The angle grinder is a versatile tool that can be used to carry out various technological processes related to cutting, deburring, grinding, brushing and polishing workpieces and surfaces made of different materials. For this, discs for the grinder are used. Removable nozzles are presented in a large assortment, they differ in purpose, shape, size and material of manufacture.

Grinder discs are presented in a wide range, they differ in purpose, size, shape and material of manufacture

Content [Hide]

- 1 Varieties of discs and attachments for the grinder by the nature of the work

- 2 Grinder discs: characteristics of the cutting wheel

- 3 Characteristics of a cutting diamond disc for a grinder

- 4 Characteristics of grinding discs for grinder

- 5 Typical disc sizes and product marking

- 6 Material for making discs for grinders for metal, wood and stone

- 7 How to properly install the disc on the grinder

- 8 What to do if the pressure flange is stuck

Varieties of discs and attachments for the grinder by the nature of the work

Depending on the type of work performed, wheels for a grinder are cutting, sawing, roughing, stripping, flap, polishing, and there are also discs for cutting seams.

Cut-off wheels make cuts and rough cuts in a variety of materials thanks to the cutting edges. The disc itself has a solid circle or is divided into segments.

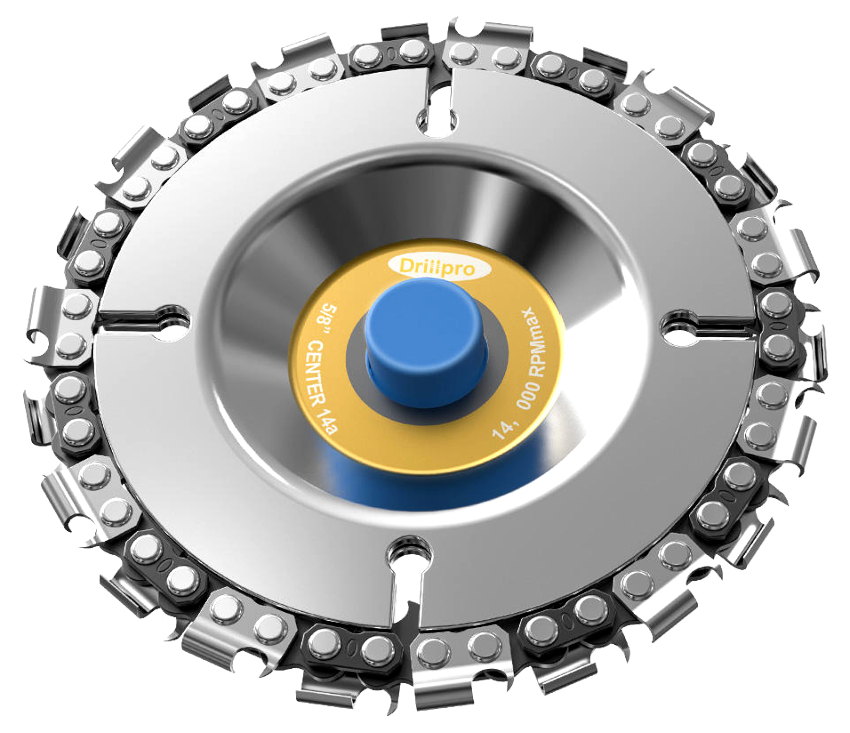

The saw blade for the grinder is a type of cutting wheel. It is designed for cutting wood products. Due to the presence of teeth on the cutting edge of the product, it is possible to carry out a clean and even cut of massive boards, parquet, plywood and drywall. The saw blade for wood for a 125 mm grinder can be used for fiberboard, chipboard and laminate. With the help of a saw wheel, you can cut grooves in a gas silicate.

Grinding attachments for grinders are designed to remove old paint, primer, varnish from the surface. With the help of such a nozzle, the workpiece is ground. The discs are available in standard diameters and 3-20 mm thick.

The angle grinder can be used to cut seams in asphalt, concrete and stone, thanks to the special grinder attachment.To polish the surface, a special emery disc or nozzle with a felt or felt wheel is used.

Stripping attachments: flap discs for grinder and coral discs

A type of grinding wheel is a grinding disc for a grinder, which is presented in the form of a disc metal brush. This nozzle is designed to remove rust and other stubborn dirt.

A coral disc is used for delicate processing of metal blanks. It is made of synthetic fiberglass material. Such an elastic structure of the nozzle gently cleans the metal surface, penetrating deeply into its structure, without destroying its integrity. This device is most in demand in auto repair work, where it is used to remove paint and varnish from a car body without damaging the metal layer. The material to be cleaned does not clog the porous base of the disc.

Flap wheels for a grinder are also referred to as cleaning nozzles. They are used for processing wood, plastic, metal products, for removing rust, cleaning welds and burrs. The petal circle is a plate overlapped around the circumference - according to the principle of a petal flower.

There are several types of petal nozzles, which are represented by an end piece, a bag product and a circle with a mandrel. The face disc is designed for normal flat or angled cutting. It can be straight or tapered. The first option is used for sanding large surfaces, and the second is necessary for finishing seams and joints.

The packet flap disc is designed for sanding large areas. When working with cavities, a grinding wheel with a mandrel is used, due to which the maximum precision of workpiece processing is achieved.

Grinder discs: characteristics of the cutting wheel

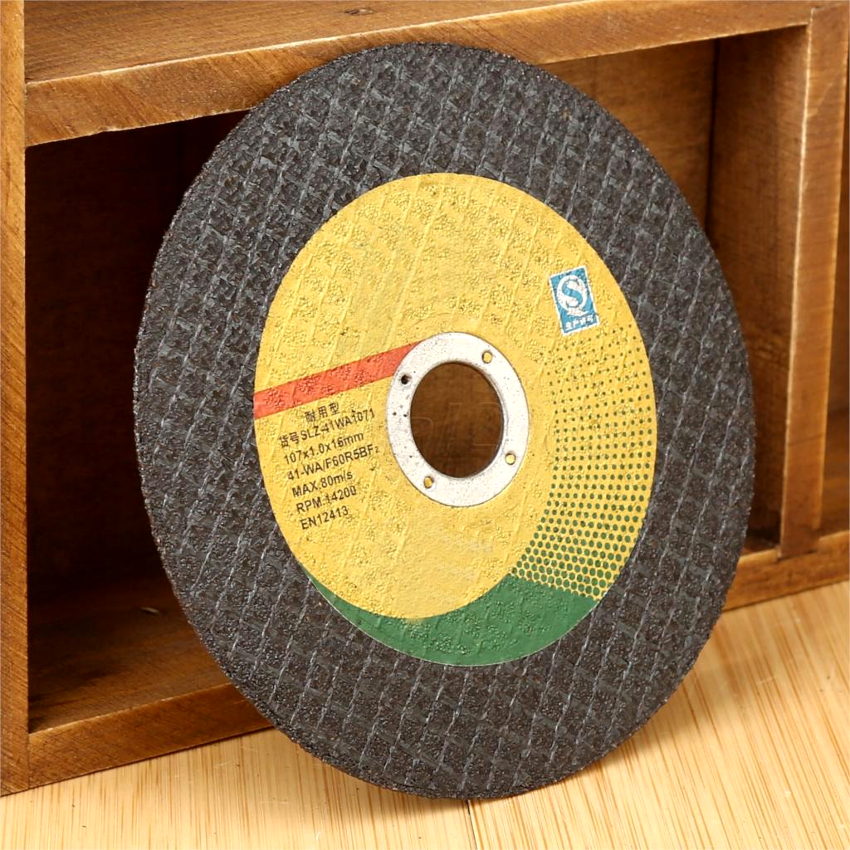

The most popular type of discs for a grinder is a cutting nozzle. It is represented by a circle with a hole inside, which is reinforced with a special metal ring for reliable fixing of the element on the angle grinder spindle.

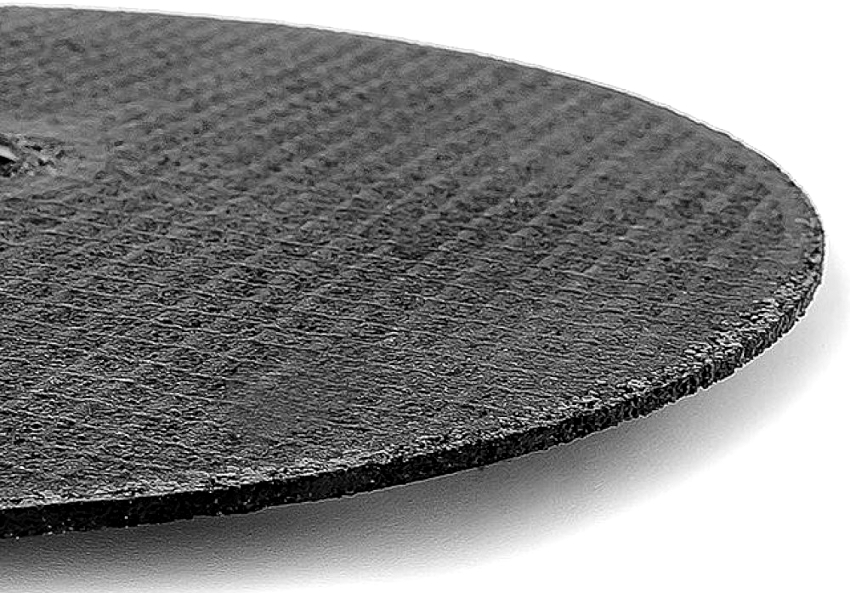

There are two types of cut-off wheel - abrasive and diamond. On the working surface of the first version of the disc, particles of abrasive material are applied, which are interconnected with a binder. A reinforced mesh made of synthetic material is applied over such a coating, due to which the strength properties and safety of using the grinder accessories are increased.

Important! During operation, the surface of the disc is gradually grinded, therefore, a nozzle with a wear of no more than 35% is suitable for effective work.

The abrasive disc has an affordable cost. Grinder wheels are presented in a wide range and can be used for working with metal, wood and stone. However, the disc wears out quickly. This is accompanied by the release of sparks during its operation, which can cause a fire. When working with a metal cutting disc for a grinder, an unpleasant smell arises, which takes a very long time to disappear, which makes the tool inconvenient to use indoors.

How to choose an abrasive cutting disc for a grinder

Abrasive grit has a certain level of graininess and hardness, which determines the quality of the surface finish. It can be formed from various materials, as evidenced by the product labeling. The abrasive can be zirconium corundum ("A"), electrocorundum ("AS"), silicon carbide ("C").

The discs for the grinder are available 115-230 mm (diameter), their thickness is 1-3.2 mm. The size of the inner ring is 22.2 mm. The size of the circle is selected depending on the type of tool.

Helpful advice! The most popular option, which is designed for household work, is a universal metal cutting disc for a 125 mm grinder.

The choice of disc thickness depends on the type of metal. For aluminum and thin steel, a circle up to 1.5 mm is used. For reinforcement and dense metal products, it is advisable to use a disc with a thickness of more than 2.6 mm.

Based on the characteristics of the disc, we can say that the smaller the thickness of the cutting wheel, the faster the cut is carried out, since the small area of the blade reduces its resistance. Fine bits heat up less and provide a smoother, cleaner cut, but they grind faster.

Helpful advice! Thin discs are best suited for low-power angle grinders that are not designed for long-term operation.

Differences between cutting discs for metal, wood and stone

Cut-off bits are classified according to the type of material being cut. There are discs for grinders for stone, metal and wood. The first two options are no different in appearance. To choose the right consumable, you must carefully consider the marking applied.

The differences between discs are in the type of abrasive used and the composition of the base disc.

Cutting discs for metal 125 mm (and other standard sizes) are manufactured in several steps. Initially, there is a process of mixing the resin with the main substance, which is used as cobalt, electrocorundum or diamond. Then special additives are introduced into the composition. The finished mass is poured into a mold. In its central part, a galvanized steel ring is placed. The edge of the disc is reinforced with fiberglass mesh. The mold is placed in an oven where the product hardens under high pressure for 24 hours.

Important! The surface of the disc for the grinder for metal 125 (and other sizes) is blue.

A disc for a grinder for concrete and tiles is made in the same way as for metal. There are options made of galvanized steel. A feature of the products is the presence of diamond dust spraying on the cutting edge of the wheel. The size of the abrasive varies from 0.2 to 0.8 mm.

Woodworking discs have fine teeth and a sharp edge all over the rim of the product. The edge is coated with tungsten carbide. The teeth can be straight, beveled or trapezoidal. The first option is used for needles and softwoods. The latter type of product is used for processing medium density material. An alternating bevel tooth disc is a versatile option.

Characteristics of a cutting diamond disc for a grinder

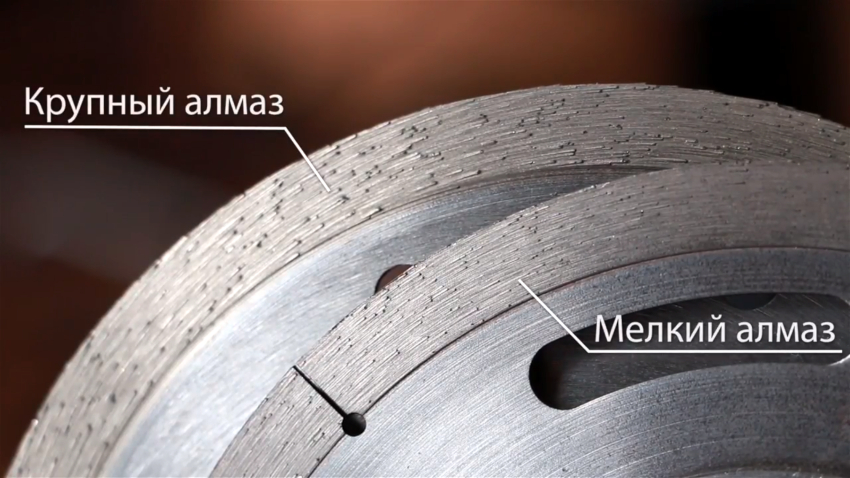

A diamond cut-off wheel is a steel disc with a cutting part coated with diamond chips and expansion grooves throughout its area. They play the role of teeth, thanks to which heat is removed and deformation stress is reduced. The slots are located strictly symmetrically, which eliminates the vibration of the disc during operation. Also, the mass of diamond chips is balanced in diametrically opposite directions, which ensures high quality and uniform cut.

Diamond particles are embedded all over the rim of the circle. They cover the rim of zinc, tin, nickel or cobalt alloys. The way the diamonds are fixed determines the purpose of the circle. When using galvanic technology, such discs are designed for processing products from soft natural stone. If laser welding or sintering is used, the wheel can be used for any type of hard material.

The diamond blade for a 125 mm grinder and other standard sizes can have a surface grain size from 50 to 3000.

The diamond disc has a number of distinct advantages over a simple abrasive wheel. It has greater productivity, durability, performs high-quality and accurate cut and shows great indicators of resource. When working with it, sparks are not formed, there is no strong smell.

Important! The diamond blade can be used on angle grinders with a speed of 12000 rpm, but it can withstand 13900 rpm, which is typical for professional machine tools.

Such a circle is afraid of overheating, so you need to take breaks when working with it. When using an unsegmented diamond blade for a 230 mm grinder and a smaller diameter, it is necessary to provide additional cooling with water. The disadvantage is also the high price of such a consumable.

What are the discs with diamond grit on the surface?

For a cut diamond wheel for a grinder, monocrystalline (in the form of solid spatial structures of regular shape) or polycrystalline diamonds can be used, which consist of several small single crystals, firmly connected to each other. Concrete blades for a 230 mm grinder and smaller diameter, equipped with the first type of material, can be used for cutting hard materials, since they are more durable.

The surface of diamond wheels for a grinder has a different color, for example, orange is intended for plaster and brick

Important! A diamond blade for a grinder for concrete can be used to carry out a straight cut, since with a curved trajectory of movement, the disk can lose diamonds or collapse completely.

Artificial diamonds on the rim of the disc can be evenly distributed or spaced at a certain period. The latter option is more productive. These discs provide less tool force, even load distribution and more efficient cooling.

Related article:

Wood disc for grinder: choosing the right tool

Varieties of wood discs for angle grinders: sawing, cutting, roughing, grinding and polishing. Rules for using angle grinders for wood.

The outer surface of diamond wheels for a grinder can have different colors. Based on the decoding of the disc colors, the blue frame has attachments for concrete and marble, gray - for ceramic products, green - for granite, yellow - for ceramics and gypsum, orange - for plaster and brick.

Classification of diamond discs for concrete for grinders, depending on the structure

Diamond wheels are predominantly designed for working with non-metallic materials. They are used for cutting ceramics, concrete, glass, asphalt and brick. There are also diamond blades for metal grinders that can handle fine material.

Diamond bits differ in structure, depending on which they are divided into solid, segmented, turbo and turbo-segmented. The first type of wheel is equipped with a continuous cutting band that is located around the circumference. Artificial diamonds are applied in several rows on it. Such discs are used for grinders for tiles, ceramics and other materials for which the accuracy of the cut is important.

Segmented wheels have radial dividing slots of the same size in several working areas. This type of diamond blade is more resistant to temperature and mechanical stress and provides greater productivity. However, the cut is not as accurate as with solid discs. In addition, they have a higher cost.This nozzle is designed for deep cuts in concrete structures.

A distinctive feature of diamond turbo discs is the presence of a slanting notch on the sides of the rim, due to which the mechanical strength of the wheel increases. It also enhances the intensity of heat dissipation, which allows you to speed up the cutting process by 75-100%. The turbo disc can be used to quickly cut various mineral materials of different hardness.

The most productive circles are turbo-segmented discs. The rim is divided into segments with turbo side notches.

Diamond blades for a concrete grinder are also distinguished by the method of application - for wet and dry cutting. The first type of product has a solid solid surface. Before starting work, it should be moistened with water. When making a disc, bronze or cobalt is applied to its cutting edge. The first option is used for cutting granite and quartz, while the second is used for tiles and drywall.

Dry cutting blades have a surface that is divided into several segments along the entire perimeter. Diamond teeth are welded to the end of each strip. Such a circle exhibits increased resistance to overheating. Despite this, it should not be operated for more than 3 minutes. This blade is designed for cutting stony and concrete material.

Characteristics of grinding discs for grinder

Grinding wheels are used to treat the surface of the product. The working part of the disk can be made of boron carbide and silicon, quartz, spherical rubins or spherical corundum. The grinding attachment is in the form of a bowl or circle with protruding plates, on the surface of which a special material is applied.

It can be diamond grit for rough grinding, sandpaper with different grain sizes for pretreatment, special coated nylon threads, which are used in conjunction with special pastes for more thorough grinding. Cloth, felt, felt or foam rubber can be fixed to the sanding attachment, thanks to which it is used for polishing the surface.

The working part of the grinding disc can be made of quartz, boron carbide and silicon, spherical rubbers and spherical corundum

Helpful advice! For processing large areas, sanding logs or rounded areas, use a cone-shaped nozzle.

There are two types of grinder discs for grinding: abrasive and flap. The first option is for rough processing. It carries out grinding of hard irregularities that appeared as a result of fusion of welded seams, large burrs formed during cutting or chopping of metal blanks. The abrasive grinding wheel can be used to sharpen the tool. Flap type grinding disc is used for finer processing. It acts gently on embossed surfaces.

Helpful advice! For rough processing of natural wood, you can use a chain disc for a grinder, which provides high productivity.

When choosing a grinding disc, the grit size of the attachment plays a major role. The higher it is, the thinner the surface will be polished. Wheels with a value of 40-80 are for preprocessing. To level the surface, nozzles with a grain size of 100-120 are used. Finishing grinding is carried out using wheels 180-240.

Diamond polishing discs are available in grit sizes 50, 100, 200, 400, 600, 800, 1000, 1500, 2000, 3000.

Features of grinding disc for wood grinder

For the finishing of natural wood products, various types of attachments are used, which are represented by cord brushes, roughing, emery, end and flap wheels.

To remove the top layer from solid wood, paint or paintwork from the surface, grinder grinding discs are used, which also help to level the surface of the boards. Products are equipped with special spikes located on the flat surface of the disc, or chips.

For rough processing of wood, a cord brush is used, which in a matter of seconds removes all irregularities from the surface, preparing it for finishing sanding. The abrasive nozzle is represented by a disc with a metal bristle in the form of a wire, which is located along the perimeter of the circle or perpendicular to its surface. The second option is in the form of a brush.

Important! For wood processing, you should choose circles with a thin wire that is not capable of damaging the workpiece itself.

For leveling the edges of the wood, which is required for oblique cuts, an end wheel is used, which provides a result comparable to processing the surface with a file.

Flap disc for grinder 125 mm and other diameters is characterized by the widest range of use. The nozzle consists of trapezoidal sandpaper petals of varying grain size, which overlap, overlapping by на each other. This disc is characterized by a slow rate of wear.

Helpful advice! If a wooden surface with a complex relief is being processed, it is advisable to use a petal nozzle, in which the abrasive elements are located radially.

The nozzle can have different surface abrasiveness, as a result of which a different degree of grinding is carried out. The gradual transition from coarse-grained to fine-grained packing allows to achieve the effect of polishing the workpiece.

Wheels for soft grinding with a polished effect are presented in the form of removable sticky products with various grains, which are characterized by high functionality. Such attachments are made of fabric, felt, foam rubber or felt.

The latter option is the most common. It provides the most even, smooth surface without the formation of roughness, which can be compared with a mirror. Such a nozzle is made of compressed material of fine-haired, semi-coarse-haired or coarse-haired origin.

Typical disc sizes and product marking

For the correct choice of a disc for a grinder, the outer diameter of the nozzle should be taken into account, which should not exceed the maximum permissible value for a particular angle grinder model. Otherwise, unpleasant consequences may arise. A low-power grinder simply cannot work with a large tool. Installing a larger accessory will require removal of the protective cover, which is a serious violation of safety rules for using the tool.

When working with a grinder on which a circle is set too large, the linear speed will be overestimated. This is fraught, first of all, with injury to the master and destruction of the abrasive disc.

Discs for grinders are produced in sizes 115, 125, 150, 180 and 230 mm. In this case, products can have different thicknesses: 115 mm circles differ in size 1; 1.6; 2; 2.5; 3; 3.2 mm. Discs for grinders for concrete 125 and 150 mm, depending on the above values, are made with a thickness of 0.8 and 1.25 mm. This indicator for a 180 mm circle is in the range of 1-4 mm, and for discs for a 230 mm grinder - 1.6-4 mm.

For low-power angle grinders, a circle with a diameter of 115 mm is purchased. For medium power units, trimming, grinding and saw blades for 125 and 150 mm grinders are suitable.The professional tool should be equipped with 180 and 230 mm discs. The rim diameter of a disc of any size is 22.2 mm.

Helpful advice! When using an older model grinder, you will need to use an adapter in the form of a ring.

Any abrasive wheel, regardless of the type of product, has a special marking, which contains information about the diameter of the disc, its thickness, the size of the seat, and the maximum rotation speed. The disc also indicates the material for which it is intended to be processed. The decoding of the inscriptions is as follows: "metal" - metal, "concrete" - stone and concrete, "steel" - steel, "aluminum" - aluminum, non-ferrous metals and alloys, "inox" - high-alloy and stainless steel, "castiron" - cast iron and cast details.

Important! Discs on a vulcanite bond can operate at a speed of 50-80 m / s, on a bakelite bond - 80-100 m / s.

Material for making discs for grinders for metal, wood and stone

Grinder discs for cutting and grinding can be made of various materials. Depending on this criterion, abrasive, carbide and diamond wheels are distinguished. Abrasive products are made of thick, waterproof latex paper, which is reinforced with fiber or mesh. On top of it, a layer of abrasive material is applied, which can be aluminum oxide, silicon carbide, corundum or tungsten carbide. The binder for the abrasive is a polymer or resin.

Abrasive wheels are represented by roughing, cutting and grinding products. A fiber sanding disc is also available and comes with a rubber or plastic backing pad. It plays the role of a stop and helps to cool the abrasive. Such a circle is used for processing wood, concrete, ferrous and non-ferrous metals. Aluminum oxide, zirconate or ceramic grain is used as an abrasive.

Helpful advice! Fiber abrasive discs are ideal for roughly removing old paint from walls, facades and other surfaces.

The carbide wheel is made of metal. The rim is made of high carbon molybdenum steels with added nickel or chromium. Such circles are represented by cutting discs for cutting metals. At the same time, a disc is selected separately for a grinder for aluminum, stainless, thin, high-carbon steel.

The diamond wheel is made of steel, on top of which diamond spraying is applied. Such discs can be cutting, grinding and polishing. They are designed for processing any metal, concrete, natural or artificial stone, glass, ceramics. This nozzle is used as a disc for a grinder on porcelain stoneware. The diamond blade provides precise, thin cuts.

A type of diamond attachment is a polishing wheel with a flexible base, the surface of which has a corrugated structure in the form of a tortoise shell. This flexible disc is fixed to a hard rubber base with Velcro.

There are also plate or support discs for the grinder. The bases of the nozzles are made of rubber or plastic. They are used in conjunction with some options for grinding, polishing, grinding wheels.

How to properly install the disc on the grinder

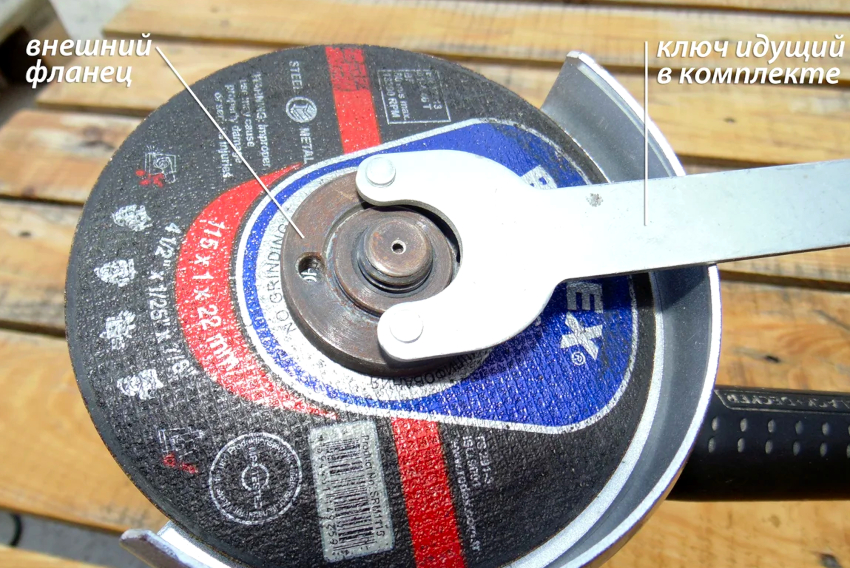

Wheels are consumables that have to be changed periodically. To do this, you need to know how to properly place the disc on the grinder. The wheel is attached to the tool spindle by means of a clamping flange. To choose the right open-end wrench, you need to know what thread is on the grinder. This value is M14.

Power off the tool to replace the disc. The grinder spindle is fixed on the front of the body with a button.When pressed, the stopper enters the bore of the circle installed in the gearbox, due to which the spindle is fixed in a stationary position.

The pins of a special open-end wrench must be inserted into the holes on the hold-down flange. The key turns to the left while holding the lock until the nut moves out of place, after which it is unscrewed and removed by hand.

Helpful advice! The clamping flange is unscrewed in the direction opposite to the direction of rotation of the tool shaft.

If it is necessary to clean the inner cavity of the grinder's casing, unscrew the lower flange. Dirt is removed with a steel brush. The bottom flange is put in place so that the grooves on the flange and spindle are aligned. A sealing gasket is put on top, which will further provide easy unscrewing of the clamping nut. The new disc is installed so that the product marking is facing outward.

A gasket is laid on the circle. The flange is manually screwed onto the shaft and clamped with an open-end wrench no more than ¼ of a turn so as not to deform the disc.

Important! It is not allowed to remove the protective casing from the grinder, since this device will prevent the occurrence of traumatic situations in the event of a wheel breakage during its operation.

The pins of the special key must be inserted into the holes on the hold-down flange and turned to the left

What to do if the pressure flange is stuck

Often there are situations when, when machining thick, durable material, the tool jams in the workpiece. In this case, the disc breaks and the rotating spindle tightens the flange tightly. There are several methods for untwisting angle grinders.

The first method involves using two gas keys. Do not use too much force when working with the tool, as this can damage the spindle lock. The bottom flange is clamped with one key, and the top flange with the other. In this case, the rotation of the instruments is carried out in different directions.

If the retainer is broken, to remove the disc from the grinder, it is necessary to disassemble the gearbox. For this, the fastening bolt is unscrewed. The cover together with the shaft is removed from the angle grinder. Then clamp the shaft in a vice and unscrew the flange using a gas wrench.

You can use the thermal method, which involves heating the nut with a hair dryer, blowtorch or gas torch. The heated element is easier to unscrew by using a standard grinder wrench.

If the above methods do not work, the grinder will have to grind the abrasive wheel. To do this, use pliers to remove the disc fragments. A piece of sheet metal is clamped in a vice. Its thickness should correspond to the size of the disc. Next, the remains of the circle are grinded against the end part of the metal workpiece.

Helpful advice! To quickly grind a damaged wheel in a vice, you can clamp an abrasive disc.

It is possible to loosen the clamping flange with the help of a special liquid WD-40, which must be poured over the junction of the element with the shaft. After 5-7 minutes, the fasteners can be unscrewed with a standard wrench.

The modern grinder is one of the most demanded tools with which you can perform various processing options for metal, wood and stone blanks. Depending on the nature of the work, a certain type of disc is selected, the diameter of which must correspond to the type of tool, which will become the key to an effective and safe working process.