Device residential building roofs often accompanied by the need to insulate it. Modern industry produces a large number of sheet and roll heat-insulating materials. What insulation is better for the roof and what parameters should be used to choose it? The answer to these questions would like to know all owners engaged in individual housing construction or renovation of their home.

The choice of roof insulation depends on the type of roof structure and the preferences of the homeowner.

Content [Hide]

Characteristics of various types of insulation

Modern heaters are of mineral and synthetic origin. Both have their pros and cons, which should be analyzed in detail. The most used today are the following materials for thermal insulation:

- mineral wool;

- Styrofoam;

- sprayed polystyrene foam;

- foam glass;

- foam concrete;

- loose insulation.

To understand which insulation is best for the roof from the listed ones, you need to know their characteristics.

Mineral wool

This insulation is either basalt or glass. In the first case, there is a crumb of rocks in the composition, which implies the regulation of the acidity of the material. This parameter strongly affects moisture resistance in direct proportion. Glass wool is made from broken glass, which makes it durable and very resilient. It is a flame retardant material that can withstand 400 degrees of temperature.

Advantages of mineral wool: excellent thermal insulation properties, light weight, environmental friendliness and low cost. This material also has disadvantages: the need to build a thick layer of up to 25 cm, which reduces the useful volume of the attic, the unpleasant effect of glass dust on the skin and respiratory organs during installation. This material is produced in slabs, rolls and mats.

Helpful advice! For quality insulation of floors or roof rafter system with mineral wool, you need to wrap all the rafters with it and lay the material between them. A film is made on top of the mineral wool vapor barrier.

Styrofoam and expanded polystyrene

This material is a foam board made of synthetic foam - polystyrene. Since this substance itself is quite flammable, during the production of insulation, special additives are added to the composition that stop combustion. Of the advantages, it can be noted: resistance to decay, poor thermal conductivity, very low weight.Of the minuses, experts single out only poor sound insulation and low strength, which is uncritical when insulating a roof.

If, when deciding which insulation is better for the roof, the choice is made on polystyrene, then you need to know some of the features of its installation. When insulating, it must be placed against the rafters with a heat-reflecting surface. Sheets must be securely anchored with anchors, as loose foam can generate wind sounds. It is advisable to lay the polyfoam with a double layer of overlapping seams and cover it with drywall on top.

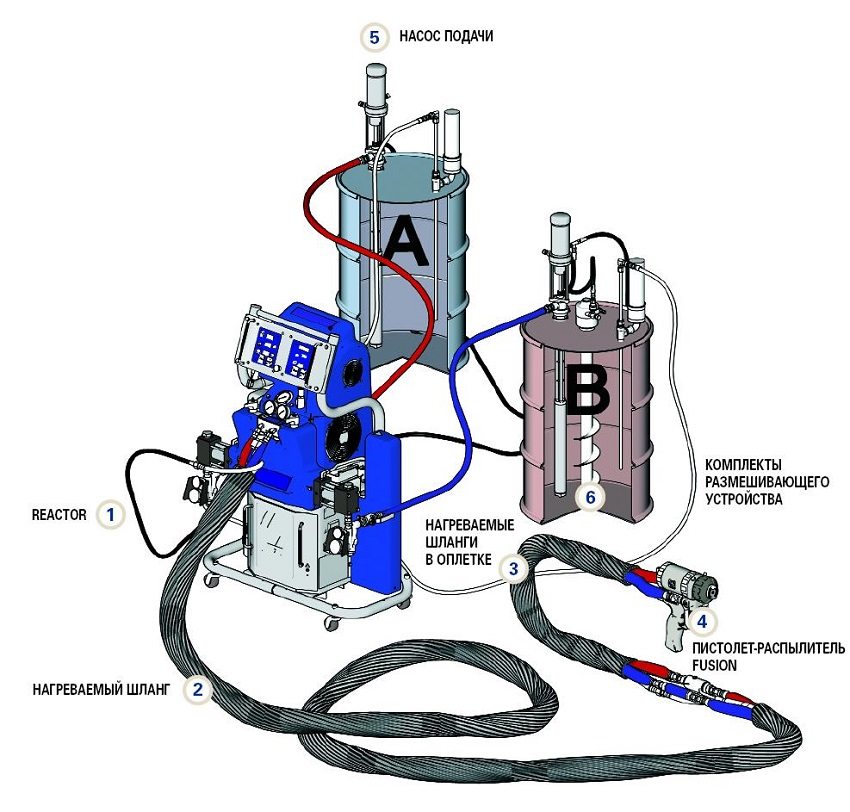

Separately, it should be noted such material as sprayed polystyrene foam. Its styling technology is completely different. Using a special device, the polystyrene mass is sprayed over the surface. Possessing fluidity, it penetrates into all cracks and irregularities, filling them. Under the influence of air, the mass foams and hardens. This type of insulation is the most convenient to install and has all the advantages of foam. Of the minuses, the high price and the need for a special installation are noted.

Foam glass

This material is obtained by heating silicate glass above 1000 degrees. This temperature causes a foaming effect in it. Plates, blocks and granules made of foam glass are used as an effective insulation. It can withstand temperatures ranging from -260 to 500 degrees. This material is completely safe in an ecological and hygienic sense.

Positive qualities of foam glass: high strength, no tendency to shrink. It does not burn or freeze, does not lend itself to acids and alkalis. Fungi and bacteria do not settle on this material. No other material for thermal insulation has so many useful properties. The technology of laying foam glass is very simple and not more complicated than that of foam.

Foam concrete

The material from which the foam blocks are prepared - light enough to withstand the floors, strong and durable, has recently become widely used in the construction industry. It is especially in demand in industrial construction. It has good thermal insulation properties and excellent sound insulation.

Loose heaters

These include expanded clay, sawdust, shavings and other similar materials. Today, few people use them in construction, since they, in addition to positive qualities, have a lot of negative ones: shavings and sawdust give rise to dampness and fungus, expanded clay is too heavy for light floors, it cannot be used in the attic roof. The main advantage of such heaters is their low price, which allows them to insulate the roofs of some outbuildings, especially in the rural outback.

Helpful advice! When using heaters, a film vapor barrier must be installed on the floors. This will prevent the ceiling from leaking in the spring when the condensation under the roof melts.

Which insulation is better for the roof: selection criteria

Most of the insulation is designed for all surfaces. All of them cope with the task of insulation perfectly if properly laid. Which insulation is best for the roof is more a matter of taste than technical features. Therefore, most consumers choose the one that they can afford. In addition, it is necessary to take into account also the convenience of installing a separate insulation on a specific type of roof. For lightweight floors, styrofoam, expanded polystyrene and mineral wool are best suited. These materials are very lightweight, which allows a multi-layer coating.

Insulation of floors begins with the installation of a vapor barrier film. Already on it it is necessary to lay several layers of insulation, depending on the climatic conditions in a particular area. All joints must be filled with polyurethane foam.

Related article:

|

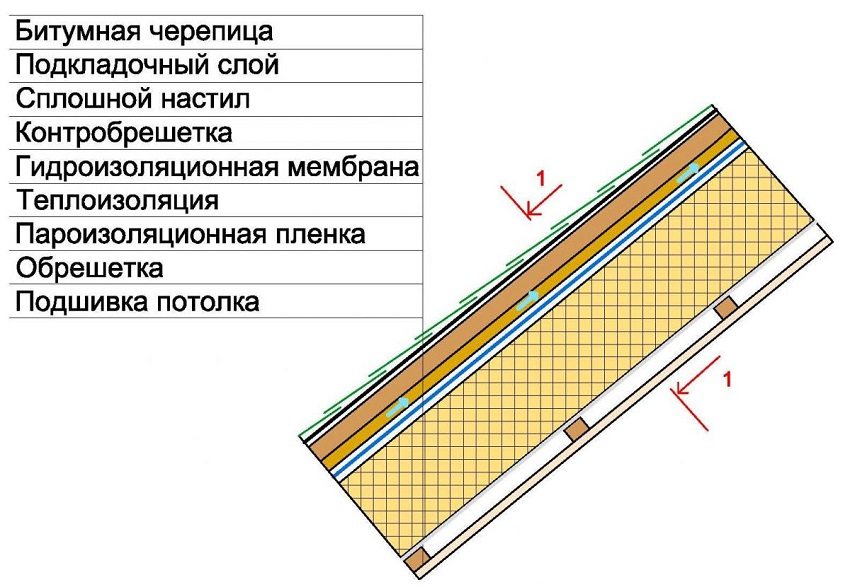

In order to insulate the roof from the rafter side, it is necessary that the roofing material be laid on top of the vapor barrier. If the insulation is done in the process of changing the roof or new construction, then it is more convenient to make it even before the installation of the battens. For this, a double crate is made. The first layer of planks or plywood is stuffed onto the underside of the rafters. Insulation and vapor barrier are already laid on them. Then the main lathing is made and the roofing material is laid.

If the insulation is done with a finished roof, then all work is performed from the side of the attic, which is less convenient, but also effective. Plates or mats are attached to the battens and rafters, and then covered with vapor barrier and drywall or plywood.

Especially it is necessary to say about heaters for the attic roof. Which insulation is better in this case depends on several factors.

Types of insulation for the attic roof: which insulation is better to choose

Often in houses and cottages attic floors make residential, which implies complete insulation. If the bulk of the house is protected by thick walls, then the attic is fenced off from the outside world only with a thin layer of lathing and roofing. In order to make a fully functional residential floor in the attic, it is necessary to carry out serious work on thermal insulation. There should be a sufficient amount of insulation under the sloping walls of the attic rooms so that they do not freeze through in winter. The same goes for the ceiling.

By and large, the slopes of the attic roof are no different from a regular roof, but they require more serious thermal protection. Therefore, the choice of insulation must be approached thoroughly. Styrofoam or mineral wool is perfect here. Both of these materials are not very expensive and are very easy to install. You can take other types of insulation for the attic roof. What kind of insulation is best for the consumer to decide.

Helpful advice! When insulating a mansard roof, the greatest attention should be paid to the corners. They need to be foamed well, since it is in them that frost can appear in winter.

Whatever material is chosen, the main thing is to lay it in accordance with all the rules set forth by the manufacturers. Otherwise, the effect may not be seen