Perhaps it will not be an exaggeration to say that the porch of a private country house should be functional and fit into the overall exterior of the building. At the same time, the stylish and original porch is the hallmark of the house. There are several different options for implementing this final stage of construction, depending on the choice of the main building material and the budget framework. At the same time, we can confidently say that the task of making a strong, durable and beautiful porch to the house with your own hands is quite solvable: projects, photos and descriptions of all stages of work can be easily found on the Internet.

Content [Hide]

Basic types and design of the porch

Structurally, the porch in a private house, photos of which are presented not only in this article, is an open area, usually with a staircase, which is made immediately in front of the entrance to the house. It can have a wide variety of shapes and be with or without a canopy, as well as a wide variety of materials.

Conventionally, the structure that determines the design of the porch of a private house (photos create a visual representation) can be divided into three main types: simple, built-in or attached:

- a simple type of porch is a platform with steps and a canopy above it. When assembling such a porch, the most difficult operation will be filling the foundation, which will be required even for a light wooden structure;

- the built-in porch is designed together with the house and under construction;

One-story house project 5.4 x 8 m with built-in porch

- an attached porch does not differ externally from a built-in one, but it can be easily modified and rebuilt. In this case, the attached porch can be arranged by alteration or minor additions to a simple porch;

Important! The foundation under the porch is necessary to prevent deformation of the steps associated with seasonal temperature changes.

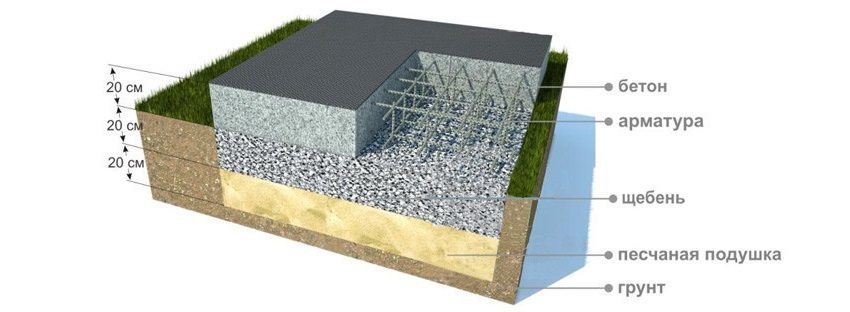

Foundation: common stage for all types of porch

The depth of the foundation for the porch must match the depth of the foundation of the entire house. Otherwise, due to soil settlement associated with its seasonal freezing and thawing, deformation of the entire porch structure is possible. If, as a result of soil settlement, a shift of the structure towards the house occurs, then it is the foundation of the porch that will collapse, as it is several times less massive.In this case, minor repairs will not work: everything will have to be redone again.

Since even a closed porch for a private house (the photo can be viewed on specialized resources), although completely glazed, is not intended for living and there will be no massive furniture and the constant presence of people, then for all types of porch, you can use a simple concrete pillow as a foundation ...

But if the material for solving the question of how to make a porch in a private house (a photo of the necessary stages will help to cope with the work) concrete, red or white brick or a stone - the foundation must be reinforced. Such a structure will put more stress on the base than wood.

The foundation for the porch begins with marking a rectangular area of appropriate dimensions: a porch of any shape must fit into this rectangle. Piles are driven into the corners of the rectangle, after which a foundation pit is dug along the marked contour. The depth of the pit should be no less than the depth of the main foundation.

Useful advice! It is also not recommended to lay the foundation of the porch to a great depth. In this case, the power load when the foundations of the house and the porch are displaced during soil shrinkage and temperature drops will be less, but destruction is still inevitable - not after 2-3 seasons, so after 5-7.

A large visor over the porch (a photo will give an idea of this design better than a verbal description), which will require the installation of supports, then the rectangle for the pit is increased by an additional 20-30 cm on each side. In this case, the piles-supports for the visor can be hammered in after the porch itself is made.

To do this, at the points of the future installation of the supports, you need to leave small rectangles (20x20 or 30x30 cm) of an unopened area. In the future, it will be possible to quickly drill wells in these sections, install and drive in a support, and pour concrete.

Formwork is highly desirable, although it is possible to do without it on stony ground. Almost anything can be used for formwork - boards left over from the main construction, thin plywood and even Chipboard... You just need to remember that thick plywood and Chipboard are hygroscopic, they will swell due to rain and groundwater and creep, therefore, after the concrete hardens, the formwork must be removed.

You can keep trimming softwood planks. Coniferous sawn timber has a very significant positive feature: being completely saturated with water (and even deeply frozen at the same time), they become very strong, maintaining elasticity.

Useful advice! If the soil is strongly deformed, for example, if the house is built on a slope, the coniferous formwork boards will act as a damper.

Waterproofing of the porch foundation is required - for its construction, it is enough to cover the bottom of the pit and the inner surface of the formwork with roofing material. For reinforcement, you can get by with several bricks, on which a mesh is laid or a lattice of pieces of reinforcement is attached.

Thus, the pit is filled with the required number of layers of bricks and mesh, after which they begin to fill the structure with concrete. So that voids do not form in the thickness of the concrete, after each layer of pouring, it is imperative to carefully tamp the solution with a shovel.

Useful advice! For compacting concrete, it is better to use an electric vibration compactor, which can be rented.

Since the concrete sets and dries for about a week, it is necessary to immediately level the surface of the foundation and cover it with roofing material or construction film with an overlap at the edges of at least 50 cm.Otherwise, in case of rain, excess water in the surface layer of concrete will make it brittle in the future, and then the whole idea with foundation will turn out to be meaningless.

Do-it-yourself porch to the house: projects, photos of different types of porch

Self-made projects found on the Internet, a photo of the porch to the house will help you decide on the choice of materials for construction. In general, they are traditional:

- wood;

- metal;

- concrete;

- brick or stone.

Since the floor in the house is always raised to the level of the foundation, a series of steps is an obligatory element of the porch.

Do-it-yourself wooden porch for a private house

Photos of wooden porches for a private house with their own hands, made of wood, are perhaps the most on the Internet. After all, wood is the most traditional material and a porch from it is the easiest to manufacture. It is enough to have skillful hands, a circular saw (or a simple saw with a fine tooth for accurate cutting) and a construction square.

The ideal material is larch, followed by spruce and other conifers: they are durable, easy to handle even by hand. After special impregnation, the material from them is little inferior, for example, to material from oak or from other hard species.

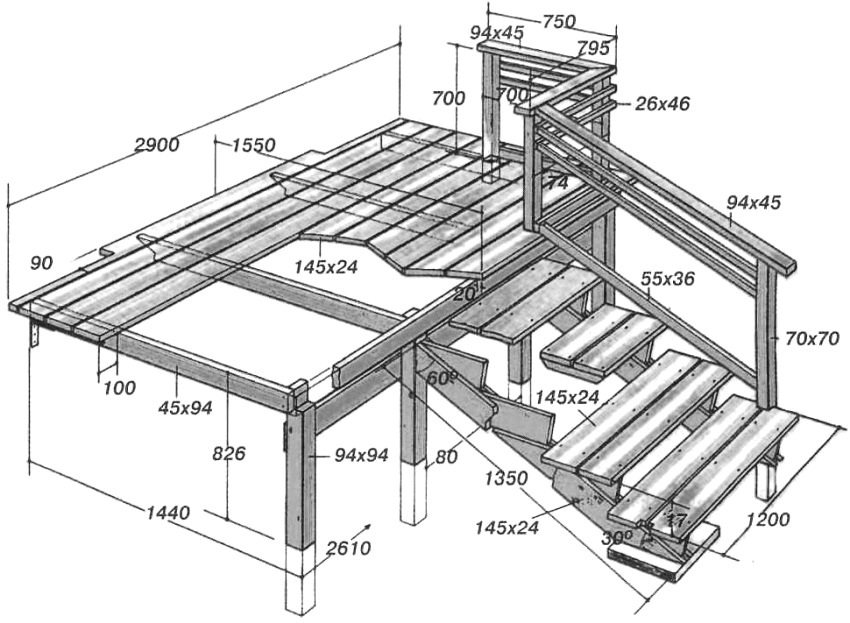

First you need to make a kosour (kosougor). Since it is simply impractical to make the width of the porch for a wooden house (photos of the most successful projects will serve as confirmation) less than 120 cm, then at least three such beams will be required. The optimal distance between the stringers is about half a meter, based on this, you can calculate how many beams are required.

This approach will ensure the strength and durability of the structure of a do-it-yourself porch for a wooden house (photos and drawings in magazines and construction manuals prove this), even if the staircase is used very actively, with a large weight load.

Interesting! Kosour is a load-bearing beam with sawn teeth, which plays the role of an additional internal support. Steps are laid on the horizontal edges of the teeth.

The bowstring (external stringer or just an inclined beam) should be 2-3 times thicker than the stringer. Both bowstrings are connected at the ends by transverse beams. Between them, the required number of stringers is attached to the beams.

When cutting out the ribs for steps, a square is a must. A gap between the teeth in parallel strings, even 5-7 mm, will provide a slight subsidence of the step in one place and swelling in another. Temperature changes will only increase the level difference of the step.

The width of the steps of a hand-made porch made of wood (with or without a canopy) is calculated under the foot of an adult with a margin, that is, 35-45 cm.The height of the riser (the height difference between the steps) should not be more than 20 cm. There must be an odd number of steps. (an additional stiffener is provided), and if there are more than three steps, then you should definitely provide the porch with a railing.

The overhang of the step can be omitted if the porch is glazed and the staircase is reliably covered from rain and snow. If the staircase goes out, then the overhang is necessary so that the water drips onto the plane of the lower step, and does not flow down the riser into the groove between them.

Useful advice! The finished assembled staircase should definitely be installed so that the planes of the steps lie with a slight slope (about 1-2 cm per meter). Then the water itself will flow down from the steps, and ice will not form on them.

The finished structure is installed on a prepared fortified platform, that is, on the foundation. For the strength of the installation, in the place of the foundation surface where the lower beam with the kosoura will be inserted, it is possible to push a small depression with this beam while the concrete has not yet completely solidified. You will get a very solid stop for the porch stairs.

The deck deck is made of the same material as the ladder. There is only one requirement: it is advisable to use boards of the maximum available width and length, and adjust the joints as accurately as possible. Well lapped boards themselves will ensure that there is no deformation, even if the tree begins to dry out over time.

Depending on the size of the site and the stairs, with the foundation ready, it will take 3-7 days to work on the arrangement of the porch to the wooden house with your own hands. Projects, photo instructions and guides will help you break the process down into steps. The time taken will most likely depend on experience with wood, but a beginner will cope without problems.

Metal porch

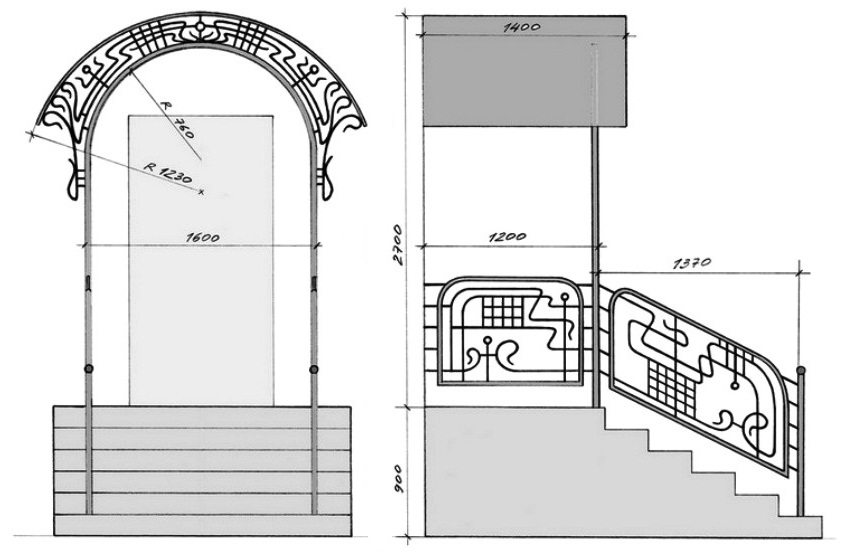

The advantages of a metal porch are that it can be mounted literally in hours with the ability to work with electric welding. In addition, metal construction will be relatively cheap if no forged elements are used. Minus - everything will have to be assembled from standard elements. But if you want a truly beautiful and stylish metal porch, then forged elements will have to be ordered and wait at least 2-4 weeks, depending on the volume of the order, despite the fact that forging is not cheap.

However, even a primitive staircase structure without frills can be made a very impressive metal porch in a private house (photos confirm this). The simplest option is assembled from channels, corners and filling material: wood, thick chipboard or porcelain stoneware... Projects, photos of a porch to a metal house clearly show the popularity of such a solution.

For a simple metal porch, you will need two identical channels with a length of the future staircase. Both channels are placed in parallel at a distance equal to the length of the future step, then the corner is marked and cut to the size of the step, adding a centimeter along the edges for the weld.

In the same way, a piece is cut from the corner with a length equal to the height between the steps. Both trims are welded to each other in an L-shaped manner (the edge-frame of the step is obtained in the section). Make the right amount, corresponding to the number of steps, of such L-shaped parts and weld them to the channel. Thus, a metal oblique is obtained. In the same way, a second skew-angle is made from another channel.

Related article:

Polycarbonate porch canopy. Photos and design features. Material properties, types of polycarbonate, advantages and disadvantages. Design options, do-it-yourself installation features.

Then both channel skewers are connected in pairs with cut corners to the width of the stairs, creating a contour of the steps, and the corner that is located under the riser is turned upside down (as if creating a side).

As a result, the finished staircase is practically assembled. Then it's a matter of taste. The most advantageous will look like a wooden step, which is simply placed on the resulting frame and attached in any way.

Even with a little experience with a welding machine, the total time spent on assembling a metal porch will not exceed several hours.

Concrete porch

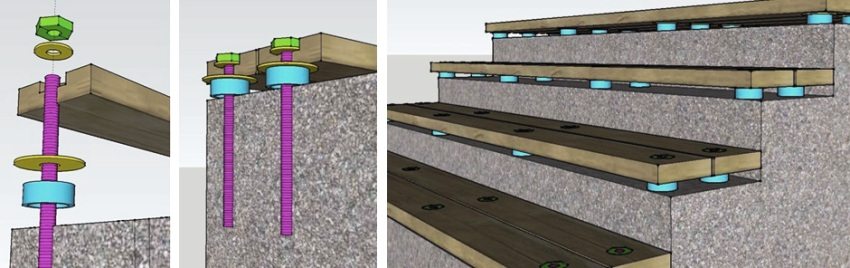

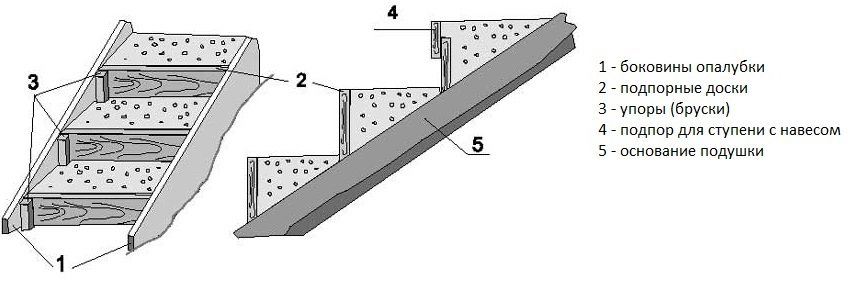

This option is a continuation of the foundation, but with the obligatory reinforcement of each step, since they will bear the main load and chips can appear very quickly - in a few months. Since, for aesthetics, a concrete porch is covered with facing tiles or stone, collapsing concrete will instantly provide chips and cracks in the facing.

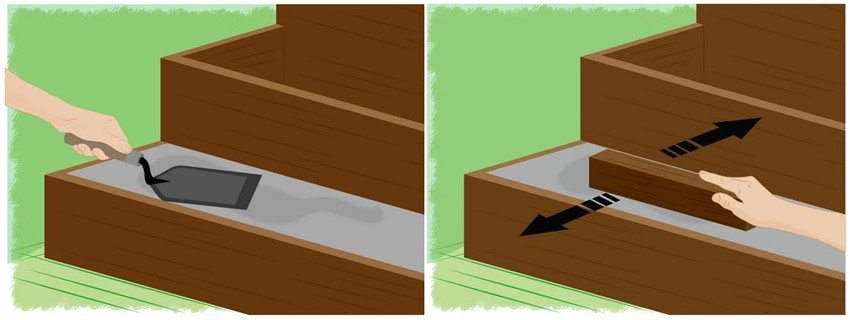

It is enough to assemble the formwork for the lower step on the already finished foundation, taking into account that the height of the lower step, due to the high load, should be 1-2 cm higher than all the others. Then exactly the same procedure is repeated as in the preparation of a reinforced foundation with the only difference that you should not regret the reinforcement or mesh.

Useful advice! The gap between the foundations of the house and the porch should be laid with mineral wool. This will create a so-called expansion joint.

You can immediately prepare a complete formwork for each step - this way, less time will be spent on work. But it will be much easier and more reliable to pour concrete on the steps in turn and let the solution set in the previous one before the device of the next step.

Then the finished solidified structure should be leveled and covered with non-slip porch tiles or facing stone.

The total time spent on work depends on whether the full formwork was used and whether all the steps were formed at once or each step was made separately, in turn. In the first case, it will take 7-10 days, and in the second - a day of work and a week for concrete hardening for each step.

Brick or stone porch

Perhaps the device of a brick or stone porch is the most time consuming option. Because it's one thing to lay a brick foundation, where accuracy is almost not required, and another thing to lay out brick or the stone is perfectly straight.

A good bricklayer lays a brick only if there are still assistants who will interfere with the concrete and bring it in time. The stone is even more difficult, as the chipped edges never fit together. So if there is no experience and a couple of people for ancillary work, then it is better to forget about a stone or brick porch right away so as not to waste material and time.

It is much easier to build a concrete staircase and choose a tile for steps, facing brick or stone of the closest possible size for the porch. Then it is easy and quick to overlay the ready-made flat concrete "frame" with one layer of brickwork or stone. This method is good in that in case of an error it will not be difficult to chop off the lining of the unsuccessful section and finish it again.

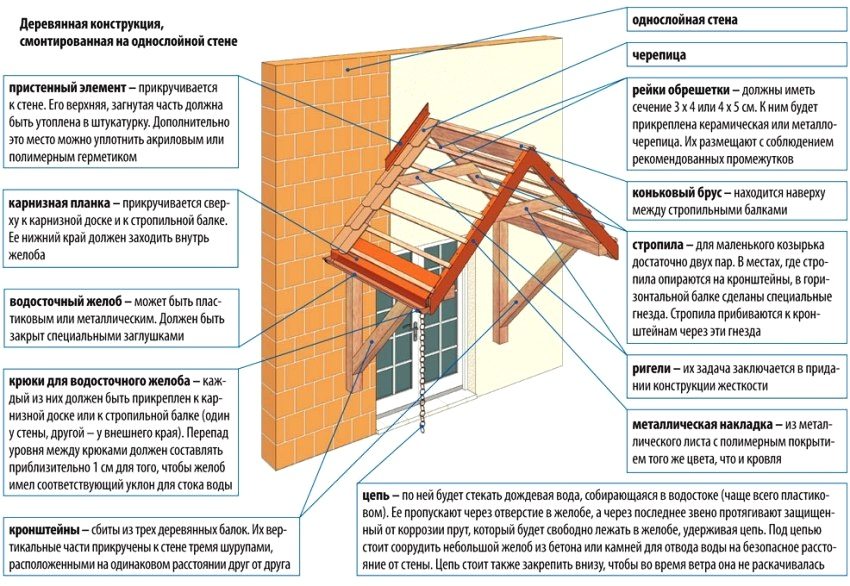

A canopy over the porch

A visor is not only a protection of the steps of a staircase and its platform from atmospheric precipitation, but also a way to arrange a porch for a summer residence with your own hands quickly and beautifully. Photos of a wide variety of canopies and awnings can be found both on the Internet and in special magazines for suburban construction.

Usually the canopy is made of metal pipes, coniferous timber for the frame and metal, any wood and plexiglass for cladding.

Wooden canopies must be tinted or treated with special compounds every 2-3 years, otherwise the tree will dry out and begin to split in the longitudinal direction, and it is better to make plexiglass planes with spans of no more than 0.7 m2 from "seven millimeters". It is not recommended to use glass - it can crack under heavy snow cover in winter or from deformation of wooden frames.

The area of the visor must exceed the area of the porch by at least half a meter, otherwise the visor will not fulfill its main protective function.

The fastest and easiest option is to make a semblance of a metal ladder, only the distance between the steps can be made 0.5 m, and L-shaped parts are not needed. The channel is also not needed, since the load on the visor is less - you can do with a corner for the outer frame. In fact, instead of "filling" in the form of wood or porcelain stoneware, you can use any material.

In the description of pouring the foundation, it was mentioned that the piles for the canopy can be easily installed even in the process of forming the base. It's best to put a visor on them. In addition, this will make it possible in the future to make a closed glazed veranda in just a couple of days.

As a covering, you can use a metal sheet on which the tiles are laid, but plexiglass or polycarbonate will look more impressive.

Useful advice! To protect against rust, the metal sheet covering the visor must be covered with paint in 2-3 layers.

The visor must be made pitched, and a metal groove with a slight slope should be welded in the lower edge of the slope. To prevent water from splashing in the rain, you should attach a regular chain to the end of the gutter almost to the ground. Water, in addition to fluidity, also has a surface tension viscosity, so that it will gradually flow down the chain. And on the ground under the drain point, you can drain and get rid of possible puddles in front of the porch.

Do-it-yourself glazed or closed porch to the house

A popular solution is a closed porch to the house with your own hands. Photos of projects of transparent, flying structures "made of glass and metal" look so attractive that they cause an understandable desire to create something similar in your own yard.

A glazed porch option is usually a concrete or stone foundation with a staircase and a canopy, necessarily resting on piles.

With the help of corners with a length along the height of the piles for the visor, a frame is formed. In this case, the corners are welded to the piles and wooden double frames are inserted with glass with a rubber lining between them.

Useful advice! The height of the glass sheet can be any, but it is not recommended to make the width more than 120 cm, since the windage of such a sheet of glass is so high that a gust of wind of 30 m / s can break a sheet 5 mm thick.

If the gaps between the piles are more than a meter, then it is better to break them with pseudo piles. To do this, a corner is welded along the bottom and top with an inward approach to the ends of the piles, and between them - a double corner, forming a pseudo-pile. In the same way, you can divide the height, forming a horizontal beam from two double corners. The load on the glass sheet will be reduced, and the structure will still look light and transparent.