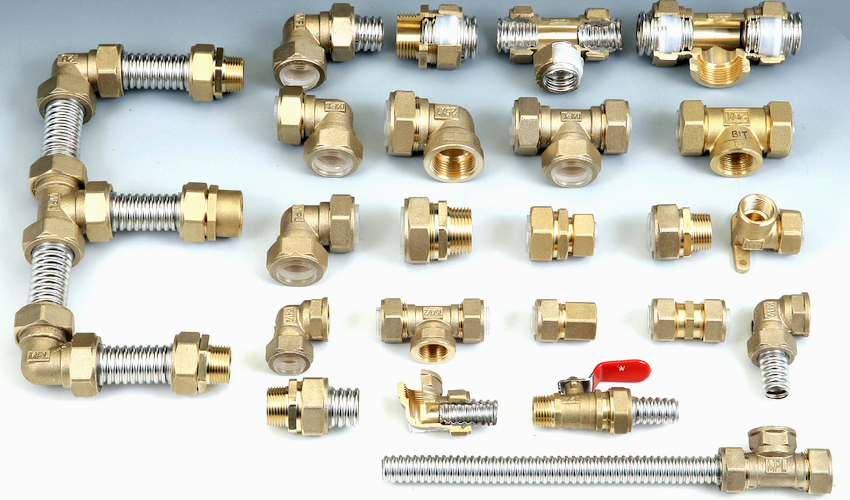

Corrugated Stainless Steel Pipe Fittings

Success in arranging a water supply or heating system using corrugated stainless pipes depends on the tightness of the connections. The smallest leak can not only entail financial costs, but also pose a threat to health and life. To ensure maximum reliability of the connections, special fittings for steel corrugations are used.

Success in arranging a water supply or heating system using corrugated stainless pipes depends on the tightness of the joints

Fittings are mounting parts of connecting fittings that perform a number of functions:

- ensure tightness at the joints of the pipeline;

- play the role of adapters between pipes of different diameters;

- change the trajectory of the laying and allow to improve the existing system;

- regulate the flow of fluid in networks;

- make it possible to increase the length of the system without interrupting its operation;

- allow you to create new branches in any system while it is running.

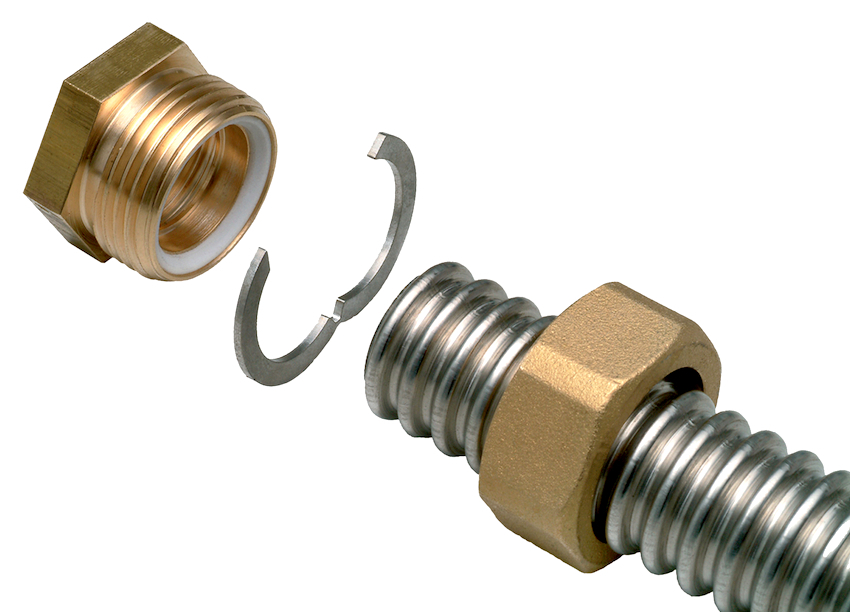

To connect individual parts of engineering communications with each other, brass fittings are most often used, which, depending on the purpose, can have a different diameter, cross-sectional shape and configuration. Such products consist of a body, a union nut, a plastic or steel ring-stopper and a silicone gasket that tightly crimps a flexible pipe.

Helpful advice! On fittings not worth saving - it is better to buy them from trusted sellers who have proven themselves well in the construction market. Poor quality parts can lead to failure of the entire stainless steel system. The price of brass fittings is significantly higher than the cost of other alloys and plastic parts, which is justified by the quality and reliability.

Types of fittings for corrugated stainless pipe

There is a wide range of fittings. They are conventionally divided into two main groups:

The fittings are divided into the following types: coupling, adapter, swivel angle, plug, tee, cross

- Seamless fittings. These are solid products with a high degree of reliability. When installing them, use special equipment, in particular crimping pliers.

- Electrofusion fittings. They are a set of parts that are precisely matched to each other, which allows you to create minimal gaps.

The type of connecting fittings is selected according to the goals set, in accordance with the total cost of the project, taking into account the diameter of the pipes and the installation conditions. The material for the manufacture can be metal or plastic. Metal fittings are more convenient and practical, therefore they are especially popular. For their production, stainless steel and brass are used. Plastic fittings are used at the junction of combined systems, as well as for connection to central highways. For example, they are used to connect corrugated pipes with polypropylene.

Depending on the functions performed, valves are divided into the following types:

- connecting sleeve - serves for joining straight segments;

- adapter - used for splicing pipes of different diameters;

- pivoting angle - helps to change the geometry of the pipeline system;

- plug - installed in order to cover a part of the system or a certain working circuit;

- tee - allows you to evenly distribute the flow in two directions from the central line;

- cross - used to branch the central fluid flow in several directions.

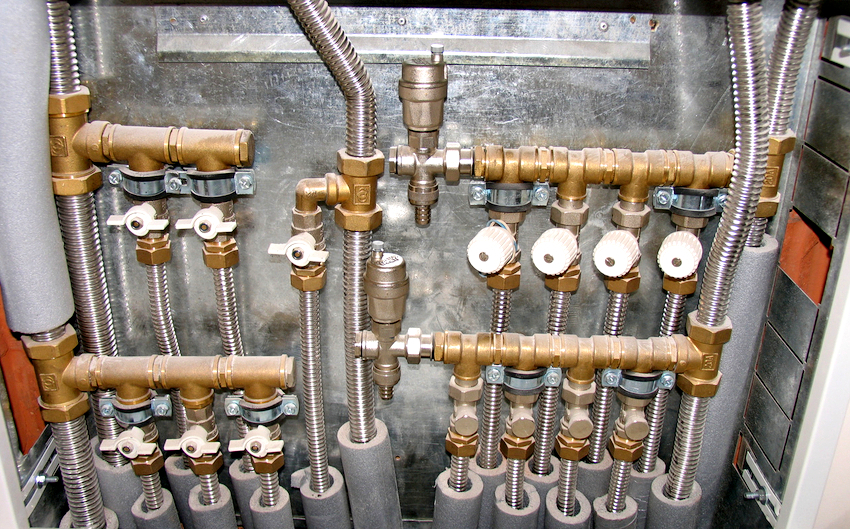

Corrugated stainless steel pipe installation technology

It should be noted that the installation of corrugated pipes is easy to process. Due to the variety of types of fittings, it is quite possible to assemble any system on your own, without the involvement of specialists. The main thing is to observe the sequence of technological steps and the correctness of the work performed during the installation process, which ultimately will allow you to get a strong, reliable and durable pipe connection.

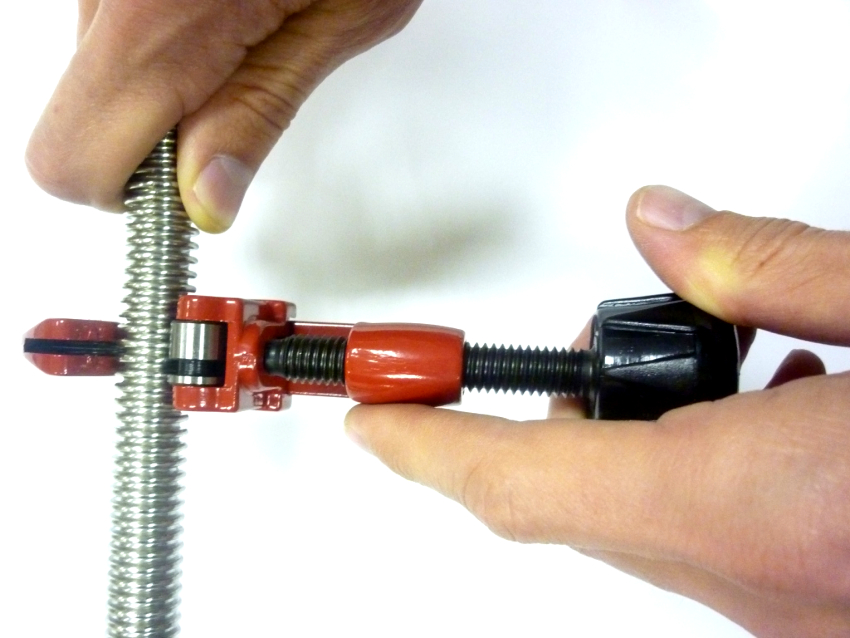

Directly the installation technology assumes a clear sequence of certain actions:

- Connecting fittings to pipes and mixers. At this point, make sure that the union nut on the side of the pipe connection is not tightened.

- Cutting off the required amount of material. This is required to be done using a special tool - a roller pipe cutter. The cut should be neat and free of burrs.

- The pipe is inserted into the fitting and the union nut is tightened.

- The pipeline is fixed in the desired position, using for this purpose special fasteners in the form of clips and clamps.

- System health check. If a leak is detected, tighten the union nuts a little more.

Due to the variety of types of fittings, it is quite possible to assemble any system on your own, without the involvement of specialists.

Interesting to know! Installation of corrugated pipelines takes significantly less time than installation of rolled pipes, since such a laborious process as welding is not involved. For example, installing a conventional annealed stainless steel pipe is three times faster than installing its counterparts from other materials.

Popular manufacturers and price of stainless steel pipes

As mentioned above, companies from South Korea are the leaders in the production of stainless steel corrugated pipes, the most popular of them are:

- Kofulso is the most famous company that pioneered the production of corrugated stainless pipes. It is on her technology that products for pipelines are produced at other enterprises in this area. The popularity has had a corresponding effect on the cost of stainless steel and its products.

- Lavita. Feedback from experts and users indicates that the products of this manufacturer are characterized by a long service life, but the fittings are of lower quality. Marriage occurs with a frequency of 2-3 cases per 100 copies. It happens that when tightened, the metal ring can cut through the wall, so the products of this company are cheaper than Kofulso pipes.

- Hydrosta. Products for the price and quality characteristics correspond to Lavita pipes. Users also complain about fittings that leak in every fifth case out of a hundred.

- Meibes. The company is quite new in the construction market, but has managed to establish itself well in the production of corrugated steel products. There are practically no complaints from consumers, except for the high price of products.

Speaking about the manufacturers of corrugated pipes, it should be noted that this type of product is not yet counterfeited. According to experts, this is due to the fact that special expensive equipment is used in production, and the technology itself is rather complicated. In addition, the production of stainless corrugated pipes is still at the development stage, so there is no particular excitement for products.

Characteristics and price of corrugated stainless steel pipe "Neptune"

Speaking about the manufacturers of corrugated pipes, attention should be paid to the domestic manufacturer - the company "Neptun".This is a new company on the Russian market that presents a line of flexible corrugated stainless steel pipes, as well as produces brass fittings and other accessories for installing pipelines.

The most popular products of the company are Neptun IWS corrugated stainless steel pipes used in the arrangement of various engineering systems, including heating, hot and cold water supply communications, as well as in the creation of water-heated floors and fire extinguishing systems. In addition, a separate production line is made up of corrugated pipes for flexible connections to gas appliances and a sealed metal hose used for laying electrical networks.

Helpful advice! It should be noted that the price of stainless pipes is relatively low, much more money is spent on consumables that are needed during installation. In this regard, the installation of a flexible stainless steel pipeline loses to the installation of plastic and polypropylene pipes, since it costs more.

Of the domestic manufacturers of corrugated pipes, it is necessary to highlight the company "Neptun"

A young enterprise in the structure of domestic production emerged relatively recently - in 2014. It was founded by the largest manufacturer of equipment for underfloor heating and heating systems SST Group. Neptun IWS, located in the Moscow Region, is the only Russian company that produces flexible corrugated pipes. It should be noted that they are produced exclusively from high-alloy stainless steel using modern European equipment.

Neptun IWS steel corrugated pipelines and fittings fully comply with the requirements of energy saving and environmental friendliness. Products are easily cut and bend without changing the flow area, without the formation of microcracks and other damages on the metal.

Tips for the selection and installation of a corrugated stainless steel pipe

When buying pipes and accessories for a pipeline system, it should be remembered that its high-quality installation and long service life depend on a number of factors that must be taken into account even in the process of purchasing materials. In this regard, the following should be considered:

During installation, it is necessary to strictly adhere to the algorithm of actions, follow the instructions

- When purchasing a product, it must be carefully inspected for mechanical damage and bends.

- The pipe must be strong and bend easily to the desired shape.

- It is better to give preference to proven and well-established brands in the construction market; you should not be seduced by low cost. The average price per meter of high quality stainless steel pipe ranges from one to three thousand rubles, depending on the type of product and the type of steel used in production.

- During installation, it is necessary to strictly adhere to the algorithm of actions, follow the instructions.

- After installing the system, it is imperative to check it for integrity using the maximum allowable pressure.

- The fittings must be complete.

- When it becomes necessary to connect a stainless corrugated pipe with another material, it is recommended to use brass fittings.

- The use of cheap, poor quality fittings at corrugated pipe joints can lead to a significant reduction in the service life of the system.

- You should not make any special efforts while tightening the plastic elements, since the plastic will simply burst from excessive pressure.

- To organize the installation, it is necessary to prepare in advance special open-end wrenches, as well as metal scissors for cutting pipes at right angles.

Corrugated stainless steel pipes are characterized by practicality and reliability during operation, therefore the popularity of such products is growing rapidly. They are successfully used in various areas of repair and construction: in the arrangement of water supply and heating, as chimneys and connections to gas appliances in the ventilation system. Their installation is quite simple, so if you approach the process responsibly and do not cheapen on materials, you can independently and quickly install a reliable and durable pipeline.