The requirements for machining various materials are quite high. Items with improperly made threads, offset holes, chipped ends after trimming, etc. The main reason for poor-quality processing of products is the improper condition of the cutting tool. A drill sharpening machine will help to avoid such problems.

Sharpening machine will help to process drills and other tools with high quality

Content [Hide]

- 1 The main types of sharpening machines for drills and other cutting tools

- 2 Design and standard equipment of drill sharpeners

- 3 Factory and home-made drills sharpening machines

- 4 Machine for sharpening milling cutters for metal, restoration of hole saws for wood

- 5 Disc sharpening machines: designs, methods of operation

- 6 Planer sharpening machines: automatic and manual

- 7 Features of the use of machines for sharpening band saws

- 8 Grinding cutters for a lathe

- 9 Diy grinding machine assembly algorithm

- 10 Drill sharpening machines: prices and manufacturers

- 11 Drill sharpening machine: how to choose the right one

The main types of sharpening machines for drills and other cutting tools

The improvement of technologies for the manufacture of various types of products makes it necessary to use cutting tools with an ideal sharpening. Otherwise, the quality of processing decreases, the performance characteristics of the manufactured items are lost. Cutting elements made of even the most durable materials require periodic restoration of the working edge. Grinding machines are used for these purposes.

Depending on the scope of application, the installations are divided:

- on professional machines for sharpening;

- household mechanisms.

There is also a division of sharpening devices into universal and narrowly focused ones. Universal units have devices that allow you to sharpen both the blades of ordinary household knives and saws, cutters, chisels, etc. Narrowly directed ones are designed for processing tools of the same type.

For the most part, professional designs are universal. They are distinguished by their large dimensions and corresponding power, and are permanently installed. Such machines require significant energy consumption. The consequence of high power is noisy work, therefore professional devices are placed in separate rooms. Working with them is most often carried out with the use of noise protection equipment.

Household drill grinders are basically mobile devices that can be mounted on any horizontal surface.The units are low-power, compact, used for sharpening household tools.

Design and standard equipment of drill sharpeners

The basic design of any grinding machine is quite simple. The device includes the following elements:

- The housing in which the engine is placed. A low power motor is used for processing elements made of soft materials. Powerful models are used when sharpening carbide parts. The speed of rotation of the sharpening devices depends on the power, and, consequently, the time required for processing the tool.

- Parallel mounted abrasive wheels made of different materials. For sharpening elements made of hard alloys, diamond wheels are used, which may vary in size. The outer diameter ranges from 125 to 250 mm. The size of the seat is important: the most common option is 32 mm, but there are sizes of 21.7, 16, 20 mm. An equally important indicator is grain size: 40-60 is enough for roughing, 80-120 for finishing.

- Sanding belt or other special tools. Additional structural elements are inherent in universal sharpening machines. Such parts can also have different dimensions, coating structure, etc.

- Screen. Transparent protective shield plate for safe work.

- Unit start and stop button.

Useful advice! Experts recommend purchasing grinding machines with asynchronous motors. Such devices are more resistant to power surges in the network.

All dimensions and features of the elements must be indicated in the passport for the grinder.

Factory and home-made drills sharpening machines

Drills are a tool that is actively used both in production and for domestic purposes. As for the industrial scale, it is worth noting that universal machines are almost always used for sharpening. The other option is simply not cost effective. But at home and in the case of small-scale periodic activities (in professional educational institutions, retraining centers, etc.), narrowly focused units for sharpening drills are widely used.

Such machines can be divided into two types:

- devices for sharpening twist drills;

- machines for restoring the cutting surface of feather drills.

The diameters of the nozzles to be reconditioned vary from 2 to 18 mm. The features of the equipment allow you to perform the tilt angle for pen drills 170-180 °, for spiral options - 140-180 °.

Many people prefer to use home-made machines for sharpening drills. More precisely, not machines, but improvised devices. This can be, for example, "swift" clamps and a grinder. The construction works as follows:

- The drill fits into the clamp at the angle required for sharpening.

- The latch rests against the machine tool, then is smoothly brought to the rotating abrasive surface. Care must be taken not to change the machining angle.

- After sharpening the cutting elements, the rear part is processed.

Useful advice! Considering that when sharpening on such a device, the angle is controlled visually, it is worth having a sample of a drill with a full cutting surface for verification.

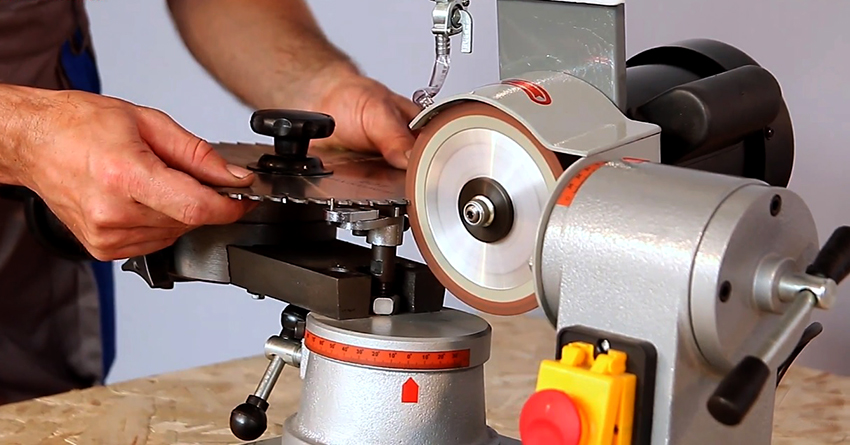

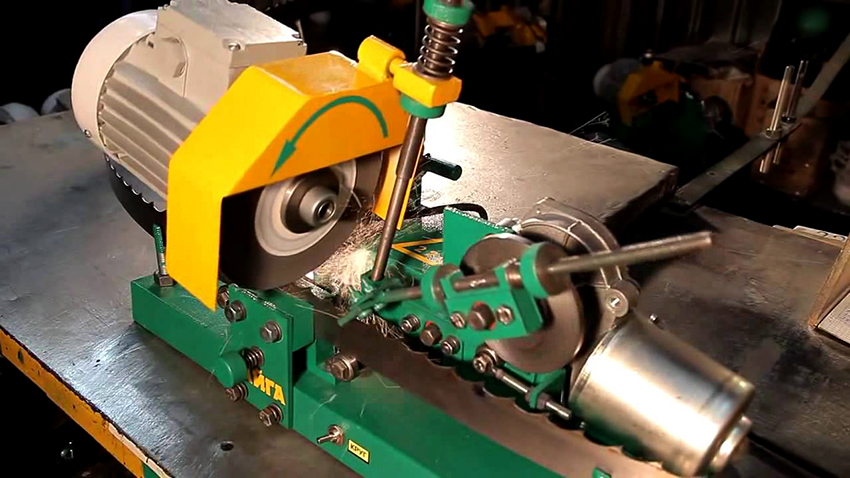

Machine for sharpening milling cutters for metal, restoration of hole saws for wood

Milling attachments can have a wide variety of shapes: cylinder, cone, hemisphere, etc. There are many standard sizes of this cutting tool. This is why sharpening is quite difficult, especially for non-professionals.In order for the result to be positive, that is, after processing, the cutter regains its functional capabilities, it is worth using a machine for sharpening cutters for metal.

Sharpening of cutters is a rather difficult process for a beginner.

The complexity of restoring the cutting surface of these bits is due to two features:

- sufficiently long;

- curved geometry of the shape of the teeth.

As for the latter characteristic, a distinction is made between cutters with pointed and recessed teeth. The first ones have a flat back surface, it is on it that sharpening is carried out. Reinforced teeth are characteristic of router bits. The complexity of the samples they make affects the way of sharpening: it is performed along the inner surfaces of the teeth. It is not recommended to use various devices for sharpening cutters for metal.

If we are talking about ring nozzles for wood, then it is worth saying that a thin diamond block can be used as a homemade grinding machine. It is fixed to the edge of the table, and the cutter is guided along its surface. It is important to take into account the degree of tool wear in order to correctly select the grain size of the bar surface and carry out effective processing.

Disc sharpening machines: designs, methods of operation

Disc sharpening machines belong to a narrowly focused category of sharpening mechanisms. By their design, they can be performed as follows:

- the motor and the grinding wheel remain static, only the processed disc moves;

- both the sharpening elements of the installation and the circular saw rotate;

- the motor mechanism and equipment move, the sharpened disk remains stationary.

The latter type includes machines for manual sharpening of discs. The principle of operation of such devices looks like this: a circular saw is fixed, a manual electrical mechanism is traced along the processed surface of the teeth. Sharpening of teeth of circular saws can be carried out in the following types of angles:

- front;

- back;

- bevel of the front and rear parts;

- sharpening (size) of the front and rear corners.

All of the above characteristics depend on the features of the use of circular saws:

- for longitudinal sawing, an angle of 15-20 ° is required;

- cross cutting requires a 5-10 ° rake angle;

- the universal saw blade has an angle of 15 ° (average).

Important! The cutting angle must be taken into account not only when selecting a circular saw for specific purposes. It is also important for the quality of the material used: the denser the structure of the workpiece, the smaller the front and rear angles should be.

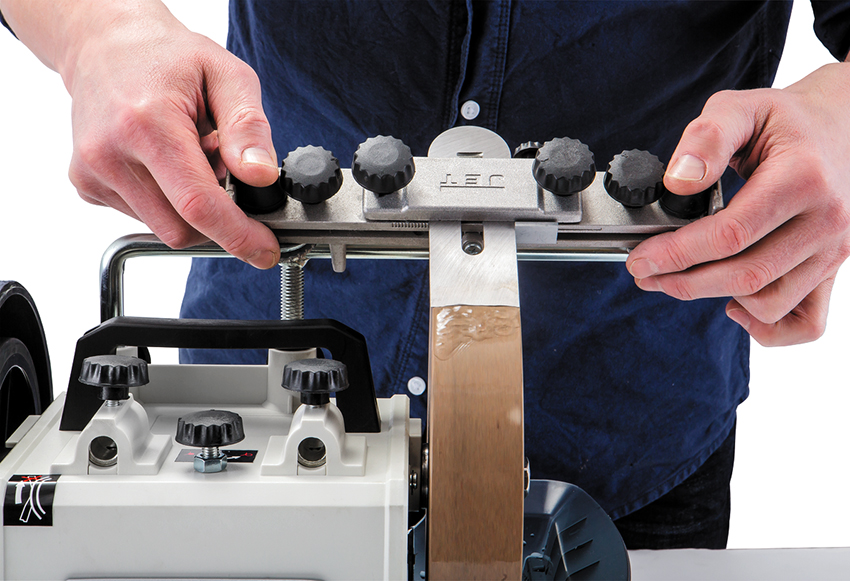

Planer sharpening machines: automatic and manual

Planing machines are available in almost every private workshop or large production where wood is processed. The following facts indicate the need to maintain the knives in the right condition:

- when planing the surface with blunt knives, it becomes covered with pile and may even have significant irregularities;

- worn cutting edges crumble during work;

- the use of worn cutting surfaces will overload the motor, which can lead to premature failure.

Knife sharpening machines differ in the way they are fed. Knives can be fed:

- manually;

- automatically.

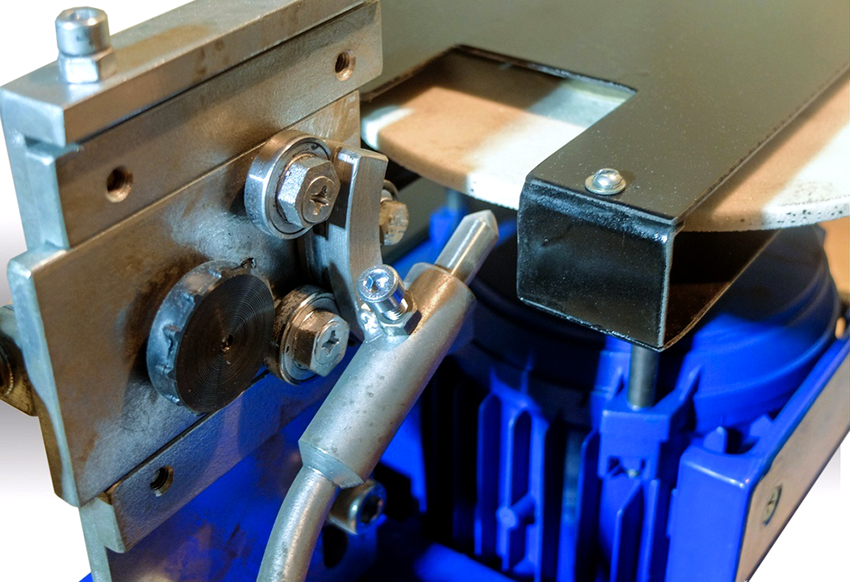

Manual feed machines have the following design:

- base platform;

- abrasive element;

- carriage for fixing the work piece.

During the operation of this device, the knife moves with the handle. Such a device is small in size, it can be placed on any horizontal surface.

Fully automated machines are installed on a cast iron bed, they are large in size and a fairly diverse range of options. The processing speed and the thickness of the removed layer are set automatically. Such devices can simultaneously process several knives.

There are automatic machines for sharpening planing knives and household appliances. They are characterized by small dimensions, and also have the ability to set the speed. However, only a tool unit can be machined at a time.

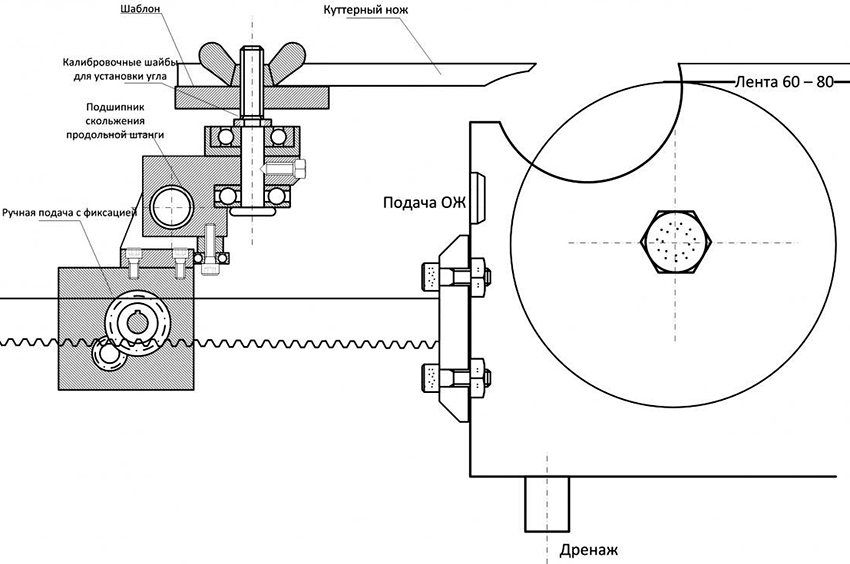

Features of the use of machines for sharpening band saws

A band saw is a metal strip with teeth along one edge with a closed loop. With this tool, a wide variety of material configurations are cut. Naturally, after a certain working cycle, such a saw must restore its potential. The main indicator indicating the need for sharpening is the excessive roughness of the processed surface.

First, the saw is sent to adjust the setting, that is, to correct the bending of the teeth in different directions. Depending on the functionality, there are different ways of positioning the cutting elements: wavy layout, every third tooth remains intact, alternate bend of each element.

After setting, the tool is processed on a saw sharpening machine of this type. The main element of the machines (circles) must correspond to the material from which the band saw is made. For bimetallic options, borazon or diamond abrasives are suitable. For saws made of tool steel, a corundum turning wheel is sufficient.

Related article:

DIY knife sharpener: how to make an effective tool

Why is it needed, which design is better. Schemes and drawings. Materials used to create an abrasive surface. How to sharpen the blade correctly.

Cutting wheels are selected according to the shape and size of the saw blades. Various types of machines can be equipped with the following types of abrasives:

- flat;

- disc-shaped;

- cup;

- profile.

Useful advice! Before sharpening on the machine, the band saw blade should be turned out and left in this state for 8-10 hours. The processing process will be more efficient.

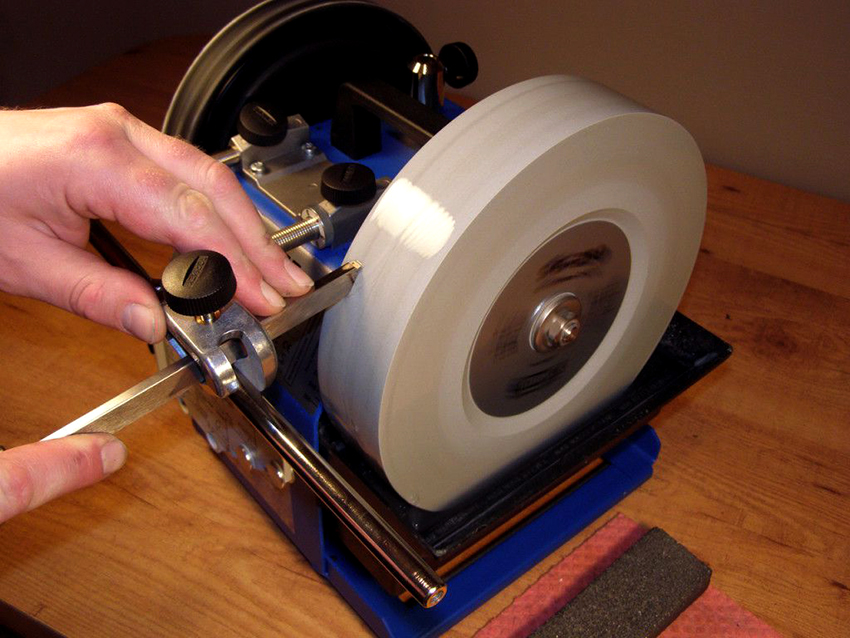

Grinding cutters for a lathe

Turning cutters consist of two main elements - the base rod, with which the tool is fixed in the machine, and the head. Metal processing is carried out by an edge formed by combining the main (rear) and front surfaces. The angles are of paramount importance when using the tool. There are several of them, in total they are 90 °.

According to the specifics of the application, the cutters can be divided into the following types:

- boring;

- for threading;

- facing;

- for making grooves, chamfers;

- shaped.

Turning tools can have removable cutting inserts. Such a tool cannot be restored. The rest of the options require constant updating of the cutting surfaces. Processing is carried out on cutting edge sharpening machines. Large enterprises most often have permanently installed units and whole subdivisions of specialists working for them.

At home, it can be a manual version of the sharpener. The cutters are brought up to the rotating turning wheel and the process is visually assessed. In this case, it is very important to choose the right abrasive material. For carbide tools, you need green carbide wheels. And cutters made of high-speed or carbon steel will recover well after sharpening with corundum wheels of medium hardness.This method of sharpening is certainly inferior to processing on electronic machines, but subject to certain rules, it can be quite effective:

- during sharpening, the tool should be poured with water at the point of contact with the turning circle;

- when sharpening dry, the tool must not be immersed in water after processing - cracks will appear;

- the pressure on the abrasive wheel during processing should be the same, not strong.

After sharpening, it is imperative to fine-tune the cutters (4 mm from the edge of the cutting part): the carbide tool must be refined with a copper touchstone lubricated with a special paste, other types - with a touchstone of medium abrasiveness using kerosene or machine oils.

Diy grinding machine assembly algorithm

Many people rarely use devices for sharpening drills. In such situations, subject to the availability of certain elements, it is quite possible to assemble a machine for sharpening drills with your own hands. For example, a device for restoring the same circular saws may consist of the following structural parts:

- an electric motor with a shaft on which a grinding attachment can be installed;

- a table or other type of support, the upper plane of which will be flush with the axis of the abrasive wheel;

- hinges and screws. The former will provide fixation of the stand on one side, the latter (rotating) - change the height on the other. A certain slope is formed, which allows for angular sharpening of the front and rear planes of the cutting teeth;

- clamps, by means of which the disc in need of sharpening will be fixed on the stand;

a device with which it will be possible to move the engine or stand with a disc during operation; - stops that ensure the strength of the installation.

The indisputable advantage of making a do-it-yourself sharpening machine is not only the price, but also the ability to take into account the technical features of the mechanism as much as possible in accordance with the intended purpose.

Drill sharpening machines: prices and manufacturers

The Diold company is very popular among domestic manufacturers. The price of drills and knives sharpening machines is quite reasonable. For example, the MZS-02 model can be purchased for 2900 rubles. The device has a powerful collector motor, high speed. The rational arrangement of the motor and nozzles made it possible to place a cooling element - an impeller - into the housing. The disadvantages of the model include a rather high noise level and non-standard abrasive wheels.

Sturm machines are also in demand. The company's head office is located in Germany, production workshops are located in many European countries, as well as in China. There are many inexpensive home models among the products of this manufacturer. In particular, this is the Sturm BG6010S machine. The device has a medium-power motor that satisfies everyday needs. It is possible to set the sharpening angle. The price of the device is 2300 rubles.

Useful advice! Before starting to tinker with a homemade sharpening machine, it is worth calculating the costs and assessing the expected result. It may be much more economical to purchase an inexpensive model.

Among the machines for sharpening circular saws, the JMY8-70 option can be distinguished. The instrument was made in China, but it should be attributed to fairly high-quality and functional models. The body is made of durable steel. Diamond abrasive disc, the most actively used diameter is 125 mm, rotation speed is 2850 rpm. The saw holder has a tilted position that allows angular sharpening.

Drill sharpening machine: user reviews and opinions

To a large extent, reviews are subjective opinions.What is considered acceptable and even very convenient for one user may be the exact opposite for another. But the same advantages or disadvantages mentioned in several reviews indicate a certain quality.

A few opinions about the Sturm BG6017S drill sharpener:

“It is assembled perfectly, no backlashes anywhere. Average noise level. Simple, straightforward, but only for home, few functions. Sharpens 4 mm drill bits. The manufacturer does not offer consumables in stock, then you get it yourself. Worth the price. "

Ivan, Kislovodsk

“I sharpened it by hand for a long time, then I bought such a machine. So what? .. I do better. A mechanism for total ineptitude. "

Evgeny, Irkutsk

“… A non-standard stone, I could hardly find a similar one. Mechanism for "four ..."

Sergey, Kursk

Opinions about the TRIOD UTG-220 123015 milling machine are more positive:

“Installed in a private workshop. Serves three milling machines. Works 12 hours a day with virtually no breaks, except weekends. With such a load, we change the bowl 1 time in 2 months. We are absolutely satisfied. Stable, powerful, perfect for sharpening. "

Vlad, Zelenogorsk

“I didn’t expect such high quality from a device with a low price. The instruction is detailed, I did not turn to anyone for help. I have been working for the second month, so far there are no problems. The rpm is high, the disc is fixed securely. Dusty too much only. "

Alexander, Serpukhovo

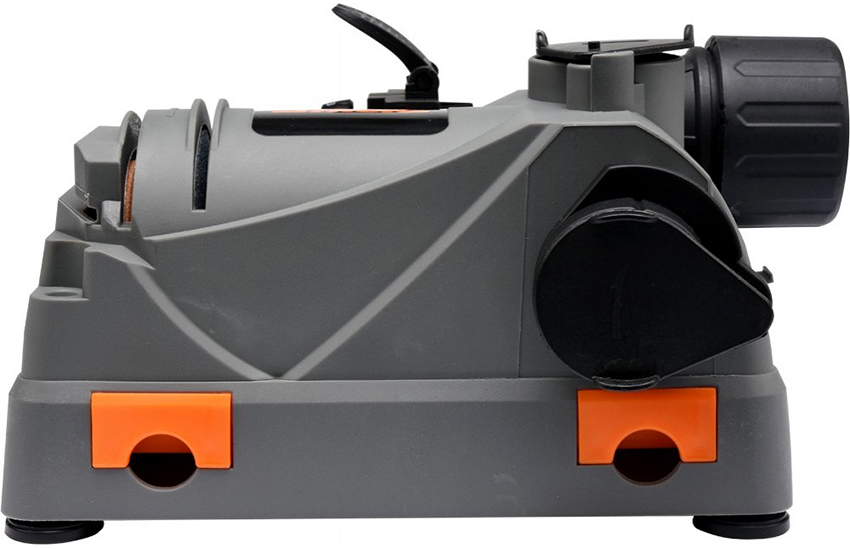

Drill sharpening machine: how to choose the right one

When choosing a sharpener for drills for metal, wood and other materials, you should focus on three main indicators:

- ergonomics of the device;

- build quality;

- options.

As for ergonomics, it is imperative to understand how convenient and safe the use will be: performing direct processing, replacing grinding wheels, moving the machine, etc.

The build quality should be perfect. In the process of work, all the existing shortcomings of such a plan will negatively affect the quality of sharpening. Vibration (it is inevitable for machines of this purpose), together with backlash, will significantly aggravate the deviation of the trajectory of moving parts.

The availability of some options will greatly simplify the use of the machine and allow you to perform the correct sharpening. Therefore, it is worth choosing the following models:

When buying a sharpening machine, you need to pay attention to its functionality, build quality and ergonomics

- with the presence of illumination of the working area;

- having the function of adjusting the number of revolutions;

- with the possibility of using an inclined position of the stand or the processed elements for performing corner sharpening;

- provided with a tank for water used for cooling;

- with a set of abrasive wheels of different grain sizes.

Useful advice! For home use, it is worth purchasing machine designs where the body is made of durable but lightweight material. This greatly simplifies the process of moving the tool.

Tool sharpening is a process that accompanies the main activity. Machine set-up should not take long, and cutting surface machining should be clear and accessible. A properly selected tool will allow you to fulfill the above requirements. And then work will really be a joy.