Recent years have been marked by the introduction of breakthrough technologies that significantly improve the quality of life of every person. One of the high-tech materials of the new generation is polymer plastic. It has been successfully used in various industries, including home construction. In this article, we will get acquainted with how to equip a polycarbonate porch canopy yourself. Photos of such awnings varied, and the design features are not complicated.

Content [Hide]

Material properties and types of polycarbonate

Polycarbonate is a polymer plastic made from polycarbonate granules with high performance properties. This material is an excellent alternative to PVC panels and has been used in various industries and in construction.

The main characteristics ensuring its widespread use are as follows:

- plastic;

- impact resistance;

- ease;

- optical transparency;

- resistance to temperature extremes;

- high aesthetic possibilities;

- low cost;

- ease of installation and maintenance of structures;

- durability.

This high-tech synthetic material is successfully used today where more expensive natural materials were previously used: metal, wood and glass.

Related article:

|

Types of polycarbonate and its scope

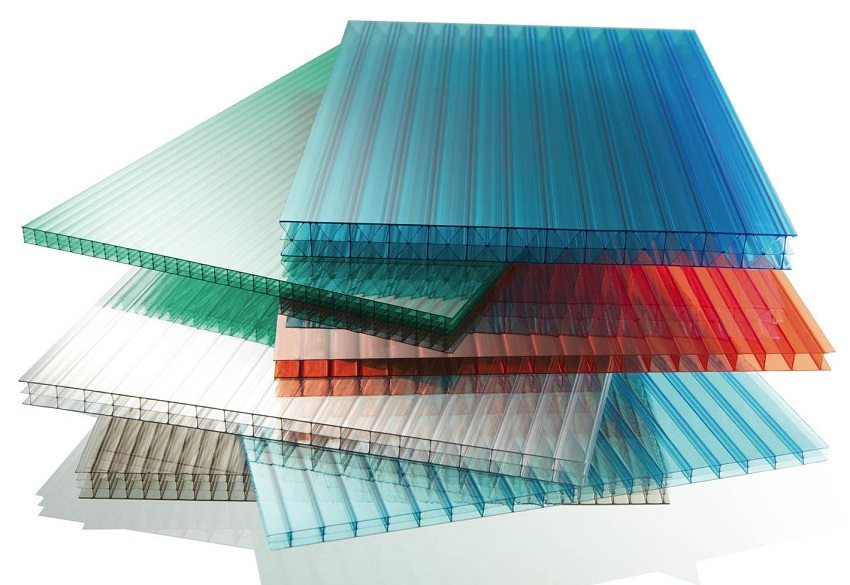

This polymer plastic is available in two types: monolithic and honeycomb.

Monolithic polycarbonate is a polymer sheet material with high transparency, impact resistance, fire resistance and fire safety. These properties ensured the use of this plastic in the automotive industry, in the design of military facilities, for the creation of technology, in advertising, construction, etc.

Cellular polycarbonate is an optically transparent or matte durable and lightweight panel that has a multi-layer construction. All elements are interconnected by internal stiffening ribs like a honeycomb. The air inside the layers provides thermal insulation properties, and the ribs provide plasticity.Thanks to these properties, this material has received widespread use in construction, in particular, in the design of canopies and awnings over the porch made of polycarbonate. Photos of these structures can be seen in various magazines for the construction of private houses.

Useful advice! Cellular polycarbonate can be a modern alternative to glass roofs and walls for various buildings: greenhouses, verandas, porch, balcony, carport or terrace for outdoor recreation.

The color variety of options from matte to transparent, as well as the possibility of creating complex geometric shapes, ensured the particular popularity of cellular polycarbonate when designing open veranda, awnings over the door or canopies over the porch. Photos and videos of self-assembly of such structures can be found on the Internet.

As an excellent replacement for glazing, polymer plastic has found its application not only in the creation of awnings and canopies, but also in the design of a polycarbonate porch in a private house. Photos and examples of such an arrangement of the entrance to the house are available on many construction sites.

Using wide aesthetic possibilities, transparency and plasticity of the material, at the entrance to the house, you can mount a modern porch with a polycarbonate canopy of any shape. The low weight of polycarbonate sheets provides a convenient self-assembly of such porch... Of polycarbonate over the porch a beautiful canopy is installed on a solid frame.

The choice of material depends on the overall aesthetics of the building, its design, as well as the financial capabilities of the owner.

When choosing a wooden frame, you can win in price and ease of assembly, but lose in durability and quality. This design has low performance properties, since wood is inferior to other materials in strength and durability.

In order for the wooden frame of the visor to last a long time, it should be treated with a special impregnation against decay

Useful advice! To make the tree last longer, before assembly it is treated with linseed oil or other impregnation that prevents decay.

The main elements of the aluminum frame for the polycarbonate canopy above the door are the aluminum profile and the polymer plastic itself. This option provides ease of assembly, since the aluminum profile is easy to cut and bend. In addition, aluminum is a light and durable metal, so it does not need special processing. The only drawback of arranging this version of a polycarbonate visor is its high price.

Steel is the next popular frame material. The polycarbonate steel frame for the porch canopy is quite heavy. It is possible to assemble such a canopy yourself, however, the assembly technology is characterized by the complexity of fastening parts.

Useful advice! It is possible to carefully fasten the parts of the steel frame to each other with the help of bolts, but the structure looks stronger and more beautiful when the joints are connected by electric welding.

The presented photos demonstrate that a steel pipe is also an excellent option for a polycarbonate porch or canopy frame.The advantage of this design is low weight and high strength. The downside is the complexity of the joints of the frame parts: the assembly of such a frame is carried out only by electric welding.

An alternative to steel roll bar is metal kraft. As you can see in the photo, you can use it to assemble a beautiful openwork structure like a forged one. Frame parts with a square cross section are sold already folded. And you can also connect them together by welding.

The illusion of a forged construction for a polycarbonate visor is successfully imitated by metal craft

Polycarbonate porch canopy. Photos and design features

In order to independently equip the visor above the polycarbonate entrance, you must first of all create a good sketch in which all the details of the structure are reflected in detail.

Useful advice! It is best to assemble the visor over the porch in the warm season or indoors, since it is undesirable to bend polycarbonate at low temperatures.

When installing a polycarbonate visor over the porch, you need to take into account that its main function is to take on snow, water and dirt, protecting the entrance to the house. This means that the best shape of this building element is arched. Such a canopy will allow precipitation not to accumulate on the roof, but to easily slide to the ground.

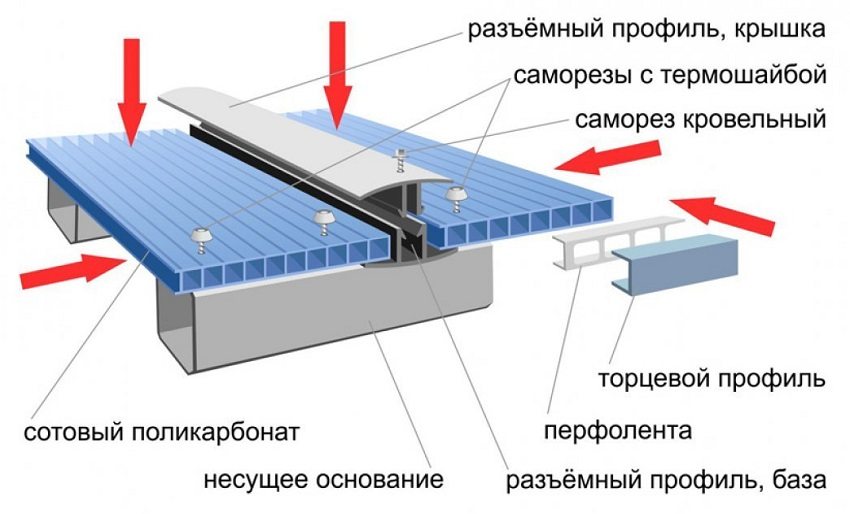

Having decided on the shape of the polycarbonate visor over the porch, it is necessary to mount the frame and cut out the canopy elements, not forgetting about the overhang length of at least 80 cm. The parts are attached to each other either using nuts and bolts, or are welded by electric welding. You can buy a ready-made prefabricated polycarbonate canopy, which already has the necessary holes in the base fittings.

Cutting of polycarbonate sheets is carried out on a protective film with a clerical knife. If the width of the panels is more than 8 mm, they can be cut with a circular saw with fine teeth. Installation of polycarbonate panels is carried out with a protective film outside, since it is this layer that is protected from UV radiation. After assembling the entire structure, the protective film is removed.

The last element of installation is to protect the open areas of the ends of polycarbonate plates from dust, water and dirt. For this, a special aluminum tape is used, which is installed on the ends of the panels (as shown in the photo).

As an excellent alternative to expensive glass, metal or wood - traditional materials for the manufacture of awnings and canopies, synthetic polycarbonate has a number of advantages over them, which made it so popular. A variety of color palettes, ease and ease of installation allow you to realize the most daring design fantasies.