Technical characteristics of DSP boards: dimensions, prices and properties have made this material one of the leaders in modern construction. Let us consider in detail what advantages and disadvantages the use of this product has, as well as in which areas this finishing material is most applicable. We will also pay attention to the features of its selection and installation.

Content [Hide]

Characteristics of DSP boards: sheet dimensions, thickness, weight and prices

Cement particle board is a versatile material, the use of which has not lost its relevance for several decades. This is largely due to the environmental friendliness of the product, as well as a wide range of sizes of DSP sheets.

It is also worth buying a DSP board because its manufacture and use is completely safe for the environment. The production uses the process of mineralization and the emission of harmful substances and vapors into the atmosphere is completely excluded.

Consists of a cement-bonded particle board of wood chips, Portland cement and a number of special additives. The manufacturing process is mixing all these components with their further pressing and fermentation. DSP boards are produced in specially equipped factories, taking into account many requirements and standards. Moreover, all products manufactured in the factory have the appropriate GOST certificates and a quality certificate.

Technical characteristics of DSP boards: advantages and disadvantages

Many factors testify to the use of DSP panels in construction, including:

- multifunctionality - they are widely used for exterior decoration of the house, for creating internal partitions, and you can often find DSP slabs for the floor;

- this material meets all the norms and standards necessary for its full use in construction: it is resistant to significant temperature changes, frost, fire, is not a breeding ground for fungi, parasites, insects and rodents;

- the manufacturing process does not use impurities hazardous to health, such as phenol, asbestos, formaldehyde resins and others;

- all materials have certificates and passports confirming the quality of the product and its compliance with the requirements of GOST, so when purchasing goods from a large manufacturer, you can be sure of your purchase;

- DSP slabs are further easily subjected to almost any finishing - from painting and plaster to facing with tiles or plastic panels;

- has noise insulation properties, with an index of up to 30 dB.

Helpful advice! DSP boards, although similar in their characteristics to wood, have greater strength, which makes their use preferable to wood.

A high strength index of CBPB boards is ensured by their three-layer structure. The panels are made up of two layers of fine shavings located on the outside and a layer of larger particles hidden inside. This makes the product more durable and not prone to bending fracture. In addition, the material turns out to be smoother and more resistant to moisture, which significantly expands the possibilities of its use in the most difficult operating conditions.

Related article:

OSB sheets: thickness and dimensions, prices, specifications. Parameters, classification, production methods and applications. Technical characteristics of various types of oriented strand board.

The only drawback of cement-bonded particle board is that in an aggressive environment its service life is about 15 years, which is quite a bit for a building material. But in order to extend the period of operation, you can create additional protection for the panels.

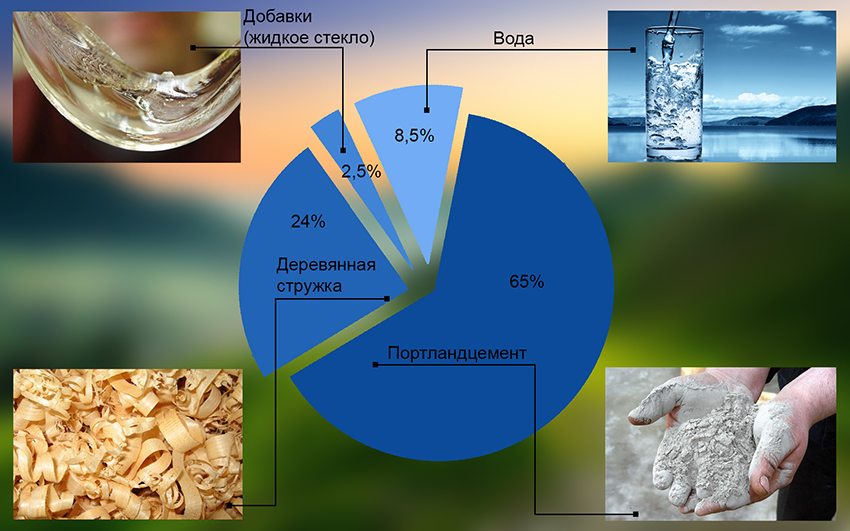

Composition and certification of CBPB boards

When choosing DSP panels, you need to pay attention to many characteristics, including the composition, properties specified in the product documentation, and dimensions: height, width and thickness of the slab, its ability to repel moisture, etc. Consider the basic requirements for this material, which are established according to GOST ...

According to the norms, the composition of a quality slab should be as follows:

- 24% of the total weight of the product - wood chips;

- 8.5% water;

- 65% - Portland cement (which ensures the strength and durability of the product);

- 2.5% - impurities (liquid glass and aluminum sulfate).

All these numbers must be indicated in the product passport, to which a certificate of product certification is attached. After all, the characteristics and use of DSPs are directly related. It will be useful to read reviews on the Internet about the manufacturer of DSP boards before buying.

DSP slabs: sizes, prices and other parameters

DSP prices for a sheet at retail are determined depending on its size. In the production of CBPB there is a so-called standard size of CBPB board, which is 3200 × 1250 mm. In this case, the thickness can vary from 10 to 40 mm.

According to GOST, deviations in terms of size (both width and length of the product) are permissible. The thicker the plate, the greater the deviation is allowed, both upward and downward. So, for panels with a thickness of 10 mm, the maximum deviation is 0.6 mm; 12-16 mm - 0.8 mm; 18-28 mm - 1 mm; 30-40 mm - 1.4 mm. However, the total error rate should not exceed 3 mm per item.

In addition to the dimensions of the DSP, there are other technical indicators for which finished products are necessarily tested, for example:

- at normal humidity, the density of the board should not exceed 1300 kg / m²;

- water absorption rate should not be more than 16%;

- at air humidity from 6 to 12%, the DSP board should not swell by more than 2%;

- the tensile strength of the finished slab should not be less than 0.4 MPa;

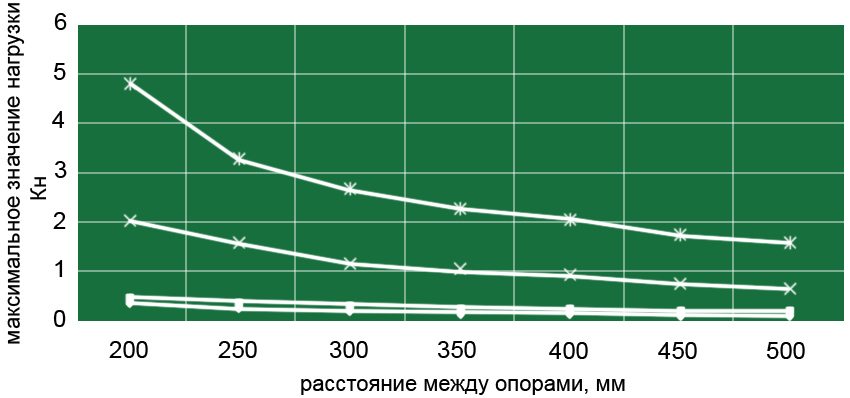

- for bending, the following standards are provided: for panels with a thickness of 10-16 mm - 12 MPa, 18-24 mm - 10 MPa, 26-40 mm - 9 MPa.

State standards regulate everything, including even the degree of roughness of the surface of the slab. According to GOST 7016-82, the maximum permissible roughness index for panels that have been processed with grinding equipment is 80 microns. And for untreated plates, a limit of 320 microns is provided.

The retail price of DSP per sheet differs depending on the size:

- the average price of a DSP board with a thickness of 10 mm is 900–1000 rubles;

- with a thickness of 20 mm - 1600-1900 rubles;

- on panels over 30 mm thick, prices start from 2000 rubles.

Helpful advice! Many manufacturers provide significant discounts for bulk buyers, so it is better to calculate in advance how much material you need and place an order once.

Weight of CBPB boards

Another important technical characteristic of DSP boards is weight, which directly depends on their thickness. For one unit of standard size 3200 × 1250 mm, the following indicators are provided:

- CBPB weight 10 mm - 54 kg;

- weight of particle board 12 mm - 64.8 kg;

- the weight of the particle board 16 mm - 80 kg;

- CBPB weight 20 mm - 108 kg.

As can be seen from the proposed data, the weight of a 10 mm DSP is half the weight of a 20 mm thick panel. Therefore, it is not difficult to calculate how much the plate of the required length will weigh.

Special characteristics of CBPB boards

The technologies for manufacturing DSP panels are constantly being improved, trying to satisfy even the most complex customer requests. Thus, advanced technologies in this industry have made it possible to manufacture ultra-thin boards - up to 4 mm. The main advantage of such boards is that they do not require processing on grinding machines, which significantly reduces their market value.

In addition, smooth embossed plates are also very popular, the peculiarity of which is that only the smallest particles are included in the raw materials for their manufacture. It is this type that is called DSP panels for brick or DSP for stone. Such panels do not require additional processing with special compounds or paints, and after purchase they are immediately ready for installation. They are used in many finishing works.

One of the most popular brands of CBPB boards is Tamak. This company produces panels of all possible thicknesses - from 8 to 36 mm, and is in great demand in the market of building and finishing materials. The catalog of the proposed DSP, reviews and prices for products can be viewed on the official website of the manufacturer.

The main areas of application of DSP panels

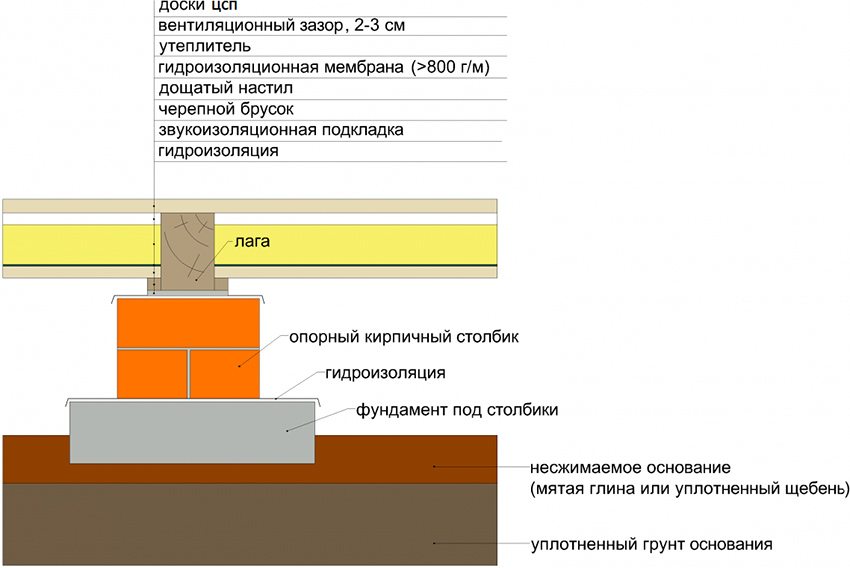

Thanks to the use of particle board panels in construction, additional thermal insulation is provided, which is so necessary in residential buildings. For this purpose, panels are sheathed on the internal and external surfaces of the walls, as well as the floors are lined. Even more often, cement-bonded particle boards are used for the construction of interior partitions. Due to its characteristics, this material is well suited for rooms with high humidity. No matter how difficult operating conditions one has to face, DSP slabs will certainly withstand their entire service life.

Application of DSP boards for flooring and creating internal partitions

Convenience of laying cement-bonded particle boards on the floor - no need for complex subsequent surface finishing. A traditional primer and a water-repellent paint or special composition will be enough. Such panels look very good and do not violate even the most demanding interior with their appearance.

Of course, the importance of high-quality DSP installation cannot be denied, because if the plates are poorly attached and processed, then their service life can be significantly reduced. Especially when it comes to particularly difficult conditions for the use of DSP panels.

The spheres of application of DSP are many, and this is largely due to the low cost of the material.At the same time, its affordable price does not affect the quality in any way, making DSP panels an ideal solution to various construction issues. Using such slabs as a rough floor finish, you get an additional thermal insulation layer, as well as a strong and durable base for further coating.

Rules for installing DSP boards on the floor

As the reviews confirm, the use of DSP slabs for the floor fully justifies everything said. This is an easy and inexpensive way to make the floor perfectly flat, with a minimum amount of time and effort. At the same time, the price of DSP slabs for the floor remains affordable even in the case of the most budgetary repair option.

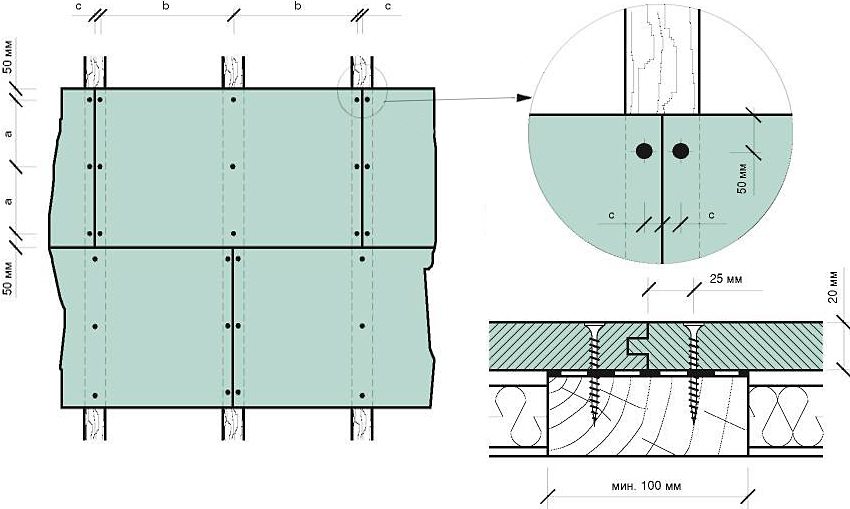

The technology for laying DSP on the floor provides for screwing to the crate. For this, self-tapping screws with a countersunk head are used, part of which is screwed into the base of the beam (20 mm in the case of using a wooden array and 10 mm for a steel array).

Particular attention should be paid to the expansion joint, since wood-based materials, including cement-bonded particle boards, although slightly, tend to expand under the influence of moisture.

Mandatory presence of expansion joints is required:

- if the coating has a large area;

- near door sills;

- near walls and any other vertical structures such as columns;

- if you need to change the thickness or appearance of the floor, for example, create a vertical projection and so on.

Technical characteristics of CBPB boards: application for formwork

Slabs also play a significant role in creating the formwork of CBPB. So, the use of these particular panels has a number of advantages:

- significant savings in the time allotted for the work;

- the ability to create more reliable structures;

- significant reduction in financial costs for construction work.

By itself, the formwork made of DSP panels looks like a complete element of architecture and does not require additional cladding. In addition, such plates are often used as a budget material for creating window sills. However, in this case, the low cost is perfectly combined with an attractive appearance and exceptional technical properties. Due to this, the use of DSP is popular in almost all areas of modern construction.

The thickness of the cement-bonded particle board for the floor, which is recommended by experts, ranges from 24 to 36 mm. Much depends on whether you will subsequently use additional finishing materials and which ones. In any case, it would be best to consult with a specialist immediately before making a purchase.

Application of DSP panels for exterior decoration of the house

The buildings with the foundation finishing with facade panels on the cement-bonded particle board have an impeccable appearance. Houses look especially stylish if you use a DSP brick. The properties of slabs of this type make it possible to additionally not cover them with special compounds, which makes this finishing option doubly convenient.

The thickness of the CPB boards that will be used for outdoor decoration should be as large as possible so that the protective layer is as thick as possible. This will not only make the appearance of the building more attractive, but also create an additional barrier between the foundation and external negative factors that can affect it, for example, rain, strong wind, etc. Photos of DSP panels used for external decoration are widely presented in the Internet.

Helpful advice! It is good to use DSP slabs for the facade. Having picked up panels suitable for the characteristics, you can quite budget and at the same time decorate the whole house aesthetically.

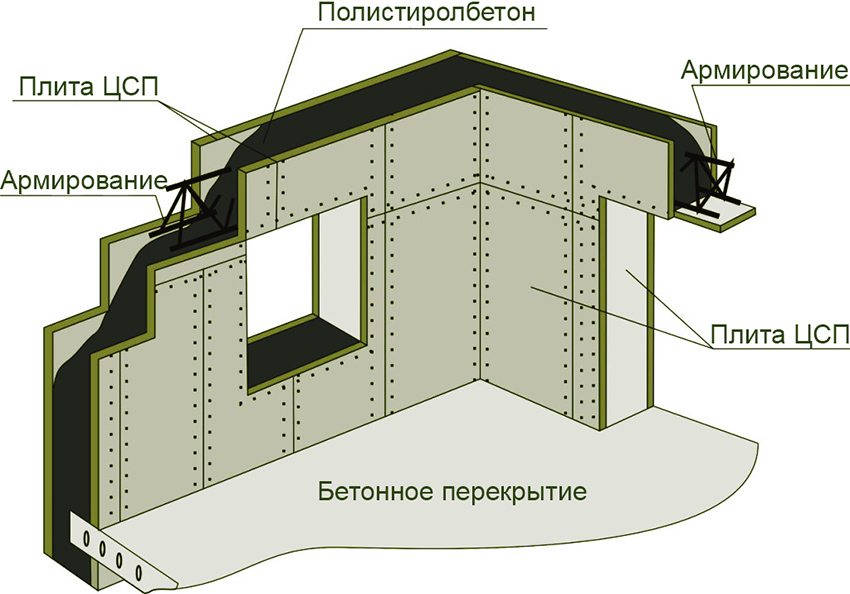

Another unusual option is SIP panels made of DSP. They are two cement-bonded particle boards, between which there is a layer of insulation.All this is fastened with glue under high pressure. Therefore, the entire structure is very durable. Due to the high quality of the insulation used, SIP panels are absolutely clean and ecological material, which, moreover, has a high fire safety index.

This option is great for use in the construction of a private house, its decoration and insulation.

Helpful advice! SIP panels are used as a final finishing material and do not require further plasterboard sheathing.

The modern market is filled with all sorts of building materials, including other panel products. However, few of them can compete with cement-bonded particleboards. The use of DSP is so wide that, one way or another, it penetrates almost all stages of construction. In addition, the environmental friendliness of the material, as well as its affordable price, of course, remain unrivaled.