The solenoid valve is used in many pipeline systems to control the transportation of various gases and liquids. These devices are widely used both in the industrial field and in everyday life, therefore, information on how they work and what characteristics they have will be useful to everyone. This article will help you understand the features of the application and installation of solenoid valves.

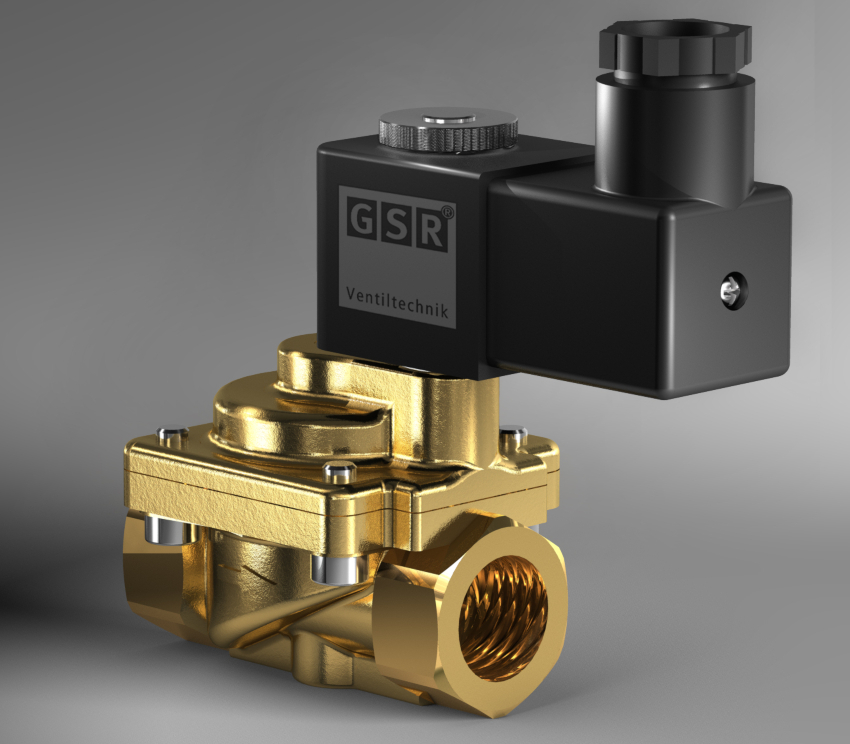

To control the transportation of various liquids and gases in pipelines, solenoid solenoid valves are used

Content [Hide]

- 1 Valve classification: what is a solenoid, the main types of mechanisms

- 2 Characteristics and features of water solenoid valves

- 3 How to install an electrovalve for water with your own hands (12 Volt, 220V)

- 4 Operational features of water valves

- 5 Solenoid valve selection: device prices and popular brands

Valve classification: what is a solenoid, the main types of mechanisms

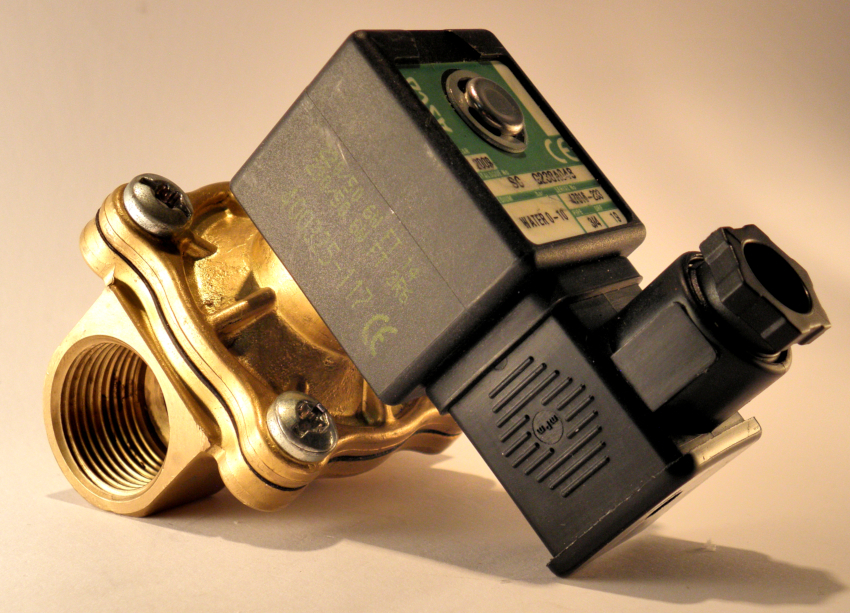

Solenoid valves are shut-off and control devices that are used to turn on and off a system inside which a liquid or gas is moving. They allow you to control the work of communications remotely. These devices contain electrical magnets called solenoids. This explains their name.

The solenoid valve has almost the same structure as the standard version of the shut-off device. The only difference is that the mechanism is triggered when an electric charge enters the solenoid valve coil. It does not require physical effort to open and close.

In industry, with the help of such valves, the process of transporting various media and liquids is controlled, and the current strength is also regulated. In addition, they are widely used in everyday life.

Solenoid solenoid valve: device classification

There are several types of solenoid shut-off devices. These devices are classified according to different criteria:

- type of construction;

- the material from which the body part is made;

- type of seal;

- the position of the lock inside when the system is in a de-energized state;

- connection method.

Each type of device is designed to work in different conditions, at a certain pressure and temperature. Different types of devices control their environment. Distinguish between water valves, gas, air, steam. There are devices that regulate the operation of systems inside which oil, gasoline and other fuels move.

Important! The solenoid valve must be selected very carefully. If you take a device that does not meet the requirements of the system, it will not last long.

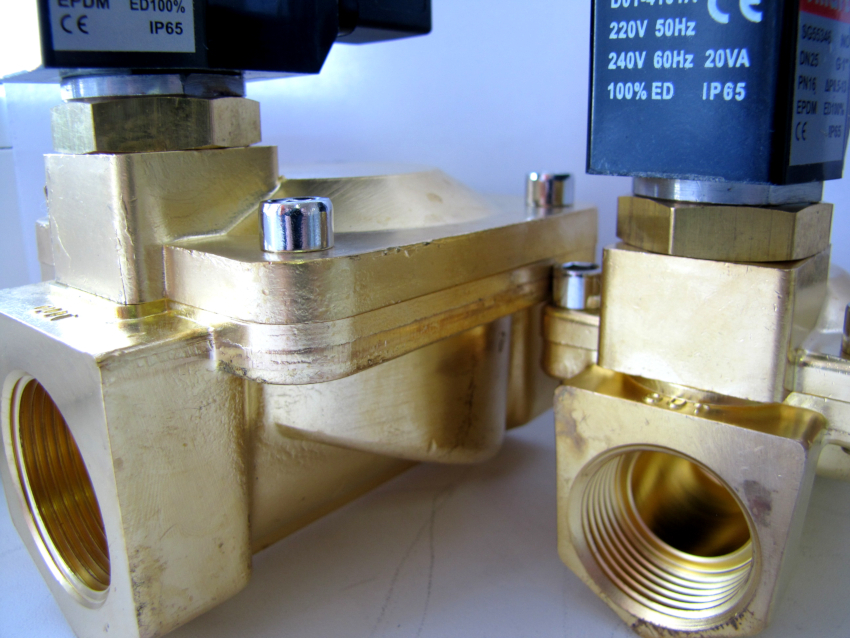

According to the method of connection, electromagnetic devices are coupling, flanged and choke. Their size varies between 6-150 DN, which allows you to choose a locking mechanism for any pipeline. For the manufacture of the body of the devices, manufacturers use stainless steel, cast iron, brass, as well as various types of plastic with an increased margin of safety.

The shut-off of the liquid by the valve is carried out thanks to the membrane installed inside it. And also a sealant is involved in this process, which is made of elastic polymers:

- ethylene propylene elastomer;

- fluoroelastomer;

- butadiene-nitrile rubber.

Fluoroelastomer products are able to withstand high temperatures and contact with gasoline and oils. Rubber seals are used for industrial purposes, as they are resistant to oil products. Electric water valves use EPDM products. They can come into contact with acids, salts and alkalis that are present in the liquid.

Classification of electrovalves for water according to the principle of operation

The functionality of the locking devices depends on the internal structure, the number of nozzles and holes. According to the principle of operation, solenoid valves are divided:

- on one-way;

- two-way;

- three-way.

One-pass products are connected to the pipeline system through one branch pipe. These devices have a protective function. If the pressure level rises in the system, they simply release excess water or steam. Solenoid valves 2/2 (two-way) have two ports - inlet and outlet.

Three-way devices are connected to pipes using three branch pipes. They have two inlets and redirect media from one pipeline to another. Such devices are usually installed in heating systems. The functionality of solenoid solenoid valves (220V) with three nozzles allows mixing the working medium by distilling the heat carrier between the two circuits. As a result, the temperature of the water in the system changes. In this case, the pipeline continues to operate in the same mode.

Note! The type of membrane must be selected taking into account the temperature of the working medium and its composition. The rust and sand present in the pipes negatively affect the condition of these products, regardless of the material of their manufacture. Therefore, any type of valve is connected to the pipeline only if there is a filter.

According to the principle of operation, solenoid valves are direct and indirect. In direct-acting devices, the core moves exclusively under the influence of an electromagnet. Indirect valves also react to the pressure of the working medium.

Characteristics and features of water solenoid valves

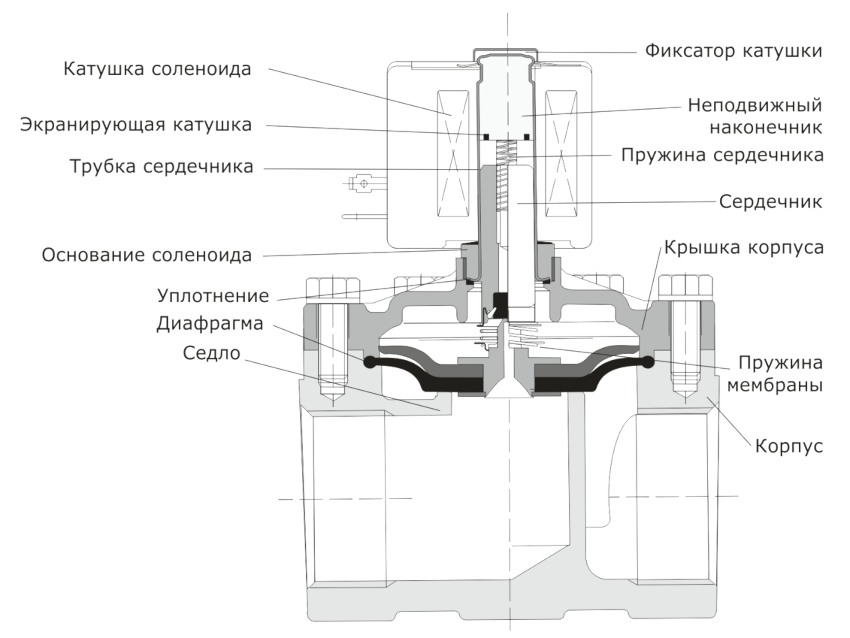

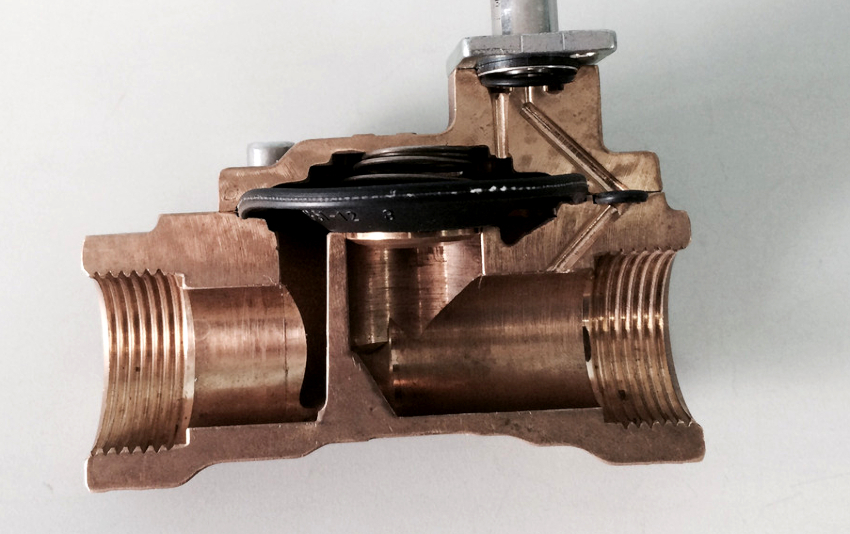

In the design of any shut-off device there is a control element, which can be diaphragm, slide valve or piston. Diaphragms are usually installed in solenoid valves for household use. They are reliable and easily cope with the regulation of water supply and heating systems.

Another classification of solenoid electrovalves for water (220V) is based on the design features of these devices, in particular, taking into account the position of the locking mechanism when the magnet is de-energized.

In the design of any solenoid valve there is a control element, it can be a spool, diaphragm or piston

According to this parameter, the following types of devices are distinguished:

- normally closed solenoid valves for water (220V);

- bistable valves;

- normally open solenoid valves.

Normally closed valves are electrically controlled. When no voltage is applied to the solenoid, the core is lowered, there is no water movement through the system. This is due to the pressure of the internal spring. The reverse process occurs in normally open solenoid valves. When the device is completely de-energized, the device channel is open. It closes when power is applied to the solenoid. Bistable or pulse valves in the absence of voltage can be both open and closed.

Scope of Application of Normally Closed Solenoid Valves for Water

The water seal is successfully used in the national and household, as well as in some industries. The most widespread devices are 220V. Several manufacturers produce 24V and 12V solenoid valves.

Devices equipped with a solenoid are used in irrigation systems for irrigation of greenhouses, vegetable gardens and orchards. Thanks to the locking mechanism, it is possible to completely control the water flows, and all processes become automatic.

Useful advice! If you connect the timer to an electromagnetic device, you can set the exact time for switching it on and off, so you do not have to constantly monitor the operation of the system.

Solenoid valves are also used in washing systems, realizing the timely drainage of water during the cleaning process. Such devices are found in industrial and household washing machines. In large scale kitchens, shutoff valves control the water supply to dishwasher and conveyor systems, as well as coffee machines. In addition, they can be part of heating and sewerage systems (toilets and showers).

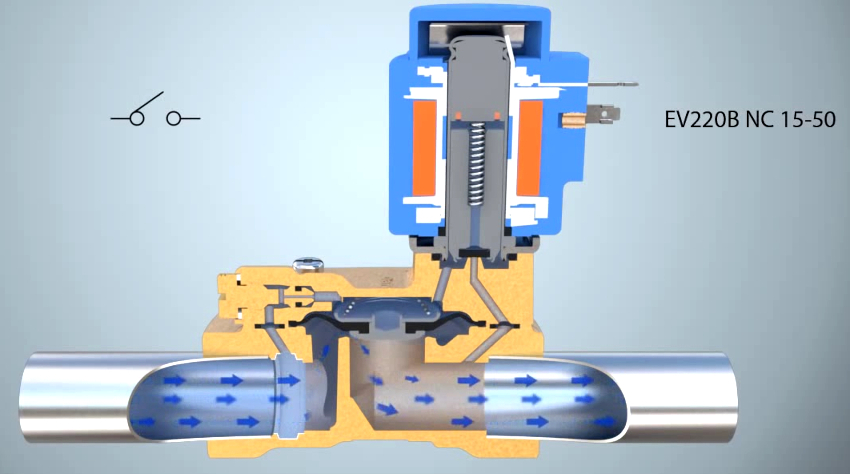

Standard design of normally closed solenoid valve (220V)

The simplest design usually has one inlet and one outlet, although there are multiple port options.

Most locking devices include the following parts:

- anchor spring;

- hole responsible for adjustment;

- coil;

- valve plate;

- main hole;

- diaphragm;

- hole responsible for alignment.

Electromagnetic solenoid valves normally closed 220V have many useful advantages, including convenience, high response speed, and the ability to control the system operation remotely. They are more accurate than manual devices, save time and effort, and improve the safety and efficiency of household appliances.

There are no worm and gear drives in the design.In contrast to a gearbox and an electric motor, valves have a simplified structure and a minimum number of moving parts, so they are more reliable, have a long service life and are subject to minimal wear.

The high reliability of normally closed water solenoid valves is due to other design features. If the remote control fails or the electricity goes out, it is still possible to use the device, which in this case will act like a regular water tap. To do this, it is enough to turn the control solenoid положение turn to the “off” or “on” position.

Note! The smaller the distance between the electromagnetic core and the stopper, the stronger the electromagnetic field. Moreover, this statement remains unchanged, regardless of the type of voltage and its magnitude.

How an electromagnetic solenoid valve works: how it works

The electromagnetic inductor is capable of operating in any AC or DC voltage. Solenoids are in sealed housings, so contact with moisture is completely excluded. Small electromagnetic systems consume little energy, so that control can be carried out using semiconductor circuits.

The strength of the magnetic field in electromagnetic systems, like the size of the stem, is much greater than in systems with a constant current. When voltage is applied to the selenoid and the gap between the core and the stopper is maximized, the AC system consumes a large amount of power. As a result, the stem rises and the gap is completely closed. In this case, the power level of the output stream increases significantly, creating a pressure drop.

Under similar conditions, when DC is applied, the flow rate increases very slowly. This happens until the voltage reaches a fixed level. For this reason, shut-off valves can only control low pressure systems. The exception is communications with a small through-hole.

In other words, when there is no current on the coil and the valve is open / closed (depending on its type), in the static position the piston creates a completely sealed connection with the device seat. When voltage is applied, the solenoid transmits a signal (impulse) to the actuator, as a result of which the stem opens. This is because a magnetic field is formed around the coil and interacts with the plunger.

How to install an electrovalve for water with your own hands (12 Volt, 220V)

You can handle the installation of a solenoid valve (12 Volt, 220V) on water yourself. To avoid mistakes in the process, it is advisable to adhere to some rules:

- installation of a locking device equipped with a coil capable of performing the function of a lever is not allowed;

- all work on the installation or dismantling of the valve can be performed only after the system is completely de-energized;

- care must be taken that the weight of the pipeline does not put pressure on the valve body.

Important! In the process of installing an electrovalve for water (12 Volts, 220V) with your own hands, you need to control the direction of the arrow on the device case. It should point in the same direction as the water flowing through the pipeline.

Locking devices can be used in open areas, for example, at local treatment facilities, which can often be found at summer cottages. In this case, the electromagnetic device needs additional protection. A standard FUM tape is suitable for these purposes.It should also be used when working at low temperatures.

Related article:

DIY autowatering: how to install and use an irrigation system on the site

Selection of the constituent components. Automatic irrigation schemes. Sprinkler irrigation, drip irrigation and automated subsurface irrigation.

When connecting the device to the power supply, be sure to use a flexible cable. The recommended cross-section of conductors is 1 mm.

In the process of installing the device with your own hands, you need to control the direction of the arrow on the body of the solenoid valve

Solenoid valve installation process (220V, 12V): practical advice

Before proceeding to direct installation, you need to determine what type of connection will be used for this.

With a threaded connection, the outlet and inlet connections have an internal or external thread. By using fittings of the appropriate size and configuration, the fittings can be integrated into the pipeline system. This option is considered the most convenient if the valve is installed by hand.

Flanged connections use branch pipes that have flanges at the ends. The same elements must be present on pipes. The parts are pulled together using bolts. The flange connection allows you to create a high flow rate in the system, as well as a considerable pressure. It is most often found on lines with medium and high pressure.

Instructions detailing the installation process are included with each valve package. If done correctly, the device will function properly, providing protection against leaks. When installing the device, you need to leave a little extra space in the installation area. This is so that the solenoid can be removed and replaced if necessary. In addition, the availability of free space will allow you to control the operation of the valve, using a mechanism for this, which provides a manual stem lift.

It is advisable to install a filter upstream of the valve. It will trap solid particles larger than 800 microns. Only a normally closed valve should be installed upstream of the expansion valve. To exclude the possibility of water hammer when opening the shut-off device, leave as little space as possible between it and the expansion valve.

Important! Installation of solenoid valves on water is carried out exclusively with the coil up.

It is not recommended to use adapters before and after the valve. These elements can narrow the pipe diameter, increasing the risk of water hammer. It is better to place the adapters in front of the expansion valve. By vertically installing a T-shaped tube in the solenoid valve, which will act as a damper, it is possible to reduce the force of the water hammer that occurs when closing. In addition, the presence of such a tube will increase the service life of the device. A damper is essential if the pipeline is long and small.

Operational features of water valves

Provided it is correctly installed, and if all requirements are met during operation, the solenoid valve can effectively serve for a long time, stabilizing the level of water pressure inside the pipeline. The solenoid extends pipe life by evenly distributing loads.

The main signs and causes of failures in the operation of electrovalves on water:

- Lack of power supply - most often occurs when the cable of the control panel is damaged.

- The valve does not work - if the spring fails, the device will not be able to function normally and respond to voltage changes.

- The absence of a characteristic click when turned on - the reason for this may be a burnt out solenoid.

The most common cause of valve failure is blockage. Therefore, if any malfunction occurs in the device, the first thing to check is the hole where solid particles can accumulate.

Useful advice! Experts recommend regularly checking the condition of the internal elements of the shut-off valve. This can only be done after the system has been completely emptied. If communications need complex repairs, it is better to hire professionals to do this work.

Solenoid valve selection: device prices and popular brands

When choosing shut-off valves for a water supply system, it is necessary to carefully study the specifications and descriptions provided by the manufacturer. This information will allow you to determine in what conditions the installation of a particular valve model is allowed.

When choosing a valve for a water supply system, you need to pay attention to the dimensions of the outlet and inlet openings

When choosing a device, you need to consider the following points:

- system type;

- temperature regime;

- pressure level;

- the chemical composition of the liquid;

- current speed, etc.

The dimensions of the outlet and inlet are of great importance. These parameters must correspond to the diameter of the pipes. It is very important that the characteristics of the system and the shut-off valves match, otherwise there may be disruptions in the hydraulics of communications. Such an outcome is possible if, in the area where the valve is installed, due to the narrow opening, the fluid flow slows down, which will inevitably affect the pressure level and temperature in the entire pipeline.

Solenoid valve prices:

| Device model | Price, rub / piece |

| Ceme solenoid valves | |

| D20 G3 / 4 | 3200 |

| D25 G1 ″ | 4750 |

| 87 G 2 1/2 D65 | 33200 |

| 87 G 3 D75 | 38650 |

| D75 G 3 D75 | 46850 |

| Shut-off solenoid valves ZSK | |

| ZSK-15 DU 15 | 12500 |

| ZSK-25 DU 25 | 13200 |

| ZSK-32 DU 32 | 14000 |

| Danfoss solenoid valves | |

| Solenoid valves EV210B | |

| EV210B G 3/8 NC | 2850 |

| EV210B DN8 G 3/8 NC | 3350 |

| EV210B G 1/4 | 4200 |

| EV210B | 4850 |

| Solenoid valves EV220B | |

| EV 220V 6B | 2800 |

| EV220B NC G1 / 2 | 5500 |

| EV220B NO G1 / 2 | 6450 |

| EV220B 20B | 11150 |

| EV220B 32B | 16550 |

Danfoss solenoid valves

Danfoss valves are used in various types of equipment - from pumps installed at petrol stations to machines that can be found in dry cleaners. The small size of these devices does not affect their reliability at all. Danfoss manufactures an extensive range of valves. Thanks to this, you can find in stores such modifications that other manufacturers make exclusively on special orders.

The advantages of Danfoss solenoid valves:

- extensive range of general-purpose devices;

- even standard modifications can solve many of the problems faced by the industry;

- The range of products allows you to select devices that can contact with very aggressive media, for example, valves, the body of which is made of stainless steel and is provided with protection class IP67.

Note! If necessary, Danfoss can modify the product according to the buyer's specification. This allows you to find optimal solutions for any industrial task. Moreover, representatives of the buying company can take part in the development process.

The shutoff devices are supplied with a complete package of technical documentation and simplified manuals are provided to allow customers to select the valve with the correct characteristics. The production process employs specialists who are experts in the field of gas, steam and liquid control. Therefore, the products are distinguished by high functionality, reliability and safety.

On sale you can find direct-acting electromagnetic locking devices and equipped with a servo drive. Two-way solenoid valves Danfoss EV220B, which are designed to regulate neutral gases, water, air, oils, are in special demand. Some modifications from this line can control steam and mildly aggressive environments.

Features of Asco solenoid solenoid valves

The American company Asco is one of the leading manufacturers of hydropneumatic, solenoid and shut-off valves, as well as pneumatic cylinders, pneumatic automation and other automation devices.

Product advantages:

- instrumentation equipment is manufactured on modern production lines with a wide range of functionality;

- if necessary, the valves can be easily repaired, and the process itself does not take much time;

- high level of reliability;

- ability to withstand contact with aggressive media and extreme loads.

The manufacturer produces more than 5000 standard types of shut-off valves. In addition, Asco manufactures special modifications and versions of these devices, the number of which exceeds 20,000. All of them are designed to meet the different needs of customers. At the same time, the manufacturer complies with the strictest quality requirements, monitoring all stages of production, including the development process, sales, and service.

Note! Before getting on store shelves, products are carefully checked for manufacturing defects, and also tested. The highest quality of the valves is confirmed by ISO 9002 and 9001 certificates.

Arcom products: characteristics of the AR HX 3 solenoid valve

Arcom supplies the market with thousands of electrical products. This list includes recorders (paperless and paper), controllers, electrical and measuring instruments, various tools and related accessories. Solenoid valves occupy a special place in the range. Buyers can purchase over 4,500 locking options at an affordable price. Moreover, all products are certified and meet a high level of quality.

In the manufacturer's catalogs, you can select fittings that allow you to control the movement of water, air and oil products. In addition, the manufacturer provides a huge selection of spare parts, relays, coils, connectors and gates for these devices.

Despite the wide range, special attention is paid to solenoid valves, the HX 3 solenoid valve, due to its many advantages, is considered the most demanded model:

- robust, durable stainless steel housing;

- fast response (reacts when pressure reaches zero);

- minimum dimensions;

- the ability to connect to sensors.

This model is designed to regulate hot and cold water, steam and air, which allows the valve to be installed even in electric irons, coffee machines and other appliances that use steam in their work.

Tork Solenoid Valves Overview

The valves under the Tork brand name are manufactured by SMS. The high quality of products was appreciated by many countries in Asia, America and Europe, so about 40% of goods are exported. The production process is fully automated.In the manufacture of valves, manual labor is practically not used, which eliminates the likelihood of defects, which can be caused by a human factor.

The production range of the company includes valves of the following types:

- bistable and monostable;

- for gases and liquids that have an aggressive and neutral effect;

- for high temperature water and steam;

- for light oil products and gasoline;

- for vacuum;

- for reciprocating compressors, etc.

Before going on sale, the fittings are examined for leaks, the strength characteristics of the body are tested (for this, the product is exposed to five times the pressure). Using a non-contact tester, the functionality of the solenoid coils is checked.

All of the listed solenoid valve companies are of the highest quality. Thanks to these devices, the operation of equipment and communication systems becomes completely controlled and safe. Valve life and performance will depend on how well the valve is fitted and on its characteristics.