The chainsaw is a necessary item in the arsenal of the owner of a summer cottage and a home craftsman. During operation, the working part of the tool wears out a lot. To restore its cutting properties, you will need a machine for sharpening chainsaw chains. This equipment is presented in a wide variety of species. To choose the right tool, you should study its technical characteristics and familiarize yourself with the types of devices.

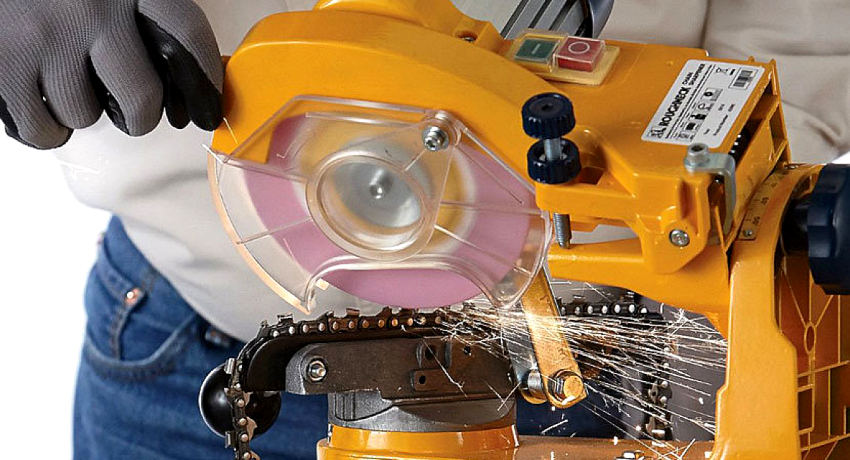

Sharpening machine chainsaw chains looks like an assembly cutting machine

Content [Hide]

- 1 How to use a chainsaw sharpener

- 2 What is a manual chainsaw chain sharpener

- 3 Chainsaw chain sharpening on semi-automatic machines

- 4 Distinctive features of automatic chain sharpeners

- 5 How to choose a machine for sharpening chainsaw chains: important recommendations

- 6 How to sharpen a chain for a chainsaw at home: useful tips

- 7 Recommendations for the manufacture of a homemade chain sharpener

- 8 Rating of machines for sharpening chainsaws

- 9 Popular budget models of grinding machines for home use

- 10 Overview of sharpening machines for chainsaw semi-professional class

- 11 The best professional automatic saw chain sharpeners

How to use a chainsaw sharpener

During operation, any chainsaw wears out the working part in the form of cutting teeth. With little wear and tear, they can be corrected with a round file. Sharpening the chainsaw chain on the machine must be done in the event that when cutting wood it is necessary to apply great efforts, when small sawdust forms instead of coarse brittle straws, burns appear on wood or sawdust, reveals incorrect operation of the device, which can jump, move back or in side.

The grinder is represented by a design that is similar in appearance to an assembly cut-off machine. Only here a grinding disc is used instead of a cutting disc. For sharpening the chain, it is customary to use a grinding wheel with a thickness of 3.5-4 mm. It is fixed on a frame with a hanging head and clamped with a special fixing vice.

Before performing the process of sharpening the chainsaw links, the machine is preset with the choice of the angle between the chain and the grinding wheel, which is determined by the pitch of the teeth. Sharpening chainsaw chains with your own hands consists in forming the end and side blades and ensuring the correct gap between the front of the cutting link and the plane of the depth gauge. Special risks are applied to the surface of the teeth to determine the required sharpening angle, on the basis of which the parameters for the operation of the machine are set.

Important! Before using the saw sharpener, read the operating instructions for important advice on setting up and using the equipment.

With the help of rotary clamps, the working part of the chainsaw is fixed on the machine. The abrasive disc rotates and is sequentially fed to each link of the unit. The sharpening machine allows not only sharpening the teeth, but also straightening the chain links.

Chainsaw chain sharpeners can be manual, semi-automatic and automatic.

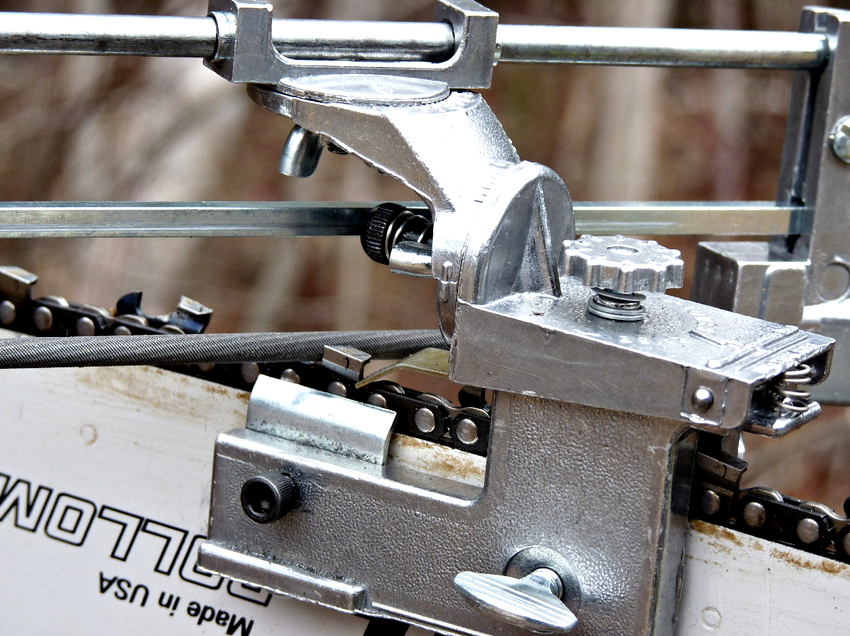

What is a manual chainsaw chain sharpener

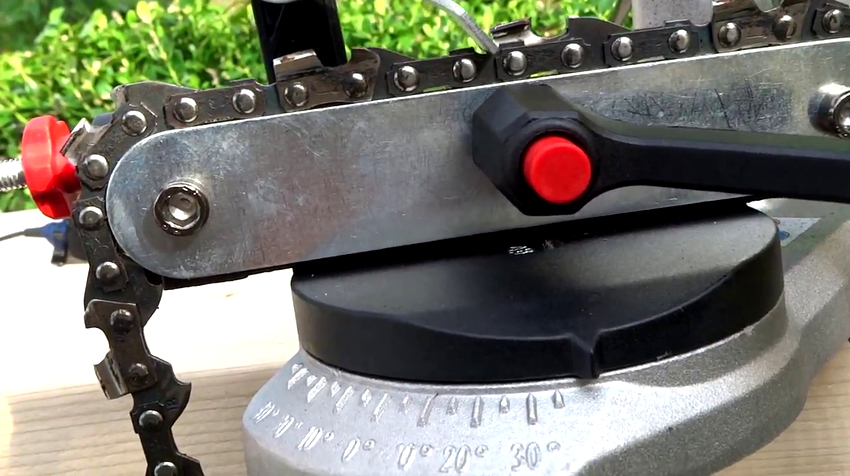

The manual chain sharpening machine is represented by a small mechanical device that is attached to the saw bar. Such a bed with a file of the required diameter is characterized by several options for adjusting the sharpening angle. The operator performs reciprocating movements, precisely maintaining the specified parameter for sharpening the links.

The manual chain sharpener for chainsaws can be used in places where there is no access to electricity. It is characterized by versatility, low weight, compact size, autonomy, no risk when performing work due to metal overheating, low cost. In addition, the mechanical machine grinds the link edge to a minimum, which significantly increases the service life of the chainsaw.

The disadvantages include the inaccuracy of the sharpening angle. In addition, when performing work, the operator must count the number of working passes of the file, which is important for uniform grinding of the teeth. Otherwise, due to the different sizes of the teeth, the cutting quality of the chainsaw will deteriorate.

In places where there is no access to electricity, a manual machine is used to sharpen chainsaw chains

Important! Hand-held machines are not used for sharpening chains fitted with carbide dusty links.

Sharpening a chain with hand-held equipment requires certain skills and dexterity. Here you should rely on intuition and eye. During work, the chain must be cooled with compressed air, and at the end it must be immersed in machine oil.

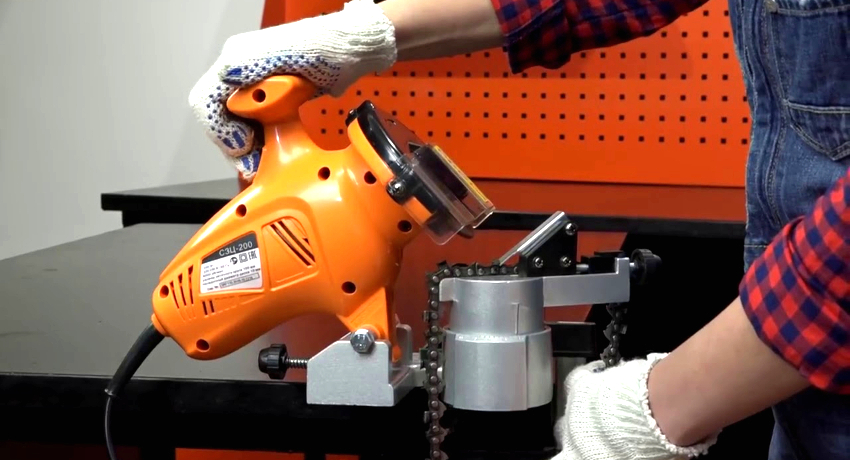

Chainsaw chain sharpening on semi-automatic machines

Machine tools equipped with an electric drive are very popular (this is due to the high productivity and quality of sharpening). The equipment is a complex structure that consists of several elements. The base of the chainsaw sharpening device is the frame on which the engine and the vice with the chain slide guides are installed. The motor is of asynchronous type with direct drive and high speed.

The sharpening disc is mounted on the motor shaft and fixed with a washer and nut. The area where the motor is attached to the bed is movable, which makes it possible to adjust the motor in space to set the correct sharpening angle.

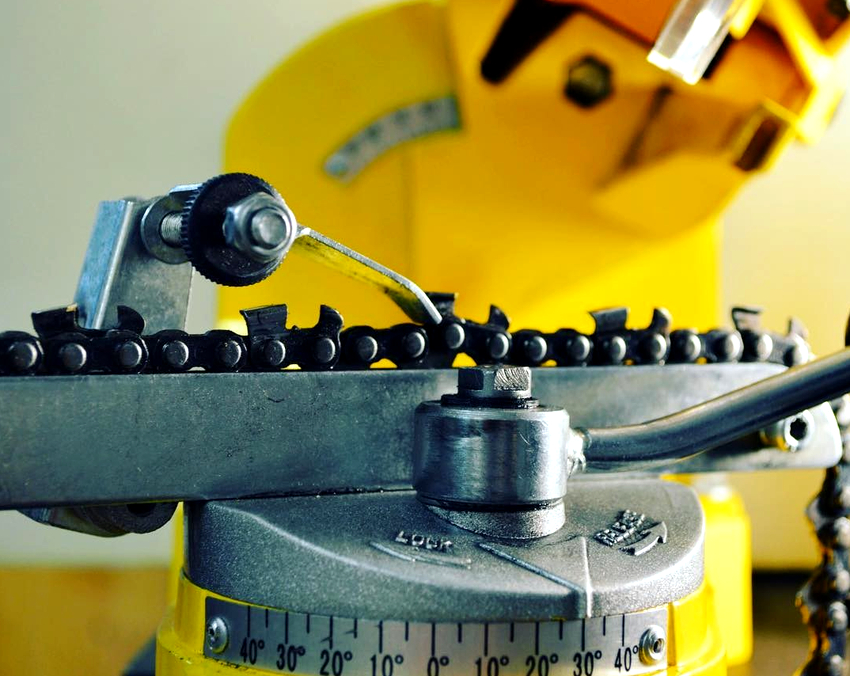

Before you start sharpening chainsaw links, you need to preset the machine with the choice of the angle between the grinding wheel and the chain

A vise with a slide is used to set the chain and hold it. A limiting plate is fixed to them, which controls the cutting depth. By turning the adjusting screw clockwise, the disc extends, increasing the sharpening depth.

Semi-automatic grinding machine for sharpening circular saws is characterized by the ability to set the exact sharpening angle, align the working tooth. The equipment can operate from 220 V and 12 V mains, which allows you to connect it using a car battery.

The principle of operation of a semi-automatic saw sharpening machine

The principle of operation of the chain sharpening machine is as follows. A chain is installed in the guide slide.The stop is lowered until it reaches a stop on the back wall of the tooth, which is sharpened without allowing it to move. Next, the engine is lowered with an abrasive disc installed on it. When it comes into contact with the teeth, the edge of the cutting element is ground.

After one side has been processed, the chain is turned over to the other, the manipulation is repeated. Next, the operator must move the chain to the next tooth with the installation of a stop bar, after which the process resumes.

The principle of operation of the machine is to install the chain in the guide slide and lower the motor with an abrasive disc

Important! To sharpen the chain on an electric machine, it is important to set the grinding depth correctly so that the teeth do not overheat and do not lose their properties during operation, which will negatively affect the further operation of the saw.

The disadvantages of electric machines for sharpening chainsaws include their high cost, which starts from 6 thousand rubles, the need to periodically replace the mounting circles, which is also a very costly measure. To extend the service life of the discs, diamond options should be used. However, they have a higher cost.

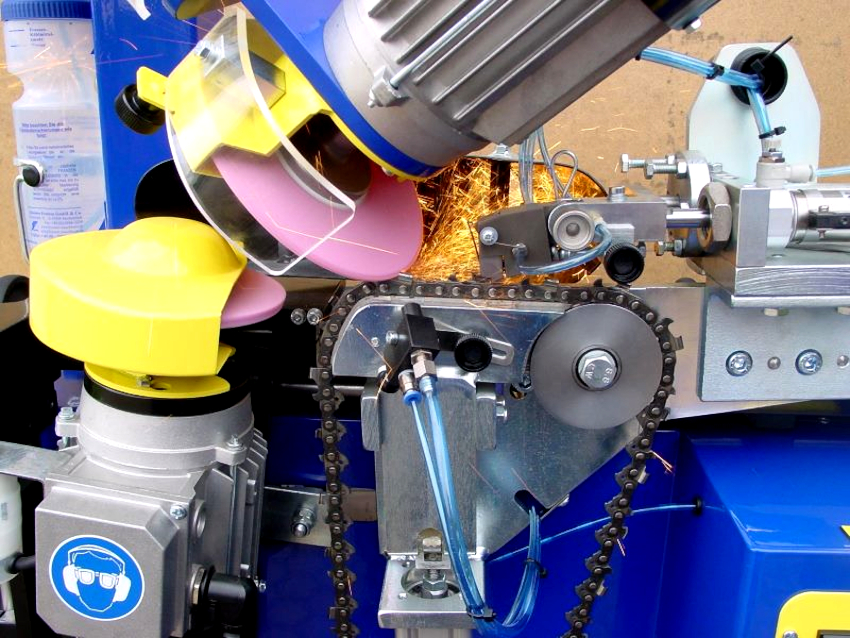

Distinctive features of automatic chain sharpeners

Chainsaw chain sharpening on a fully automatic machine is carried out without direct human intervention. This type of equipment has a completely professional purpose and is used in large logging enterprises. It is advisable to use it in repair shops, which are characterized by large volumes of grinding work. The carbide-tipped circular saw sharpening machine is available in automatic version only.

The chainsaw chain is installed manually on the machine. Further, certain parameters are configured and the device starts up for operation. The working bodies are moved using hydraulic drives, which are controlled by the controller. The chain is sharpened by two heads simultaneously. The upper element is used for the cutting tooth, and the lower one serves as a cutter depth limiter.

Important! Sharpening of the chain is carried out on both sides in one pass due to the fact that the upper head rotates in both directions.

Automatic machines for sharpening chainsaws are characterized by versatility, reliability, durability, high quality and speed of work, and an increased level of safety. The main disadvantage is the high cost of such equipment, which is unjustified for private use. Such professional machines for sharpening chainsaw chains also provide a standard finishing of each saw link without taking into account the degree of wear of the element according to a single template, which may negatively affect the period of further operation of the working part of the saw.

Important! The automated process of chain saw chain sharpening reduces the working resource of the equipment by 15-20%.

How to choose a machine for sharpening chainsaw chains: important recommendations

To decide which machine to choose for sharpening chainsaw chains, you should first consider the main parameters of the equipment. First of all, it is necessary to clarify the diameter, thickness and speed of rotation of the disc for sharpening. The latter indicates the performance of the device and the rate of metal removal from the cutting surface of the tooth. The optimal value is 30-35 m / s. This parameter is not indicated by the manufacturer, but it can be calculated mathematically, knowing the disk rotation speed and its diameter.

When choosing a machine for sharpening chainsaws, you need to pay attention to the thickness, diameter and speed of rotation of the blade

The next important criterion is the power of the machine. This figure should be in the range of 85-180 W, which is quite enough.This is due to the fact that the disc is in contact with the metal tooth for several seconds, so the equipment does not need high power for a high-quality sharpening process.

Useful advice! If the machine model has a power of 400 W or more, this parameter is redundant. In this case, this device is recommended to be used for sharpening knives and any locksmith tools.

When choosing a device for sharpening chainsaws, you should pay attention to the equipment. In addition to the machine, the structure may include a set of abrasive discs of various thicknesses, templates, check gauges and other keys.

Important! The machine must have a protective screen, which is the main safety requirement.

When buying a machine for sharpening chains, it is imperative to check the motor and guide mountings for backlash

It is necessary that the machine be equipped with mechanisms that facilitate and accelerate the sharpening process, in the form of a chain tensioner, a synchronizer for automatic locking of teeth when lowering the sharpening disc, a chain movement mechanism and a device for its clamping. The machine can be fixed to the horizontal part of the workbench or to a vertical wall.

When choosing a machine, it is necessary to check the mounting location of the motor and the guide for the absence of backlash. Their presence is evidence of low-quality equipment that is unable to perfectly maintain the chain sharpening angle.

How to sharpen a chain for a chainsaw at home: useful tips

Before you start sharpening the chain on the machine, you should study in detail the technological instructions for working with the tool. On the chainsaw, loosen the clamp screw and remove the chain. Next, the saw element is installed at a certain angle on the seat, which is located on the base. The chain links of the chainsaw should point towards the circle.

The sharpening angle can be between 0-30 degrees. The device should be fixed in a fixed position with the clamp adjustment screw. For each product, the angle is selected individually. For this, a special scale and a rotary structural element are used. The choice is made by the smallest prong. The first step is to sharpen it. Then the rest of the links are processed according to the set settings.

With the help of a special scale and a rotary mechanism, the sharpening angle for each product is selected individually

Then the grinding disc must be precisely aligned with the edge of the teeth. The machine is put into operation, and the chain is sharpened. The process is performed sequentially for each element of the working cutting part of the chainsaw or through one tooth. The second option is faster and more convenient. After the end of the process, the machine must be disconnected from the power supply and loosened the chain tension adjustment screw.

Related article:

What brand of chainsaw to choose: a review of the best modern models

Features of self-service devices. The advantages and disadvantages of each option.

After sharpening on the machine, the chainsaw chain must be cooled. To do this, blow it with cool air. Then the chain is lubricated with oil before installing it on the chainsaw. Both last manipulations can significantly extend the service life of the saw element.

Recommendations for the manufacture of a homemade chain sharpener

The price of a hand-made chainsaw chain sharpener will be several times lower than the cost of a factory tool. One of the main structural elements is a strong and reliable bed. As a basis for the independent manufacture of a tool, you can use a locksmith's vice, in which holes are located for fastening to the surface. To fix the structure on the surface of the workbench, it is necessary to make a blank for fasteners.

Degree scale is in progress.A rotary tire with latches is attached to the base of the device, on which the chainsaw chain will be installed. To fix the sharpening angle, the mechanism is equipped with a screw clamp.

You will need a bracket to install the sharpener. A low-power motor is suitable as an electric drive. A mechanism with an indicator of 80 watts is enough. It is better to use a three-core wire with a cross section of 0.75 mm² as a power cable.

Useful advice! Self-made machines are rarely equipped with protective screens, therefore, for the sake of safety, it is better to work with special glasses.

To raise and lower the engine, one cannot do without a support handle, which at the same time protects a person from electric shock when exposed uninsulated metal structural elements. An abrasive wheel of the required diameter is installed on the engine. To turn on / off the device, you can position the button on the case.

Rating of machines for sharpening chainsaws

When deciding which machine is better to choose for sharpening chainsaw chains, you should pay attention to the Brigadier Professional GM4P model. The device is characterized by a power of 650 W and an engine speed of 6300 rpm. The grinding wheel has a diameter of 104 mm. The seating shaft value is 22 mm. One of the advantages of the model is improved chain retention. When operating the machine in a low-light room, the tool is equipped with local illumination. You can buy the device for 3.5 thousand rubles.

The Rebit IKA1-85 machine from the Latvian manufacturer is able to sharpen the chain in just 5 minutes

The compact machine Rebit IKA1-85 for household use is offered by a Latvian manufacturer. The model develops power up to 160 W. In this case, the spindle speed reaches 4800 rpm. It only takes 5 minutes to sharpen the chain.

Important! The machine can work continuously for 10 minutes, after which it is necessary to take a break.

Chainsaw chain sharpening kit includes fasteners, a handle and two abrasive wheels with a diameter of 108 mm. The cost of the chain sharpening machine averages 3.4 thousand rubles.

Another popular model, ideal for domestic purposes, is the Proton TE-130 machine. It can work with different types of circuits, which are characterized by different geometric parameters. The power of the machine is 400 W. The engine rotates at only 3000 rpm. The instrument, thanks to its precise scales, is characterized by universal properties. They provide the required angle of the cutting edge. You can buy the tool for 3.1 thousand rubles.

Important! This model of the machine will cope with sharpening the cutting edge of significantly worn chains.

The small-sized model Kraton CSS-180 is popular. The machine is ideal for home use. The power of the device is 180 W at a speed of 3000 rpm. The sharpening angle is between 0-35 °. An abrasive wheel with a diameter of 100 mm with a bore of 10 mm is used for the tool. The base of the fixture is made of die-cast aluminum. The machine is equipped with a transparent plastic protection. The cost of the device is 3 thousand rubles.

Popular budget models of grinding machines for home use

For home use the machine "Caliber Master EZS-130M" is suitable. The engine rotation speed reaches 3000 rpm, its power is 130 W. The model has a low weight and compact dimensions, which provides easy transportation and easy storage. Due to the fact that the sharpening angle can vary from 0 to 30 degrees, the tool can be used for different saw models, including "Makita" and "Husvarna".

The bed is securely attached to a workbench or table for a high level of stability.The model is characterized by a low noise level when sharpening the chainsaw. The price of the machine is 2.6 thousand rubles.

A good machine is offered by the Ukrainian company Sаdko. The SCS-85 PRO model is a semi-professional equipment, characterized by a power of 85 W and an engine speed of 5000 rpm. Tool weight - only 2.5 kg. The sharpening depth is adjusted using a special button. Increased safety when sharpening the chain is ensured by the convenient backstop. The cost of the machine is 2.5 thousand rubles.

The budget semi-automatic machine "Zhuk-220", which operates from a 220 V network, has proven itself well. The model is characterized by a power of 85 W and a spindle speed of 5500 rpm. The tool has a compact size and low weight, making it ideal for use in the country or in a small workshop. A circle with a diameter of 105 mm is used to sharpen the chain. The tool body is made of impact-resistant plastic. You can buy a machine for 2.2 thousand rubles.

A popular machine for sharpening chains "Whirlwind CZTs-200" of a domestic manufacturer. The tool has an impact-resistant plastic case, which guarantees reliable protection of the electric motor from damage. The engine power is 200 W, its rotational speed is 6000 rpm. The machine features a solid cast base, which provides it with increased stability during operation. The main advantage of such a tool is its low cost, reaching only 2 thousand rubles.

Important! The machine is equipped with a transparent protective cover that protects hands, eyes and clothing from sparks and abrasives.

Overview of sharpening machines for chainsaw semi-professional class

A good model is the Champion C2001 semi-automatic chain sharpener, which is small and weighs only 6 kg. It can be transported, installed in minutes on a workbench or table. The device is equipped with a convenient fastening system that allows you to securely fix it on the surface in a fixed position.

The abrasive disc changes the angle of inclination within the range of 0-35 degrees, allowing the processing of the main and persistent teeth. It can also be adjusted according to the sharpening depth. Fine adjustment of the working part is carried out using a special scale. The sharpening discs have a diameter of 145 mm and a rotation speed of 3000 rpm. The power of the "Champion" machine for sharpening chains is 230 W.

The model is equipped with an illuminated work area for ease of use and a protective cover for safe storage. The device is equipped with two abrasive discs, special keys and calibration gauges. You can buy the Champion chain sharpening machine for 6.9 thousand rubles.

The Rezer EG235-CN machine is made of stainless steel and is characterized by low noise and vibration free operation.

The machine Rezer EG235-CN is distinguished by low noise operation and absence of vibration during operation. It has a stable platform that allows the tool to be securely positioned on the base. The engine power is 200 W at a speed of 4500 rpm. The tool, which is made of stainless steel, is characterized by a reliable clamping mechanism. For ease of use, the work area is illuminated in low light. The cost of the machine starts at 6.5 thousand rubles.

The machine Oregon 590181, which can be safely used in home workshops, deserves attention. The power of the equipment is 85 W, the rotation speed of the grinding wheel is 5000 rpm. You can buy an Oregon machine for sharpening chainsaw chains for 7.8 thousand rubles.

The best professional automatic saw chain sharpeners

One of the best professional chainsaw sharpening machines is the Sthil USG. The power of the device is 180 W. The disc rotation frequency of the "Calm" chain sharpening machine is 2800 rpm. When the device is in operation, the noise level reaches 75 dB.

Important! This model of the "Calm" machine for sharpening chainsaws is not equipped with a swivel mechanism.

The frame is made of impact-resistant plastic and is securely fixed to a workbench or other flat surface. The complete set of the Shtil chain sharpening machine includes a swivel support and two profile grinding wheels. The tool can be used as a sharpener for carbide-tipped chains and teeth with a grinding edge. The price of the "Calm" machine for sharpening chainsaw chains reaches 27 thousand rubles.

Another professional machine is the Oregon 519789, which has 214 watts of power. This tool can sharpen chainsaw chains in ¼-3/4 inch increments. Thanks to the improved workpiece clamping system, the process is fast and safe. The machine can use abrasive wheels with a thickness of 3.2, as well as 4.7 and 6 mm. Due to the presence of a torsion spring, work productivity is significantly increased.

According to numerous reviews, the chainsaw chain sharpener is very convenient to use, which is possible thanks to the ergonomic handle with the start button and the optimal level of illumination. The machine is supplied with three grinding wheels. You can buy a model for 31 thousand rubles.

The machine for sharpening chains "Oregon" is able to sharpen any kind of chain with different pitch of links

Another professional model of this manufacturer is the Orgon 620-230 machine. This is an advanced tool, which is characterized by a 50% reduction in sharpening time, which was made possible by the presence of a hydraulic booster. The machine also has an improved geometry for sharpening teeth with an angle of up to 55 °.

The Oregon chain sharpening machine is equipped with 3 grinding wheels of different diameters. To work in a low-light place, the device is equipped with a backlight in the form of a 15 W bulb. The tool can develop a power of up to 214 W, providing a spindle speed of 6000 rpm. The machine is capable of sharpening any kind of chain with different pitch of links. The cost of the instrument is 32.2 thousand rubles.

The saw mechanism of any model of a chainsaw fails sooner or later. To return it to work, you will need to sharpen the chain. There is a wide range of tools for this. For fast and high-quality execution of work, the best option would be a chain sharpening machine. When choosing equipment, you should focus on its main characteristics and take into account the feedback from experts and consumers about popular models of world brands.