District heating multiplies housing maintenance costs. Owners of private houses choose an autonomous heating method. The best option for individual housing construction is the installation of heating a two-story private house with your own hands. Schemes, calculations and binding of a typical project are performed independently. The heating scheme of a 2-storey private house is one of the components of the engineering part of the project.

An effective heating scheme for a private house will provide a comfortable microclimate in cold weather

Content [Hide]

- 1 Heat engineering calculation of the heating system of a 2-storey private house

- 2 Components of the heating system of a private house

- 3 Varieties of heating systems

- 4 Collector in the heating scheme of a two-story house with forced circulation of the coolant

- 5 Heating medium distribution along the height

- 6 Horizontal types of heating systems

Heat engineering calculation of the heating system of a 2-storey private house

The heat engineering calculation determines the operating parameters of the heating system - the total amount of heat loss in the building, the power of the equipment, the number of heating devices, etc.

The power of the heat generator is calculated by the sum of the heat loss of the house, which takes into account:

- area of heated premises;

- climatic conditions of the area;

- the presence and condition of the thermal insulation of the premises;

- material and thickness of external (bearing) walls, floors and ceilings;

- roof structure, technical floor;

- tightness and size of windows, street (balcony) doors.

Components of the heating system of a private house

Boiler - heat generator in the heating and hot water supply system. Average power standard 100 W per 1 m2 area, provided that the height of the insulated room is not more than 3 meters. Provides a margin of up to 20% of the boiler performance for unaccounted losses. Hot water supply requires an increase in power reserve of 50%.

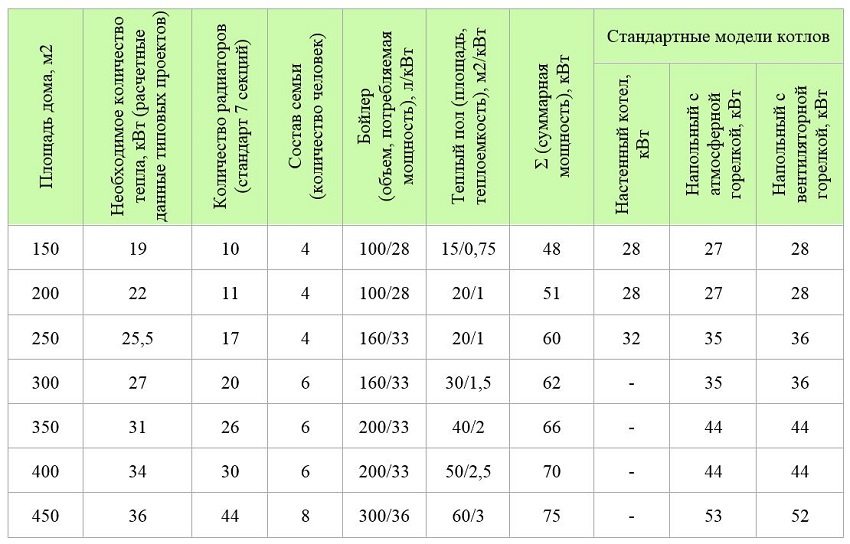

The summary table, with options for typical heat engineering calculations of the boiler power, allows you to compare the approximate results of the selection and existing models of heat generators.

The boilers can run on diesel, coke, coal, wood, peat, pellets, natural gas or electricity. The choice of fuel depends on its availability. More than 70% of consumers use gas boilers... Electric boiler (convector) are considered as a backup or combined option.

Cast iron or steel generators of thermal energy are produced in floor and wall versions.Stationary floor standing boilers are installed in a separate room, which is equipped with a boiler, an expansion tank, a chimney and a forced ventilation system (in accordance with the norms and requirements of the gas service).

Wall mounted gas boilers do not require a chimney and a separate room. Oxygen for gas combustion is supplied through a flexible corrugated pipe. The single-circuit unit is designed for heating. The use of a heating scheme for a two-story house with a double-circuit boiler provides heating and hot water supply.

Methods of transferring the thermal energy of the boiler to the system: forced circulation of the coolant and natural circulation (non-volatile heating method). The boiler design with two circuits contains an integrated circulation pump and a closed expansion vessel.

Carriers of thermal energy in the heating system: water, antifreeze or electrolyte coolant for flow-type electrode boilers.

Water has a high heat capacity and density, but requires a constant temperature regime in the room in winter. Homeowners who use the house irregularly prefer antifreeze as a coolant.

The choice of the type of heating distribution and the type of heat carrier is made at the stage of project development. The viscosity, expansion coefficient and heat capacity of antifreeze slow down the heat exchange process and reduce the heat dissipation of radiators. For the non-freezing coolant, it is required to increase the power of the pumps and the flow area of the system.

Important! The presence of ethylene glycol in antifreeze limits its use in double-circuit boilers. Some additives destroy parts made of polypropylene, cast iron, non-ferrous metals, and rubber.

Heating device - steel, aluminum, combined, cast iron or anodized radiator (battery), which gives off its heat and provides a favorable microclimate in the room.

Heat transfer and inertia depend on the material and dimensions of the device. The length of the battery structures is changed by adjusting the required number of sections. An air vent (Mayevsky's valve) and a thermostatic valve installed at the inlet of the coolant to the heater ensure a uniform design heat removal. A shut-off valve on the outlet is required for maintenance during operation.

The installation locations of heating devices are indicated in the regulatory technical documentation: along the perimeter of the heated room, under window openings, near the front door. Thermal curtaininstalled at the front door will not allow cold air from the street to enter the residential building.

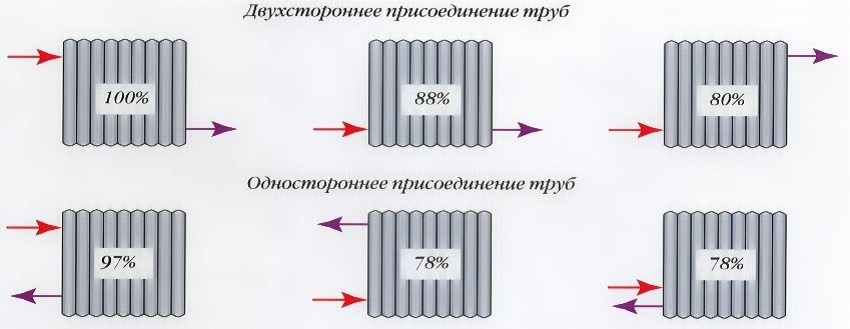

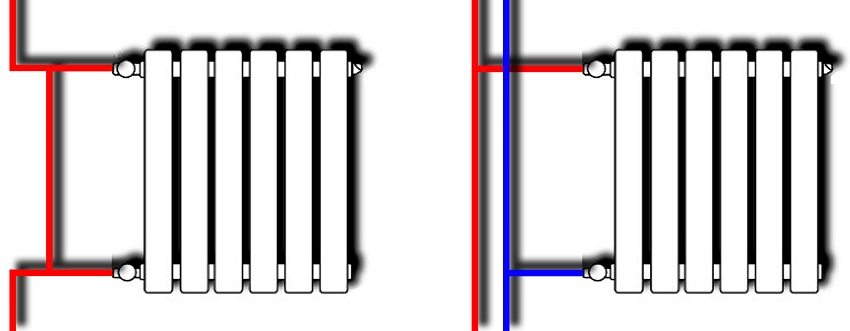

Connection methods radiators with risers and piping: one-way, diagonal and bottom piping.

The number of radiators (I) is calculated by the formula:

I = S * k1* k2* k3* k4* 100 / P (pcs), where

S - room area, (m2);

P is the passport value of the power of one section, (W);

k1 - increasing coefficient for double-glazed windows;

k2 - reducing coefficient of losses, which depends on the area of the outer walls;

k3 - dependent coefficient on the design and roof insulation (with or without an attic);

k4 - dependent coefficient on the ceiling height (k4 = 1, with h = 2.5 m), the higher the interfloor space, the greater the correction value.

Note! The manufacturer indicates the calculated parameters in the product passport: internal volume, and the power of the radiator.The coolant consumption in a 7 kW battery is 7 liters per minute.

Pipeline transfers, distributes and returns the heating medium to the boiler. The directed movement of the flow is slowed down by the rough inner surface of the pipes, the change in the diameter of the flow area, and turns. The value of the hydraulic resistance determines the way of circulation (natural or forced).

The piping (closed loop) ensures that the system is sealed. The power of the boiler is directly proportional to the flow rate of the coolant, which determines the internal radiator volume, the capacity of the boiler heat exchanger and the filling of the pipeline sections.

In heating systems of private houses, seamless steel and polypropylene pipes with a minimum coefficient of internal resistance (roughness) are used.

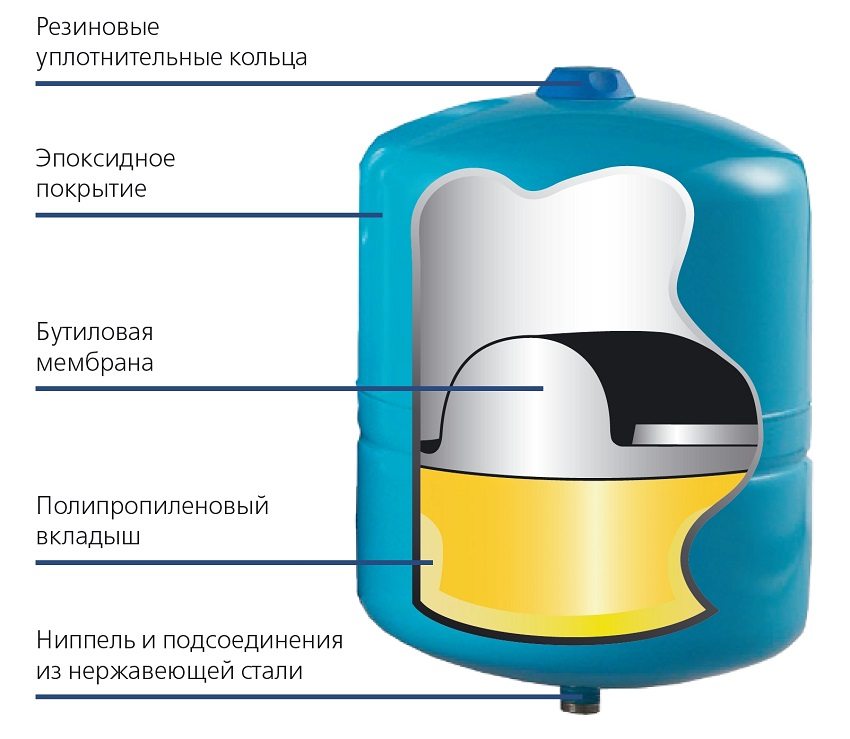

Expansion tank for closed or open heating is present in all heating systems of a two-story private house. The pressure that the circulation pump or gravitational forces create in the pressure pipeline changes the boiling point of the coolant. A sharp boil of water can provoke a spontaneous jump in pressure, release of dissolved gases and a multiple increase in volume (thermal expansion), which leads to the destruction of the components of the heating system. Expansion tank helps to avoid such problems.

The diaphragm divides the sealed, closed-type expansion tank into a water chamber and an air chamber. In closed-type systems, the tank is installed on the return pipe, in front of the suction pipe of the circulation pump. The dependent layout implies that the tank is raised to a height of at least one meter.

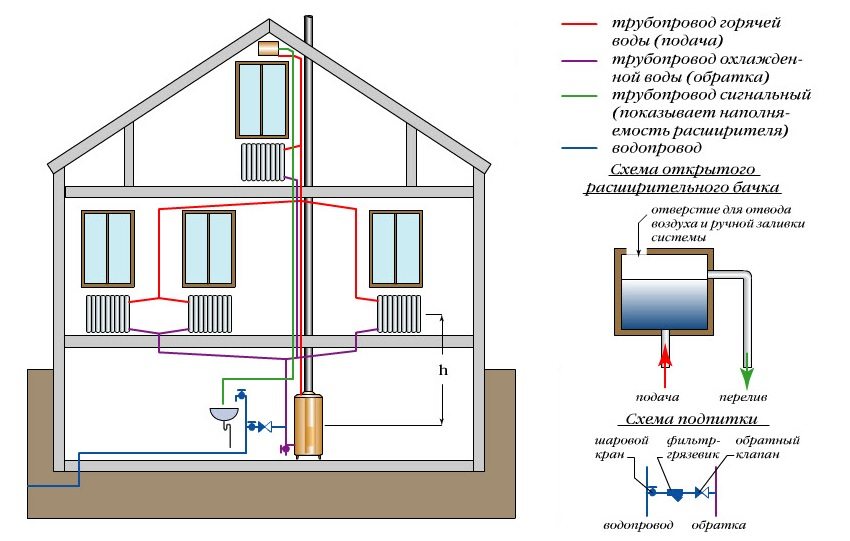

An open expansion tank is installed at the top of the booster (main) riser in the attic. An overflow pipe and a feed pressure pipeline are cut into the body. The design requires careful thermal insulation, since at low temperatures the non-insulated tank and overflow can "defrost". The estimated volume of the tank (10% of the total filling volume of the network) provides savings in the heated coolant during overflow and air removal. The disadvantage of an open-type expansion tank is the evaporation of the coolant.

Fitting - the connecting part of the pipeline, installed in the places of its branches, turns, transitions to another diameter

Important! In heating systems with antifreeze, closed-type expansion tanks are installed as a heat carrier, which ensure tightness, preservation of the original volume and properties of the heat carrier.

Installation shut-off valves in the heating system provides the opportunity to turn off a section of the network or equipment for prevention, repair or replacement. Ball valves are installed on risers, before and after heating devices, pumps, collectors, boiler, boiler.

Safety fittings - non-return and safety valve, automatic air vent, balancing valve. They protect the pipeline from throttling flows and hydraulic shocks the heating system (pump, radiator, boiler). The shut-off valve stops the fuel supply when the gas analyzers are triggered, the electricity is cut off and the circulation through the heat exchanger stops.

Control valves (electronic or electromechanical control valve, thermostatic valve) equalize the indicators in the heating system.

The main condition for fittings and fittings in the heat supply system is that the fitting must provide proper permeability with lower pressure losses and tightness of branches, turns, diameter transitions in the pipeline.

Related article:

|

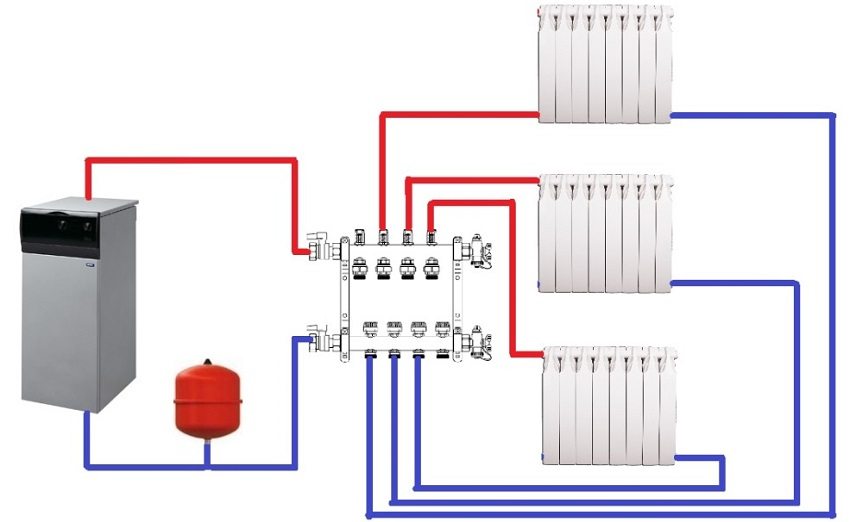

Hydraulic gun and distribution manifold separate hydraulic circuits, reduce losses, increase permeability, distribute heat load. Additionally, they serve as a place for the installation of measuring instruments of the safety group (thermal sensors, flow meters, manometer, thermometer). The thermodynamic arrow ensures the removal of dissolved gases and suspended particles from the coolant.

Hydrostrel and distribution manifold separate hydraulic circuits, reduce losses, increase permeability, distribute heat load in a multi-circuit heating system

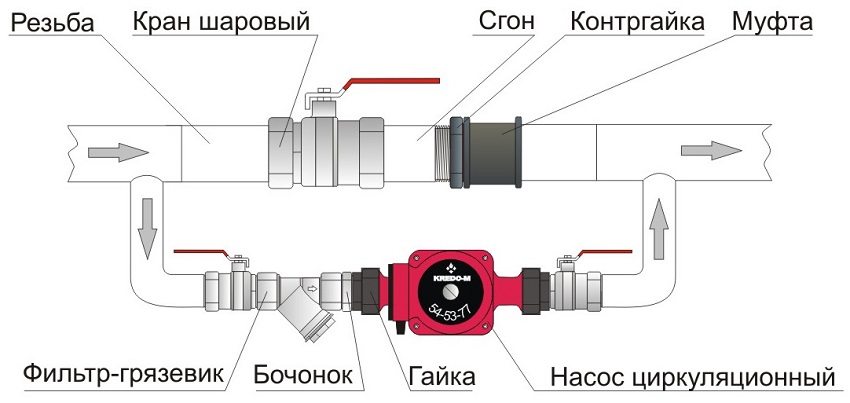

Circulation pump in system heating a private house moves the flow of heated water in a closed loop, so the height of the house does not significantly affect the pump power. In "wet" circulation pumps, the rotor with the impeller is located in the heating pipe. The working medium lubricates the parts and cools the engine. The principle of operation and functional features of the pumps depend on the power, head (m), flow and efficiency

Formula for calculating pump performance:

Q = P / ΔT * 1.16 (m / s, l / s, m3/hour),

The formula for calculating the pressure:

H = R * L * Zƒ (pascal).

| Designation | Decoding the symbol | Units |

| Q | Maximum pump flow (flow) | l / s, m3/hour |

| P | Maximum boiler power (passport data) | kWh |

| ΔT | Heat removal from heating devices, conventionally taken 20 ° C | ° C |

| 1,16 | Specific gravity coefficient of water | W * hour |

| H | Closed loop head | Pascal |

| R | Hydraulic losses in the pipeline (for two-storey house 150 Pa / m) | Pa / meter |

| L | The sum of the lengths of the circuits in heating | meter |

| Zƒ | Roughness coefficient in connections, shut-off valves, devices for adjustment and protection from incorrect system operation. | 1.3 for standard fittings and ball valves;

1.7 for thermostatic, two- or three-way valves |

The circulation pump is traditionally installed on the return pipe in front of the boiler or the pressure blower is brought out to the bypass. The manufacturer develops the installation and operation manual for the device.

Varieties of heating systems

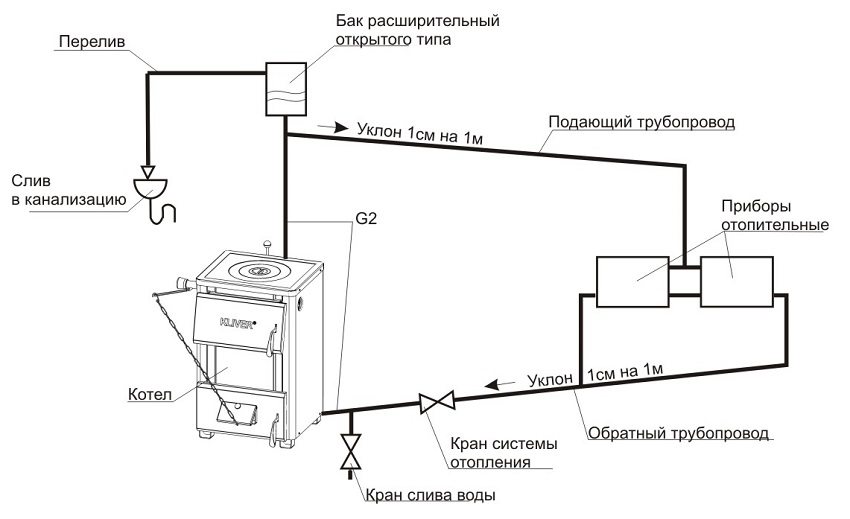

The principle of the device one-pipe heating system (the diagram is shown below) - serial connection of radiators in the wiring of the heating circuit. The thermodynamics of the process is based on the increased diameter of the pipeline (at least 32 mm), the slope of straight sections (0.5% of the length) and the excess of the radiator axis over the central line of the boiler (H).

Self-regulation in the circuit is due to the temperature difference between the first / last radiator and the force of gravity. The flow passes alternately through each heater (the return of the previous one is the supply of the next radiator). The temperature decreases with distance from the heat source, while the density of water, on the contrary, increases.

The figure shows a schematic diagram of natural circulation heating.

Important! A one-pipe scheme with natural circulation is used to heat houses with an area of less than 100 m2... The scheme excludes the possibility of underfloor heating and hot water supply.

The one-pipe circuit for connecting heating devices is known as the "Leningradka" heating system.To increase the efficiency of the system, the Leningradka circuit can be supplemented with a pump, valves, thermostats and balancing valves, a bypass is installed between the supply / return pipes.

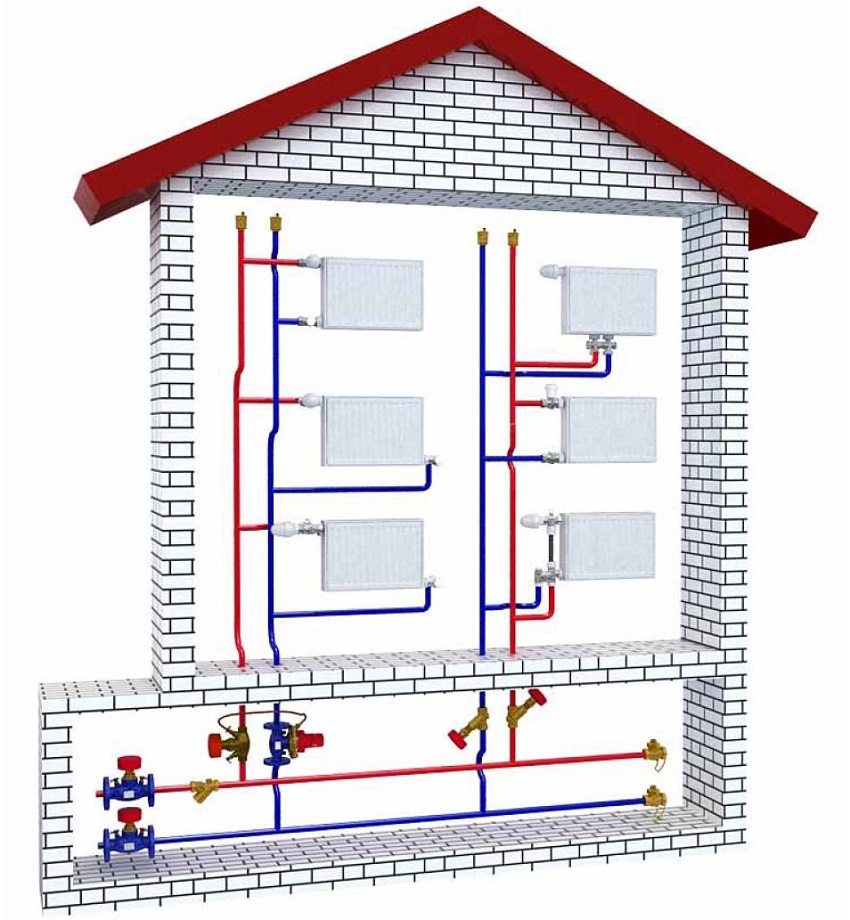

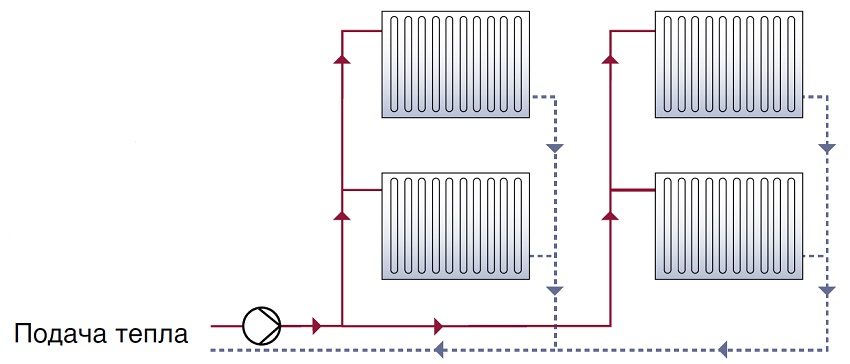

Two-pipe heating system separates the supply line and the return line. The wiring increases the efficiency of the system, reduces heat losses and hydraulic resistance.

The two-pipe circuit determines the parallel connection of the inlet and outlet pipes of the heater. The coolant temperature in the radiators is leveled, heating does not depend on the distance of the heat source.

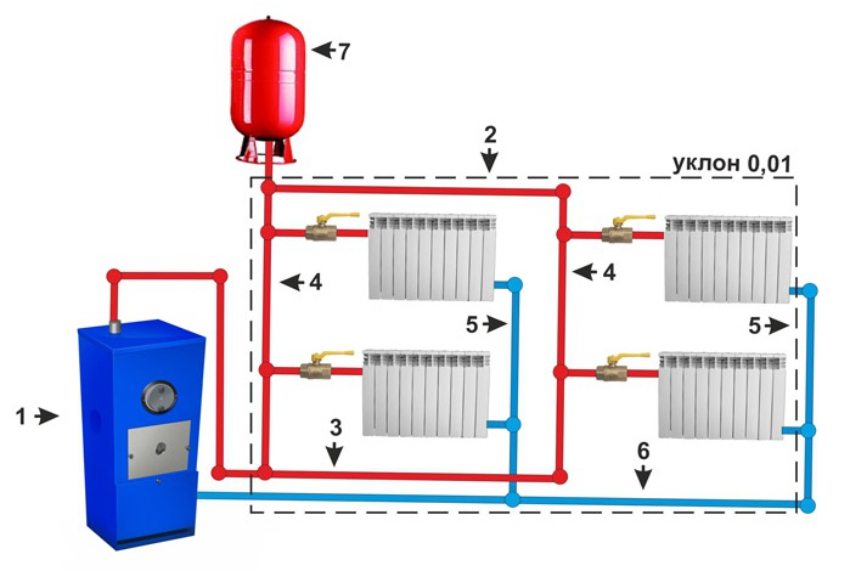

Water heating system with two-pipe lower wiring and natural circulation: 1 - boiler; 2 - air line; 3 - wiring; 4 - supply risers; 5 - reverse risers; 6 - return line; 7 - expansion tank

Installation of valves and thermostatic valves allows repair and replacement of the battery without shutting down the system. By supplementing the two-pipe wiring with a hydraulic module (arrow with a coplanar manifold), it is possible to separate the circuits of radiators (high-pressure), underfloor heating (low-pressure) and hot water supply. There are no technical drawbacks in the system with the correct heat engineering calculation.

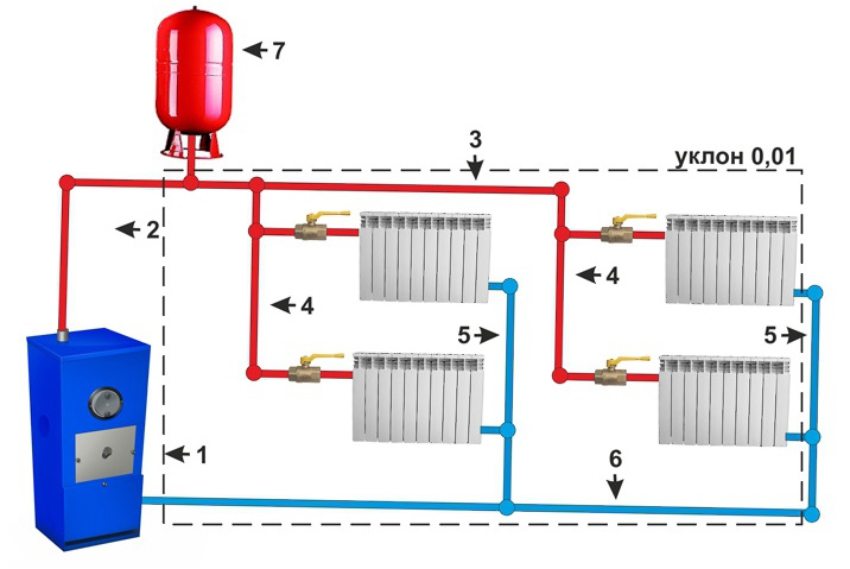

Water heating system with two-pipe top distribution and natural circulation: 1 - boiler; 2 - main riser; 3 - wiring; 4 - supply risers; 5 - reverse risers; 6 - return line; 7 - expansion tank

Collector in the heating scheme of a two-story house with forced circulation of the coolant

Radial piping and connection of independent circuits in the central part of the floor. Equal length and diameter of the beams of the circuit provides hydraulic balance, reduces resistance and improves heat transfer. The estimated volume of supply in independent links of the chain is achieved by installing control valves (balancing valve) and circulation pumps inside the circuits.

The increased consumption of materials and complex installation pays for the high level of accuracy of regulation and ease of use.

Heating medium distribution along the height

Bottom feed in the heating wiring diagram of a two-story house, it implies inserting heating risers into the ring of the first floor (basement or technical underground). With two-pipe bottom wiring, the distributing circuit (supply) is laid parallel to the ring of the outlet pipe (return). The coolant rises up, passes through the radiators, descends along the return pipes into the collecting pipeline, through which it returns to the boiler.

The supply risers are raised above the radiators of the second floor and combined with an air line, with an automatic valve to remove air from the system. An air vent valve is additionally installed on each heater (Mayevsky crane).

Top wiring distinguishes the direction of movement of the work flow (top to bottom). The main riser (a pipe that rises from the boiler through the floors to the central expansion tank) supplies the coolant to the ring or dead-end sections of the upper wiring. The supply risers are lowered from the attic, supplying hot water to the radiators. Vertical risers collect the coolant in a return line, through which the flow returns to the boiler.

The upper wiring is used in the southern regions of Russia. In the central and northern regions, the method of supplying and distributing the coolant from above requires the arrangement of a warm attic.

A two-pipe vertical heating system (with upper and lower water supply) requires permanent balancing. Possesses hydraulic and temperature stability when setting conditions are met.

Parallel connection of radiators in a two-pipe heating system of a two-story house (circuit with a closed-type expansion tank)

Horizontal types of heating systems

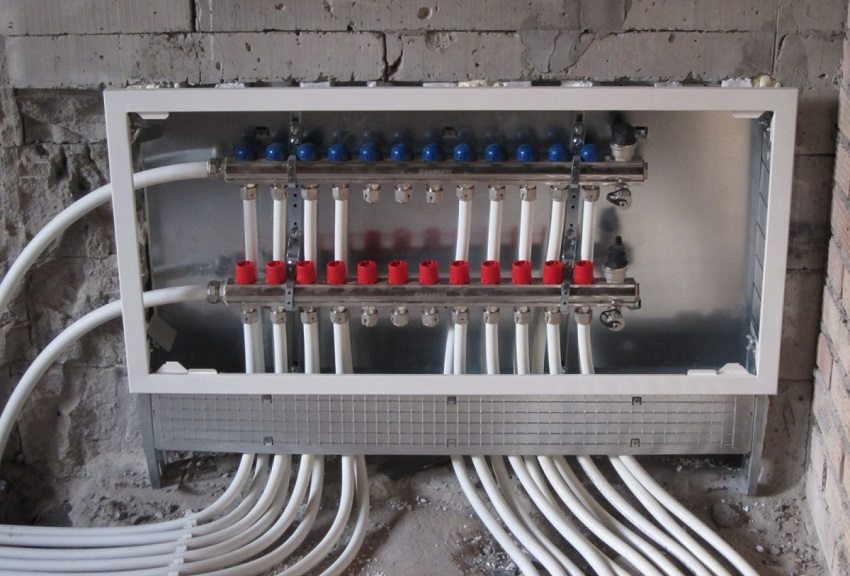

The horizontal two-pipe distribution system is based on the collector connection of heating radiators. The comb is placed in a special factory-made cabinet. System elements made of polypropylene are supplied by the manufacturer.

Branded shut-off valves and fittings speed up installation, improve the build quality of a two-pipe heating system with bottom propylene distribution. The device of individual inserts ensures the independent operation of the elements, increases the stability of the system.

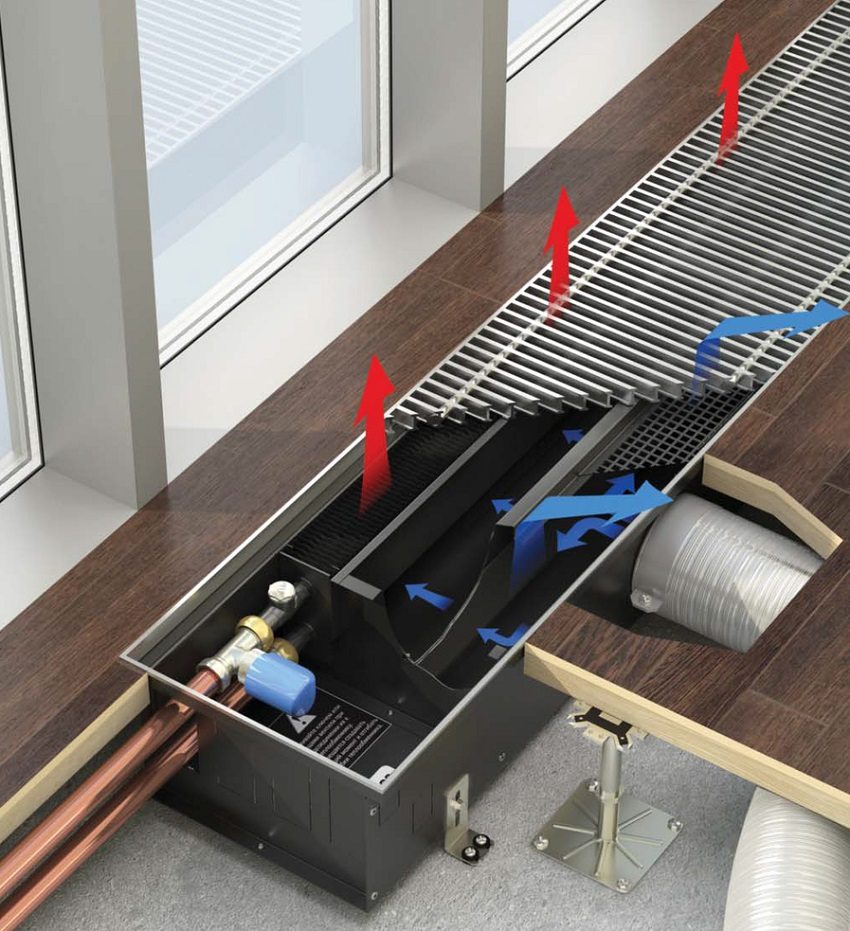

Underfloor heating - type water heatingin which heating elements, coils made of polymer pipes, are laid in floor structures. Each link is connected to a distribution manifold according to an independent heating scheme from propylene pipes. In a private house, which is equipped with underfloor heating, balancing of independent circulation circuits is required.

Important! The automatic control system must maintain the temperature of the working environment of the underfloor heating not more than 55 ° C.

It is not difficult to understand the device of the heating system of a private house on your own. But for high-quality provision of a comfortable microclimate in a cold season, it is better to turn to specialists.